Trane 4 Chiller Plant Controls

-

Upload

edward-siu -

Category

Documents

-

view

325 -

download

24

Transcript of Trane 4 Chiller Plant Controls

1

Chiller Plant Control

Introduction to Trane Control Systems2 © 2010 Trane

What We Will Cover

• Factory-integrated controls on chillers

• Chiller plant control strategies

• Tracer control features

• Reliability and serviceability

• Chiller plant optimization

• Additional discussion

Introduction to Trane Control Systems3 © 2010 Trane

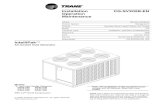

Trane AdaptiView™ Control System4th Generation Microprocessor Chiller Control

• Adaptive control – Reliable operation through difficult

operation conditions

• Feed-forward control– Accurate and stable control under

the most dynamic system transients

• Sophisticated diagnostics

• Fast restarts

• Operator tested – informative display

• Multiple open protocol communication options

Introduction to Trane Control Systems4 © 2010 Trane

Feed-forward control enables the chiller to respond

faster to load changes

• Feed-forward control uses flow change and entering water

temperature as an indication of load change

• It proactively compensates for load changes

Trane AdaptiView™ Control SystemFeed-forward Control

Introduction to Trane Control Systems5 © 2010 Trane

PID Feedback

42º?º

Typical Controller

Trane

UC800/AdaptiView

UC800 Feedback

40º56º

Feedforward

ΣΣΣΣ

DP

627 gpm

• Return Water Temp• Evaporator Flow

Trane AdaptiView™ Control SystemFeed-forward Control

Introduction to Trane Control Systems6 © 2010 Trane

• Directly measures chilled water flow

• Enhances leaving water temperature control during rapid flow rate changes of up to 50%/min.

– >30 % /min commercial control

– 10% /min precision process control

• Auto-tunes control gains to maintain stability and accuracy over chiller’s full range of flow rates.

Trane AdaptiView™ Control SystemVariable Flow Compensation

Introduction to Trane Control Systems7 © 2010 Trane

What Do Customers Really Care About ?

• Reliable chilled water flow

• Operating cost (energy efficiency)

• Operator safety

• Environmental awareness

• Reduced maintenance cost

Introduction to Trane Control Systems8 © 2010 Trane

Tracer Chiller Plant Control• Repeatability – performance from plant to plant

– Maximize the use of pre-engineered features

– Minimize on-site customization

• Flexibility – supports a variety of:– Plant layouts

– Chiller types

– Control strategies

• Maximized energy savings

– Load matching

– Chiller tower optimization

– Distributed pump pressure optimization

– Thermal ice storage

– Minimize manual intervention

• Minimized operational costs

– Minimize manual intervention, but anticipate it

– Maintain chilled water flow and temperature

– Minimize service surprises

Introduction to Trane Control Systems9 © 2010 Trane

LoadDetermination

Chiller Plant Control

ChillerSequencing

Chiller Plant Control

UserInterface

SystemOptimization

Introduction to Trane Control Systems10 © 2010 Trane

Plant Layout FlexibilityConstant Flow

Chiller #1

Chiller #2

CW SupplyTemp

CW ReturnTemp

UCP2UCP2

UCP2UCP2

Introduction to Trane Control Systems11 © 2010 Trane

Plant Layout FlexibilityVariable Flow - Decoupled

Air Handling Units

Control Valves

Variable-Speed

Drive

Pressure Differential Controller or Transmitter

Production

DistributionBypass Line

SU

PP

LY

DE

MA

ND

Chiller #1

Chiller #2UCP2

UCP2

UCP2UCP2

Introduction to Trane Control Systems12 © 2010 Trane

Plant Layout FlexibilityVariable Primary Flow

Air Handling Units

Control Valves

Production

DistributionBypass Line

SUP

PLY

DE

MA

ND

Variable-Speed Drive

Flow

Meter

UCP2UCP2

UCP2UCP2

Differential Pressure Sensor or

Transmitter

Introduction to Trane Control Systems13 © 2010 Trane

Pre-engineered Features

• Load determination

• Capacity matching

• Rotation

• Chiller setpoint control

• Failure recovery

• User interface

Installation and operating reliability and efficiency

Introduction to Trane Control Systems14 © 2010 Trane

Load Determination (when to add or subtract a chiller)

What is the optimal sequencing for chillers?

• Should I run one chiller at 100% or two chillers at 50%?

• The givens…– whether you run one chiller or two…

� The building load does not change

� The outside wet bulb temperature does not change

– When you run two chillers…

� You may double the number of pumps

� You may double the number of tower cells

Introduction to Trane Control Systems15 © 2010 Trane

0.4

0.5

0.6

0.7

0.8

0.9

1

1.1

1.2

1.3

1.4

0 20 40 60 80 100

Percent Load

kW

/to

n

One Chiller at 100%? orTwo Chillers at 50%?

Constant Speed Centrifugal ChillerUnloading at constant condenser water temperature

Introduction to Trane Control Systems16 © 2010 Trane

Capacity Matching(turn the right chiller on)

Dependent on chiller plant design

• Normal - identical chillers

• Base - heat recovery/super efficient

• Pea - back up/alternate energy source/inefficient

• Swing - match the load!

• Custom - mix and match/nested CPC objects

Reduce operating costs

Introduction to Trane Control Systems17 © 2010 Trane

UCP2

450 Ton Chiller (Swing) 900 Ton Chiller

(Normal-1)

900 Ton Chiller (Normal-2)

UCP2

UCP2

0 2250450 18001350900

UCP2

Building Load (Tons)

Reduce operating costs

Introduction to Trane Control Systems18 © 2010 Trane

Flexible Rotation Which chiller is next?

• Schedule based

• Run-time

• Manual operator decision

• Customized

– Number of starts

– Other?

Reliable chilled water

Introduction to Trane Control Systems19 © 2010 Trane

Unload Before StartKeep chillers online

• Ride out flow transients on startups

– Deals with less sophisticated chiller controllers

• Variable flow / multiple pump systems

• Low supply water temperatures

Reliable chilled water

Introduction to Trane Control Systems20 © 2010 Trane

Failure Recovery Keep chilled water flowing

• No manual intervention required

• Follow the standard sequence

• Multiple failure inputs

– Chiller level

– System level

Reliable chilled water

Introduction to Trane Control Systems21 © 2010 Trane

Intuitive User Interface

• Minimize training time

• Minimize undesirable manual control

• Maximize operator efficiency

Reduced Operational Costs

Introduction to Trane Control Systems22 © 2010 Trane

Chiller - Tower Optimization Tower Setpoint Optimization

• Load

• Condenser watertemperature

• Wet bulb

• Tower design

• Load

• Condenser watertemperature

• Chiller design

Introduction to Trane Control Systems23 © 2010 Trane

Chiller - Tower Optimization Chiller–Tower Interaction

Condenser Water Temperature, °°°°F

400

74

En

erg

y C

on

su

mp

tio

n, kW

76 78 80 8272

300

200

100

084

Tower

Optimalcontrol point

Chiller

Total

Introduction to Trane Control Systems24 © 2010 Trane

Chiller - Tower OptimizationNorth America

350K

An

nu

al

Op

era

tin

g C

os

t, $

US

D

300K

250K

200K

150K

100K

50K

0Mexico City Orlando San Diego Toronto

55°°°°F Lvg Tower

Optimal Control

Design ECWT

Control Strategy

Introduction to Trane Control Systems25 © 2010 Trane

Air Handling Units

Control

Valves

Pressure

Differential

Controller or

Transmitter

• Critical valve reset

• Benefits

– Reduced pump energy

– Better coil control

– Extend pump life

Distribution Pumping Critical Valve Pressure Control

Reduce operating costs

Introduction to Trane Control Systems26 © 2010 Trane

Chiller Plant Dashboard Details

Daily Average MetricsPump Pressure

Pump Status

System and Chiller Status

Chilled Water Temps

Tower Water Temps

System Load

System Efficiency

Pump Flow

Introduction to Trane Control Systems27 © 2010 Trane

Summary

Key points to remember

• Integrated chiller controls

– Factory quality; better performance, efficiency and serviceability; lower risk

• Performance

– Temperature control; reliability; extended equipment life; automatic failure response

• Efficiency

– Lower energy and maintenance costs

• Sustainability

– Maintain performance over time

– Document performance

28

Thank you!