Training Hireg Rev01

-

Upload

maria-paula -

Category

Documents

-

view

258 -

download

8

Transcript of Training Hireg Rev01

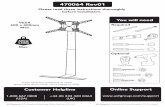

HiREG®

Electrodes Regulator Training

DANIEL

I

Know-How in Process Control

Danieli Automation HeadquartersVia B.Stringher, 433042 Buttrio (UD) Italy

Tel. (39) 0432.518111Fax (39) 0432.673177E-mail: [email protected]

DANIELI AUTOMATION

This document contains proprietary information of Danieli Automation S.p.A. not disclosable, not reproducible. All Rights Reserved

• Aim of the application• Power Supply layout• Measuring system• Current and Voltage Transformer• M.V. Interface Transformer table• Hardware connection to PLC• PLC Interface• Electrode Regulator: Position Control

Loop• Linearization and regulation

parameters• Counter pressure: pressure control

loop• Cold test• Hot Test• Data Analysis (Fda® )

HiREG® – Training program

This document contains proprietary information of Danieli Automation S.p.A. not disclosable, not reproducible. All Rights Reserved

REGULATION PRINCIPLESREGULATION PRINCIPLES

This document contains proprietary information of Danieli Automation S.p.A. not disclosable, not reproducible. All Rights Reserved

• Impedance regulation:Istantaneous control of the arc length by hydraulic electrodes position control

• Individual regulators for each phase, with phase balancing

• Electrode saving function1. Overcurrent reaction.

2. Not conductive material reaction

• Logging and real time trends for machine tuning and performance improvement

HiREG®– Aim of the application

Pos

REACTOR POSITIONPRIMARY VOLTAGE

CURRENT VALUETAP CHANGER POSITION

REGULATOR

SET-POINTCALCULATION

V

I

Z set

Z measure

Z error

TUNING PARAMETERS

INITIALCONTACT

LOGIC I

V

Speed

Control Loop Regulation

Standard PLC

This document contains proprietary information of Danieli Automation S.p.A. not disclosable, not reproducible. All Rights Reserved

HiREG® Position Control Loop

Regulation Algorithm

Ki * I ‑ Ku * U = 0

Main Parameters:PAR. I , PAR. U : inputs U, I parametering and limiting functionsKi : conversion table from primary current to secondary current Kiph : function for the balancing of the phasesKu : table for the furnace working points

This document contains proprietary information of Danieli Automation S.p.A. not disclosable, not reproducible. All Rights Reserved

HIREG BLOCK DIAGRAMHIREG BLOCK DIAGRAM

This document contains proprietary information of Danieli Automation S.p.A. not disclosable, not reproducible. All Rights Reserved

HiREG® - Automation Block Diagram

HiREGHiREGEAFEAF

This document contains proprietary information of Danieli Automation S.p.A. not disclosable, not reproducible. All Rights Reserved

HIREG HYDRAULICHIREG HYDRAULIC

This document contains proprietary information of Danieli Automation S.p.A. not disclosable, not reproducible. All Rights Reserved

HiREG® Hydraulic Overview

InletInlet

Regulation Regulation ValvesValves

UnlockingUnlockingValvesValves

Line PressureLine Pressuretransducerstransducers

Lifting Lifting ColumnsColumns

OutletOutlet

Counter PressureCounter PressureTransducersTransducers

AccumulatorsAccumulators

Counter PressureCounter PressureRegulation ValveRegulation Valve

This document contains proprietary information of Danieli Automation S.p.A. not disclosable, not reproducible. All Rights Reserved

HiREG® Valve system

Actuator: Valve Tech. Spec.

Signal command ±10VDigital Regulator ± 10000

This document contains proprietary information of Danieli Automation S.p.A. not disclosable, not reproducible. All Rights Reserved

HiREG® Valve system

Actuator: Valve Electrical drawing

This document contains proprietary information of Danieli Automation S.p.A. not disclosable, not reproducible. All Rights Reserved

MV TYPICAL LAYOUTMV TYPICAL LAYOUT

This document contains proprietary information of Danieli Automation S.p.A. not disclosable, not reproducible. All Rights Reserved

HiREG® Power Supply Layout

Transformer HV-MVTransformer HV-MV

BreakerBreaker

P.F. CompensationP.F. Compensation

Series ReactorSeries Reactor

Furnace transformerFurnace transformer

Secondary system and ElectrodeSecondary system and Electrode

This document contains proprietary information of Danieli Automation S.p.A. not disclosable, not reproducible. All Rights Reserved

FIELD SIGNALS MEASUREFIELD SIGNALS MEASURE

PT and CT connection

This document contains proprietary information of Danieli Automation S.p.A. not disclosable, not reproducible. All Rights Reserved

HiREG® Measuring system

Voltage transformer PT (TV)

Important: Avoid shortcircuit condition for PT (TV)

50Hz

This document contains proprietary information of Danieli Automation S.p.A. not disclosable, not reproducible. All Rights Reserved

HiREG® Measuring system

Adaptive Current transformer TA

Trafo connection Delta/Delta

Diris

Important :always verify short circuit condition for CT (TA)

5/5 A

This document contains proprietary information of Danieli Automation S.p.A. not disclosable, not reproducible. All Rights Reserved

HiREG® Measuring system

Trafo connection Star/Delta

Adaptive Current transformer TA

5/5:√3 A

Important :always verify short circuit condition for CT (TA)

This document contains proprietary information of Danieli Automation S.p.A. not disclosable, not reproducible. All Rights Reserved

HiREG® Measuring system

Trafo connection Star-Delta/Delta

5/5:√3 A

Important :always verify short circuit condition for CT (TA)

This document contains proprietary information of Danieli Automation S.p.A. not disclosable, not reproducible. All Rights Reserved

HiREG® Voltage and current transducer

RMS converterRMS converter Input 0:100V or 0:8A Input 0:100V or 0:8A

ACAC Output 0:10 V DCOutput 0:10 V DC Time response < Time response <

50ms50ms Precision < 0.5%Precision < 0.5% Cl.= 0.5Cl.= 0.5 Supply 230 V 50Hz Supply 230 V 50Hz

or 110 V 60 Hzor 110 V 60 Hz

This document contains proprietary information of Danieli Automation S.p.A. not disclosable, not reproducible. All Rights Reserved

HIREG ELECTROTECNICHIREG ELECTROTECNIC

Main Principles

This document contains proprietary information of Danieli Automation S.p.A. not disclosable, not reproducible. All Rights Reserved

HiREG® Electrical Parameters (1)

Base electrical circuit:

Base circular diagram

This document contains proprietary information of Danieli Automation S.p.A. not disclosable, not reproducible. All Rights Reserved

Real Circular DiagramReal Circular Diagram

APPARENT POWER [MVA]

RATED POWER [MVA]

MAX. POWER [MVA]

POWER FACTOR [-]

LOAD CURVES [V]ELECTRODES CURRENT [kA]

ARC LENGTH [mm]

For each tap of the reactor (if any), a circular diagram can be produced to represent the allowed working area for the furnace.

HiREG® Electrical Parameters (2)

This document contains proprietary information of Danieli Automation S.p.A. not disclosable, not reproducible. All Rights Reserved

EAF

P_fu+jQ_fu

P_fu+jQ_fu+jQ_react

P_arc + losses = P_fu

S_2

S_1

SERIES REACTOR

FURNACE TRANSFORMER

P_arc = 3 (V_arc x I_arc)

MV BUSBAR

P_fu/S_2 = 0,77-0,78

P_fu/S_1 > 0,8

Theory of Series ReactorTheory of Series Reactor

ProfileProfile

Boring : P.F.<0.75 Varc < 300÷400 CC = 6

Melting : P.F. >0.75 max Power

Refining : R.I. Arc coverage condition

HiREG® Electrical Parameters (3)

Power

Boring

Melting

Refining

This document contains proprietary information of Danieli Automation S.p.A. not disclosable, not reproducible. All Rights Reserved

HIREG HW INTERFACESHIREG HW INTERFACES

Fail safe logic

This document contains proprietary information of Danieli Automation S.p.A. not disclosable, not reproducible. All Rights Reserved

HiREG® Hardware connection to PLC

This document contains proprietary information of Danieli Automation S.p.A. not disclosable, not reproducible. All Rights Reserved

HIREG INTERFACE SIGNALSHIREG INTERFACE SIGNALS

With main automation PLCs

EAF or LRF

This document contains proprietary information of Danieli Automation S.p.A. not disclosable, not reproducible. All Rights Reserved

HiREG® PLC Interface (1)

HIREG_WC_REMHIREG_WC_REM DATA TO FURNACE PLCDATA TO FURNACE PLC

dp couplerdp coupler: 64 bytes: 64 bytesSTRCT: STRCT: EREG_REMEREG_REM

DBW000DBW000 INTF_WS_WATCHDOG_RGINTF_WS_WATCHDOG_RG watchdogwatchdog ININ 0÷300000÷30000 Always Always changingchanging 0000

DBX002.00DBX002.00 INTF_BS_GEN_FLTINTF_BS_GEN_FLT Regulator generic alarmRegulator generic alarm BBBB 0>10>1 1= true1= true 0000

DBX002.01DBX002.01 INTF_BS_TRP_FLTINTF_BS_TRP_FLT Regulator higher priority failureRegulator higher priority failure BBBB 0>10>1 1= true1= true 0000

DBX002.02DBX002.02

DBX002.03DBX002.03

DBX002.04DBX002.04 INTF_BS_BRK_OPN_CNSINTF_BS_BRK_OPN_CNS furnace breaker open consentfurnace breaker open consent BBBB 0>10>1 1= true1= true 0000

DBX002.05DBX002.05

DBX002.06DBX002.06 INTF_BS_ARC_ONINTF_BS_ARC_ON Furnace Arc OnFurnace Arc On BBBB 0>10>1 1= true1= true 3131

DBX002.07DBX002.07

DBX003.00DBX003.00 INTF_BS_ELS_LW_QTAINTF_BS_ELS_LW_QTA Electrodes have all reached requested quotaElectrodes have all reached requested quota BBBB 0>10>1 1= true1= true 3131

DBX003.01DBX003.01

DBX003.02DBX003.02

DBX003.03DBX003.03

DBX003.04DBX003.04 INTF_BS_EL_CUR_HIGHINTF_BS_EL_CUR_HIGH Phase 123 cumulative high currentPhase 123 cumulative high current BBBB 0>10>1 1= true1= true 0000

DBX003.05DBX003.05 INTF_BS_EL_CUR_HHIGINTF_BS_EL_CUR_HHIG Phase 123 cumulative high high currentPhase 123 cumulative high high current BBBB 0>10>1 1= true1= true 0000

DBX003.06DBX003.06

DBX003.07DBX003.07

DBX004.00DBX004.00 INTF_BS_EL1_LW_QTAINTF_BS_EL1_LW_QTA Electrode 1 has reached requested quotaElectrode 1 has reached requested quota BBBB 0>10>1 1= true1= true

DBX004.01DBX004.01 INTF_BS_EL1_CUR_HIGHINTF_BS_EL1_CUR_HIGH Electrode 1 high currentElectrode 1 high current BBBB 0>10>1 1= true1= true 0000

DBX004.02DBX004.02 INTF_BS_EL1_CUR_HHIGINTF_BS_EL1_CUR_HHIG Electrode 1 high high currentElectrode 1 high high current BBBB 0>10>1 1= true1= true 0000

DBX004.03DBX004.03 INTF_BS_EL1_POS_FLTINTF_BS_EL1_POS_FLT Electrode 1 Encoder faultElectrode 1 Encoder fault BBBB 0>10>1 1= true1= true 0000

DBX004.04DBX004.04 INTF_BS_EL1_SP_ZEROINTF_BS_EL1_SP_ZERO Electrode 1 speed is zeroElectrode 1 speed is zero BBBB 0>10>1 1= true1= true 0000

DBX004.05DBX004.05 INTF_BS_EL1_HISP_VLVINTF_BS_EL1_HISP_VLV Electrode 1 high speed valve opening commandElectrode 1 high speed valve opening command BBBB 0>10>1 1= true1= true 3333

DB 156 To Furnace PLC

This document contains proprietary information of Danieli Automation S.p.A. not disclosable, not reproducible. All Rights Reserved

HiREG® PLC Interface (2)

DB 156 To Furnace PLC

DBX010.00DBX010.00 INTF_BS_RCT_BRK_CLS_ENAINTF_BS_RCT_BRK_CLS_ENABB

Saturable reactor: furnace breaker Saturable reactor: furnace breaker closing enabledclosing enabled BBBB 0>10>1 1=true1=true 3131

DBX010.01DBX010.01

DBX010.02DBX010.02 INFT_BS_RCT_CUR_REACHINFT_BS_RCT_CUR_REACH Saturable reactor target current is Saturable reactor target current is reachedreached BBBB 0>10>1 1=true1=true 3131

DBX010.03DBX010.03

DBX010.04DBX010.04 INTF_BS_RCT_CUR_ALR_HIGINTF_BS_RCT_CUR_ALR_HIGHH

Saturable reactor current over high Saturable reactor current over high limit-STOP CONVERTERlimit-STOP CONVERTER BBBB 0>10>1 1=true1=true 3131

DBX010.05DBX010.05 INTF_BS_RCT_CUR_ALR_LOWINTF_BS_RCT_CUR_ALR_LOW Saturable reactor current under low Saturable reactor current under low limit-STOP CONVERTERlimit-STOP CONVERTER BBBB 0>10>1 1=true1=true 3131

DBW012DBW012 INTF_WS_EL1_VLT_RGINTF_WS_EL1_VLT_RG electrode 1 _ voltage electrode 1 _ voltage ININ 0÷12000÷1200 VV 0÷12000÷1200 0000

DBW014DBW014 INTF_WS_EL1_CUR_RGINTF_WS_EL1_CUR_RG electrode 1 _ currentelectrode 1 _ current ININ 0÷50.000÷50.00 KAKA 0÷50000÷5000 0000

DBD016DBD016 INTF_WS_EL1_POSINTF_WS_EL1_POS electrode 1 actual absolute positionelectrode 1 actual absolute position FLFL 0÷60000÷6000 mmmm 0÷60000÷6000 3333

DBW020DBW020

DBW042DBW042 INTF_WS_PRIM_VLINTF_WS_PRIM_VL Primary voltagePrimary voltage ININ 0÷42.000÷42.00 KVKV 0÷42.00 KV0÷42.00 KV 0000

DBW052DBW052 INTF_WS_RCT_CUR_REFINTF_WS_RCT_CUR_REF Saturable reactor current referenceSaturable reactor current reference ININ 0÷1650.00÷1650.0 AA 0÷165000÷16500 3131

DBW054DBW054 INTF_WS_RCT_CUR_LIM_HIGINTF_WS_RCT_CUR_LIM_HIGHH

Saturable reactor current high limit Saturable reactor current high limit valuevalue ININ 0÷1650.00÷1650.0 AA 0÷165000÷16500 3131

DBW056DBW056 INTF_WS_RCT_CUR_LIM_LOWINTF_WS_RCT_CUR_LIM_LOW Saturable reactor current low limit valueSaturable reactor current low limit value ININ 0÷1650.00÷1650.0 AA 0÷165000÷16500 3131

This document contains proprietary information of Danieli Automation S.p.A. not disclosable, not reproducible. All Rights Reserved

HiREG® PLC Interface (3)

DB 156 From Furnace PLCDBW100DBW100 INTF_WC_WATCHDOG_RGINTF_WC_WATCHDOG_RG watchdogwatchdog II

NN0÷300÷30000000

Always Always changingchanging 0000

DBX102.0DBX102.000

INTF_BC_EL1_LIFT_RGINTF_BC_EL1_LIFT_RG electrode 1 lifting (regulator)electrode 1 lifting (regulator) BBBB

0>10>1 1= true1= true 0000

DBX102.0DBX102.011

INTF_BC_EL1_LOWR_RGINTF_BC_EL1_LOWR_RG electrode 1 lowering (regulator)electrode 1 lowering (regulator) BBBB

0>10>1 1= true1= true 0000

DBX102.0DBX102.022

INTF_BC_EL1_AUTO_RGINTF_BC_EL1_AUTO_RG electrode 1 automatic (regulator)electrode 1 automatic (regulator) BBBB

0>10>1 1= true1= true 0000

DBX102.0DBX102.033

INTF_BC_EL1_UNL_RGINTF_BC_EL1_UNL_RG Electrode 1 unlocked (regulator) Electrode 1 unlocked (regulator) BBBB

0>10>1 1= true1= true 0000

DBX102.0DBX102.044

INTF_BC_EL1_HIGH_RGINTF_BC_EL1_HIGH_RG electrode 1 in high pos. (regulator)electrode 1 in high pos. (regulator) BBBB

0>10>1 1= true1= true 0000

DBX102.0DBX102.055

INTF_BC_EL1_LOW_RGINTF_BC_EL1_LOW_RG electrode 1 in low pos. (regulator)electrode 1 in low pos. (regulator) BBBB

0>10>1 1= true1= true 0000

DBX102.0DBX102.066

INTF_BC_EL1_HSPD_RGINTF_BC_EL1_HSPD_RG electrode 1 high speed (regulator)electrode 1 high speed (regulator) BBBB

0>10>1 1= true1= true 0000

DBX102.0DBX102.077

DBX103.0DBX103.000

DBX103.0DBX103.011

DBX103.0DBX103.022

DBX103.0DBX103.033

DBX103.0DBX103.044

DBX103.0DBX103.055

DBX103.0DBX103.066

DBX103.0DBX103.077

This document contains proprietary information of Danieli Automation S.p.A. not disclosable, not reproducible. All Rights Reserved

HiREG® PLC Interface (4)

DB 156 From Furnace PLC

DBX108.00DBX108.00 INTF_BC_ARC_INT_CMDINTF_BC_ARC_INT_CMD furnace breaker arc interruption furnace breaker arc interruption (command)(command)

BBBB

0>10>1 1= true1= true 0000

DBX108.01DBX108.01 INTF_BC_BRK_CLS_STAINTF_BC_BRK_CLS_STA furnace breaker closed (status)furnace breaker closed (status) BBBB

0>10>1 1= true1= true 0000

DBX108.02DBX108.02 INTF_BC_BRK_OPN_CMDINTF_BC_BRK_OPN_CMD furnace breaker opening request (command)furnace breaker opening request (command) BBBB

0>10>1 1= true1= true 0000

DBX108.03DBX108.03 INTF_BC_CLAMPSINTF_BC_CLAMPS electrodes clamps modeelectrodes clamps mode BBBB

0>10>1 1= true1= true 0000

DBX108.04DBX108.04 INTF_BC_MAINTINTF_BC_MAINT Furnace in maintenance modeFurnace in maintenance mode BBBB

0>10>1 1= true1= true 0000

DBX108.05DBX108.05 INTF_BC_HEAT_ENDINTF_BC_HEAT_END Furnace Heat EndFurnace Heat End BBBB

0>10>1 1= true1= true 0000

DBX108.06DBX108.06 INTF_BC_BCK_ENDINTF_BC_BCK_END Furnace Bucket EndFurnace Bucket End BBBB

0>10>1 1= true1= true 0000

DBX110.00DBX110.00 INTF_BC_RCT_AUTOINTF_BC_RCT_AUTO Saturable reactor automatic modeSaturable reactor automatic mode BBBB

0>10>1 1= true1= true 3131

DBX110.01DBX110.01 INTF_BC_RCT_RUNINTF_BC_RCT_RUN Saturable reactor is runningSaturable reactor is running BBBB

0>10>1 1= true1= true 3131

DBX110.02DBX110.02 INTF_BC_RCT_BYPINTF_BC_RCT_BYP Saturable reactor is by-passedSaturable reactor is by-passed BBBB

0>10>1 1= true1= true 3131

This document contains proprietary information of Danieli Automation S.p.A. not disclosable, not reproducible. All Rights Reserved

HiREG® PLC Interface (5)

DB 156 From Furnace PLC

DBW112DBW112 INTF_WC_PRIM_VLTINTF_WC_PRIM_VLT primary - voltageprimary - voltage ININ 0÷50.000÷50.00 kVkV 0÷50000÷5000 0000

DBW114DBW114

DBW116DBW116

DBW118DBW118 INTF_WC_TAP_POS_RGINTF_WC_TAP_POS_RG tap changer position tap changer position ININ 1÷321÷32 1÷321÷32 0000

DBW120DBW120 INTF_WC_CUR_SET_RGINTF_WC_CUR_SET_RG current curve position (SET)current curve position (SET) ININ 1÷61÷6 1÷61÷6 0000

DBW122DBW122 INTF_WC_RCT_POSINTF_WC_RCT_POS reactor positionreactor position ININ 1÷61÷6 1÷61÷6 0000

DBW124DBW124 INTF_WC_ACT_PWRINTF_WC_ACT_PWR Active powerActive power ININ 0÷1000.00÷1000.0 MWMW 0÷100000÷10000 0000

DBW126DBW126 INTF_WC_RCT_PWRINTF_WC_RCT_PWR Reactive powerReactive power ININ 0÷1000.00÷1000.0 MVAMVARR

0÷100000÷10000 0000

DBW128DBW128 INTF_WC_COSPHYINTF_WC_COSPHY CosphyCosphy ININ 0÷1.0000÷1.000 0÷10000÷1000 0000

DBW142DBW142 INTF_BC_RCT_CUR_TRG_MAINTF_BC_RCT_CUR_TRG_MANN

Saturable reactor target current in Saturable reactor target current in manual modemanual mode ININ 0÷1650.00÷1650.0 AA 0÷165000÷16500 33

11

DBW144DBW144 INTF_BC_RCT_CUR_ACTINTF_BC_RCT_CUR_ACT Saturable reactor real currentSaturable reactor real current ININ 0÷1650.00÷1650.0 AA 0÷165000÷16500 3311

This document contains proprietary information of Danieli Automation S.p.A. not disclosable, not reproducible. All Rights Reserved

HIREG OWSHIREG OWS

This document contains proprietary information of Danieli Automation S.p.A. not disclosable, not reproducible. All Rights Reserved

HiREG® Communication Overview

This document contains proprietary information of Danieli Automation S.p.A. not disclosable, not reproducible. All Rights Reserved

HiREG® Communication settings

DPI CONFIGURATOR

This document contains proprietary information of Danieli Automation S.p.A. not disclosable, not reproducible. All Rights Reserved

HIREG OWS PARAMETERSHIREG OWS PARAMETERS

This document contains proprietary information of Danieli Automation S.p.A. not disclosable, not reproducible. All Rights Reserved

HiREG® Electrical Parameters (1)

Reference document:

Admittance Table

This document contains proprietary information of Danieli Automation S.p.A. not disclosable, not reproducible. All Rights Reserved

HiREG® Transformer Table (1)

Transformer Primary side connection

Important: Electrode line current

CT Settings

KI-KA Automatic calculation

This document contains proprietary information of Danieli Automation S.p.A. not disclosable, not reproducible. All Rights Reserved

HiREG® Transformer Table (2)

KIKA

This document contains proprietary information of Danieli Automation S.p.A. not disclosable, not reproducible. All Rights Reserved

HiREG® Regulation Parameters

Regulation Valve settings

PI Regulator settings

Electrode Speed settings

Boring phaseSettings

Touch DownSettings

Notch Filter Settings

V/I presence

AdditionalSettings

This document contains proprietary information of Danieli Automation S.p.A. not disclosable, not reproducible. All Rights Reserved

HiREG® Regulation Parameters

Phase BalancePhase Balance PHASE 1PHASE 1 PHASE 2PHASE 2 PHASE 3PHASE 3

PHASE BALANCEPHASE BALANCE 11 11 11

CURRENTCURRENT 11 11 11

ARC LENGHTARC LENGHT == == ==

PHASE BALANCEPHASE BALANCE 11 0,90,9 11

CURRENTCURRENT 11 1+ 1+ ΔΔ 11

ARC LENGHTARC LENGHT --ΔΔ - - ΔΔ + + ΔΔ

PHASE BALANCEPHASE BALANCE 11 0,90,9 0,90,9

CURRENTCURRENT 11 1+ 1+ ΔΔ11 1+ 1+ ΔΔ22

ARC LENGHTARC LENGHT (-(-ΔΔ11 + + ΔΔ22)) (-(-ΔΔ11– – ΔΔ22)) (+Δ(+Δ11 – Δ – Δ22))

This document contains proprietary information of Danieli Automation S.p.A. not disclosable, not reproducible. All Rights Reserved

HiREG® Linearization (1)

Sequence:1. Zero Valve 2. BIAS 1 mm/s3. Linearization

Automatic cycle

SPEED RESPONSE CP=680 PSI

-300

-200

-100

0

100

200

300

400

-10000 -6000 -2000 2000 6000 10000reference [mV]

spee

d [

mm

/s]

EL3

EL2

EL1

This document contains proprietary information of Danieli Automation S.p.A. not disclosable, not reproducible. All Rights Reserved

HiREG® Regulation Parameters NLG

Gain increase in case of cave-in

Maintain symmetric system response

This document contains proprietary information of Danieli Automation S.p.A. not disclosable, not reproducible. All Rights Reserved

HiREG® Plant Parameters

Typical Measuring setting: pay attention to the correct value

This document contains proprietary information of Danieli Automation S.p.A. not disclosable, not reproducible. All Rights Reserved

HiREG® Counter Pressure

Pressure control :Pressure control :• Counter pressure set ~80% Pb= Pcp Down Speed ~200mm/s (Pb: Pressure Counter pressure set ~80% Pb= Pcp Down Speed ~200mm/s (Pb: Pressure

balance)balance)• Accumulator set ~65% PcpAccumulator set ~65% Pcp

Valve Parameters

Backpressure

Set Points

BackpressureTrend

Alarms

Line pressureTrends

Line Pressurealarms

SwitchingSettings

This document contains proprietary information of Danieli Automation S.p.A. not disclosable, not reproducible. All Rights Reserved

HiREG® Communication settings

Dispatcher settings

DB MidddleWareLocation

This document contains proprietary information of Danieli Automation S.p.A. not disclosable, not reproducible. All Rights Reserved

• Automation system technical specification - HiReg (o HiReg Plus) • Functional Specification - HiReg (o HiReg Plus) • Operator manual – HiReg OWS • Ac electric arc furnace - Furnace calculations - Working points, circ.diagram, electrode reg.table • Commissioning manual

HiREG® Reference documentation