Training catalogue - Tiama...

Transcript of Training catalogue - Tiama...

Training catalogue

Eng

lish

vers

ion

More Than Inspection — Tiama Worldwide Services 3

CONTENT

General information

The Tiama group— Tiama Training modules…………..….………………………………………………………………….…………………….P6

The Tiama Vourles site — access map………………………………………………………………………….………………….…………………..P7

Training selection.......………………………………………………………………….…………………………………………………….……………………...P8

The key benefits for your machines…………...........……….……………………………………………………………….………………………..P9

Practical information.…………………………………………………………………………………………………………….……………………..……......P10

How to read our training summaries....………………………………………………………………………………………………………....….….P11

COLD END

4th generation machines

MCAL4 modules

Operator ……………………………………………………………………………………………………….……………....……………………..…VIS-OP-611

Adjuster…………………………………………………………………………………………………………..……………VIS-RE-611 — VIS-RE-613

Maintenance…………………………………………………………………………………………………………….VIS-MA-611 — VIS-MA-615

MULTI4 modules

Operator ……………………………………………..…………………………………………………….………...…...………...…………………VIS-OP-711

Adjuster……………………………………………………………………………………………………………………....VIS-RE-711 — VIS-RE-714

Maintenance……………………………………………………………………………………………….……….…VIS-MA-711 — VIS-MA-715

MCAL4 / MULTI4 modules

Maintenance…………………………………………………………………………………………….………….……………………………….VIS-MA-311

MX4 modules

Operator ………………………………………………………………………………………………..……………………………………………..CAR-OP-301

Adjuster……………………………………………………………………………………………….………………..…CAR-RE-301 — CAR-RE-302

Maintenance……………………………………………………………………………………..………..………CAR-MA-301 — CAR-MA-304

ATLAS……………………………………………………………………………………………………………..……...CAR-RE-501 — CAR-MA-501

NCG…………………………………………………………………………………………………………………….....CAR-RE-502 — CAR-MA-502

NCL………………………………………………………………………………………………………...…………..….CAR-RE-503 — CAR-MA-503

More Than Inspection — Tiama Worldwide Services 4

CONTENT

Machines of previous generations

MCAL3 modules

Operator ………………....……………………………………………………………………………………………………………………………..…VIS-OP-601

Adjuster…………………………………………………………………………………………………………….……………VIS-RE-601 — VIS-RE-603

Maintenance…………….……………………………………………………………………………………………….VIS-MA-601 — VIS-MA-605

MULTI3 modules

Operator ……………………………..………………..………………………………………………………………...…………...…………………VIS-OP-701

Adjuster……………………………………………………………………………………………………………………....VIS-RE-701 — VIS-RE-704

Maintenance…………………………..…………………………………………………………………………….…VIS-MA-701 — VIS-MA-705

MCAL3 / MULTI3 module

Maintenance………………………………………………………………………………………………………….……………………………….VIS-MA-301

CHECK+V6 modules Operator …………..…………………………………………………………………………………………………………………………………..CAR-OP-001

Adjuster…………….…………………………………………………………………………………………………..…CAR-RE-001 — CAR-RE-002

Maintenance…………………………………………………………………………………………………..……CAR-MA-001 — CAR-MA-005

More Than Inspection — Tiama Worldwide Services 5

CONTENT

HOT END

HOT mass training Adjuster………………………………………………………………………………………………………………......HOT-RE-001 — HOT-RE-002

Maintenance…………………….…………………………………………………………………………………………………………..………HOT-MA-001

HOT lab training Operator ………………....…………………………………………………………………………………………………………………….………HOT-OP-201

Adjuster………………………………………………………………………………………………………………...…HOT-RE-201 — HOT-RE-202

Maintenance……………..…………………………………………………………………………………………………………………..………HOT-MA-201

ICARE modules Operator …………....………………………………………………………………………………………………………………….………………HOT-OP-301

Adjuster……………………………………………………………………………………………………………………HOT-RE-301 — HOT-RE-303

Maintenance………………..………………………………………………………………………………………HOT-MA-301 — HOT-MA-302

More Than Inspection — Tiama Worldwide Services 6

General information

The Tiama group

TIAMA is a world leader on the market of quality control solutions for the container glassware industry. We work continuously

to offer you the best tools:

- to improve the efficiency of the glass manufacturing process,

- to control the integrity of the glass container by detecting different defects (critical defects, sidewall defects, defects not

visible to the naked eye, dimensional defects, etc.)

Tiama training modules

We receive you in our training centre on our Vourles site. Entirely designed for and devoted to training, it features an informal

reception area, training rooms, virtual simulation rooms and machines for hands-on exercises.

The TIAMA training centre is officially registered with the Direction Régionale des Entreprises, de la Concurrence, de la Consommation, du Travail, de l’Emploi of the Rhône-Alpes region (DIRECCTE - Regional Business, Competition and Consumer Department).

Accreditation number 82.69.12919.69

We also offer you the possibility of organizing these training modules on your premises. In this respect, and in order to create the best possible conditions for your trainees, you should make available a meeting room for the theory lessons and a machine corresponding to the training module. The machine should ideally be placed offline to avoid

potential disruption of your current production.

1,000 trainees

trained per annum

1/3 of the modules

at Vourles (France)

2/3 of modules on

customer sites

26 countries

More Than Inspection — Tiama Worldwide Services 7

General information

The Tiama Vourles site

ZA des Plattes

1 Chemin des Plattes

69390 Vourles

France

www.tiama.com

How to get here

GPS coordinates:

N 45.6579°

E 4.7619°

Tel. : + 33 4 37 20 15 80

E-mail : [email protected]

More Than Inspection — Tiama Worldwide Services 8

General information

Training selection

This catalogue includes all the training modules offered by TIAMA. We will submit a training plan tailored to your

needs. Do not hesitate to contact us for any special requests.

Identify the type(s) of machine you use or have ordered:

Body sidewall inspection machine

Finish and base inspection machine

Multi-inspection machine

Identify the profile of the trainee(s):

As all our customers are unique, we have opted for a detailed breakdown to enable you to adapt your training as best

you can to the trainees' tasks.

Operator: The person ensuring the good working order of the machine.

The operator must master the functioning of the machine, know how to stop and start it and be able

to react in the event of an alarm. He also performs control sampling.

Adjuster: The person in charge of job changes and of making adjustments to the machine's detection

systems.

Maintenance technician: The person in charge of diagnostics and of repairing the machine. The

engineer must understand the architecture and functioning of the equipment to comprehend all

aspects of preventive and corrective maintenance.

Identify the level of the trainee(s):

This indicator determines the level of proficiency you wish the trainee(s) to attain at the end of

the module.

2 1 3

Target level

More Than Inspection — Tiama Worldwide Services 9

General information

The key benefits for your machines

Our training modules aim to enable you to optimize the use of your machines according to 3 key criteria of optimal operation:

The following 3 indicators with their relative levels are presented in each of the training programmes to help you choose the

module that best meets your needs.

Inspection performance

By helping you understand the functions and master adjustments, these modules will enable you to use all the options and possibilities of your machine to their full potential. With advanced knowledge you will be able to configure your machine to select rigorously the articles that meet your quality criteria; reject those that show defects while limiting false rejects as

much as possible.

Machine uptime 24/7

BY acquiring the notions you need for proper maintenance of your machine, you have tools for ensuring continuous

operation and, in the event of an incident, as little downtime as possible.

Optimizing the job change

The job change is a key moment on a glass-maker's production line: these training programmes will give you full control

over parameters and cut downtime while attaining optimal levels of performance as quickly as possible.

More Than Inspection — Tiama Worldwide Services 10

General information

Before the module

Together with our offer we will send you a contract that you can forward to your training organization for funding

purposes. We will also send you the detailed training programme and the timetables for each of the trainees.

End of the module

At the end of the module you will be given a comprehensive package including:

The individual attendance sheet(s) signed by the trainee(s) every half-day of attendance, signed off by the

trainer.

The certificate(s) of attainment based on the end-of-module assessment.

The training certificate(s) specifying the type of module completed.

The invoice.

The evaluation questionnaire

Cancellation

In the event of a withdrawal, you must e-mail a letter of cancellation ([email protected]) no later than

5 business days before the start of the module.

Otherwise, the training costs will be deemed “effectively spent and committed” and you will be invoiced

20% of the cost of the module by way of compensation.

If the module is not carried out in full through the fault of TIAMA, the invoice will be prorated to the hours

of training provided. You will be offered additional training.

Reception and accommodation

For modules held at our training centre, participants are asked to report to the site's reception desk.

A dedicated car park is at the disposal of visitors.

Hours: 9 am - 5 pm. Times can be adjusted if necessary.

To facilitate your stay, TIAMA also offers the following range of services:

- Shuttle service from Lyon Saint Exupéry airport or Part Dieu or Perrache stations, car hire

- Lunch

- Transfer to the hotels

Do not hesitate to contact us to benefit from these conveniences in your organization.

More Than Inspection — Tiama Worldwide Services 11

General information

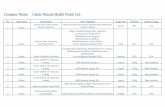

How to read our training summaries?

The trainee's

level

The type of machine The trainee's profile The reference number of the module to

quote when communicating with our teams

The key benefits

for the machine

Module

content

The number of

days' training

General

information

Module title

More Than Inspection — Tiama Worldwide Services 13

Body sidewall inspection machine

MCAL4 modules

VIS-OP-611: Operation

VIS-RE-611: Detection adjustments

VIS-RE-612: Expert Settings

VIS-RE-613: Adjustments specific to customer's product(s)

VIS-MA-611: Basic maintenance

VIS-MA-612: Mechanical maintenance

VIS-MA-613: Electronic maintenance

VIS-MA-614: IT maintenance

VIS-MA-615: Full maintenance

For more information, contact: [email protected] V1 12/2016

Target audience

This module is designed for line operators.

Prerequisites

Experience in handling manufacturing

machinery.

Aims

Acquire the knowledge needed to operate

the machine.

Practical arrangements

Location: on site or at TIAMA Vourles

Module for up to 5 people

Teaching resources

Theoretical explanations

Demonstration and practical exercises

Assessment

Each trainee is monitored during practicals.

Machine

Module content 1 day

2 1 3

Target level

General presentation of the machine (in the classroom and on simulators) Presentation of the MCAL4 Presentation of the SIDEWALL, STRESS, DIM and FC

inspection systems Presentation of the equipment Line management Presentation of the user interfaces Operation of the MCAL4

Getting the feel of the MCAL4 (on the machine)

Navigating in the user interface Resetting the counters Resetting the alarms Sampling Saving images and virtual samples Questions and assessment

Availability

Performance

Job change

Basic operation

MCAL4 — Operator VIS-OP-611

For more information, contact: [email protected] V1 12/2016

Machine

Module content 5 days

Target audience

This module is designed for line operators

and adjusters.

Prerequisites

Experience in handling manufacturing

machinery.

Aims

Acquire the knowledge needed to adjust the

machine (job change) and operate it.

Practical arrangements

Location: on site or at TIAMA Vourles

Module for up to 5 people

Teaching resources

Theoretical explanations

Practical exercises on simulators

Demonstration and practical exercises on

the machine

Assessment

Each trainee is monitored during practicals.

General presentation of the machine (in the classroom and on simulators) Presentation of the MCAL4 Presentation of the SIDEWALL, STRESS, DIM and FC

inspection systems Presentation of the equipment Line management Presentation of the user interfaces Job change principle (article record, optical settings) Adjusting SIDEWALL detection settings Adjusting STRESS detection settings Adjusting DIM detection settings Adjusting LC detection settings

Getting the feel of the MCAL4 (on the machine)

Alarm configuration Saving images and virtual samples Carrying out a job change Adjusting SIDEWALL detection settings Adjusting STRESS detection settings Adjusting DIM detection settings Adjusting LC detection settings Advanced settings (dynamic masks and dynamic zones) Questions and assessment

Availability

Performance

Job change

Detection adjustments

MCAL4 — Adjuster VIS-RE-611

2 1 3

Target level

For more information, contact: [email protected] V1 12/2016

Machine

Module content 5 days

Target audience

This module is designed for line operators

and expert adjusters.

Prerequisites

Experience in handling manufacturing

machinery

Have completed the adjuster

module

Aims

Acquire the knowledge needed to adjust the

machine (job change) and operate it.

Practical arrangements

Location: on site or at TIAMA Vourles

Module for up to 5 people

Teaching resources

Theoretical explanations

Practical exercises on simulators

Demonstration and practical exercises on

the machine

Assessment

Each trainee is monitored during practicals.

General presentation of the machine (in the classroom and on simulators) Further training in fine-tuning the SIDEWALL detection

(dynamic masks and dynamic zones) Further training in fine-tuning the STRESS detection Further training in fine-tuning the DIM detection Further training in fine-tuning the FC detection

Getting the feel of the MCAL4 (on the machine)

Further training in fine-tuning the SIDEWALL detection Further training in fine-tuning the STRESS detection Further training in fine-tuning the DIM detection Further training in fine-tuning the FC detection Fine-tuning advanced settings (dynamic masks and

dynamic zones) Questions and assessment

Availability

Performance

Job change

2 1 3

Target level

Expert Settings

MCAL4 — Adjuster VIS-RE-612

For more information, contact: [email protected] V1 12/2016

Machine

Module content 1 day

Target audience

This module is designed for line operators

and expert adjusters.

Prerequisites

Experience in handling manufacturing

machinery

Have completed the adjuster

module

Aims

Acquire the knowledge needed to adjust the

machine according to the customer's article.

Practical arrangements

Location:

- on the customer's site

- If the module is held at TIAMA's, the

customer's articles must be sent at least

15 days before the module

Module for up to 5 people

Teaching resources

Theoretical explanations

Practical exercises on simulators

Demonstration and practical exercises on

the machine

Assessment

Each trainee is monitored during practicals.

General presentation of the machine (in the classroom and on simulators) Job change principle (article record, optical settings) Optimized settings

Getting the feel of the MCAL4 (on the machine)

Carrying out a job change Optimizing settings Questions and assessment

Availability

Performance

Job change

2 1 3

Target level

Adjustments specific to customer's product(s)

MCAL4 — Adjuster VIS-RE-613

For more information, contact: [email protected] V1 12/2016

Machine

Module content

Availability

Performance

Job change

2 1 3

Target level

Basic maintenance

MCAL4 — Maintenance VIS-MA-611

Alarm configuration, maintenance and cleaning

Alarm configuration Calibrating the photoelectric cells Cleaning the cameras, light sources and photoelectric

cells Questions and assessment

0.5 day

Target audience

The module is designed for the maintenance

department or adjusters.

Prerequisites

Experience in handling manufacturing

machinery

Operator module

Aims

Acquire the knowledge needed to carry out

maintenance and basic cleaning.

Practical arrangements

Location: on site or at TIAMA Vourles

Module for up to 5 people

Teaching resources

Theoretical explanations

Practical exercises on simulators

Demonstration and practical exercises on

the machine

Assessment

Each trainee is monitored during practicals.

For more information, contact: [email protected] V1 12/2016

0.5 day

Machine

Module content Target audience

The module is designed for the maintenance

department or adjusters.

Prerequisites

Experience in handling manufacturing

machinery

Operator module

Aims

Acquire the knowledge needed to carry out

mechanical maintenance on the machine.

Practical arrangements

Location: on site or at TIAMA Vourles

Module for up to 5 people

Teaching resources

Theoretical explanations

Practical exercises on simulators

Demonstration and practical exercises on

the machine

Assessment

Each trainee is monitored during practicals.

Mechanical architecture of the machine (in the classroom and on simulators) Changing components (encoder) Adjusting the cameras

Getting the feel of the MCAL4 (on the machine)

Changing components (encoder) Adjusting the cameras Simulation and trouble-shooting Questions and assessment

Availability

Performance

Job change

2 1 3

Target level

Mechanical maintenance

MCAL4 — Maintenance VIS-MA-612

For more information, contact: [email protected] V1 12/2016

2 days

Machine

Module content Target audience

The module is designed for the maintenance

department or adjusters.

Prerequisites

Experience in handling manufacturing

machinery

Operator module

Aims

Acquire the knowledge needed to carry out

electronic maintenance on the machine.

Practical arrangements

Location: on site or at TIAMA Vourles

Module for up to 5 people

Teaching resources

Theoretical explanations

Practical exercises on simulators

Demonstration and practical exercises on

the machine

Assessment

Each trainee is monitored during practicals.

Electronic architecture of the machine (in the classroom and on simulators) Programming and changing electronic components

(CALIA, INCA and light sources) Diagnostic tools

Getting the feel of the MCAL4 (on the machine)

Programming and changing electronic components (CALIA, INCA and light sources)

Simulation and trouble-shooting Questions and assessment

2 1 3

Target level Machine

Availability

Performance

Job change

Electronic maintenance

MCAL4 — Maintenance VIS-MA-613

For more information, contact: [email protected] V1 12/2016

1 day Module content

Target audience

The module is designed for the maintenance

department or adjusters.

Prerequisites

Experience in handling manufacturing

machinery

Operator module

Aims

Acquire the knowledge needed to carry out

IT maintenance on the machine.

Practical arrangements

Location: on site or at TIAMA Vourles

Module for up to 5 people

Teaching resources

Theoretical explanations

Practical exercises on simulators

Demonstration and practical exercises on

the machine

Assessment

Each trainee is monitored during practicals.

IT architecture of the machine (in the classroom and on simulators) Data retrieval and backups Cloning hard drives Networking

Getting the feel of the MCAL4 (on the machine)

Practical exercises Questions and assessment

2 1 3

Target level Machine

Availability

Performance

Job change

IT maintenance

MCAL4 — Maintenance VIS-MA-614

For more information, contact: [email protected] V1 12/2016

4 days

Machine

Module content Target audience

The module is designed for the maintenance

department or adjusters.

Prerequisites

Experience in handling manufacturing

machinery

Operator module

Aims

Acquire the knowledge needed to carry out

full maintenance on the machine

(mechanical, electronic and IT).

Practical arrangements

Location: on site or at TIAMA Vourles

Module for up to 5 people

Teaching resources

Theoretical explanations

Practical exercises on simulators

Demonstration and practical exercises on

the machine

Assessment

Each trainee is monitored during practicals.

2 1 3

Target level

General presentation of the machine (in the classroom and on simulators) Presentation of the mechanical assemblies The principle of changing light sources, cameras and

encoders

Presentation of the electronic assemblies Description and roles of the printed circuit boards Diagnostic tools Programming and changing boards

Presentation of the IT architecture Data retrieval and backups Networking Cloning hard drives

Getting the feel of the MCAL4 (on the machine)

Mechanical Changing components (encoder) Adjusting the cameras Simulation and trouble-shooting

Electronics Programming and changing electronic components Simulation and trouble-shooting

IT Practical exercises

Questions and assessment

Availability

Performance

Job change

Full maintenance

MCAL4 — Maintenance VIS-MA-615

More Than Inspection — Tiama Worldwide Services 23

Finish and base inspection machine (MCF/STRESS/CSBCLO)

MULTI4 modules

VIS-OP-711: Operation

VIS-RE-711: Detection adjustments

VIS-RE-712: Expert Settings

VIS-RE-713: Additional station

VIS-RE-714: Adjustments specific to customer's product(s)

VIS-MA-711: Basic maintenance

VIS-MA-712: Mechanical maintenance

VIS-MA-713: Electronic maintenance

VIS-MA-714: IT maintenance

VIS-MA-715: Full maintenance

For more information, contact: [email protected] V1 12/2016

Target audience

The module is designed for line operators.

Prerequisites

Experience in handling manufacturing

machinery.

Aims

Acquire the knowledge needed to operate

the machine.

Practical arrangements

Location: on site or at TIAMA Vourles

Module for up to 5 people

Teaching resources

Theoretical explanations

Practical exercises on simulators

Demonstration and practical exercises on

the machine

Assessment

Each trainee is monitored during practicals.

Machine

Module content 1 day

2 1 3

Target level

General presentation of the machine (in the classroom and on simulators) Presentation of the MULTI4 Presentation of the MCF, CSBCLO, CRB inspection

systems... Presentation of the equipment Line management Presentation of the user interfaces

Getting the feel of the MULTI4 (on the machine)

Resetting the counters Resetting the alarms Sampling Saving images and virtual samples Questions and assessment

Availability

Performance

Job change

Basic operation

MULTI4 — Operator VIS-OP-711

For more information, contact: [email protected] V1 12/2016

Machine

Module content 5 days

Target audience

This module is designed for line operators

and adjusters.

Prerequisites

Experience in handling manufacturing

machinery.

Aims

Acquire the knowledge needed to adjust the

machine (job change) and operate it.

Practical arrangements

Location: on site or at TIAMA Vourles

Module for up to 5 people

Teaching resources

Theoretical explanations

Practical exercises on simulators

Demonstration and practical exercises on

the machine

Assessment

Each trainee is monitored during practicals.

General presentation of the machine (in the classroom and on simulators) Presentation of the MULTI4 Presentation of the MCF, STRESS, CSBCLO inspection

systems Presentation of the equipment Line management Presentation of the user interfaces Operating the MULTI4 Job change principle (article record, optical settings) Adjusting the MCF detection Adjusting the STRESS detection Adjusting the CSBCLO detection

Getting the feel of the MULTI4 (on the machine)

Alarm configuration Saving images and virtual samples Carrying out a job change Adjusting the MCF detection Adjusting the STRESS detection Adjusting the CSBCLO detection Advanced settings (dynamic masks and dynamic zones) Questions and assessment

Availability

Performance

Job change

Detection adjustments

MULTI4 — Adjuster VIS-RE-711

2 1 3

Target level

For more information, contact: [email protected] V1 12/2016

Machine

Module content 5 days

Target audience

This module is designed for line operators

and expert adjusters.

Prerequisites

Experience in handling manufacturing ma-

chinery

Have completed the adjuster

module

Aims

Acquire the knowledge needed to adjust the

machine (job change) and operate it.

Practical arrangements

Location: on site or at TIAMA Vourles

Module for up to 5 people

Teaching resources

Theoretical explanations

Practical exercises on simulators

Demonstration and practical exercises on

the machine

Assessment

Each trainee is monitored during practicals.

General presentation of the machine (in the classroom and on simulators) Further training in fine-tuning the MCF detection

(correlators and image rotation) Further training in fine-tuning the STRESS detection Further training in fine-tuning the CSBCLO detection

(advanced settings: algorithms)

Getting the feel of the MULTI4 (on the machine)

Further training in fine-tuning the MCF detection (correlator and image rotation)

Further training in fine-tuning the STRESS detection Further training in fine-tuning the CSBCLO detection Questions and assessment

Availability

Performance

Job change

2 1 3

Target level

Expert Settings

MULTI4 — Adjuster VIS-RE-712

For more information, contact: [email protected] V1 12/2016

Machine

Module content Target audience

This module is designed for line operators

and adjusters.

Prerequisites

Experience in handling manufacturing ma-

chinery

Have completed the adjuster

module

Aims

Acquire the knowledge needed to adjust the

machine (job change) and operate it.

Practical arrangements

Location: on site or at TIAMA Vourles

Module for up to 5 people

Teaching resources

Theoretical explanations

Practical exercises on simulators

Demonstration and practical exercises on

the machine

Assessment

Each trainee is monitored during practicals.

1 day

General presentation of the machine (in the classroom and on simulators) Presentation of the detection Presentation of the user interfaces Job change principle (article record, optical settings) Adjusting the detection

Getting the feel of the MULTI4 (on the machine)

Alarm configuration Saving images and virtual samples Carrying out a job change Adjusting the detection Questions and assessment

Availability

Performance

Job change

Additional station (LNMP/LNMC/SPIKE/CRBC)

MULTI4 — Adjuster VIS-RE-713

2 1 3

Target level

For more information, contact: [email protected] V1 12/2016

Adjustments specific to customer's product(s)

MULTI4 — Adjuster

Machine

Module content Target audience

This module is designed for line operators

and expert adjusters.

Prerequisites

Experience in handling manufacturing ma-

chinery

Have completed the adjuster

module

Aims

Acquire the knowledge needed to adjust the

machine according to the customer's article.

Practical arrangements

Location:

- on the customer's site

- If the module is held at TIAMA's, the

customer's articles must be sent at least

15 days before the module

Module for up to 5 people

Teaching resources

Theoretical explanations

Practical exercises on simulators

Demonstration and practical exercises on

the machine

Assessment

Each trainee is monitored during practicals.

1 day

General presentation of the machine (in the classroom and on simulators) Job change principle (article record, optical settings) Optimized settings

Getting the feel of the MULTI4 (on the machine)

Carrying out a job change Optimizing settings Questions and assessment

Availability

Performance

Job change

2 1 3

Target level

VIS-RE-714

For more information, contact: [email protected] V1 12/2016

Machine

Module content

Alarm configuration, maintenance and cleaning

Alarm configuration Calibrating the photoelectric cells Cleaning the cameras, light sources and photoelectric

cells Questions and assessment

Availability

Performance

Job change

2 1 3

Target level

Basic maintenance

MULTI4 — Maintenance VIS-MA-711

0.5 day

Target audience

The module is designed for the maintenance

department or adjusters.

Prerequisites

Experience in handling manufacturing ma-

chinery

Operator module

Aims

Acquire the knowledge needed to carry out

maintenance and basic cleaning.

Practical arrangements

Location: on site or at TIAMA Vourles

Module for up to 5 people

Teaching resources

Theoretical explanations

Practical exercises on simulators

Demonstration and practical exercises on

the machine

Assessment

Each trainee is monitored during practicals.

For more information, contact: [email protected] V1 12/2016

Machine

Module content

Make mechanical and optical adjustments

Adjusting the cameras Positioning the light sources

Fix mechanical components

Changing components (belts, encoders and motors) Simulation and trouble-shooting Questions and assessment

Availability

Performance

Job change

2 1 3

Target level

Mechanical maintenance

MULTI4 — Maintenance VIS-MA-712

1 day

Target audience

The module is designed for mechanical

maintenance technicians.

Prerequisites

Experience in handling manufacturing ma-

chinery

Operator module

Aims

Acquire the knowledge needed to detect

and replace faulty mechanical components.

Practical arrangements

Location: on site or at TIAMA Vourles

Module for up to 5 people

Teaching resources

Theoretical explanations

Practical exercises on simulators

Demonstration and practical exercises on

the machine

Assessment

Each trainee is monitored during practicals.

For more information, contact: [email protected] V1 12/2016

Module content

Electronic architecture of the machine

Functional presentation of the electronic components (CALIA, INCA, sources and control boxes)

Presentation of the different electronic architectures. Diagnostic tools

Repair the main electronic components

Programming and changing electronic components (CALIA, INCA, light sources and control boxes)

Simulation and trouble-shooting Questions and assessment

2 1 3

Target level Machine

Availability

Performance

Job change

Electronic maintenance

MULTI4 — Maintenance VIS-MA-713

Target audience

The module is designed for electronic

maintenance technicians.

Prerequisites

Experience in handling manufacturing ma-

chinery

Operator module

Aims

Acquire the knowledge needed to detect

and replace faulty electronic components.

Practical arrangements

Location: on site or at TIAMA Vourles

Module for up to 5 people

Teaching resources

Theoretical explanations

Practical exercises on simulators

Demonstration and practical exercises on

the machine

Assessment

Each trainee is monitored during practicals.

2 days

For more information, contact: [email protected] V1 12/2016

Module content

IT architecture of the machine (in the classroom and on simulators) Data retrieval and backups Functional presentation of the IT components Cloning hard drives Networking

Fixing the main IT components (on the machine)

Practical exercises Questions and assessment

2 1 3

Target level Machine

Availability

Performance

Job change

IT maintenance

MULTI4 — Maintenance VIS-MA-714

Target audience

The module is designed for IT maintenance

technicians or adjusters.

Prerequisites

Experience in handling manufacturing ma-

chinery

Operator module

Aims

Acquire the knowledge needed to carry out

IT maintenance on the machine.

Practical arrangements

Location: on site or at TIAMA Vourles

Module for up to 5 people

Teaching resources

Theoretical explanations

Practical exercises on simulators

Demonstration and practical exercises on

the machine

Assessment

Each trainee is monitored during practicals.

1 day

For more information, contact: [email protected] V1 12/2016

Module content

2 1 3

Target level Machine

Availability

Performance

Job change

Full maintenance

MULTI4 — Maintenance VIS-MA-715

General presentation of the machine

(in the classroom and on simulators)

Presentation of the mechanical and optical assemblies Positioning the light source Changing belts, encoders and motor

Electronics architecture Description and role of the printed circuit boards Diagnostic tools Programming and changing the main electronic compo-

nents

Computing architecture Data retrieval and backups Cloning hard drives Networking

Repairing the main components (on the machine)

Mechanical Changing components Simulation and trouble-shooting

Electronics Programming and changing electronic components Simulation and trouble-shooting

IT Practical exercises Operations on hard drives (installing a new hard drive

and configuring a backup hard drive)

Questions and assessment

4 days

Target audience

The module is designed for the maintenance

department or adjusters.

Prerequisites

Experience in handling manufacturing ma-

chinery

Operator module

Aims

Acquire the knowledge needed to carry out

full maintenance on the machine

(mechanical, electronic and IT).

Practical arrangements

Location: on site or at TIAMA Vourles

Module for up to 5 people

Teaching resources

Theoretical explanations

Practical exercises on simulators

Demonstration and practical exercises on

the machine

Assessment

Each trainee is monitored during practicals.

More Than Inspection — Tiama Worldwide Services 35

MCAL4/MULTI4 modules

VIS-MA-311: Full maintenance of MCAL4/MULTI4

Combination of inspection machines

body, finish and base

For more information, contact: [email protected] V1 12/2016

5 days

Machine

Module content Target audience

This module is designed for line operators

and adjusters.

Prerequisites

Experience in handling manufacturing ma-

chinery

Operator module

Aims

Acquire the knowledge needed to carry out

full maintenance on the machine

(mechanical, electronic and IT).

Practical arrangements

Location: on site or at TIAMA Vourles

Module for up to 5 people

Teaching resources

Theoretical explanations

Practical exercises on simulators

Demonstration and practical exercises on

the machine

Assessment

Each trainee is monitored during practicals.

General presentation of the machines (in the classroom and on simulators) Presentation of the mechanical assemblies The principle of changing light sources, cameras,

encoders, belts and gear motors

Presentation of the electronic equipment Description and role of the printed circuit boards Diagnostic tools Programming and changing boards

Presentation of the IT architecture Data retrieval and backups Cloning hard drives Networking

Getting the feel of the machines

Mechanical Changing components Adjusting the cameras Simulation and trouble-shooting

Electronics Programming and changing electronic components Simulation and trouble-shooting

IT Practical exercises

Questions and assessment

Availability

Performance

Job change

2 1 3

Target level

Full maintenance of MCAL4/MULIT4

MCAL4 / MULTI4 — Maintenance VIS-MA-311

More Than Inspection — Tiama Worldwide Services 37

Multi-inspection machine

MX4 modules

CAR-OP- 301: Basic operation

CAR-RE-301: Detection adjustments

CAR-RE-302: Adjustments specific to customer's product(s)

CAR-MA-301: Basic maintenance

CAR-MA-302: Mechanical maintenance

CAR-MA-303: Electronic maintenance

CAR-MA-304: Full maintenance

CAR-RE-501: ATLAS detection adjustments

CAR-MA-501: Full ATLAS maintenance

CAR-RE-502: NCG detection adjustments

CAR-MA-502: Full NCG maintenance

CAR-RE-503: NCL detection adjustments

CAR-MA-503: Full NCL maintenance

General presentation of the machines (in the classroom and on simulators) Presentation of the mechanical assemblies The principle of changing light sources, cameras,

encoders, belts and gear motors

Presentation of the electronic equipment Description and role of the printed circuit boards Diagnostic tools Programming and changing boards

Presentation of the IT architecture Data retrieval and backups Cloning hard drives Networking

Getting the feel of the machines

Mechanical Changing components Adjusting the cameras Simulation and trouble-shooting

Electronics Programming and changing electronic components Simulation and trouble-shooting

IT Practical exercises

Questions and assessment

For more information, contact: [email protected] V1 12/2016

Target audience

The module is designed for line operators.

Prerequisites

Experience in handling manufacturing ma-

chinery.

Aims

Acquire the knowledge needed to restart the

MX4 machine (after an alarm stop) and ope-

rate it.

Practical arrangements

Location: on site or at TIAMA Vourles

Module for up to 5 people

Teaching resources

Theoretical explanations

Demonstration and practical exercises

Assessment

Each trainee is monitored during practicals.

Machine

Module content 1 day

2 1 3

Target level

General presentation of the machine (in the classroom and on simulators) Presentation of the MX4 General presentation:

- Mechanical - Electric - Electronic - Inspections

Line management Presentation of the user interfaces Operating the MX4

Getting the feel of the MX4 (on the machine)

Navigating in the user interface Statistics/Last 10 rejects menus Mould management Marker management Sampling Fault management (physical and software) Machine safety Questions and assessment

Availability

Performance

Job change

Basic operation

MX4 — Operator CAR-OP-301

For more information, contact: [email protected] V1 12/2016

Machine

Module content 5 days

Target audience

This module is designed for line operators

and adjusters.

Prerequisites

Experience in handling manufacturing ma-

chinery.

Aims

Acquire the knowledge needed to adjust the

machine (job change) and operate it.

Practical arrangements

Location: on site or at TIAMA Vourles

Module for up to 5 people

Teaching resources

Theoretical explanations

Demonstration and practical exercises on

the machine

Assessment

Each trainee is monitored during practicals.

General presentation of the machine (in the classroom and on simulators) Presentation of the MX4 Description of the machine:

- kinematics - electronics - interactions with line management

Presentation of the equipment Line management Presentation of the user interfaces and different menus Operating the MX4 Job change principles Adjusting the Calibration detection Adjusting the DIP (leak) detection Adjusting the Checks detection Adjusting the contactless thickness measurement detec-

tion Adjusting the mould number reader Adjusting the Ovalization detection

Getting the feel of the MX4 (on the machine)

Operating the MX4 Carrying out job changes Adjusting the Calibration detection Adjusting the DIP (leak) detection Adjusting the Checks detection Adjusting the contactless thickness measurement detec-

tion Adjusting the Ovalization detection Adjusting the mould number reader Alarm configuration Questions and assessment

Availability

Performance

Job change

Detection adjustments

MX4 — Adjuster CAR-RE-301

2 1 3

Target level

For more information, contact: [email protected] V1 12/2016

Adjustments specific to customer's product(s)

MX4 — Adjuster

Machine

Module content Target audience

This module is designed for line operators

and expert adjusters.

Prerequisites

Experience in handling manufacturing ma-

chinery

Have completed the adjuster

module

Aims

Acquire the knowledge needed to adjust the

machine according to the customer's article.

Practical arrangements

Location:

- on the customer's site

- If the module is held at TIAMA's, the

customer's article drawings must be sent

at least 1 months before the module and

the articles 15 days before the module

Module for up to 5 people

Teaching resources

Theoretical explanations

Practical exercises on simulators

Demonstration and practical exercises on

the machine

Assessment

Each trainee is monitored during practicals.

1 day

General presentation of the machine (in the classroom and on simulators) Operating the MX4 Job change principle (article record, transport) Optimized settings

Getting the feel of the MX4 (on the machine)

Operating the MX4 Carrying out a job change Optimizing settings Questions and assessment

Availability

Performance

Job change

2 1 3

Target level

CAR-RE-302

For more information, contact: [email protected] V1 12/2016

0.5 day

Machine

Module content Target audience

This module is designed for line operators

and adjusters.

Prerequisites

Experience in handling manufacturing ma-

chinery

Aims

Acquire the knowledge needed to carry out

machine maintenance and level-one repairs.

Practical arrangements

Location: on site or at TIAMA Vourles

Module for up to 5 people

Teaching resources

Theoretical explanations

Demonstration and practical exercises on

the machine

Assessment

Each trainee is monitored during practicals.

Availability

Performance

Job change

2 1 3

Target level

General presentation of the machine (in the classroom and on simulators) Cleaning and mechanical, electric, electronic and optical

maintenance Presentation of the various elements Calibrating the photoelectric cells

Getting the feel of the MX4 (on the machine)

Cleaning and maintenance Questions and assessment

Basic maintenance

MX4 — Maintenance CAR-MA-301

For more information, contact: [email protected] V1 12/2016

1 day

Machine

Module content Target audience

This module is designed for line operators

and adjusters.

Prerequisites

Experience in handling manufacturing ma-

chinery

Aims

Acquire the knowledge needed to carry out

mechanical maintenance on the machine.

Practical arrangements

Location: on site or at TIAMA Vourles

Module for up to 5 people

Teaching resources

Theoretical explanations

Demonstration and practical exercises on

the machine

Assessment

Each trainee is monitored during practicals.

Availability

Performance

Job change

Mechanical architecture of the machine (in the classroom and on simulators) Changing consumables Changing mechanical components

Getting the feel of the MX4 (on the machine)

Changing mechanical components (Belts, control parts) Simulation and trouble-shooting mechanical problems Questions and assessment

2 1 3

Target level

Mechanical maintenance

MX4 — Maintenance CAR-MA-302

For more information, contact: [email protected] V1 12/2016

2 days

Machine

Module content Target audience

This module is designed for line operators

and adjusters.

Prerequisites

Experience in handling manufacturing ma-

chinery

Aims

Acquire the knowledge needed to carry out

electronic maintenance on the machine.

Practical arrangements

Location: on site or at TIAMA Vourles

Module for up to 5 people

Teaching resources

Theoretical explanations

Demonstration and practical exercises on

the machine

Assessment

Each trainee is monitored during practicals.

Availability

Performance

Job change

Electronic architecture of the machine (in the classroom and on simulators) Printed circuit board functions Communication and networks between the different

components Programming electronic components Diagnostic tools

Getting the feel of the MX4 (on the machine)

Programming and changing electronic components (inverters, PLC, printed circuit boards)

Using the diagnostic tools Understanding the wiring diagram Simulation and trouble-shooting Questions and assessment

2 1 3

Target level

Electronic maintenance

MX4 — Maintenance CAR-MA-303

For more information, contact: [email protected] V1 12/2016

4 days Module content

Target audience

The module is designed for the maintenance

department or adjusters.

Prerequisites

Experience in handling manufacturing ma-

chinery

Aims

Acquire the knowledge needed to carry out

full maintenance on the machine

(mechanical, electronic and IT).

Practical arrangements

Location: on site or at TIAMA Vourles

Module for up to 5 people

Teaching resources

Theoretical explanations

Demonstration and practical exercises on

the machine

Assessment

Each trainee is monitored during practicals.

2 1 3

Target level

General presentation of the machine Cleaning and mechanical, electric, electronic and optical

maintenance

Mechanical architecture of the machine

Changing consumables Changing mechanical components (Belts, control parts) Principles and job change

Electronic architecture of the machine

Printed circuit board functions Communication and networks between the different

components Programming and changing electronic components

(inverters, PLC, printed circuit boards) Using the diagnostic tools Understanding the wiring diagram

IT architecture of the machine

Data retrieval and backups Cloning hard drives Networking

Getting the feel of the MX4 (on the machine)

Practical exercises Questions and assessment

Machine

Availability

Performance

Job change

Full maintenance

MX4 — Maintenance CAR-MA-304

For more information, contact: [email protected] V1 12/2016

Machine

Module content 2 days

Target audience

This module is designed for line operators

and adjusters.

Prerequisites

Experience in handling manufacturing ma-

chinery.

Have completed the adjuster module for the ATLAS host ma-

chine

Aims

Acquire the knowledge needed to adjust and

operate the ATLAS detection.

Practical arrangements

Location: on site or at TIAMA Vourles

Module for up to 5 people

Teaching resources

Theoretical explanations

Practical exercises

Demonstration and practical exercises on

the machine

Assessment

Each trainee is monitored during practicals.

General presentation of the ATLAS detection (in the classroom) Concept and operating principle Accessing the menus, navigation Description of the Settings menu Description of the Production (Run) menus Article management principle Job change principle

Getting the feel of the ATLAS (on the machine)

Running the ATLAS on the host machine Carrying out job changes Adjusting the ATLAS detection alarm configuration Questions and assessment

Availability

Performance

Job change

ATLAS detection adjustments

ATLAS detection — Adjuster CAR-RE-501

2 1 3

Target level

For more information, contact: [email protected] V1 12/2016

2 days Module content

Target audience

The module is designed for the maintenance

department or adjusters.

Prerequisites

Experience in handling manufacturing ma-

chinery

Have completed the operator module for the ATLAS host ma-

chine

Aims

Acquire the knowledge needed to carry out

full maintenance of the ATLAS (mechanical,

electronic and IT).

Practical arrangements

Location: on site or at TIAMA Vourles

Module for up to 5 people

Teaching resources

Theoretical explanations

Practical exercises

Demonstration and practical exercises on

the machine

Assessment

Each trainee is monitored during practicals.

2 1 3

Target level

General presentation of the ATLAS detection Concept and operating principle Routine maintenance of the ATLAS detection

(mechanical, electronic and IT) Navigation and accessing the various menus

Electronic architecture of the machine

Printed circuit board functions Communication between the ATLAS and the host

machine Programming and changing electronic components

(Printed circuit boards, cameras, PC, light sources) Using the diagnostic tools Understanding the wiring diagram

IT architecture of the machine

Data retrieval and backups Cloning hard drives

Getting the feel of the detection (on the machine)

Practical exercises Trouble-shooting and simulation of faults Questions and assessment

Machine

Availability

Performance

Job change

Full ATLAS maintenance

ATLAS detection — Maintenance CAR-MA-501

For more information, contact: [email protected] V1 12/2016

Machine

Module content 0.5 day

Target audience

This module is designed for line operators

and adjusters.

Prerequisites

Experience in handling manufacturing ma-

chinery.

Have completed the adjuster

module the NCG's host machine

Aims

Acquire the knowledge needed to adjust and

operate the NCG detection

Practical arrangements

Location: on site or at TIAMA Vourles

Module for up to 5 people

Teaching resources

Theoretical explanations

Practical exercises

Demonstration and practical exercises on

the machine

Assessment

Each trainee is monitored during practicals.

General presentation of the NCG detection (in the classroom and on simulators) Concept and operating principle Accessing the menus, navigation Description of the Settings menu Description of the Production (Run) menus Article management principle

Getting the feel of the NCG detection (on the machine)

Running the NCG on the host machine Carrying out job changes Adjusting the NCG detection alarm configuration Questions and assessment

Availability

Performance

Job change

NCG detection adjustments

NCG detection — Adjuster CAR-RE-502

2 1 3

Target level

For more information, contact: [email protected] V1 12/2016

0,5 day Module content

Target audience

The module is designed for the maintenance

department or adjusters.

Prerequisites

Experience in handling manufacturing

machinery

Have completed the operator module for

the NCG host machine

Aims

Acquire the knowledge needed to carry out full maintenance on the NCG (mechanical,

electronic and IT).

Practical arrangements

Location: on site or at TIAMA Vourles

Module for up to 5 people

Teaching resources

Theoretical explanations

Pratical exercises

Demonstration and practical exercises

on the machine

Assessment

Each trainee is monitored during practicals.

2 1 3

Target level

General presentation of the NCG detection

Concept and operating principle Routine maintenance of the NCG

detection (mechanical, electronic and IT) Navigation and accessing the various menus

Electronic architecture of the machine

The detection's function Communication and networks with the host machine Programming and changing electronic components

(Printed circuit boards, cameras, PC, light sources) Using the diagnostic tools Understanding the wiring diagram

Getting the feel of the detection (on the machine)

Practical exercises Questions and assessment

Machine

Availability

Performance

Job change

Full NCG maintenance

NCG — Maintenance CAR-MA-502

For more information, contact: [email protected] V1 12/2016

Machine

Module content 0,5 day

Target audience

This module is designed for line operators and adjusters.

Prerequisites

Experience in handling manufacturing

machinery .

Have completed the adjuster module for

the NCL host machine

Aims

Acquire the knowledge needed to adjust and

run the NCL detection

Practical arrangements

Location: on site or at TIAMA Vourles

Module for up to 5 people

Teaching resources

Theoretical explanations

Pratical exercises

Demonstration and practical exercises

on the machine

Assessment

Each trainee is monitored during practicals.

General presentation of the NCL detection (in the class-

room and on simulators)

Concept and operating principle Navigation and accessing the various menus Description of the settings menu Description of the Production (Run) menus Articles management principle

Getting the feel of the NCL detection (on the machine)

Running the NCL on the host machine Carrying out job changes Adjusting the NCL detection Alarm configuration Questions and assessment

Availability

Performance

Job change

NCL detection adjustments

NCL detection — Adjuster CAR-RE-503

2 1 3

Target level

For more information, contact: [email protected] V1 12/2016

0,5 day Module content

Target audience

The module is designed for the maintenance

department or adjusters.

Prerequisites

Experience in handling manufacturing

machinery

Have completed the operator

module for the NCL host machine

Aims

Acquire the knowledge needed to carry out full maintenance on the NCL (mechanical,

electronic and IT).

Practical arrangements

Location: on site or at TIAMA Vourles

Module for up to 5 people

Teaching resources

Theoretical explanations

Pratical exercises

Demonstration and practical exercises on

the machine

Assessment

Each trainee is monitored during practicals.

2 1 3

Target level

General presentation of the NCL detection Concept and operating principle Routine maintenance of the NCL detection (mechanical,

electronic and IT) Navigation and accessing the various menus

Electronic architecture of the machine

The detection’s function Communication and networks with the host machine Programming and changing electronic components (Printed

circuit boards, cameras, PC, light sources) Using the diagnostic tools Understanding the wiring diagram

Getting the feel of the detection (on the machine)

Practical exercises Questions and assessment

Machine

Availability

Performance

Job change

NCL Full Maintenance

NCL detection — Maintenance CAR-MA-503

More Than Inspection — Tiama Worldwide Services 51

MCAL3 modules

VIS-OP-601 : Operation

VIS-RE-601 : Detection adjustment

VIS-RE-602 : Expert settings

VIS-RE-603 : Adjustments specific to customer’s product(s)

VIS-MA-601: Basic Maintenance

VIS-MA-602 : Mechanical Maintenance

VIS-MA-603 : Electronic Maintenance

VIS-MA-604 : IT Maintenance

VIS-MA-605 : Full Maintenance

Body sidewall inspection machine

For more information, contact: [email protected] V1 12/2016

Machine

Module content 1 day

2 1 3

Target level

Availability

Performance

Job change

Basic operation

MCAL3 — Operator

Target audience

The module is designed for line operators.

Prerequisites

Experience in handling manufacturing

machinery.

Aims

Acquire the knowledge needed to operate

the machine.

Practical arrangements

Location: on site or at TIAMA Vourles

Module for up to 5 people

Teaching resources

Theoretical explanations

Demonstration and practical exercises

Assessment

Each trainee is monitored during practicals.

General presentation of the machine

MCAL3 presentation Presentation of the ASPECT, STRESS and DIM inspection

systems Presentation of the equipment Line management Presentation of the user interfaces Operation of the MCAL3

Getting the feel of the MCAL3 (on the machine)

Navigating in the user interface Resetting the counters Resetting the alarms Sampling Saving images and virtual samples Questions and assessment

VIS-OP-601

For more information, contact: [email protected] V1 12/2016

Machine

Module content 5 days

Target audience

The module is designed for line operators

and adjusters.

Prerequisites

Experience in handling manufacturing ma-

chinery.

Aims

Acquire the knowledge needed to adjust the

machine (job change) and operate it .

Practical arrangements

Location: on site or at TIAMA Vourles

Module for up to 5 people

Teaching resources

Theoretical explanations

Demonstration and practical exercises on the machine

Assessment

Each trainee is monitored during practicals.

General presentation of the machine

Presentation of the MCAL3 Presentation of the ASPECT, STRESS and DIM inspection

systems Presentation of the equipment Line management Presentation of the user interfaces Operation of the MCAL3 Job change principes

(article record, optical settings) Adjusting the SIDEWALL detection Adjusting the STRESS detection Adjusting the DIM detection

Getting the feel of the MCAL3 (on the machine)

Operation of the MCAL3 Alarm configuration Saving images and virtual samples Carrying out a job change Adjusting the SIDEWALL detection Adjusting the STRESS detection Adjusting the DIM detection Questions and assessment

Availability

Performance

Job change

Detection adjustments

MCAL3 — Adjuster VIS-RE-601

2 1 3

Target level

For more information, contact: [email protected] V1 12/2016

Machine

Module content 5 days

Target audience

The module is designed for line operators and

expert adjusters

Prerequisites

Experience in handling manufacturing

machinery

Have completed the adjuster module

Aims

Acquire the knowledge needed to adjust the

machine (job change) and operate it.

Practical arrangements

Location: on site or at TIAMA

Vourles

Module for up to 5 people

Teaching resources

Theoretical explanations

Demonstration and practical exercises on

the machine

Assessment

Each trainee is monitored during practicals.

General Presentation of the machine

(in the classroom and on simulators)

Operation of the MCAL3 Further training in fine-tuning the SIDEWALL detection Further training in fine-tuning the STRESS detection Further training in fine-tuning the DIM detection

Getting the feel of the MCAL3 (on the machine)

Operation of the MCAL3 Further training in fine-tuning the SIDEWALL detection Further training in fine-tuning the STRESS detection Further training in fine-tuning the DIM detection Questions and assessment

Availability

Performance

Job change

2 1 3

Target level

Expert Settings

MCAL3 — Adjuster VIS-RE-602

For more information, contact: [email protected] V1 12/2016

Machine

Module content 1 day

Target audience

The module is designed for line operators and

expert adjusters

Prerequisites

Experience in handling manufacturing

machinery

Have completed the adjuster module

Aims

Acquire the knowledge needed to adjust the

machine according to the customer’s article.

Practical arrangements

Location:

- on the customer’s site

- If the module is held at TIAMA's, the

customer's articles must be sent at

least 15 days before the module

Module for up to 5 people

Teaching resources

Theoretical explanations

Demonstration and practical exercises on

the machine

Assessment

Each trainee is monitored during practicals.

General Presentation of the machine Operation of the MCAL3 Job change principes

(article record, optical settings) Optimized settings

Getting the feel of the MCAL3 (on the machine)

Operation of the MCAL3 Carrying out a job change Optimized settings Questions and assessement

Availability

Performance

Job change

2 1 3

Target level

Adjustments specific to customer's products

MCAL3 — Adjuster VIS-RE-603

For more information, contact: [email protected] V1 12/2016

0,5 day

Machine

Module content Target audience

The module is designed for the maintenance

department or adjusters.

Prerequisites

Experience in handling manufacturing

machinery

Operator module

Aims

Acquire the knowledge needed to adjust

the machine (job change) and operate it.

Practical arrangements

Location: on site or at TIAMA Vourles

Module for up to 5 people

Teaching resources

Theoretical explanations

Demonstration and practical exercises

on the machine

Assessment

Each trainee is monitored during practicals.

General presentation of the machine

Cleaning the cameras, light sources and photoelectric cells Calibrating the photoelectric cells

Getting the feel of the MCAL3 (on the machine)

Alarm configuration Cleaning the cameras, light sources and photoelectric cells Calibrating the photoelectric cells Questions and assessment

Availability

Performance

Job change

2 1 3

Target level

Basic Maintenance

MCAL3 — Maintenance VIS-MA-601

For more information, contact: [email protected] V1 12/2016

0,5 day

Machine

Module content Target audience

The module is designed for the maintenance

department or adjusters.

Prerequisites

Experience in handling manufacturing

machinery

Operator module

Aims

Acquire the knowledge needed to carry ou

the mechanical maintenance on the machine.

Practical arrangements

Location: on site or at TIAMA Vourles

Module for up to 5 people

Teaching resources

Theoretical explanations

Demonstration and practical exercises

on the machine

Assessment

Each trainee is monitored during practicals.

Mechanical architecture of the machine

Changing components (encoder) Adjusting the cameras

Getting the feel of the MCAL3 (on the machine)

Changing components (encoder) Adjusting the cameras Trouble-shooting Questions and assessment

Availability

Performance

Job change

2 1 3

Target level

Mechanical Maintenance

MCAL3 — Maintenance VIS-MA-602

For more information, contact: [email protected] V1 12/2016

2 days

Machine

Module content Target audience

The module is designed for the maintenance

department or adjusters.

Prerequisites

Experience in handling manufacturing

machinery

Operator module

Aims

Acquire the knowledge needed to carry out

the electronic maintenance of the machine.

Practical arrangements

Location: on site or at TIAMA Vourles

Module for up to 5 people

Teaching resources

Theoretical explanations

Demonstration and practical exercises

on the machine

Assessment

Each trainee is monitored during practicals.

Electronic architecture of the machine

Programming and changing electronic components (IA 2000, I 02, IES and light sources)

Diagnostic tools

Getting the feel of the MCAL3 (on the machine)

Programming and changing electronic components (IA 2000, I 02, IES and light sources)

Simulation and trouble-shootings Questions and assessment

2 1 3

Target level Machine

Availability

Performance

Job change

Electronic maintenance

MCAL3 — Maintenance VIS-MA-603

For more information, contact: [email protected] V1 12/2016

1 day Module content

Target audience

The module is designed for the maintenance

department or adjusters.

Prerequisites

Experience in handling manufacturing

machinery

Operator module

Aims

Acquire the knowledge needed to carry out

the IT maintenance of the machine.

Practical arrangements

Location: on site or at TIAMA Vourles

Module for up to 5 people

Teaching resources

Theoretical explanations

Demonstration and practical exercises

on the machine

Assessment

Each trainee is monitored during practicals.

IT architecture of the machine

Data retrieval and backups Cloning hard drives Networking

Getting the feel of the MCAL3 (on the machine)

Practical exercises Questions and assessment

2 1 3

Target level Machine

Availability

Performance

Job change

IT maintenance

MCAL3 — Maintenance VIS-MA-604

For more information, contact: [email protected] V1 12/2016

4 days

Machine

Module content Target audience

The module is designed for the maintenance

department or adjusters.

Prerequisites

Experience in handling manufac-

turing machinery

Operator module

Aims

Acquire the knowledge needed to carry

out full maintenance of the machine

(mechanical, electronic and IT).

Practical arrangements

Location: on site or at TIAMA

Vourles

Module for up to 5 people

Teaching resources

Theoretical explanations

Demonstration and practical exercises on

the machine

Assessment

Each trainee is monitored during practicals.

2 1 3

Target level

General presentation of the machine

Presentation of the mechanical assemblies The principle of changing light sources, cameras and en-

coders Presentation of the electronic assemblies Description and role of the printed circuit boards Diagnostic tools Programming and changing printed circuit boards

Presentation of the IT architecture Data retrieval and backups Networking Cloning hard drives

Getting the feel of the MCAL3 (on the machine)

Mechanical Changing components (encoder) Adjusting the cameras Trouble-shooting

Electronic Programming and changing electronic components

Trouble-shooting

IT Practical exercises Questions and assessment

Availability

Performance

Job change

Full maintenance

MCAL3 — Maintenance VIS-MA-605

More Than Inspection — Tiama Worldwide Services 61

MULTI3 modules

VIS-OP-701 : Operation

VIS-RE-701 : Detection adjustments

VIS-RE-702 : Expert settings

VIS-RE-703 : Additional station

VIS-RE-704 : Adjustments specific to customer’s product(s)

VIS-MA-701 : Basic maintenance

VIS-MA-702 : Mechanical maintenance

VIS-MA-703 : Electronic maintenance

VIS-MA-704 : IT maintenance

VIS-MA-705 : Full maintenance

Finish and base inspection machine (MCF/STRESS/CSBCLO)

For more information, contact: [email protected] V1 12/2016

Target audience

The module is designed for the line operators.

Prerequisites

Experience in handling manufacturing

machinery

Aims

Acquire the knowledge needed to operate

the machine.

Practical arrangements

Location: on site or at TIAMA Vourles

Module for up to 5 people

Teaching resources

Theoretical explanations

Demonstration and practical exercises on

the machine

Assessment

Each trainee is monitored during practicals.

Machine

Module content 1 day

2 1 3

Target level

General presentation of the machine

(in the classroom and on simulators)

Presentation of the MULTI3 Presentation of the MCF, CSBCLO, CRB inspection

systems Presentation of the equipment Line management Presentation of the user interfaces

Getting the feel of the MULTI3 (on the machine)

Operating the MULTI3 Resetting the counters Resetting the alarms Sampling Saving images and virtual samples Questions and assessment

Availability

Performance

Job change

Basic operation

MULTI3 — Operator VIS-OP-701

For more information, contact: [email protected] V1 12/2016

Machine

Module content 5 days

Target audience

The module is designed for line operators and

adjusters.

Prerequisites

Experience in handling manufacturing

machinery

Aims

Acquire the knowledge needed to adjust the

machine (job change) and operate it.

Practical arrangements

Location: on site or at TIAMA Vourles

Module for up to 5 people

Teaching resources

Theoretical explanations

Demonstration and practical exercises on

the machine

Assessment

Each trainee is monitored during practicals.

General presentation of the machine

Presentation of the MULTI3 Presentation of the MCF, STRESS, CSBCLO, CRBC,

LNMP, LNMC, BNR inspection systems Presentation of equipment Line management Presentation of the user interfaces Operating the MULTI3 Job change principle

(article record, optical settings ) Adjusting the MCF detection Adjusting the STRESS detection Adjusting the CSBC or CSBCLO detection

Getting the feel of the MULTI3 (on the machine)

Operating the MULTI3 Alarm configuration Saving images and virtual samples (depending of the

version) Carrying out a job change Adjusting the MCF detection Adjusting the STRESS detection Adjusting the CSBC or CSBCLO detection Questions and assessment

Availability

Performance

Job change

Detection adjustment

MULTI3 — Adjuster VIS-RE-701

2 1 3

Target level

For more information, contact: [email protected] V1 12/2016

Machine

Module content 5 days

Target audience

The module is designed for line operators and

expert adjusters.

Prerequisites

Experience in handling manufacturing

machinery

Have completed the adjuster module

Aims

Acquire the knowledge needed to adjust the

machine (job change) and operate it.

Practical arrangements

Location: on site or at TIAMA Vourles

Module for up to 5 people

Teaching resources

Theoretical explanations

Demonstration and practical exercises on

the machine

Assessment

Each trainee is monitored during practicals.

General presentation of the machine

Operating the MULTI3 Further training in fine-tuning the MCF detection Further training in fine-tuning the STRESS detection Further training in fine-tuning the CSBC standard detection Further training in fine-tuning the CSBCLO detection

(advanced settings: algorithms ) Further training in fine-tuning the LNMα detection Further training in fine-tuning the CRBC detection Further training in fine-tuning the BNR detection

Getting the feel of the MULTI3 (on the machine)

Operating the MULTI3 Further training in fine-tuning the MCF detection Further training in fine-tuning the STRESS detection Further training in fine-tuning the CSBC standard detection Further training in fine-tuning the CSBCLO detection Further training in fine-tuning the LNMα detection Further training in fine-tuning the CRBC detection Further training in fine-tuning the BNR detection Questions and assessment

Availability

Performance

Job change

2 1 3

Target level

Expert settings

MULTI3 — Adjuster VIS-RE-702

For more information, contact: [email protected] V1 12/2016

Machine

Module content Target audience

The module is designed for line operators and

adjusters.

Prerequisites

Experience in handling manufacturing

machinery

Have completed the adjuster module

Aims

Acquire the knowledge needed to adjust the

machine (job change) and operate it.

Practical arrangements

Location: on site or at TIAMA Vourles

Module for up to 5 people

Teaching resources

Theoretical explanations

Demonstration and practical exercises on

the machine

Assessment

Each trainee is monitored during practicals.

1 day

General presentation of the machine

Presentation of the detection Presentation of the user interfaces Job change principle

(article record, optical settings ) Adjusting the detection

Getting the feel of the MULTI3 (on the machine)

Alarm configuration Saving images and virtual samples Carrying out a job change Adjusting the detection Questions and assessment

Availability

Performance

Job change

Additional station

MULTI3 — Adjuster VIS-RE-703

2 1 3

Target level

For more information, contact: [email protected] V1 12/2016

Adjustments specific to customer's product(s)

MULTI3 — Adjuster

Machine

Module content Target audience

The module is designed for line operators and

expert adjusters.

Prerequisites

Experience in handling manufacturing

machinery

Have completed the adjuster module

Aims

Acquire the knowledge needed to adjust the

machine according to the customer’s article.

Practical arrangements

Location:

- on the customer’s site

- If the module is held at TIAMA's, the