TOOLING Coating catch-up - MARK ALLEN GROUP · super fine levels of coating through the application...

Transcript of TOOLING Coating catch-up - MARK ALLEN GROUP · super fine levels of coating through the application...

There are continual coatingdevelopments, with all of the major

cutting tool manufacturers keen tolaunch coated tools that offer newadvantages. For example, Horn’s in-house developed TH35 titaniumaluminium nitride coating has beendeveloped specifically to combat theproblem of built-up edge. This ispotentially a major problem in sub-miniature machining applications suchas those for which the company’sSupermini boring and internal profilingtools are designed. TH35 provides highhardness and oxidation resistancecombined with an exceptionally smoothsurface. Another recently introducedcoating, WNT’s HCF 1130, comes into itsown when turning high tensile steels,HSS materials and chrome-nickel steels.WNT says that this new coating can

reduce massively the friction betweeninsert and workpiece.

Also, the

multi-layer composition of the HCFcoating delivers a high elasticity that hasthe effect of damping cutting forces.

Within the same family of inserts,WNT has introduced its HCF 3110 gradewhich, while visually the same as HCF1130, has been developed specifically formachining cast iron. The combination ofthe friction-reducing and multi-layerattributes of the coating combined witha K10 carbide substrate provides acompetitive alternative to ceramics.

“The move to PVD coatingtechnology in the production of cuttinginserts has resulted in edges that aremuch ‘sharper’ than can be achievedwith CVD,” says Adrian Fitts, WNT (UK)’sbusiness development manager. “This isideal for applications in stainless andhigh alloy steels.” WNT says it willcontinue to introduce innovativecoatings for its range of cutting tools,placing emphasis on the relationshipbetween the coating and the carbide

substrate. It is fully expected thatparting and grooving

systems will

be next to benefit from PVD coatings.WNT is part of the Ceratizit

consortium, which itself is recognised asa pioneer in coating, a recent case inpoint being HyperCoat technology,which features a particular resistance toheat and a low tendency to stick.HyperCoat combines optimised carbidesubstrates with multi-layer CVD coatingsand an innovative final surfacetreatment to improve the surfaceproperties, cutting edge protection andwear resistance of the insert.

NANO LAYERSAccording to Sumitomo ElectricHardmetal, today more than 80 per centof turning operations and 50 per cent ofmilling applications are performed withcoated carbide, cermet and CBN tools.This has led the Japanese to developsuper fine levels of coating through theapplication of nano-technologyprinciples. The thickness of each of thecoating layers – over 2000 of them –totals less than 3 micron.

Already a Sumitomo standard, theSumitomo ZX coatings have a film-likethickness that allows cutting edges to

remain sharp after the coating process,enabling high shear geometries toform part of the insert design that

reduces cutting force and permitshigher feed rates on lower powered

machines using higher feed rates.The ZX coating is 4000 Hv, almost as

hard as CBN which itself is almost ashard as diamond, yet Sumitomo’s latest

35

www.machinery.co.uk ● March 2007

TOOLING

Coating catch-upSelecting the right cutting tool coating can increase tool life, decrease cycle time and promote

enhanced surface finish. Steed Webzell catches up with the ate of the art

Walter’s PVD Tiger.Tec provides a wear-resistant, defined cutting edge, andmaintain a controllable edge temperature

Tooling_1.qxd 22/2/07 11:33 am Page 35

nano-technology coating is called SuperZX, which has a hardness value of 5300Hv. Super ZX is a multilayer PVD coatingthat is formed using thousands ofalternate titanium aluminium nitrideand aluminium chromium nitride filmlayers. Compared with commontitanium aluminium nitride coats, thisnew PVD coating offers improvedhardness and oxidation resistance.

Another new coating fromSumitomo, the Super FF, is a smoothmultilayer thin film structure comprisedof titanium carbo-nitride and aluminiumoxide film. This gives a higher resistanceto chip adhesion and edge wear thanconventional CVD coatings. Super FFcoated grades are recommended for castirons and ductile irons

DIAMOND LIKE CARBONOther new coating developments atSumitomo Electric Hardmetal includeDLC (diamond like carbon) for the drymachining of aluminium using itsWavemill Auroracoat inserts. DLC is anamorphous film that is more like carbonthan diamond. It is a hard, thin film thatfeatures high hardness, superiortribology properties and excellentadhesion resistance. It has a low frictioncoefficient when used without lubricant.

Many machine shops will beinterested in sourcing a solution that

covers a range ofmachining tasks. Onesupplier offering an‘umbrella’ solution is Sandvik Coromant– its new GC4225 insert grade is able tomachine steels in the P25 spectrum fromlow carbon through to high alloy.Durability is improved, partly throughthe insert’s ability to better withstandboth thermal demands and physicalvariations. This is achieved by removingthe gold TiN coating, which has anumber of additional benefits. Theseinclude the reduction in built up edge,improved resistance to coating flakingand increased edge line toughness. Allthese advantages combine to make itmore suitable for wider applicationwithin the broad area of general steelturning, including extremely toughautomotive crankshaft forgings, whereSandvik tests show highly advantageousresults.

Also new from Sandvik is its versatileGC4230 insert grade, which is optimisedfor light to heavy milling of alloyed andunalloyed steels. Sandvik says that“stressless” coating technologies helpensure this new grade brings improvededge line toughness far beyond standardCVD grades.

At Walter, recent emphasis has beenon the development of what it calls theworld’s first PVD aluminium oxide

coated carbide (PVD-AL2O3).Traditionally, aluminium oxide couldonly be applied with the CVD process athigh temperature, efficient for plaincarbon materials but compromisedwhen cutting chrome or nickel alloys dueto loss of cutting edge definition andhigh cutting temperatures. Walter’sPVD-Al2O3 Tiger.tec inserts provide awear-resistant, defined cutting edge,while maintaining controllable edge

temperature.Also utilising a basic

AL2O3 aluminium oxidestructure is Seco’s newTP2500 turning grade,which is applied usingthe company’s innovative“Duratomic” process. Thegrade is targeted at P15-P30 applications, as wellas stainless steel turningand cast iron turning,

effectively machining in the M20 andK30 application areas.

ATOMIC MANIPULATIONSeco’s Duratomic process (insert, above)employs new process methods andcrystallographic control to manipulatethe coating at the atomic level.Duratomic grew out of Seco’s search todevelop a grade with a new level of wearresistance and toughness, twocharacteristics that have always beendiametrically opposed.

The IMC Group includes Iscar,Ingersoll and TaeguTec, so its presidentJacob Harpaz is an important voice in thecutting tool sector and he has his ownopinions on the subject of coating trends.

“PVD tooling now accounts for 56 per cent of global cutting toolconsumption as opposed to 20 per centin 2000,” he says. “Uncoated cuttingtools are set to disappear as there is nowno real need for them. Why docustomers still use HSS? There are newgenerations of coatings that can be PVDapplied to maintain sharp edges ontooling – this leaves no excuses.”■■

� Enter 110 atwww.machinery.co.uk/enquiry

TOOLING

36

March 2007 ● www.machinery.co.uk

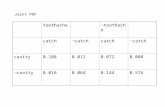

Coating types

Today’s coatings are typically applied using PVD (physical vapour deposition) orCVD (chemical vapour deposition) techniques. Common coatings include:❐ Titanium nitride (TiN) – a general purpose PVD coating that increases hardnessand has a high oxidation temperature❐ Titanium carbo-nitride (TiCN) – the addition of carbon adds more hardness andbetter surface lubricity❐ Titanium aluminium nitride (TiAlN) – a formed layer of aluminium oxide givesthis tool better life in high heat applications❐ Chromium nitride (CrN) – the anti-seizure properties of this coatingmake it preferred in situations where built-up edge is common❐ Diamond – a CVD process that offers the highest performanceavailable for working non-ferrous materials such as graphite, metalmatrix composites and high silicon aluminium.

Tooling_1.qxd 22/2/07 11:34 am Page 36