Today's Woodworker - 01 - Jan-Feb 1989

-

Upload

neilradcliffe -

Category

Documents

-

view

209 -

download

4

description

Transcript of Today's Woodworker - 01 - Jan-Feb 1989

~

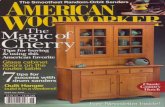

WOODWORKERPROJ E C T S , T I P S AND TE C H N I Q UE S

•6 The Rolling Tool Center 2 Today's Wood

/ly Annette Weir an d Gary Morin A brief look at Teak , one of the mostIf you're like most home woodworkers, beaut iful woods around.

you've got a problem with space. Th e 3 On the levelauth ors' tool chest and cart design is A new magazine' Why now: why us'aimed at solving that prob lem once \\ fhat 's next...and a few more

and for all. Questions and answers.

4 Today's ShopRoger Cliffe offers ten tips forbuying used tools.

5 What's In Store12 ARotating End Table Insight s into some IIt'W jigs. hand y

/ly Greg Kossow workshop kno bs and Vix bits.

Reduce living room clutte r with this 17 Calendarpopular rotating end table design. Events of interest to woodworkers

everywhe re .

18 Tricks of the TradeTi ps and techniques from ourreaders and friend s.

\(j Family Bookshelf 19 Yesterday's Woodworker •Ily Rick White j ohn Goff sinl(s the praises of hot

A wall mounted bookshelf for all your hide glue.

household re ference books -fenturing 20 Finishing Thoughtssliding dovetail joints . jer ry TerH ark compares dyes and

stains.

•r TODAY'S WOOD

Teak (tectona grandis)One of the world 's premi ere natural resources, tru e teakis harvested in commercial volumes in India , java, Burma. Thailand , Laos, Cambodia. Vietn am and the EastIndies. Plantation s have also been es tablished in LatinAmerica and Africa. Th ailand continues to produce themost desired teak - a fact not lost on that country 's govern ment, which imposed expor t res trictions in the ea rly19805. Teak is expens ive: there is a limit to supply levelsand harvest cost s are the highest of any wood fiber.Teak trees attain a height of 70-100 feet with a circumference of 5· 12 feet. The weight of a mature tree is soimmense that harvesters typically make a cut aro undeach tree into the heartwood and let it die over a periodof 2-3 years before felling . The tree is then ligh t enoughto be moved by elephant and floated to market.

Th e wood has an oily surface and an odd odo r, (not

unlike old shoe leather), as the result of very high concentrations of silica. Woodworkers often find the woodhas a dulling effect on their stee l hand tools, not foundwhe n using most other wood s. Teak can be sa tisfacto rily finished and glued, but s pecia l produc ts havebeen designed just for teak to aid in quality bonding.

When surfaced. teak reacts to steel and on occasioncan take on a wide var iety of colors, typicallycalled speckk-bull-a yellow. orange ,bro wn and black pattern. Over time,however. the wood will turn tothe deep rich brown color thathas made it a favorite am ongwoodworkers for years. .

Richard O. Jones

•January/February, 1989

Volume I, Number 1

•lARRYN. STOIAKEN

Edilur

NANCY EGGEllTPruduction Manager

JOIl N KEl.L1I1ERATI Director

.. ON THE LEVEL

ANew Magazine With A34 Year History

•

•

j EFFjACOnSOI(Tecbnitat lllustratnr

(;ORIJON HANSOl(CopyEd itor

•ASN jACKSOK

Publishtr

JIM ERNERDirector 0/MaTkfting

VAl. E. (;ERS"ll NGCircula tion Manage r

•NORTON ROC KLER

RICKWllm :PAULTHOMSVERN RURNS

JACK1I00,\ lIlER(;Editorial Advisors

•ROGER W. CUFFE

JOIlN GOFFj EllHY'I: TERIIAI<KContributing Editors

•Toda y '. Woodworker, (ISSN: 104' 8113) is published bimonthly (January,March, May. July. September, November) by Rockier Press. Rogers. MN55374·0044, Today's Woodworker is atrademark of RockIer Press. Copyright1989. Sec ond class postage paid atRogers. MN 55374 , and at additionalmailing offices .

One year SUbscription price. $18.95(U.S. and possessions).

Send new subscriptions to the attentionof the circulation department.Subscribers are welcome to submit theirprotect proposals, tips and techniques, 10the editor, Today's Woodworker, Rogers,MN 55374·0044.

For purposes of clarity, illustrations andphotos are somelimes shown withoutproper protective guards in place .Today's Woodworker recommends torlowing ALL safety precautions while intheshop.

Postmaster; P tease send change 01address to Today's Woodworker. Rogers.MN 55374·0044.

Copyright 1989 , by Rockier Press.All rights reserved.

TODA'I:"S \\·O()IJWO~KER JA.~ / FEU l~J

Welcome 10 th e prem ie r" issue ofToday's Woodworker.

Wh y publish a new magazine forwoodworkers now? Because woo dworking is one of the fastes t growinghobbies/ crafts in the United States today. One recent survey claims that almost 10 million Americans now coun tthemselves among the ranks of woodworkers.

What ties them all together?Go from the most rudimentary base

me nt s hop to th e fully equ ip pe dprofessional shop and you'll fi nd outsoon eno ugh. II's the love of makingthings with your hands. II's the smellof sawdust. the occasional perfec tlycra fted joint, the relaxation and e njoyment that star ts on the drawing boardand co ntinues long afte r the p rojectleave s the sho p a nd head s fo rits home. And it's finding jus t theplane you always wanted at a ga ragesa le for one dollar, or saving up allyea r for the lathe thai will add a newdimension and level of excitement toyour work.

II's all of thai, and one more very import ant thing. II's a love of learn ing.Woodwork ers have an ex trao rdinarypassion for lear ning and sha r ingtheir ideas.

Here, more than anywhe re else, iswhere Today's Woodworker fi ts in.Because whil e this is a new magazine.you could say it's been on the drawingboard for over three decades. It was34 ye ars ago that Norton (No rdy)Rockier star led up 111e Woodworkers'Store. It was just about that time thathe found he was also in the field of answering questions. Woodwork ers, hequickly discovered, ask a 101 of questions. Before long, he had written oneof the earlier books on veneering techniques. "111e questions kept coming.

Today, Th e Woodworkers' Sto re isone of the largest suppliers of hard-

ware and woodworkin g materi als inthe country. "111e staff at the home office includes a number of people withjust one job -answering woodwork"er's questions. And all nine of the retail stores now feature frequent seminars on everything from basic joineryto advanced turn ing techniques. Andstill the questio ns keep com ing.

T h ree yea rs ago , Ann J ac ks on ,chief executive office r of Th e Woodworkers' Store, came up with anotheridea. "Let's sta rt a magazine: shesaid, "one aimed at providing a forumfor all these quest ions . One that hasno advertisements to clull er it up andmaintains a tight foc us on projec ts,tips and techniques."

You now hold the frui ts of that ideain your hands. The Rockier Press wasborn and Today's Woodworke r wentinto production. As this firs t issuegoes 10 press, our forem ost hope isthaI you, the reader, will continue asking ques tions and sha ring new techniques -and that you' ll ge t activelyinvolved with the magazine.

What pr oject skill le ve l is mos tapprop riate to you' Which technicalareas are you most in need of help on?Today's Woodworke r, due to its affiliation with "111e Woodworkers ' Store,has a vas t network of woodwo rkingexperts that it can call on. They'll becovering all the innovations and newproducts available to woodworkers today - and sometimes reviewing techniques as relevant now as they were ahundred years ago.

We hope you enjoy this first issue ofTo day's Woodworker and promiseb igger and better thi ng s to co me .We'll be looking forwa rd to receivingyour ideas and comme nts.

I

,. TODAY'S SHOP

Ten Tips For BuyingUsed ToolsBy Roge r W. Cliffe

arbors. '111is means thal your prizedsaw blade with till' standard 5/8"arbor h ole mav not fit vour "new"used sa\,·. . .

•People often ask me if there are anyhard and fast rules for buying usedIDols . BpinR' a woodworker I IWVt>fthink in terms of strict rul es. bu t I canoffer some buying' tips based on pastexperiences.

These tips should help you buy usedtools with less hassles and rnore value . Re me mbe r, these a re tips andtheft' will always be some exceptionsto them. \\11o:n in doubt. sleep on thedeal and think it ov... r. Tl u-re is alwavsso me tool for sale. .

Know The MarketIt 's impossible 10 know a ba rg-ain orgood price for a lIsl'd tool if yo u don' tknow fair marke t value, If you've everbeen to an auction a nd watched used(and beat up) clamps se ll for mort'than list price you understand what isnu-ant by fair market value.

To know the mar ket, you can studycatalogs and mail order flye rs to findthe list price and salr- price on a specific tool. It's common to see seasonedauction buyers carryinJ,:' tool ca talogswith them to check prices before bidding. Some people limit the ir bid to nomore than 60'1', of list price. Decide onwha t you think is fair and stick with it~

Be Sure Older Is Beller"They don 't make 'em like th ...y usedto" is a favorite sayinz among woodworkers. In some cases. they don't"make 'e m" that way h('(.'au~e newtechnology has replaced th e old tool.Electricity rusts have made today'smotors milch more efficient. Considering 111(> increased electrici ty consumption and the increased weight.the old 1001 may no t be a bargainunless the old motor ca n be replacedeasily without mo dification . 111at willbe disrussed bf,low.

Some wuodwork<.> rs favor heavy castiro n tools b('causp they resis t vibra·tion . The to leraon's and qua lity oftm la y's mach inin Jr{ may ma ke t h e

added weigh I a liabi lity rather than anasset. And remember the extra weightwhen you move llie tool to the basemcnt. Will the s teps SUPI~lrl it'

Determine Your NeedIf you don't nl'(.'d the tool. it's not abargnin at any price. \Vood worke rsare notorious for buyi ng' a toolbecause of its price. They don't consider necd first. Wh e n you buy a tool.be sure you will be able to use it. Atoo l that gathers d us t in your shop willeventually just become a "bargain" forano ther wuorlworkc-r tomorrow, Ah orn e s hop woodworke r ma y betempte d by tho price 011 a mor tiser,yt't wh..-n m-ed is co ns idered. the mortiser is best left wher... it is. \\11Ytie upabout six square fel'! of floor space ona machine tha t will be us ...d on ly a f...wtimes per year,

Best Deals Go To The BigSpenderslr uring an estan- sa le, too ls are oftensold as a lot. The pe rson who boys allti l<' tools at one time usually COIlU'S

out way ahead. Many times this buyercan sell individual tools. recoup hismoney. and ket'p just those tools hereally wanted.

Bankers. insurance agents ann taxagents all wish 10 sell le quickly withone sa le . Don't be afraid to find ot herwilling woodworkers prior to the auction and pool your money to buy allthe tools offt·n',1. Two or three buversand sellers can g't't rid of the excesstoo ls much faster.

Be Sure The Tool Is Compatible1\0 tool is a bargain if the electricalsystem is not compat ible with thepower so urce. It is b..'s t to check YOll relectrical soun.'(· for volts. phase an damps before buyi ng us...d tools. \\11i1eit may be possibll' tu chang-l' motors.sorut' o lder tools had motor mo untsthat we re u nique to the tool. Old,' rta b le saws abo had va rious sized

Be Sure PartsAre AvailableAny t'~11. from Ihe small ...st hand toolto the larJ{t's t stationary power tool. isuseless without span' parts. Spareparts fall into two categories: standardhardware. like nuts and bolts, andre placenu-nt parts, like the beam on acompass or the blade of a combinationsquare. Replacemen t parts can be aproblem if they ar... no longer stock...d.In SOIJlt' cast's. they can be made bycombining s ta ndard hardware pa r ts,bu t in other cases, you're out of luc k.

Don't thi nk you're saving money ona tool if you have to hire a machinistto make some pa rts for you, Unlessyou or so meone yo u k now is amachinist, this is not a barg-ain. Theremay be SOIUl' cases where yo u canbuy a com para ble pa r t for th e toolm issi ng a pa r t. Fo r exa mple . yo umigh: find a retrofit f...nee for an oldtable saw. 'I11l' saw mav work like newwith th at addi tion. .

Let The Seller Find YouHuying' used tools usually bt'J,dns witha search of the wan t ads. Individualads and ads for auctions and estatesales lead all till' readers to the tool.This means a sing-Ie supplier and amuch larger g-roup of buyers - an dhij(lwr price-s, A better approach is totake out vour own ad: "Wanted to buv:woodworking be nch vise: will pay f;irprice, "all ." This ad setsyou up as the only buye r, and the supply is usually la rger than the demand.I have bought air compressors andradial arm saws this way,

When someone sees you r ad a ntiremembers that old vise in the Kant~t'.basement or barn. they call your number. You art' the only buye r. and havemore leve rag« whe n it comes to d iscussin~ tht' priee.

Compare Apples To ApplesIf you art' looking at more than oneto o l, IH' s lIn' you art' l'o mpar i n~

apples to appl...s. For t'Xample, o ne

JAWFEB 1!1..~!1 nlll:\' ~S WOOlIWORKER

•

•

The VII bil ls adrlllbtl wllhln a jig that

automatically cenlersthe bit.

A sl ig ht ly di ffe reot take 00 thi stheme is olfered by the Vick Company, which literally built a jig right intotheir product. Their sell centeriog VI.Bils automatically center and plumbthe drill through a hioge hole lor perfect hardware installation. Various sizeVix b its are ava ilable , accord iog toscrew sizes.

As usual , suc ces s is breed ing anumber of foreign imitations. However ,the genuioe Vix bits, made in the USA.are definitely superior in performanceand durability 10 the rash of imitators.Vix bits feature a hardened dr ill guidewith a high speed dri ll adjustablefor depth .

Replace your wingnutswith anewline 01wortcshop knobs and handlesandadd anew dimension 10 your Ilgs.

Store, which seems to beiotent on makingwoodworkiog aseasy and safe aspossib le for itsc ustomers. Theirnew full size workshop knobs andlevers will cast yourho memade jigs in aneotire ly dit teren t light. Star and Tkno bs, which come in a variety ofsizes, fit the hand comfort ably. A pushbutton ratchet lever is perfect wherelimited luming space makes the use ofa star or T-koob imprac tical. A posthand le is also available for applications requiring lever action. The tall ,slender shapeallows for asecure grip.The hold down kil

shown alle«works well lorapplying downward pressurewhile ripping.

The stop blockkit. perfect loruseona drillpress or rouler,Includes a knob,Holl and a 2"rabbeted stop.

The leatherboardkit Includes a livestar knob, alhreadedr-seuand an adjustablelealherboard.

For centuries woodworkers have beeorelying on jigs in their shops to improvecontrol and increase precision. Whilejigs tend to be personat , custom devices, The Woodworkers' Stole (612·428·3200) has come up with a universal T..slot Jig system that provides agreal toundanon for an eodless variety01 jigs. Their jigs are ooly available askits , allowiog wood workers to cus tomize them for virtually any workshopapplication.

The key to the system is aT-bol t ,similar to those that hold toilet tanks inplace . The bolt travels in either a metaltrack o r a T-slot route d into a woodb ase. Th is T-s lot desigo sec ure lyholds the jig 0 0 track while allowiog forincremental adjustments.

The Iioe of T-stot jigs includes a holddowo jig (per fect for benches. routertables , machioe feoces and miscellaoeous jigs). a featherboard jig (greatfor improving safety around router taobles, d rill presses and table saws), amaster jig (the most complete kit with astop assembly , cla mp assemb ly and40· T-bo lt track) aod a simple slopblock . Router bits for cuttiog a T-slotand a metal track are also availab le.

Anyone who has strug g led w iththose small wing outs on homemade jigs will also aop re-ciate another new linefrom The WOOdworkers'

r WHAT'S IN STORE

Improving Your Shop Jigs

table s;w..' mav have several blades anda dado lu -ar! ' includ,'d in th" package.These accesso ries can cloud the valueof the tool. If you need the accessories.they ca n ra ise th e va lue of the tablesaw, but the tab le saw itself mav not beas good in co mparison. At this point.vou have to ask vourself what vou'nbu ying , the t abl~ saw o r the ;u..·...cssones.

In some cases, a matrix of [eaturesca ll be used t o com pare OIl(' too l toothers. List the tools down one side.an d lis t the features ac ross till' top.T he matrix makes ana lysis and compariso n easy.

Oon'\ Be Alraid To Walk AwayFrom A DealFinally, once you've deci ded 0 11 a purchase. do n't he afra id to walk away ifthe deal cha nges at the last minute. Ifyou lind some unscru pulous sc lh-r trvin;: the o ld "bait and sw itc h" ll'c i"nique: or arrive to make your purchaseonly to find tha t some accessories orizinally included in Ihe sail' have mvsieriously di sappeared - that's a deai VOl I

should walk away from. '!11l'owner 'hastold you en ough about his ch a racterto bring the future potential of his 10 01into se rious question. Don't let yourl'gO trip your hillfolrl!

Consider The Previous OwnerHow the tool was used (or abused ) bvt he p rev io us ow ner can h el p Y O ~Idete rmine its va lue . Stationar y toolsthat have seen 10-20 years in a schoo lor ca binet s hop wili probably s howsigns of wea r and abuse. Compare this10 th e 10 0 1 tha t has been used bv aho meu wne r 10 b u ild a g a rag e a ndsome kitche n ca binets.

One clue to how the tool was used orab used is tlu - owne r's man ual. If i t hasg reasy thumbprints and pencil mar kson it, cha nces a re the re have bee n severa l repa irs made, In fact, the pen cilmark s may tell yo u wha t parts havebeen replaced .

Hand tools ho ld up better than powcr tools. so k nowi ng the previous owne r is not as impor tan t. In fact. somehand too l s are guaran tee d for li feregnrdless of who ow ns them. Guarantees vary from one hand tool to anet her, so cheek with the manufacturer,

Dr. Roger Cliffe is the author of "Table SawTechniques" ana "Radial A rm Sau' Techniques", published by Sterling Publishing Co.ofNew Yr"k, Ne w lurk.

•

•

•

"]'(l !>AY'S wnOUW()RKER JAI'\/ FEB 1 ~ IX! 1

A portable tool chest and cart design for thewoodworker with limited space and good taste.

THEROLLINGTOOLCENTER

By Annette Weir and Gary Morin

INthe ho me woodworkingshop, space is always ata premium. Th is porta ble tool ce nter isdesigned to roll out of

the way whe n the sho p is closed and provide quick and easy access to a "i de ar rayof tools when it's time to ge t 10 work. If itseems a bit fancy for the shop. considerthat it will still be rolling and useful whenyour g-rand childr en cut their first mo rtiseand tenon. Like most woodworkers, webe lieve in building projec ts tha t look goodan d last a long time.

Gelling Started(I ) Dimension all lumber 10 the width andthic kness speci fied in th e mater ial list.jointing' all t'dgt's square. If your plywoodis un de rsi zed in thickn ess. be s ure tored uct' the thickness of all 3/4" wood edgiog according ly(2) Cut the hardwood to leng-th. adding a1/4" to pieces 2·1. 25. 27. 28 an d 29 toallow for fi nal trimm ing after th e rails havebeen ~Iut'd to tht"panels.(:~) Cu t the 3/ -1" hardwood plywood tosize. add inz an additio nal 1/ -1" to the widthof pieces 1. 2. 6 and 7 and tilt' length ofpiece 9. to allow fur final siz ing after thera ils haw been I(lued on, ("UTE: wh encrosscutting plywood . avoid tcarout byus ing a sha rp plywood blade and maskingtape over all cutting lines.I

(4) Glue and clamp the cart and chest railsto plywood panels 1. 2. 6 and 7. leaving therails just shy of flush at one edge (see fi~·

u rc 1) to insu re a square edge against thesaw fence when tr im ming to exact s ize.(~OTE: Omi t the chest's top front rail atthis time .)(5) Sizl' the en d and back panels to exact'Wid ths. To avoid tear ou t on the rail ends .d amp a piece of :V·1" scrap to the har k ofti lt' ra il t"dg('.(6) If necessa ry, belt sand th e e nd andback panel s to insure flu shness of panelsand rails. Be ca reful to reta in flatness ofpanels to insure clean joints with the horizonta l panel s and rail s. Fin ish sa nd theoutside of the panel s for the ca r t.(7) Using a 1/ 4" rou ndovcr hit. rout one('d Re of the l"x3t1 st iles. (see fi~urt" 2 ),where tin- inside t'c1,1{t' meet s the panel.(8) Glut.' and d amp the stiles to the endpanels, "Th e cart st iles sho uld be flush withlilt.' inside of the pane l and 1/4 11 round onthe outside. TIlt' chest stilt'S are flush onboth sides. Usint: splint's or a plate joineris very helpful for alignment purposes onthese steps. Ta ke ex tra care to avoid gluesqueeze-out nn the oute r surface- of thecarl pane ls, Any sq ue-eze-out should becleaned up with a sharp chisel before gluege ts brittle.(9) Cut l/4"x3 l 1" stop dados for the bottom and drawe r rail in tilt' side.' panels. anda full dado on the bottom rail of the back

panel . Be sure to size tilt' dados for theactual thickness of the plyw ood. Repeat asappropriate for the chest. (See elevationdrawing on pagt' 11 for dado loc ations.)

Assembling The Cart( la) Clamp the end panels together and.usin~ a ban dsaw, n it a 21t radius on theUPI)('r front corners of the ca r- t st ile s ,Clean-up the cut us ing a f ileor belt sander.(2.1) Before ghlin~ the front rails to thehorizontal panels, dry assemble th e cartwith damps and check the fit of the rails.

Inside is flush

Round over

-To insure a square edge against the sawfence.(for final trimming), theplywood sidesand backsarecut a 1/4- wide.

The inside edges of thestiles arerouted with a1/4" roundover bit prior to glueing and clampingto the panels.

Using a cau l while clamping Is recommended, Dueto their slight are, clampingpressure is distributedalong the full width of the joint.

JAN/ FEB I~ TUllAY'S WOODWORKER

A challenging project. the authors' tool chestandcart design is not recommended tor beginners.

•

•

•

Using a square. draw a pencil line acrossthe rail and pane l 10 mark the exact position for ~1t1 ing.

(3a) Rout a 1/ 4" roundovr-r on the insidet"dge of th e- top rail.(.Ia) Glue the fron t rails to lilt' horizontalpanels an d drawer rail. tak ing ca fe to accura te ly alig n the pencil marks that youmath-in :--h"p 2a.(Sa) Finish sand a ll panels to 150 grit(leave t'dges until nfu-r assembly).(()a) Th e ca rcass should be glued in twostage s, First glut.' the lop and bottom tothe back panel. dry damping tilt.' sides toassure proper align ment . Using cauls atthis stage , (Sl'l' fiJ!u n ' :i ). will aid in distributing the clamping pressure alung thejoints .

TO[J.'\Y'SWOODWORKER JAj\;/ FEB I~

(7a) Glue the end pane ls to the she-If. backand d rawe r rail, again usinl{ cauls and piped amps.(&1) Mark the loca tion for the end panelscrews, ce ntering 7/ 16" bac k from allt 'd~('s . Drill holes using a fuller bit (counterborr-yhi t combined) or counte rburewith a :VS" brad poin t bit followed by a7/ (iV' pilot holt, fo r #Sx l 5/ S" screws.Install the sc rews and walnut plugs, pari ngthe pluJ!s flush tu the su rface with a sharpch isel.(9a) Us ing a I l l " rou ndover bit, rout allou ts id e r-dp r-s , includi ng the bo ttom .(NOTE: Do not rou t tlu- ('dges of the dooror drawer openings .)(10~1 ) Finish sa nd all t'flges , plugs. stiles (i fmarred by d am ping) and soften the edges

9

Thetop front rail of the chest Is cut Into twopieces androutered with a covebit . The twopieces are reassembledandglued to the front.

of the- door and drawer openings.(J 1a) Rip the door panel to provide twopieces 11 7/ 16" wid e , and c rossc ut therails to 11 1:1/ 16" long . Ma rk th e CuIedues of adjoining ra ils an d panels toassure prope r placement, keeping g rainpatterns intact . Glue the ve r tical ban dingnil the door edges using 1/ 1" at openingedge'S and 1/ 8" at hinge edges. Trim tothe correct length. as discussed in step 5on pa~t' six. Glue on the top and bottomrails, making: su re 10 keep the ends flushwith the do or edges, Maintaining fullwidth, trim it .j' bevel on the inside edgeof doors to aid in filting and 10 preventbinding. Belt sand all sur faces flush .(12a) Glut' the bark lip and fro nt edge tothe pull-out shelves. keeping edges flushat the side of the shelves. tJ~ing a 5/ S"cure bux bit. rout the finger pull on top ofthe front edge . centering the cut 7/ 8"back from the edge , An alternative wouldbe to cut a cove , using the table saw.

Assembling The Chest(:\OTE: To assure thai the lid will fit accura tely. the che-st sho uld be bui lt as a sixsided box and the lid cu t off afte r asscrnbly.)( Ib) Rip the top front rail. (piece 3ll1, intotwo pierr-e 113/ 16" and 9/ 16" wide . Markmating edges 10 ma intain th e grain pattern. using a 1/ 2" cove bit, rout the fingergri p alung the fro nt marked edge of thewide piece and then san d the rou ted area.(2 b) Glue th e 9/ 16" strip (unmarkededge) and 1/ 8" strip to the plywood frontas shown in figu re -I above. Xow glue themar ked. rout ed edge of the 1 13/ 16·' piec eback onto the 9/ 16" piece (see figure 4).Trim the ends, sizing the panel to its proper dimensions, Bell sand to flush all surfaces .(Sb) Drv assemble the chest to chec k thefit an d mark th e location of the bottomfront rail as described in step 2a on page6. Disas semble- and gilit' the rail to thebottom.(11h) Finish sanding all ins ide su rface s,Glue and clamp the back and front to thetop pa ne l, bei ng ve r y careful to keepedjn-s flush and panel s square. Slide the

MATERIALS LIST!" .Inese p,.cesshoo,"be over","'.y 1/4'10 , IIowlor Imaltnmmmg I

PLYWOOO T X W X L1 Cart Sides (2) '1 4+ x 261'4 (Oak)2 Can Back (1) °24.. 26 (Oak)3 Cart Top (1) 19x24",(Oak)4 Ca rt Bottom (1) 19 x 24 314 (Oak)5 Cart Door Panel (1) 23 x 173/8 (Oak)6 Chest Sides (2) '9114+ x 111/4 (Oak )7 Chest Back (1) °223'6+ x 111 /4 (Oak)8 Chest Top (1) 12 1f4 x 223.'8 (Oak)9 Chest Front (1) °31/4 x 223'8+ (Oak)

10 Cart Pull Out Shelves (2) 314 x 229/16 x 159116 (Particle Board)' 1 Cart Drawer Rail (1) 3/4 x 31/2 x 24 (Particle Boa rd)12 Chest Bottom (1) 3/4 x 12 112x 221/8 (Panicle Board)13 Ches t Tray Bottom (1) 3/8 x 12314 x 22 1/8 (Birch)14 Cart Shell Slide Spacers (4) 3/8 x 1 x 18 (Birch)15 Can Drawer Bottom (1) 318 x 171 3116)C 227/16 (Birch)16 Chest Drawer Bottoms (3) 318 x 11g,,'6 x 201 311 6 (Birch)17 Cart Drawer Sides (2) "2 x 31.'8 x 18318 (BIrch or Apple)18 Cart Drawer Front/Back (2) 1/2 x 3 118 X 227/1 6 (BIrch or Apple)19 Chest Drawer Sides (4) 1/2 x 2,l.'8 x 12118 (Birch or Apple)20 Chest Drawe r Sides (2) 1/2 x 3,l.'8x 121/8 (Birch or Apple)21 Chest Drawer Fronts/Backs (4) 1/2 x 2318 X 20718 (Birch or Apple)22 Chest Drawer Front /Back (2) 1/2 x 331'8 x 201/8 (Birch or Apple)

HARDWOOO23 Cart Stiles (4)24 Cart Side Rails (4)

25 Cart Back Rails (2)26 Cart Lower Front Rail (1)27 Top Front Rail (1)28 Cart Drawer Rail Banding (1)29 Cart Ooor Rails (2)30 Cart Door Edging (opening) (2)31 Cart Door Edging (h,nge) (2)32 Cart Drawer Front (1)33 Chest Side Shies (4)34 Chest Bottom Side Ralls (2)35 Chest Top Side Rails (2)36 Chest Bottom Back Rail (1)37 Chest Top Back Rail (1)38 Chest Top Front Rail (1)39 Chest Bottom Front Rail ( 1)40 Chest Front Banding (1)41 Chest Drawer Fronts (2)42 Chest Drawer Front (1)43 Chest Handle Stock (1)44 Shell Front Edge (2)45 Shell Back Up (2)

HAROWARE46 11/2" Dla. Walnut Knobs (4)47 1" Dra. Walnut Knobs (6)48 Lid Supports (2)49 6' l ength 11/2" Brass Piano Hinge (1)50 18" Pull Out Shelf Slides (2 pairs)51 18" Full Extension Slides (1 pair)52 12" Full Extension Slides (3 pairs)53 1 Pkg. Rubbe r Door Bumpers (4)54 Cupboard Ca tches (2)S5 a" Industrial Swive l Caste rs (4)

56 5/16" x 1114" Carriage Bolts (16)57 5/16" Flat Washe rs (16)58 5116" Sell l ocking Nuts (16)59 318" Walnut Plugs (24)60 #8 1518· Wood Screws (24)61 #10-131·..• Machine Brass SCrews (4)62 . 10-131'''" Brass Washers (4)63 #10·1314" Brass Nuts (4)

15/16 x3 x323,4+ (Oak)'3/4 x 3 x 14+ (Oak)'3/4 x 3 x 24+ (Oak)3/4 x 1112 x 24 (Oak)

'314 x 11/" x 24 (Oak)°3/4 x 114 x 24 (Oak)'3/4 x 3 x 23+ (Oak)3/4 x 1/4 x 173l8+ (Oak)3/4 x 1/8 x 17318+ (Oak)314 x 4 x 231/8 (Oak)3/4 x 2114 x 157/8 (Oak )3/4 x 21." x 9 1101+ (Oak )3/4 x 231'8x 9 1/4+ (Oak )314 x 2114 x 2~+ (Oak)314 x 23'8x 22318+ (Oak)314 x 25:8 x 22318+ (Oak)314 x 1 112 x 223/8(Oak)

3/4 x 118 x 22" . (Oak)1/2 x 2112;t2211.. (Oak)112 x 31f2 x 221.'4 (Oak)7/8 x 1 x 9 (Walnut)3/4 x 2 x 229'16(Oak )112 x 111'2 x 229116 (Oak)

CartChestChestChestCart (Accunde C322 '18°)Cart (Accuride C3800 -18")Chest (Aceuride C3800-12 ·1CartCartCartCartCartCartCart & ChestCarcase ScrewsHandle FastenersHandle FastenersHandle Fasteners

Cuta stop rabbet on the backedge of the chestand chest top to accommodate the planohinge,

tray bottom into till' dudes cut earlier ills tep 9 (set' page 6) to help square assembly. If the edges an' not perfectly (lush ,carefully plane them (lush when the gluedries.(5b) Due to limited space in the drawercom partment, tht-, drawer slides are bestinstal led at this poin t. Mark ou t th edrawer sizes on tilt' side P31Wls, allowing 1/ 16'1 space between each one. Drawce nter line of each dra wer anti use thisline for locating mounting screws. «01·low the instructions sUllplit'd with yourdrawer slides.(6b) Glue and damp the sicks to the topand bottom assembly, (~OTE: Chec..k forsquare by measuring diagonals.)(7b) Ins ta ll screws a nd plugs asdescribed in step Sa on page 7.(Hb) Flus h off all outside surfaces.(9b) Set lilt' saw fence Oil your tab le sawto I :~;'I 1t and raise the blade 10 Ill. Carefully cut off the lop of the box, one sideat a time. For the third and fourth cu t,inser t 1/8" spacers in first two nits andhold togr-ther with clamps, (NOT": Becareful nut to go so slowly that you burntln-cut edges.)(lOb) On the back ,-liRe of the chest andlid cut a stop rabbet 5/ ().II' x 21/:l2" wide.',to accommodate the hil1~e.~. Run till ' rubbel the full length of 111l' rails (see lil/u rc 5) . Cut the piano hinge.' to the exactlength of the rabbet and mou nt, usingon ly two SlTl'WS in each leaf. Test th ealignrueut of the lid, adjusting if nccessary, and install the rest of the screwsand the lid su ppor ts.(l Ib) Use aI / I" rou ndo vcr bit on alloutside ('dges. Again, do not round thedrawer openings.(l2b) Usi ng an orbital sa nder, fin is hsan d the outside of the chest to 150 gritand soften the edges of the drawer compar uncnt and lid ope nirur,

Chest Handles(NOTE: Th ere arc a variety of ways toconstr uct these hand les. as long as (heweig ht of the full chest is cons idered inth e se lection process. We ch ose to makeour's out of walnut to accen tuate the wal-

JA~/FEn19S!) ·' " )l )AY's W(J() () WORKEH

One door assembly is not shown for clarity.

--------

-- -

~31~

55

30

Chest is a six sided box; top is cut 0« atter assembly.

•

•

•

11)f)I\Y'S WOODWORKER JI\II:/F1':8l~

1st cut @ iI-_ ---i

;=J

19 I ~dcut@ $I Side View

Drawer construction lor this project involn s the use of lip L.n- d:-d7.":d":o-c-o":rn-.-' :-jo"'"ln"'ts-."'Wh::::-.-n-c-u"'"tt""in-g-'dadoson1ft" plywood. the key measurement is between the boltom o' the dado and the outsidesurface. (see "A" . above). This Is dueto thevarying thicknesses lound with plJWood.

Thewalnut chelt handles are coyedon theirundersideusing an aUl iliary fence on the tablesaw, set al a 2S angle to the saw blade.

End View

~

•

nul plugs already bcin~ used.(Ic) 111l' chest han dle is basicall y a rectangu lar piece of walnut which is roved on1)1(' un ders ide usinJ.{ the tabk-saw, To duth is. St ' ! the sa w blad e 1/ 2" abo ve thetable. Clamp all angled auxiliar y fence tothe saw table at approxim ately 25' to theblade and about I" in fron t of the blade(from the point where the blade emergesfrom 1}1(' tab le inser t). Using a 7/8" x I"scrap at leas t a~ll lung, mak e> a short testcut . Check the resulting profile and adjustthe position of the auxiliary fence as need cd. maintaining the fence angle, as sh ownin figure fl,(2c) Round over the corner (opposite coverut) usinz a 3/8" roundover bit. Cut two -I1/ 2" pit·c,·t's fro m machi ne d s tock andmark the scn-w bob -s with an awl. Drill thesc rew holes with a Fulle r brand dri ll bit(with a 3/8" diameter co unte rs ink) . set ting the drill pres s stop so a :V I6" dee pcoun ter bon' is obtained , Using the dri llpress, increase the diameter of the shankhole with a 3/ Hi" bit.(:k) Complete the drilling ope ra tion byclamping the partia lly formed handles tuthe ends of the chest in their proper position (cenu-n-d front to back, 2 1/4" downfrom tilt' top edge. with lid open) . Nowdrill holes usi ng th e han d le 's ho les togu ide the hand drill.(40) Rem ove handles fr o m ch e st an dshape ends using a bd t sandC'r in a station ar y jig ur a wuod rasp. J-inish san ding andinstall un r hl's t us ing 1 :\/4" by #10 brassmarhi n(' St.-n 'ws .

Drawer Construction Using Lip AndDado Corner Joints(1<1) Adjusllhe lable saw so V I" of material remains bl'lw('ell the botlom of a dadorut in a sc.:rap of 1/2" drawer stock and itsouter facc. ( 'otC': If you just sc i thl' sawblade 1/,11

' abovC' the Hlble , youIre likely tnbe left with a dado that's too dC't' ll and a

dra we-r thai 's tou nar row, siure most 1/2 11

plywood is real ly a litth' le-ss tha n 1/2" ,)Now set the rip fence so dimension "B"(Sl·t.· l'iJ!urc 7) is slightly J.!rt'at l'r than thethickness of the drawe r stock. After makinJ: satisfactory tes t cut s, dado all ends ofthe drawer sides.(2d) Leaving blade depth as sr-t in step 1«1,set the rip ft'nct' at I / H't and make test cutsin some scrap drawer stock until the lipfits s nug ly into the samp le dado. :\OW

mak e this ru t ill the en ds of all front andback pieces. Next, set the rip fence so therabbet sho ulder is re-fe-renced tu the bottum of the previous cut. Fine tune to preciso lit using a test piec e. first making thecut slightly shallow, and then adjusting therip fence away from the blade until all surfan' s lit well when squared.Ckl) Dr y asse mble the drawers and makea pencil mark at the inside bottom edge ofall drawer Ilit'n ' (as a reference for thenext step) , Disassemble and rut a 1/·1"dado 1/4" deep and a 1/ ·1 " up from thebot tom edgl' of the ch est drawers. and3/8" up from the bottom of the cart drawer.(td) Rabbe t the edm-s of 111l' 3/8" plywooddrawer bottoms to fit tlu 1/4 " WCK)Vt'S intill' dra wer dados.(Sci) Finish sa nd the interior sur faces of alldrawers and dry assemble with clamps toinsure good fits on all corner joints.(6<1) Disassem ble and <"ardully apply Itlm'to appro priate joint surfaccs. taking care to3\'oid squt't·zt..·..out on lh t' insidt' cornt·rs .Reasse mble and clamp t'at·h drdwer on aOat sud an'. making sun' t'<Irh is restingon all four cornt·rs. CIIt_'ck diagonals forsQua rC'llC'ss , rhal1~inJ.! d amp pos itions ifany dis cre pan cy l'xisls. \\1wn glue stifft '!lS, rt'1l10Vl' damps and snape cxn 'ssfrum all extl'rior surfan ·s.(7d) Bdore sa nding the oUlside of thedrawer box('s, mark a rt'l1lt'r lilll' along tilt'length of the sidt' s .md mount til(' slide

membe rs. sC'ltinJ.! them back from th efront (follow instruction s su pplied withdrawer slides) , nt.' sure to U S( ' slott edho les fur fina l adju stment. Test fit thedrawers and adjust until you have an even1/16" between all drawers, Now removedrawers and d amp tlW J11 to the ir front s,stayirur flush on the top and bottom andexactly cr-nn-red Iro tu side to side', Drillanel install apprupriate 1('IlJ{th screws (#8 x:{j,1" on ch est and #8 x I" 011 car t), Checktlu: flt of 111e fronts and adjust if necessaryIf you are very careful about side to sidemea surem ents. adjustment shouldn't benec essar y, Mark and drill for knobs. ccunu-rb oring if needed to accommo date thelength of sc rews provided. I 'ow rem oveknobs and install the fixed sc revv-s in slidemembers. Finish sand all boxes and frontsand so ften all edges.(Hd) You're now read y In install the pu llout slides in the car t, however, it's veryimportan t to install the bottom castersbefo re start ing th is process. For mounti ngthe pull-out slide s. A 3/ ft" x 1" shi m isneed ed between the slidt· and case side inorder to dear the hinzes and duors .(NOTE: A th icker shim may be used if youprefer nu t to open doors co mple te ly inorde r to USt· the pull-outs) . Drill mountingholes ill till.' cabinet sklc and sligh tly ove-rsize holes in the shims . Now drill mountiug ho le s in the bottom of the she lves.Install in th e ca binel. "d ry fil" the pullout s, cht'('k movement and trim if ll('l-'dNlInstall Sl:r~WS.

Hanging The Doors(I e) Cut thl' two piano hil1gf"S l /X" shorterthan l'a rl"3SS. Install h inge on the 1/ 8"b~md('d edge of tlt(' first dnnr, an 1/8" fromthe inside' door fart'.(2c) Install tht' first duor on lh l' carcass,using a re(e re nr e Illark 5/8" from Ihefro nt e dge of thl' cart'ftss st i lc ~ _ At th issl.age, lise only two serews, second hole ill

JAf' / FEB I !~' TI)!h\ 'f 'S WOODWURKER

• Elevation

0---- - ..... 20· - -'-- -.;

'. -1_- - -_-:.: :::.:::.__ ::. ~

o

.~ - - - - - --- - -- - "~ 1/1 /2" cove?: :c: ~ :1:-_.:::_-_-_- - -_- "';..?..b,

: P,: b

,-

26"

23 7,11" --

I----- - - -- -------- 1 ~'" ip ].

15~,"------ - ---- - _.0 0 2' /2·

-0 0 2 ' /2"

- - I0 0 3 1/2" I

I :J~~ 1 ~14"" - ,,- " - - - - - --.

I---"J I

0 0 ,--

0

~ 323,1

53·'8"I

IL~ --------- ---- ------------ ,

U U

.;-~

b

()i ,~ - - ----- -,"O:.:'.:~ -_-::: =:. __-_-_-:,_1 _,,,

1---- 14 "'- --1

•

•

from eac h e nd. Check the fit of the doseddoor (flush with face of carcass or slightlyrecesse d. if you prefer) in reference to thecarcass face . If adjus tment is re quired.100s(,11 screws an d reposition an d installtwo more screws in thi rd holes from eac hend. (r\OTE: W(, used a Vix bit . whi chmakes alignment quilt" easy. Hopefully.you will achieve a ~o()d fit after one readjustment. If nut. tr y a~ain.) Repeat thisstell for the se-conddoor.(:~.) Aner fitting the second dour. closedoors and de termine if any planing mustbe done on the I1ll'(·tjn~ edges. Also clu-ckthe top and bo ttom clea rances. Re movethe doors. plane mee ting ('d~('s to ach ievel /Hi1

' clearance ..md trim the top and bottO I11 edges with a table saw tu align .

(·le) Ht'han~ the doors with tilt' four "corn -et" screws and assess tln- need for anyadditiona l tr im ming . Re peat step Sc asneeded unt il the fit is achieved. Finishsand In 150 J.,.'T il.(5<') When the desired fit is achieved. drillthe remaining hol es for the piano hing(using a Vix bit if possible) and t..omplctcinstallation.(64...) Ins tall the roller carches - s tar ting.....ith th... male end 011 top of door edge.PIa..-c ro ller port righ t on this ma lt' en dand close the door. Mark t ilt' placement ofthe roller with an awl while holding theduor in the correct close-d position. Installthe roller (it can be adjusted slightly toco rrect any discrepancy thai occurs in theprocess) .

Finishing UpGivt' th ... proiect a final inspt'ction. doinzany last minute sandinz n-qu irvd. \Ve finlsh ed tilt' prnjt'i..t usin~ gold en oak Walennil. app lying 3- 1 coats. sandi ng with f)O()wet dry for a smooth finis h . After oil istho rou gh ly dry. you may wish 10 applyWan-e satin wax. for extra protection and anice sheen.

ilm'r/tl' Ur i r operates Wrir Woodu'orks.building custom jIlrnisllillgs. She specialieesill solid wood construction utilizing traditional joinery Gary Mo ri n describes himsri! as -a social womer turned woodworkerturned social toorker/woodtoorkrr: Garyand ,1lllll'ttr ' WU' skare a woodusorking'shop ill Minneapolis. Minnesota.

ROTATING END TABLEThis popular end table/bookshelf design offers a surecure for living room clutier.

By Greg Kossow

What I re-ally needed was anice en d table fo r th ecouch, Nothing fancy, justsomet hinz to ho ld theaverage couch overflow

...remote control. books. video tapes. and acup of l'offt'(· or two. AddinR up all that living mom paraphernalia. however, presented a ~big" problem .

And I didn't n....d a big- table .Browsing through a number of caralous

(a grt~at place 10 god ideas! ( carne acrossseve-ral ve-rsions of a rotating boo kshelfthai would solve my probh-m withou t dominating the living room. :\1y version usescherry hardwood and plywood and rota tesquie tly un a sligh tly oversized lazy SlIS<t11

bearing. It neatly takes can.. of as many as7'2video tapes or books and provide's plc nty of sur face spat,'(' for all your t.'vt'ni ll~

re fn-s lum-nts.

CUllingUsing the material list, cut all plywood.r-dge handing. vcr tical slats and baseassembly pi('('t~S to silt'. I ripped both thet'{lgt' handing and ver tical slats from hardwood, bUI used veneer edging on thedivider pieces since the-y'll experience litth- wear and lear. To cut and apply the patu-rn for the veneer top. please refer to tilt.'box on page 15.

AssemblyGlue and damp the edge banding to tilt'bottom shell. middle shelf an d sub top ,mak ing s ure to position it so tha t theex posed cndgrnins will later he covered by

the slats (sec fiJlurl' I ). Li kewise . glue theveneer edging to the divider pieces . Aftervent'•rring your top <this can be done laterif desired) apply the 3f.1" mitered edg-ebanding. Here I used Illy new biscui t joiner'0 I could line up the edge banding and topexactly before the glut' dried. If you don' thave a biscuit joiner, glut' and damp.

Next, glue and nail (the nail holt's will behidden by your books or video tape-s) oneof the two divider assemblies together, Tomake things easier, I n it a piece of 6"x10"scrap to USl' as a spacing guiclt· (see fiJ!ure 2). Lay till' dividers on top of one oflilt' shelves and, u sin~ the spacing guide,

This ,otating bookshelf is designedto sene double dutyas an end tabletor the li,ing room touch. Small Instature. it nonethelesscanholdadeceptivelylargenumber a. booksor video tapes. The author's 'ers ionusescherrystock and a uniqueeight piecereverse diamond veneerpattern lor the top,

de termine where each piece got'S by working you r way slowly aroun d the shelf.

When you have the d ividers spacedexactly right. mark them and glut.' and nailthern together. 1{('lx'al lilt' procedure forthe second divider assembly, It's criticalthat they be exactly the same so they linelip perfectly when assembled.

You're now ready to nail the sub top tothe lop divider assembly, Carefully posilion nne o( the divider assemblies on top oftho sub toI>and outline it in pendI (secfigure :~) . Using your sparing guide. putthe assemb ly back below tho sub top andposition it. Th en carefully nail through the

•

Makesureto positionbull Joints a. banding sothe vertical slats willcoverexposed endgrains.

Use a 6110 scrap asa spacing guide to positionthe two dividerassemblies.

Belorenailing the di.,ider assembly Into placeuseIt to nuthneyournailing pattern.

JAN/FEH 1!1.~) 'n m AY'SWOODWORKER

MATERIAL LIST

Top Banding (4)

T xWx L

314' 8 ' 12 x 10' 12 (Plywood)

314' 16'12' 16 ' 12 (Plywood)

314 , 17 '12 ' 17. 12 (Plywood)

314 , 3/4 x 19 (Hardwood)

Front sla ts a re not show n for cla rity.

1•,,,,

Sub Top (I)

Top (1)

Dividers (8)4

3

2

5

•

•

5 Slats (16) 112x 314 '2311' (Hardwood)

6 Shelves (2) 314"6'12' 16 ' 12 (Plywood)

•7

8

9

10

11

12

Shell Banding (12)

Mitered Base (4)

Base Na ilers (4 )

Sub Base (1)

Legs (2)

Veneer Top (8)

118' 314 ,'~. (Hardwood)

314 x 2~. , 18 (Hardwood)

314 x 314 x 15.12 (Hardwood)

314' 16.12 x 16 .12 (Plywood)

314 x 2 , 15 (Hardwood)

8518 Right Angle Triangles (Veneer)

13 Lazy Susan Bearing ( 1) 12"x 5l16

TOI>AY'S \\'OOnWO RKER JA.:'1/Jolm 1!lS!1

I

II

A framing square Is used to Insure that all four sides 01 th e twomajo r sub-assemblies are plu m b and even.

Spring cla mps and scra p wood are used on th ree sides wh ile thefou rth Is dr illed and toe nail ed .

III,---- ---,

Using nailers on the Inside 01 the base assembly (to support thesub base) reduces the number 01 nail ho les on exposed pieces.

When you 're ready to attach th e state. nail the two outer pieces ofeach set first, us ing a square to ma in tain nice clean lines.

•

•sub top (following the pencil outlines youjust made) into the top divider assembly.Use the sallie procedure in reverse ou thebottom shelf and divid er assembly.However, before you nail these two piecestogether list' the bottom divider assemblyto trace a nailing pattern on the top of thecenter she lf. Following yo ur nailing pattern s, atta ch the bottom and midd le shelfto the bottom divide r.

Stac k th e top divider assembly (nowattached to the sub top) on top of th e bottom divider asse mbly (now attached to thebottom and middle shelf). Using a fram ingSQuare, line up the two major co mpo nentsso they're standing plumb and even on all[our sides (sec fi!."'rc ,I ). When they 'relined up e xac tly, clamp th ree pieces ofscrap wood on the midd le sh elf to serve asstoppers. This will kee p th e two dividerassemblies from movinz whi le they'renailed t()~ether, Now start dri lling and toenailing- the top divider assembly to themiddle shelf (set:' figur e 5). Rotate andre-clamp your stoppers un til all four sidesarc drilled and tocnalk-d, bei ng' cons tantlyon the watch tn not move the twu assemblies,

Now cut and assemb le the base. Glut'and damp the four mi te red pieces and,usin~ this assembly for a patt er n, cu t apitx'e of plywood for the sub base so it fitssnugly into the ope ning (flush with top) , Ididn't want to put any more nail ho les inth e ex posed piece th an nece-ssary. so Inailed and glued :1/.1" by :1/I" nailers onthe inside of the base an d nailed the su bbase down to these (Sl'C fiJ!urt~ fi}, 'o wscrew the base assembly to the rest of thebookcase up from the bo ttom.

At this point I na iled the vert ical s latson, nailing the ('nd pit,t'es of eac h ~t firs t-one direc tly on the corn er uf the cabiIWI. the- other dir ectly in line with thedividers . Use .1 square to come off thedivider l'tl~l' to ~t't th e exact loca tion. assh own in fiJ!un' 7 . To posi tion th e twocente r strips, cut a spacer block to size byusing a littl e math , Sim ply su btract th ecombined width of the two remaining slatsfrom the distance be tween the two alreadyup and divide this number by 3: that's thewidth of the spacer block that you'll needfor posi tioning.

Now screw the venee red top ( sri' bOI,

next page) on from under tilt" sub top. Be

very care ful thai your spacing is the sa meon all four sides.

Finally, c ut th e legs out (sa explodedI'iel(', prerious page) and screw the m to thelazy su san bea ring , Cen ter and screw thisasse mbly tn the sub base ,

FinishingI used (hrt'l' coats of natural oil finish forthis projt'1..'t , (two befon- assembly and oneafter) . lI si n~ a ra~ to wi pe off excess aftera bout 15 minut es. On the plywoo d andveneer I used 320 grit sand paper to sandthe oil in while applyin).t lilt:" first coal. Thiscrea tes a cher ry colored "mud" which fillsin cracks and provides a smooth sur face.On the following coats I rubbed in the oilanti wipe-d off all eXl'I:'S~ afte r ten minu tes.

!'l lling- in nail holes presented a bit of adilemma, due to the varying' color one getswhen working with cherry. [ experimentcd with some filler 011 a scrap piece andended up using a mixture of two partslight birc h and on e par t che r r y fille rmixed t o~( , t lwr, Tn really do the job rig-ht •you 're better off using diffe re nt co loredfille r on differe nt pieces, de pending ontheir dark ness,

JA.~UARY l~J n) IJA~ W()ODWU({KER

•VENEERING THE TOP

Far this project , I decided to create ahybrid reverse diamond by using eightpieces of veneer, cutting identical triangles from Iwo successive sheets foreach quarter of the diamond .

Step 1: Carefully cut a window in slillca rdboard In the shape of a fightangle triangle with two sides 8 5/8'long . Lay this over two stacked sheetsof veneer at a 45 ' angle to the grainand search for an Interesting visualpattern . Mark lighlly w,th pencil. Usinga razar kmfe and straightedge , repeatedly cut edge A with light strokes (seefigure 1) right on the line. Cut edge Band C as well , but leave an extra 1/4'for Irimming lale r.

Step 2: Using a penci l and straightedge, divide the 17.1/4' table top intofour quarters and divide each quartermto two triangles (see figure 2).

Step 3: Take the two triangles ofveneer cu t in step I , place on thetable top and flip over the top piece so

edge A of both pieces meets on thepencil line (see figure 3). Making sureedge A is right on the pencil line. cutedge C (refer to figure 1) for each triangle , following the pencil lines drawnin step 2. Lay these two matchedp ieces aside , and repea t steps 1-3three more times to finish cutting thepallern. In each case , edge B isallowed to overhang the edgo of thetop, to be trimmed after assembly.

Step 4: When all cuts are comp leted ,layout the pattern and, usinggummed veneer tapa, tape all piecestogether on the side to be finished ,tirst with short strips and then withone long strip (see figure 4). Now foldthe veneer back to expose the edgesand run beads of glue on all joints ,lorming one solid sheet of veneer.Wipe off all excess. App ly a qua litysolvent based contact cement on thetable top and on the back side of theveneer pattern and let it dry. (Do notuse a water-based contact cemen t).

Then apply a second coat, let it set andcarefully lay the veneer in place. Usingtwo coats of contact cement serves tohelp retard the penetration of the 0,1 finish, which otherwise might allect bonding Use a venee r roller or smooth ingblade to assure a good bond . Beforeapplying 0'1, the top should be allowed todry for another 48 hours to allow all thesolvents in the glue to evaporate.

Step 5: Once the top is dry, remove alloverlapping edges (edge B, as shown infigure 3) to within 1/16' , usrnq a ul rlilyknife or plane. The rest can be taken offwith fine sandpaper. App ly a V€fY lightfirst coat of Oil, using 320 grit sandpaperto sand ,t In (to fill in any cracks andholes) . Wipe oll after seve ral minutes .Once the project is completely assembled, two addi tio nal coats can beapp lied .

Greg Kossow of Milaca, Minnesota is a finiShcarpenter u'110 recently attended u moden boatbuilding school in Port Townsend. tYashingto1l.

II

•

•

D

EI

TODA'''SWt) ()I )\ \ '() RKER JAN/F EB1989

..

B

I

By Rick White

•

FinishingConsidering th e nature of a sliding dovetail, I reco mmend that all surfaces be thoroughly sealed with a finish . finishing willinhibit swelli ng of the sliding dovetail components during periods of high humidity.In addition, if yuu are planning to stai n theproject prior to finishing, I recommendusing an oil-based slain.

•

Wall MountingTaper co nnectors provide strong, conceale-d joints fo r wall mountings. To install •them, first ro ut a groove in the backside ofeach wall bracke t slightly wider than thetaper connectors being used. l 11C de pth ofthe b'TOOVe sho uld equal the taper counce-

Second. rout two dovetail grooves on theshelf underside to serve as tracks fo r thewall brackets. BN.'au S(~ the wall bracketswilleventually be anchored into wall studs,positioning these two tracks depends cornpletc ly on the exact location of the studson your selected wall.

Finally, dovetail pins should be cut in thebookends and bracke ts to trave l withintheir respec tive tracks {see fi~ure 1) .The sli ding dovetails for the bookendtrack 111 11St have a relatively tight fit to ho ldbooks firmly uprig ht .

Sliding DovetailsThis design features sliding dovetails forboth the bookends and brackets. Threedovetail J{Tooves are cut in the shelf, andpins an' cut in the bookends and brackets.

First. cut one dovetail groove from endto en d on the top side of the shelf. Thisgroove serves as the track for the dovetailed boo kends. a nd should be locat edabout 3 1/ 2" fro m till' back.

hard .....ood strips on both ends and thefront of the panel. Cut the hardwood forthe two shelf brackets and two bookendsto size , (NOTE: Use a minimum of 3/4 lt

stock for the brackets to accommodate thewidth of the ta pe r connec tors to beattached later.)

Now make cardboard template-50 for theshelf pa nel . wall b racket an d booke nddesign. Trace the pattern s from the ternplate s on tu the respective pieces, whic hran be cut with a band saw or scroll saw.(NOTI';: to keep your pallern symetrica l.fold your paper, draw OIl one hall, and cutprior tn unfolding.) Use a roundover bit inyour router to soften the sharp edges ereated from the initial cutting.

The author's sliding dovetail bookshelf mounts conveniently In an,room a. the house. Theweight 01 the books locks the bookendsintoplace. assuring a safe resting place '01 all famil y reference books.

Preparing MaterialsThe sizes un the materials list (Sit page/ 7) are for an average size shelf. You caneasily customize th is shelf by us ing a larger or smaller plywood panel for the basicpiece. CuI the primary shelf plywood pa nelto size and then clamp and glue the 2"

Sliding dovetails accommodate changingfamily needs.

FAMILYBOOKSHELF

M}' search for the family dietionary one night turnedinto an exhausting hunt.Everyone in the house. itseemed, had a different

place to leave it once they were finished.After checking about five potential hidingplaces. I finally found it tucked away in myson's room. Clearly, it was time to dt ·sig·nate a sinJ.dt· plarr- for storing this and other com monly used hou sehold boo ks .

A cen trally loca ted wall shelf hand y toall fami ly mem be rs . wou ld be a perfectsolution . I wanted a shelf that would keepbooks erect. but wasn't too thrilled overthe idea of heavy bookends on a wallmounted shelf. The answer to my needswas a shelf with built -in sliding' bookendsthat could easily accommodate an everchanging number of books.

JAN/F..:H 1989 TOllAY'S WOODWORKER

I' OLlSIIElJ I'ERJ:ELTION: TIlE ARTOF TURNED·WOOD 80\\1.5Tlu-collcrtiun of Ed ward (Bud) Jacobsonwill be on display in Mad ison. Geo rg iauntil March 26th.('onCk1: Madison-Morgan Center, 4.'/4So. Main si, Madison, GA .'/0650.

WOOIlWORKING WOIUJl SHOWThe w oodwork ing Associ ation elfNor thAmerica will hold their "Woodwork ing:Worl d Show" this year at th e locatio nslisted below. Shows include free seminars, demonstratio ns an d sa il'S:Washin~ton , u.C, (Feb . IH-20); l lou stun.TX (March :1-5): Buffalu, NY (ApriI T·9):Toledo. 0 11 (April 14·16); Bos'n". MA(April 28-~O).Cnntal'C WANA , PO Hex 706. I 'lymouthNil 03264. (603) 536-3876.

FLORIDA STATE FAIRWO OOTlJRl"ERS CO~II'ETITION

The Florida Wes t Co as t wood tum ers willcosponsor a turn ing:compet itio n inTampa, Florida fro m Feb. 3-19th.((Xltat Larry Hasiak, 42 7 f.'. LakeDr,Land O' lnkrs, FL 3·1639.(813) 996-3211.

ACC CRAFT FAIRSAme rica n e mf! Enterprises will ho ldtheir cra ft fairs this year at the followinglocat ions: Baltimore, MD (Feb 17-19) ; St.Paul. ~I :-: (March :J I-ApriI 2): New York ,NY (May -1-7): Springfield. ~IA (lu ue Z~25); San Francisco. CA (Augus l 11-13) .('OOt' k1: American Craft Enterprises,l nc.. Box to.Ne« Paltz.Nv: 1256 /.19 J4) 25.';,(1039.

WOOIlTIi RNING:Th e Arrowmont Sc hool o f Arts a nd Craftswill conduct four, one- week wood turningworksh ops. fro m Feb. 27-t\itard l 2-1 inGatlinburg. TN .Con 1<k1: ArroU'ItlOHt, Schoo! OfArts andCrafts. Bos567, Gattinbnrg. TN 37738.(615) 43~860. .

PR OFF$ SIO NAL CRAl-T S11J DlESTh e worcester Center for Crafts will behold ing- special classes th rou g hout th eyea r with famous woodworkers .Cont-w:t: lVorcrstrr Center for Crafts. 25Sagamore Road, Hvrcester, AlA 01605.15OS) 753-8183.

TAGE FRi ll WORKSIIOI'Th e Nor thwest ( iu ild o f Fin e wood worke rs and T he Ce nte r For Wood t'n Boatspresent s a Tagr- Fried Lecture and Workshu t), from April l -l-lfi.Con tk1: 711e Centerfor IHwdrn Boats•1010 Vallry St.. Seattle, 1114 98103.(206) 382-2628.

CALENDAR

Groove

Taper connectors (below) are an excellentoption for hanging heavy objecls on awall . To get a nush mounting , router agroove on Ihe back 01each wall bracket

pis so tha t the taper co nnectors cometocethor.

From here tilt' pieces dovetail togethern ic el y. Sli de the she lf o n to the b rac ket sand the bookends onto the shelf. To prevent the w ho le she ll from slid ing off th eb ra cke ts wh e n pulling off th e d ic tio nar y, Irecommend secu ring the shelf onto th ebrackets by drilling a hole in each end ofthe shelf to p leading into its re spe ct ivebra cke t. Inse r ting a brad in each hole safely secures the s helf..------R ick White, a professional woodwo rker,sert'es 011 the edit oria l advisory board ofTodny's Wnndzm rkrr.

A router table makes cutting the dovetails for thisproject easier.

tor ts de pth to ach ieve a flus h mounting(see figu re 2 ). Fasten half of each taperconnec tor into the brack et groove'. pos itinning the d osed end of the hardware'justbelow the dovetail pill on the bracket, Fasten the compan ion piece s of eac h tape rconnector into the wall. mak ing sure thehardware is ancho red into the studs andprope rly aligned to rec eive the shelf brackets. Now simply slide on the shelf brac k-

MATERIAL LIST

T xWx L

1 She ll (1) 314 x 9 x 32 ", (plywoo d)

2 She ll End s (2) 3/4 x 2 x 11 (hardwood)

3 SheIt Front (1) 3/4 x 2 x 36 1.'2 (hardwood)

4 Wall Brackets (2) 3/4 x 6 x 8 (hardwood)

5 Bookends (2 ) 3/4 x 4112 )( 5 (hardwood)

6 Taper Connectors (2) 4" (hardware)

D

•

•

•

TODAY'$ WOODWORKER JAJ'\/FEB 1~89

... TRICKS OF THE TRADE

Tips And Techniques For ToolMaintenance And Improvement

•

•

•

necessar y. One of the drawbacks ofusing th is 7' be vel bit is marring thepiece of laminate that the pilot rid esagainst. Most woodworkers so lve thispro ble m by lub ricating the edge th epilo t rides on with pe troleum je lly.'I1tis is still nor perfect. 11,e method Iuse is to cove r the edge with 3/4"masking tape and then lubr icate thetape . , ot on ly is there no marring bUIalmost all of the lubricant comes offwhen you remove the tape.

Bruce KiefferSI. 1'0111, /liN

Easy 011Creosote buildup on your saw bladescan be a drag . .. litera lly, Not only willyour blades lose their edge quicker.but tlu- buildup will quickly accelerateto a point where you're putting unnecessary stress on your saw's motor.

A trick I learned many years ago isto use oven cleaner to eliminate ereOSOll' problems. Spray it on. let it sitfor 10 minutes and scru b off with ()()()()steel wool. Then rinse off any excessove n cleaner with water and thoroughly dry your blade.

Tim MaurenMinneapolis, MN

--- - - .-- - - -Improved Bandsaw Bevel IndicatorIn till' boatsh op, where bevels are away of life, we use this se tup on ourhandsaw, It e nables th e ope rato r tocheck th.. saw angle without ge lling astiff neck and also makes the cuttingof swinging bevels possible. Swingingbevels. whic h cha nge angles du ringthe same cut. req uire two peop le, oneto saw the piece and one to move thelable 10 th e correct degree sett ing.Whi le you may not need to cut swingiug bevel s, the large scale indicatormight come in handy anyway. To addone to your ban dsaw, cut a piece ofwood to se rve as the far e of the ga ugeand bolt it to the handsaw, (holes willhave to be drilled and tapped into the

Ted GordonSt. LOllis Park, MN

Trimming Plastic laminateWhen trimming plastic laminate youhave several options for carbide trimming bits to use . I have found that thesolid carbide bits with self pilots workbest. Usc the flush bit wheo trimminglaminate agains t particle board, andusc the 7' bevel bit when trim minglaminate against laminate. You canadjust the height of the 7' bevel bit soaccur atel y that vir tually no filing is

Coming UngluedIf you've had the problem of a nicelydone veneer jo b coming completelyung lued after a couple of coats of fi nish. here 's a till that may help. Typ ically. the separation is ca used by thestai n (if used) or the finish pene trating through the th in veneer and slowly releas ing or d iluting the contac trenn-nt. To so lve till' problem. I recommend two coats of so lvent basedcontac t cement (allowing the first 10comple te ly dry). a non penetra tingtype stain. and very light coats of sealer and fi nish unt il there is no dangerof penet ratio n of the top coats.

Vem BurnsMenomonie, WI

Tighter ThroatplatesTo ge t the best quality cross cuts (andalso for safety) replace the throatplateon your table saw with a sho p-builtone of wood. 11,e dose fit will suppor tthe wood fibers as the sawblade cutsthem on the underside of the board,resulting in less tear out. Here are thesteps I recom mend to put in your custom throatplate.(I) Rem ove the saw blade and lowerthe carriage com plete ly.(2) Using the metal or plastic throatplate th at came with yo ur saw as atemplat e . cut a repl aceme nt out ofhardwood of s light ly less th icknessthanthe original.(3) Fit il ca refully to the ope ning inyour saw table so that it doesn't movearo und (This is best done on so mekind of edge sa nder or with a beltsa nde r in a fixture.)(4) Drill a fi nger hole that won' t interfere with the blade.(5) Mark the new pla te where themetal tabs in the table saw ope ningsupport it.(6) Drill a pilot hole at each ma rk .counters ink th e holes, and install a3/8" #6 flat head wood sc rew in eac hhole.(7) Level the throatplate with the sawtable, turning the screws in or out asnecessary. At this point, you may want10 install some type of catching deviceat the front end 10 preven t kickback.

(8) Ins tall a blade , andwith t he ca r r iage sti llco mple te ly lowe red, putin the th ru atp late an dcareful ly run tilt' blade UI'th rou gh it to the heigh tyo u plan to li se it at.Watch your hands! (Use a2x4,) Each time you haveto raise thc blade fur ther,be sure to have it re-curyour plate fi rst.

Make d iffe renl plates<,..i__.....""-- - - - - - - - - - - - ---t for eac h dado size and

molding cutter as you need them.kee ping tilt' orig ina l throa t plate formaking bevel cuts,

J.<\.~/ FEn 19m TOIlA''1""S WO() I)\\'()RKER

r YESTERDAY'S WOODWORKER

Hot Hide Glue•

•

•

saw casting) . The handle. which isalso the degree indicator, is then bolted onto the ou tfeed sid e of the sawtable . A 6" square is place d on th etablc to line it up 10 ninety degrees tothe blade. This poi nt is then read offof the pointer and mark ed on to theface of the wooden ind icator. Repeatth e pro cess and mark the gau ge atfor ty-five deg rees. Then lightly markoff, in five deg ree incre me nts . th eang les between, by using the markings on the existing factory gauge checking for accuracy with a se t ofdividers. This is critical in orde r to getan accurat e gauge. Then divide thespaces between these into five equalparts and you are done . On myoidRockwell I can get ·lS' ovcrbcvel andabout II ' und crbevel. Mark these onthe new indicator face. using the sameprocess .

Greg KossowMilaea .MN

•Grinding Fine ToolsBurned edges oft en result when usinga grinder to sharpen high carhon andhigh speed steel tool s. When a too lhas be e n b ur ne d , it loses temper(hardness) at th e affected area. Youca n prevent th is. and pro long the lifeof yo ur to ols. by usi ng the soft er.whit e aluminum oxide whe els ratherthan the gray ones provided with newgrinders. They cut qu ick ly and ef ficicntly, but also break down faster andco st more . Better them than yourexpensive tools'

Martin DaughenbaughMinneapolis. MN

Today's Woodworker pays $30.00for all Tr icks of the Trade published .Send yours to Today's Woodworker,Dept. TrT, Rogers, MN 55374-0044.

TODAY'SWOUDWORKER lAS/FE D 1~9

By John Goff

T he use of hot h ide glue in woodworking is nea rly as old as civilizationitself. dat inz bac k to Ki nl(Tutankh amen 's reign 3000 years ago ,Since th e invention of plastic g lues,how ever. hot hide glue has seen asharp decl ine in use in woodworki ng ,

I first began us ing hot hid e glu e. almost five years ago whe n face d

with a tric ky ve neer ing sit ua tio n.Since I "di scovered " ho t hide g lue,th e advantages it has over plasticglues have made it my glue of choicealmos t exclusively.

To get star ted . you will need a I(luepot to heat the g lue with water, turning it into a workab le adh e si ve . Iboug ht an electric glue pot that has afactory adjusted temperature of abo ut140 degrees. However, l use th e g luepot as a dou ble boiler by ac tuallywarming my glue in a one pint pea nutbutter jar. The jar sits inside the metal g lue pot a nd is s urrou nded bywater. T his wat e r is jus t the righ ttemperature to add to the g lue asnecessary and is used to clean excessg lue fro m around joints when glueing-up,

The glue I now use. un like otherbrands I've tried . has a uniform colorto the pellets and seems to be mor esticky. Oth er brands have pellets thatvar y in co lo r fro m light to da rkamber. Th is varia tion of co lor hasalways raised the ques tion of purit yand uniformity in my mind.

I have discovered two advantagesto usi ng a plastic co ntainer as a lidover my gluc pot. First. the lid causesthe glue to hea: UI' fas ter and it staysa litt le hotter. This ad de d temperature increases the amo unt of work ingtime of the glue. Secon dly, the use ofa lid s lows the evapora tion of waterfro m the ghw and almost stops theformi ng of a har d crust on the surface of the g lue.

I keep an acid bru sh in my glue atall lime s . T his br ush serves as agood applicator for most gluing jobsand I use it .to sti r the g lue wh enadd ing water to get the proper co nsistency, The best cons iste ncy seemsto be wh en the g lue r uns off th e

brush in a stream when the brush isheld above the g lue sur face. To addwater. I have been using a plasti c 12cc medical syringe .

fly nnw, you're probably wonde ringwhy go to all the trouble of measu ring, cooking, moni tori ng and adjus ti ng th e co ns is te nc y of h ide g luewhen it's much easier to jus t pick upa bottle of modern plast ic g lue andsqueeze it out? Following are th emain reasons I've made hot hide gluemy glue nf choice.

First. it's reversible. With the application of heat and moisture (stea m) .joint s th at are g lue d toget her withhide I(lue can be disassembled forrepair or cor rec tio n wit h out anydestr uction to the joint. Th is may beone of the main reasons that chairsbuilt du ring the 18th Centur y are stillsur viving and functional today.

Second. hide glue was used almostexclus ively whe n the ve neering offurni ture was a true art form. Furniture fro m this era with loose or bliste red veneer can be re paired by simply ad di ng ne w h ot h id e g luebetween the veneer and s ubstrateand then clam ping . Hide g lue alsomakes it poss ible to apply veneer byusing the ham mer veneering technique. This technique ma kes it possible to veneer curved or nat sur faceswithout using a press or caul.

Thi rd , hot hide g lue d ries to provide a rig id joint that wnn't c reep andcause a glue line to appear after theproject is completed. As with ot herg lues. the bond between two pieceswhe n join c d wit h hi d e g lu e isstro nger than the wood itself.

Fourth. hide g lue won't show up asa wh ite spo t on the surface of yourproject should you fail to remove allsqueeze out after g lucing-up. T hereason it accepts sta in and finish isbe cau se hid e g lue is o rga nic innatu re. muc h th e sa me as wo oditself.

The last good reason for using hothide I(lue is that it gives you a goodexcuse to have that extra cup of coffee and plan your day while waitingfor the glue pot to heat.

TWW ISSUE 'I J/F 89.CORR

//1/11/ 11//11///1/1/1/1/1/////_------ FINISHING THOUGHTS

Dyes Versus StainsBy Jerry TerHark

38414000000 3.95 •

The projects for the next issue of Today 's Woodworker are already shaping up.but we want you to know that we're saving space in the departments for reader'sreactions and ideas. How can you get involved? Here's four ways :

C7 If you have a reaction to this issue 's contents (projects too easy. too hard...)drop a "Letter to the Editor,"cia Today's Woodwo rker, Rogers. Minnesota55374-0044.

;'"l Have a "Trick of the Trade"you'd like to share? Send us a description and arough skelch (we'lf redraw it). If we use your idea. we'lf pay $30.00.

;'"l Have a new 1001 (or an old favorite) that you think warrants mention in Today 'sShop ? Let us hear abou t it.

o Have you ever used a photo from a catalog as the basis for a project? Sendus a color slide of the piece and the appropriate page from the catalog . Add abrief description of the project and, if we use it in our "REPROs " department.we'Ifpay you $100 .00.

S hould I use a dye or a stain? Thi s isa question asked at every level of finishing and an area that is often misleading. First nf all, what is a stain andwhat is a dye? According to the 1825issue of the Cabinetmaker's Guide:"Staining differs from th e process ofdyeing inasmuch as it penetrates justbelow the sur face of the wood. insteadof co lou ring its su bs tance throughout.•

'111t> stains covered ill this ar ticle areoil based. but the ideas presented holdtrue for most solvent base stains aswell. First of all, a stain has three components; a carrier, a binder, and a pigment. The carrier is the solution thatmakes the stain a liquid - typicallymineral spir its . Nex t is the binder,which makes it stick to the surfa ce .Th e most commonly used substancehere would be oil modi fied alkyds .IA1st but not least is the pigment, orthe color. T his cou ld be any so lidmaterial that can be reduced into apowder. For example, you could takesome dirt out of you r ga rden , gri nd itfinely (pigme nt) . add a litt le wat er(car rier) , then add a little yellow glue(binder) and you have crea ted a sta in.Probab ly a pr etty ug ly stain. bu t astain nonetheless

Chemical companies spend millionsof dollars each year to produce qu ality

NEXT ISSUE

products at a reasonable price, so itwould not be practical or cost-efficientto make your own.

Dyes are soluble in water, alcoholand oil. an d are usu ally cl ass ifiedaccording to solubility as well as color.A dye will actually be carried into thepores of the wood by the carrier. andwhen th e solve nt evapora tes it willleave the color behi nd. Water solublecolors are known for their light fastness and clarity, alcohol solub le colorsfor their quick dryi ng and penetration.and oil solubles for th eir penetrat ionand ease of application.

Just to confuse the issue, there are afew products that are a little misleading , such as the non-grain raising(NGR) stains. Th ese usually consist ofalcohol and dye but an' called stainsfor marketi ng pu rposes. Th ere ar ealso some pro du ct s that cons ist ofboth dyes and stai ns. They have an oilcarrier and use an oil dye/pigmentedoil stain combination.

When a student ask s me whether 10use a dye or stain. Illy answer dependson the piece in question. If it's a refinished piece, I typically reco mmend astain - for two reasons. Th e first Isbased on the conservatory aspect ofwoodworking. Remember. the designer of the piece chose a par ticular typeof stain or dye, whether it was all that

was availab le or all th at the personcou ld afford . We need to ob se rvewhat was original on the piece of furniture and it is our job as finishers totr y to preserve our her itage. The second reason I would choose stain forthe piece involves application. A stainwill apply a lot easier, and the clari tyof the stains today is greatly improvedover yes ter year, Dyes are not readilys ug ges te d for a refini sh ed piecebeca use the pores are 1I0 t necessa rilyope n to accept the dye.

On the oth er hand. alcohol dyeswork great for touch-up. Say you havea piece of wa lnu t th at has bee nstaine d and the sap wood appearslight. A mixture of dye with alco ho land 10 percent water applied over thefinish in the light spot will darken itnicely. If water is not used, the alcoholwill bite too qu ickly and there will bevery little con tro l. I want 10 stress thatthis procedure is used only over thefi nish.

Now if the piece in quest ion is thestude nt's own creation , I tell him toput on whateve r he wants - it's hispiece . and who's to say the choice iswro ng. On my own pieces I usuallyprefer a dye becau se of the clarity andthe depth achieved with this material.

Last but not least, always rememberthat dye s are per manent. as the resultof their ability to penetration. Theyare impossible to remove completely,eve n with sanding . While there aresome products available that claim 10remove dye s, I have not experi mentedwith the m enough to see how wellthey work. If they live up to the manufacturer 's claims, this could be a greatmile st on e fo r the wood fini sh ingindust ry.

Until we meet again, remember, theproje c t is nev er don e unt il it 'sfinish ed!

•j erry Terl tark, who lectures nationwide on •unod fin ishing, studied under master fin ish-er George Frank. Jerry is the head of Uak o-ta County Technical Institute's woodfinish-ing program ill Rosemount. Minnesota.