TO - DTIC · Laboratory-burner tests. - Th.9 burner and the auxiliary apparatus used in the...

Transcript of TO - DTIC · Laboratory-burner tests. - Th.9 burner and the auxiliary apparatus used in the...

UNCLASSIFIED

AD NUMBER

CLASSIFICATION CHANGESTO:FROM:

LIMITATION CHANGESTO:

FROM:

AUTHORITY

THIS PAGE IS UNCLASSIFIED

ADA801401

unclassified

restricted

Approved for public release; distribution isunlimited.

Distribution authorized to DoD only;Administrative/Operational Use; SEP 1945. Otherrequests shall be referred to NationalAeronautics and Space Administration,Washington, DC. Pre-dates formal DoDdistribution statements. Treat as DoD only.

NACA index of technical publications dated 31Dec 1947; NACA TR Server website

*;--.

MR No. E5F20, .._

• • ' « r, I ,-,-,;I—•*• :

NATIONAL ADVISORY COMMITTEE FOR AERONAUTICS^-^

WÄRTIME REPORT ORIGINALLY ISSUED

June and September 1945 as Memorandum Reports E5F20 & E5I12

SMOKING CHARACTERISTICS OF VARIOUS FUELS AS DETERMINED

BY OPEN-CUP AND LAB ORATORY-BURNER SMOKE TESTS

By Earl R. Ebersole and Henry C. Barnett

Aircraft Engine Research Laboratory Cleveland, Ohio

NACA WASHINGTON

NACA WARTIME REPORTS are reprints of papers originally issued to provide rapid distribution of advance research results to an authorized group requiring them for the war effort. They were pre- viously held under a security status but are now unclassified. Some of these reports were not tech- nically edited. All have been reproduced without change in order to expedite general distribution.

E-190

HA.GA MR IToB. E5F20, E5I12

ilATIOKAL ADVISORY COMMITTEE FOR AEZ20iTAUTICS

MEMORANDUM REPORT

for the

Air Technical Service Command, Army Air Forces

SKOKISG OHAEACmVJSTICS OF VARIOUS FUELS AS DETERMINED

BY OPES-CUP AHD LAB3RATOEY-BURHER SM02E TESTS

By Earl R. Xbersole and Henry G. Barnett

INTRODUCTION

At the request of the Air Technical Service Command, Army- Air Forces, the Cleveland laboratory of the IIACA is conducting tests in an I-lj combustion chamber to obtain performance data on a variety of hydrocarbon fuels.

Inasmuch as the smoking tendeicy of ,1et-v>ropulsion f^els is of interest, a laboratory program has been co-ducted to ob- tain data on the smoking behavior of fuels. Tho results of open-cuo smoke tests of 25 hydrocarbon fuels and of two series of -irepnred blends are presented. In order to determine tho effect of fuel-air ratio .".s well as hydrocarbon clam en the smoking behavior of fuels, 21 hydrocarbons were tested in a laboratory burner *vt fuel-oir ratios ranging from C.0£? to 0.119. The results of these controlled-burning smoke tests r.re also presented. Correlation with data from full-scalo jet- propulsion tests will be necessary to determine the applica- bility of the results.

APPARATUS AllD TES,r PROCEDURE

Open-cuo tests. - The apparatus used in the open-cup tests is shown schematically in figure 1. A 3~milliliter sample of the fuel to be tested was placed in the open cup and ignited with an open flame. Smoke passing up the chimney absorbed a portion of the light beam from the light source. The effect of this light absorption on the photoelectric cell was registered by the recording microammeter. Before each test, the recording

MCA ME 7os. B5T20, E5I12

microammeter was adjusted to zero, if necessary, "by varying the resistance in the lamp circuit. A check run was made on each fuel. The readings in microamperes were converted to percentage light absorbed by means of the calibration curve shown in figure 2. In the calibration of the recording instrument the light beam was interrupted with screens of varying mesh. The trans- mission through these screens wan measured in a atcndard opec- trophotometer using light with a wavelength of approximately 6000 A. The percentage light absorbed was then plotted against microampen readings to obtain the calibration curve.

Each of 25 hydrocarbon fuels was burned in an open cup in order to determine smoking characteristic!:. In each test the burning rate of the fuel was determined by measuring the tine required to burn a 3-milliliter sa-nple.

The fuel3 tested included representative hydrocarbons of the pari.ffinic, cycloparaffinic, olefinic, and aromatic classes na veil as mixed fuels. Kerosene and the sanie kerosene from which aroi.iatics had been removed were included in the mixed fuels tested. Ti'o series of birsary blends consisting of toluene in hydrogenat ed triisobutyle:ie and triisobutylene in hydrogen- ated triisobutylene were tested over the range of concentrations from 0 to 100 percent.

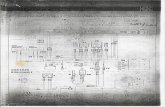

Laboratory-burner tests. - Th.9 burner and the auxiliary apparatus used in the laboratory-burner tests are shown schemat- ically in figure 3« Primary air was massed through the pre- heater ot a constant flow rate of U.l +0,1 liters per minute. Secondary air was introduced at the base of the burner at a constant flow rate of 10.h +C.2 liters per minute. The fuel to be tested was placed in a graduated burette, which was modified to give low and constant flow rates. (See reference 1.) The fuel was then admitted to tho primary air stream and was vapor- ized and mixed with the primary air in the preheater at a tem- perature of ISO0 to 200° T above the boiling point of the hydro- carbon. After the fuel was ignited through the small hole in the side of the chimney, the hole was sealed off by means of a slip ring.

The flow rate of the air was maintained at 1~.5 ±P»3 liters per minute for all fuel-air ratios. Tho fuel-air ratio was varied by changing the flow rate of the fuel from the graduated burette. The rate of fuel flow was measured by determining to the nearest 0.01 minute the time required for a given volume (0.825 ml) to flow from the burette.

3TACA ME Eos. E^O, E5II2

Each of 21 fuels Including representative hydrocarbons of paraffinic, cycloparaffinic, olefinic, aromatic, and dlcyclio classes was tested for smoking tendency at various fuel-air ratios. -Smoke particle size was not measured in these tests.

DISCUSSION OF RESULTS

Open-cup tests. - The results of the open-cup smoke tests are presented in table I. Smoke is reported as percentage light absorbed. Total smoke from a 3-milliliter sample was determined by measuring the area under the curve traced by the recording mlcroacmeter. Values of average smoke were computed by dividing the total smoke by the burning time. Values of peak smoke were obtained by visually averaging the deflections in the highest portion of the curve.

The data in table I ahov/ that, with the exception of the cycloparaffins, the fuels of a given hydrocarbon class gave readings within a range of S percent light absorbed arid that the arjmatics gave highor readings than the other classes. The greater smoking torjdency of the aromatics can be further shown by the tests on kerosene and dearo.natized kerosene. Zeroscno gavo a peak value of 21 percent light absorbed as compared with 5 percent for doaromatized kerosene.

In order to ascertain the offect of burning rate on the smoking tendency, average smoke ( percentage light absorbed) was plotted against burning rato (grains per min) in figure h. Both test run and check run for each fuel are plotted. The five-carbon ring cycloyj&raffins are not shown in this figure because data vrere obtained for only two compounds in this scries. It can be seen in table I that considerable difference in smoking tendency was found between the five-carbon ring and the six-carbon ring cycloparaffins. The fuels tested (fig. k) show that tho type of hydrocarbon exerts a much greater influence on the smoking tendency than does the burning rate of the fuol.

Figure 5 shov/e the variation of the burning rate of the fuels with boiling point. As in figure h both test and check runs are plotted. 5"or the fuels tested, tho burning rate of hy- drocarbons within a given class decreased with increasing boiling point. It is of interest that two fuels of differont classes with different boiling points will burn at thu same rate; for example, from the curves of figure 5t a paraffinic hydro- carbon with a boiling point of 176 T will burn at approximately

I'TACA Ml iJos. E5F20, E5I12

the same rate as an aromatic hydrocarbon with a "boiling -ooint of 3050 r.

In order to show the relation of smoking tendency and com- position for fuols having equal boiling points, tests were made on blends of triisobutylene in hydrogenated triisobutylene. A linear relation was obtainod. (See fig. 6.) Figure 7 shows the results of tests of two fuels (toluene and hydrogenatod tri- isobutylene) having different boiling points.

Laboratory-burner tests. - The results of the laboratory- bornor smoke tests are presented In table II together with the boiling point end the stolchiometrio fuel-air ratio of each fuel tested. At the maximum fuel-air ratios that would support com- bustion in the burner no smoke was obtained for parafiinic, cy- cloparaffinic» or olofinic hydrocarbons with the exception of triisobutylene, which gavo detectable smoke at a fuel-air ratio of 0.102.

Aromatic and dlcycllc hydrocarbons began smoking at approx- imately their stoichiomotric fuel-air ratios. Figures 8 pud 9 show the vpriatiin of smoke (percentage light absorbed) vith fuel-air ratio for aromatic and dioyclic hydrocarbons, rospec- tivoly. Korosene is also included in figure 9« Within experi- mental error the smoking tendency appears to be e linear func- tion of the fuel-air ratio for aromatic and dicyclio hydrocar- bons. Comparison of figures S and 9 indicates that the smoking tendency of ncphthalcnic hydrocarbons is grantor than that of aromatic hydrocarbons.

STCMAHT OP HBSULTS

The data obtainod from an investigation of the smoking char- acteristics of 25 hydrocarbons indicate th*>t for uncortrolled burning in an open cup:

1. Che smoking tendoncy of a hydrocarbon fu^l is more dependent upon the type of hydrocarbor. than upon its boiling point cr burning rate.

2. The burning rate of hydrocarbons within a given class tended to decrease with increasing boiling T>oint.

3« The smoking tendency of a commercial kerosene was about four times that of the same kerosene from which aromatics had been removed.

HACA ME NOB. E5T20, 35112

Ee suits obtained from controlled-buming smoke tests indi- cate that:

1. The smoking tendency of hydrocarbon fuels is dependent upon both the class of hydrocarbon and the fuel-air ratio.

2. Within experimental error the smoking tendency of aro- matic and dicyclio hydrocarbons is a linear function of the fuol-air ratio.

The following table summarizes the data obtained:

OFEH-CUP SHCT TESTS

Boiling Hydrogen- Fook Burning rate (grams/min) •DOint carbon smoke

Class "(°i0 rptio (-oorcont "light absorbed)

Paraffins 122-23c O.IS9-O.I9G 10-15 O.69-I.O7 Six-curb on ring 178-2,9 -1^7 g-13 .62- .85 cyclo-jp-r.-1 f f ins

Eivc-carbon ring 122-1Si .167 23-31 .97-1.13 cycloparaffirn

Olofins 101-172 .1S7 4o-47 •97-1.33 Arora.-. tics 23O-323 .09?- .111 68-75 .75-1.36

Lii30aA.T0Ry-3TJIG^.*l SMOKE CESTS

Hydrocarbon class

Paraffins Cyclohexanes Olcfins Aromatics Dicyclics

Bcilin^- po in t range (°r)

17G-350 17S-270 133-350 17S-465 365-605

StDichionotric fuol-air ratio

I

O.Oo^-O.Ooo .O67 .067 .070- .075 .O69- .077

Tuel-air-raticj Smoke (riorcent r«\nf:e light

absorbed)

0.064-0.114 .073- .115 .062- .109 .O63- .108 .O69- .119

0 0 0-3 0-47 3-80

Aircraft Engine Research Laboratory, National Advisory Coramittje for Aeronautics,

Cleveland, Ohio, Juno 20, 1945; Sept. 12, I9U5.

BEFEEENCE

1. Zentner, E. Thomas. Dollvory of Liquids at Low and Constant Ratos. Ind. and Eng. Chem. (Anal, ed.), vol. l6, no. 7» July 21. 1944. pp. 471-472.

MACA MR No. ESF20 TABLE I* - RELATIVE SMOKIHO CHARACTERISTICS OF

VARIOUS FUELS BURNED III OPBM CUP

Class of Compound Peak Average Total Rate of Boiling Hydrogen- hydro- smoke smoke smoke burning

(grama/ point carbon

carbon observed (percent (area (°F) ratio (percent light in sq min) light absorbed) in.) absorbed)

Paraffins 2,2-Dlmethyl- 11 10 1.4 1.052 122 0.196 butane 13 11 1.7 1.076 2,3-Dimethyl- 11 11 2.0 .941 137 .196 butane 13 10 1.7 .978 2,2,3-Tri- IS 11 2.2 .805 178 .192 methylbutane 15 11 2.4 .779 2,3-Dimethyl- 10 7 1.4 .772 193 .192 pehtane 10 6 1.4 .723

2,2,3-Tri- 13 10 2.5 .679 230 .189 me thylpent ane 11 8 2.0 .688

Cyclo- Cyclopentane 26 20 3.6 1.125 122 0.167 paraffina 23 18 3.3 1.125

Methylcyclo- 31 26 5.4 .965 161 .167 pentane 31 24 5.8 .965 Cyclohexane 8 8 1.8 .825 178 .167

10 7 1.5 .849 Methyl- 11 8 2.0 .755 212 .167 cyclohexan« 13 10 2.5 .787

Ethyl- 11 9 2.8 .617 269 .167 cyclohexane 13 8 2.3 .617

Olefins Trimethyl- 42 37 5.8 1.325 101 0.167 ethylene 44 37 5.8 1.325

2,3-Dimethyl- 44 37 6.4 1.223 133 .167 butene-1 43 37 6.6 1.223 2,3-Dlmethyl- 40 33 6.9 1.026 164 .167 butene-2 42 35 7.6 .968

Trlptene 46 38 8,2 1.063 172 .167 47 38 8.2 1.063

Cyclo- Methyl- 50 41 8.0 1.323 216 0.143 oleflns cyclohexene 47 37 8.1 1.142

Aromatics Toluene 71 50 10.7 1.363 230 0.095 68 49 11.2 1.280

Xylene 68 52 18.3 .844 279-288 .104 1domere 75 57 19.1 .893

n-Propyl- 70 52 18.7 .816 320 .111 ""benzene 70 54 19.7 .816 m-Ethyl- 70 51 19.4 .763 323 .111 ~toluene 72 55 22.7 .745

Mixed fuels

Virgin base stock Hot-acid octanes

21

13

0.698

.652

115-298

174-257

Trliso- butylene*

35 340-350

Hydrogenated 16 335-350 triiso- butylene* Kerosene 21 302-486 Kerosene (dearo- matized)

5

NAT COMMITT!

ONAL ADV :e FOR AE

ISORY RONAUTICS

a Listed as mixed fuels because their purity Is questionable.

NACA MR No. E6II2

TABLE X. - SMOKING CHARACTERISTICS OF HYDROCARBON FURLS

DETERMINED FROM CONTROLLED-BURNING TESTS

Class of Compound Boiling Stoichi- Fuel-air- Hydrogen- Smoke hydrocarbon point

<6F) ometrie ratio range carbon (percent fuel-air ratio light ratio absorbed)

Paraffins Triptane 178 0.065 0.067-0.103 0.191 0 Diisopropyl 137 .065 .064- .071 .195 0 Neohexane 122 .065 .070- .085 .195 0 2,2,3-Trimethyl- 230 .066 .074- .083 .188 0 pentane

Hydrogenated 335-350 .066 .083- .114 .181 0 triisobutylene

Cyclohexanes Cyclohexane 178 .067 .073- .093 .167 0 Ethylcyclo- 26» .067 .073- .115 .167 0 nexane

Olefins 2,3-Dimethyl- butene-1

133 .067 .060- .096 .167 0

2,3,3-Trimethyl- 172 .067 .062- .090 .167 0 butene-1 Triisobutylene 340-350 .067 .092- .109, .167 0-3

Aromatics Benzene 176 .075 .063- .104 .083 0-37 Ethylbenzene 277 .073 .076- .100 .104 3-34 Isopropylbenzene 306 .072 .063- .100 .111 0-32 1,2,4-Trimethyl- 337 .072 .076- .108 .111 3-47 benzene Triisopropyl- 465 .070 .073- .107 .133 5-44 benzene

Dieycliea 1-Methyl- naphthalene

473 .077 .073- .114 .076 3-80

Dimethy1- 511 .075 .078- .102 .083 11-59 naphthalene

Monoamyl- 535-608 .073 .069- .097 .101 9-50 naphthalene

Tetralin 405 .073 .076- .108 .101 7-61

Mixed fuels

Decalin

Kerosene

365-682

302-486

.069 .084-

.060-

.119

.108

.150 3-18

0-5

NATIONAL ADVISORY COMMITTEE FOR AERONAUTICS

NACA MR No. E5F20

H h-

£ XL T

/VtM^\MVA.

1 6-volt -3- battery*=-

J

A Photoelectric cell B Chimney C Light source D Recording mlcroammeter E Open cup

NATIONAL ADVISORY COMMITTEE FOR AERONAUTICS

Figure 1. tests*

- Schematic diagram of apparatus for open-cup smoke

NATIONAL ADVISORY COMMITTEE FOR AERONAUTICS

II 1 l Mil' TTTT 11 in Mil ITT I1 MTT Till 1 111 nil nil lilt Mil TTTB jTTTT TTTT.

70 \ "

\ j

60 \ \

10 0)

\ '•

u « P. §50 o u o s «40

CO u c •o a 230 » H

"•

\

I \

\ •

\

\ a

8 (0

20

a

1 j

10 ;

;

0 VUS. JXLL JJULL JXLL J-LLL ml JLLLL JXLL XLLL ALU. JXLL jjLLL JXLL JXLL XLLL Jill JJXL 1111 Uli. nil 10 20 30 40 50 60 70

Light absorbed, peroent Figure 2. - Calibration ourve for photocell.

80 90 100

m

to o

NACA HR No. E5II2

fhoto- • l»ctrlc-C=i; eel I ^-^ '

Secondary air

Light source

Burner

Slip ring

Hole for ignition

>>V——Secondary air Itiatlfc«!

*'ll I I I I II1' Preheater

Open to air

ft

Fuel supply

10-ml. graduated burette

Throttle

Primary air

MIO v-J

NATIONAL ADVISORY COMMITTEE FOR AERONAUTICS

Figure 3. - Schematic diagra« of burner and auxiliary ap- paratus.

1.*

1.3

1.2

c ri

10

s to

.1

« u to a c u 9 n

1.0

.6

NATIONAL ADVISORY COMMITTEE FOR AERONAUTICS

6hlllll

TTTTTTTTT TTTT TTTI ITT

nil In i ill ii ill ml ii nl ii ii I in iln nil in IIIIIIIII.IIIIIIIIIIIIIII lnii

TTTT TTT TTTT TTTT M III Mill Mill 11111 11 111 111111111.

O Paraffins D Six-carbon ring cycloparaffins O Olefins V Cyclooefins A Aromatics

nix 10 20 30 ko 50 6o Average 6moke, percent light absorbed

Figure 4. - Effect of burning rate on smoking tendency of hydrocarbon fuels.

iiiiiitiiiimiiii

SO

O • m <ji -n ro o

1.*

1.3

1.2

e

3

.1

I 60 e

.1.0

.9 :

.8

.7 -

.inn mil mi i n in ii in i ii ii NATIONAL ADVISORY

:COMMITTEE FOR AERONAUTICS

mi IIII 1 III Illl TTTT TTTT TTTT TTTT TTTT mi TTTT TTTT TTTT TTTT TTTT TTTT 4

I \

•

m \ ,

' •

m <0 \ O Paraffins D Six-carbon ring

cycloparaffins OOlefins . AAromatlcs

\ ' i ;

\ \

\ 0 \ i

'•

\ •

I \l p •

\ •

\ «

\ \l A\

V a a •

I v° \P •

I o • • 1

•

" 1

Lux xux XUX 1111 1111 XUX • III XUX JLU. XL IX xuu. • 111 XUL till XUX xux XUX XUX XUX XUL xux

1

•

0 1*0 80 120 160 200 240 280 320 36O Boiling point, °F

Figure 5* - Variation of burning rate with boiling point.

o

«a .2 Ho u o V

flj

60

g20 o

•gio

M <d

P« 0

NATIONAL ADVISORY COMMITTEE FOR AERONAUTICS

TTTT II II 1 11 11 II II i in i ii i TTTr • ill 1 1 II TTTT TTTT TTTT TTTT TTTT TTTT TTTT.

• •

; :j I i

I \

1 \

1 '• i :. •

1 j

1 •

1 \

•

*"""""< ) \

'•^ -* •

\ ,

•

\

Till Jill i ii i 1111 Mil in I ii i i ii n Jill. Mil mi ULI. .Uli • III 1111 JJJJ- 11UL JU1I 1111 111! ÜLL, JXLL

o

100 io 20 30 4o 50 6o 70 go 90 Volume percent trlisobutylene in hydrogenated triisobutylene

Figure 6. - Variation of smoking tendency with concentration for blends of two fuels with similar boiling points«

-n 10

70

60

t O

to H1|<) *» fi v o h

P.30

o M O a (0

20

NATIONAL ADVISORY :COMMITTEE FOR AERONAUTICS

TTTT TTTT TTTT llll rrrr TTTT llll III! TTTT llll TTTT TTTT TTTT TTTT TTTT TTTT.

; • .'•' ;

m \

; •

; " •

I t 1

l « >

\

l • \

l ':

l \

I \

J '•

y \

\ '•

\ '•

jnr

llll im in i LLUl IIIX .11 1 1 I I i i llll jj_U_ MM llll Mil llll llll llll llll llll llll nil llll. Jin!

10

0 10 20 30 4o 50 6o 70 SO 90 100 Volume percent toluene In hydrogenated triisobutylene

Figure 7» ~ Variation of smoking tendency with concentration for blend6 of two fuels with different boiling points.

<J»

o

ja

6 (0 JO it

s

o

NATIONAL ADVISORY COMMITTEE FOR AERONAUTICS

TTTT I i I • • 111 • 11 • TTT'I nn TTTT TTTT TTTT1 TTTT TTTT TTTT TTTT TTTT TTTT TTTT

\ •

o Benzene a Ethylbenzene O Isopropylbenzene A I,2,l|-Trlmethylbenzene V Trllsopropylbenzene

I

60 • •

. j

50 •

A '•

Ho V I

: [

i

30 [ °o A

O V 0

1 i [

20 \ '

' r v . /

ft 5 5^*^ O 0 •

10 s J i

i v rv

u i

0 iixj. 1111. rrrr till JLUU. ii 11 llll • ••I .mi »in IJJ-L • 111 Uli, in • LLLL JJJJ llll,. ALU llll. JJU mi JXLL' .070 .075 .080 .0*5 .105 .110 .115 .090 .095 .100

Fuel-air ratio Figure g, - Variation of smoke with fuel-air ratio for aromatic hydrocarbons.

.120

80 i NATIONAL ADVISORY

COMMITTEE FOR AERONAUTICS

llll TTTT TTTT TTTT TTTT TTTT TTTT TTTT TTTT TTTT TTTT TTTT TTN llll TTTT TTTT.

70

• •

j

6o

l <5 >

•

>«< 4 •

• •

'S < <q •

ft

i l?o

^ / <\ . . •

• ^P V

> 1-Methylnaphthaiene < Dlmethylnaphthalene V Monoamylnaphthalene ^ Tetralln fck Deealin A Kerosene

m

m <T V "

Pi PV

*

^20

P p

>

- K^

10

V ' ^ <.*"

> "

: V ^

A "

0 Uu. -LLLL

> XLLL 7777 in i J.1LL 1 II llllll llll llll JLLLL jjji. XX u. nil JXLL xux iiii

.:

SO

at O

m

i-i

•070 .075 «080 .085 «090 .095 .100 .105 .110 .115 .120 Fuel-air ratio

Figure 9. - Variation of smoke with fuel-air ratio for dloyello hydrocarbons and kerosene.

«amiMI (am«rv Ebereole, Earl Barnett, Henry

AUTHORS)

ASStFt C - /J - J-J DIVISION: Fuels and Lubricants (12) SECTION: Liquid Fuels (2) ^-— CROSS REFERENCES: FuelB, Liquid - Smoking characteristics

(U2679)

AMER. TITLE: smoking characteristics of -various fuels

TOWN. T1TU.

ORIGINATING AGENCY: "atonal Advisory Committee for Aeronautics, Washington, D. C.

TRANSLATION: COUNTRY U.S.

LANGUAGE | Eng.

fOtG-NOASf J ffiK DATE I PAGES IUUS. 12 B

FEATURES table, dlagr, graphs

ABSTRACT Investigation of smoking characteristics of uncontrolled burning of hydrocarbons In on

open cup showed that smoking tendency of a hydrocarbon fuel is much more dependent upon the type of hydrocarbon than upon its boiling point or burning rate. The burning rate tended to decrease with Increasing boiling point within a given class of hydrocarbons. Sacking tendency of a commercial kerosene was about four times that of the same kerosene from which aromatlcs had been removed.

KOTE: Requests for copies of this report must be addressed to N.A.C.A., Washington, D. c.

T-2, HO., AIR MATERIEL COMMAND IIJT^CMNJCAJNDEX WRIGHT HELD. OHIO. USAAF