TNPC-4110 Series - Shimadzu Scientific...TNPC-4110 / TNPC-4110C Service area 1500 140 665 300 400...

Transcript of TNPC-4110 Series - Shimadzu Scientific...TNPC-4110 / TNPC-4110C Service area 1500 140 665 300 400...

TNPC-4110 Ser ies

C391-E076

Shimadzu On-l ine Total Ni t rogen/ Phosphorus/TOC Analyzer

Product Introduction

Nitrogen and phosphorus are substances considered factors in the over-proliferation of organisms in rivers, lakes, coastal waters, and other public waters, particularly enclosed bodies of water. For this reason, there is a strong need to monitor wastewater and public bodies of water. The Shimadzu On-line Total Nitrogen/Phosphorus Analyzer TNPC-4110 Series addresses this need. With a simple design, only small quantities of chemical solutions and waste liquids are required,and maintenance operations are simple. Chemiluminescence, a method that is resistant to interference from compounds,for example, when measuring seawater, is used for total nitrogen measurement. In addition, we offer the TNPC-4110C,a model capable of measuring the organic pollutant index, TOC. This is the optimal on-line water analyzer for comprehensive assessment of water quality, including organic pollutants.

FeaturesA simple design with a proprietary metered distribution system. Only a few parts require periodic replacement, and maintenance is easy.Only small quantities of chemical solutions are used, and waste liquids are also minimal.Reagent replacement is once per month, and waste liquid management is every two months(assuming a 1-hour measurement cycle).A chemiluminescence system is adopted for TN measurement.Suitable even for samples containing seawater, metallic ions and other compounds that interfere with the UV method.

ApplicationsWastewater monitoringMonitoring of influent and effluent from wastewater treatmentMonitoring of public waters including rivers, lakes, and dams

Shimadzu Proprietary Metered Distribution System: 8-Port Valve Syringe Pump

Measurement Procedure

All operations, from water sampling to dilution, reactant distribution, mixing, and solvent delivery, are performed by the syringepump and 8-port valves

This unit will reduce maintenance frequency and flow blockages, the biggest problems for on-line analysis.The design is suited to measuring samples of suspended particles.

It has a unique sampling mechanism that does not use solenoid valves.By obtaining only the minimum sample quantity necessary, not only are problems with suspended particles reduced, but problems with slime and algae are reduced as well.A strainer-equipped homogenizer is included.All sample contact components are rinsed and the strainer is backwashed immediately after samples are obtained.

Compatible with multi-stream measurement. Contamination between streams is minimized with this pretreatment unit.

Simple and effective sample pretreatment unit.

Air* pushes the sample material out of the sampler to

prevent adhesion of contaminants, slime, and algae, and

acts to backwash the strainer to prevent clogging.

A sterilizer is installed along the air flow path, preventing blockage of

the strainer from the growth of micro-organisms, and controlling the

production of slime and algae within the chamber.

When collecting water samples, the sample enters the

sampler through the strainer.

*Compressed air and rinse water (tap water) are required.

Backwash Strainer Sample Pretreatment Unit

This unit will reduce trouble with flow blockages,the biggest problem for on-line analysis.The design is suited to measuring samples of suspended particles.

The electrically operated suspended solids pretreatment unit does not require a compressed air source.Stable measurement values are obtained by means of a 2-stage pretreatment process. This consists of removing foreign matter with the strainer, and then pulverizing the suspended particles and ensuring homogeneity with the homogenizer.Samples are sent via the strainer to the pretreatment section only when obtaining samples. Furthermore, all sample contact components are rinsed with rinse water immediately after samples are obtained. By introducing only as much sample as is necessary and then promptly washing, problems with slime and algae are also reduced. In addition, a built-in sterilizer provides even more effective control over slime and algae production.

Single-Stream Suspended Particle SamplePretreatment Unit

Multi-Stream Suspended Particle SamplePretreatment UnitAir

Sample

Sample

Sample inlet

Rinse water

Homogenizer

Sample(to the syringe pump)

Drain Drain

Pinch valve

Pinch valve

StrainerReagent

*Rinse water (tap water) is required.

TP reactor

Air

Span solution

On-line sample

Off-line sample

Combustion tube

L-ascorbic acid

Ammonium molybdateAntimony potassium tartrate

Sulphuric acid

Exhaust

Dilution water

Measurementunit

Standardsolution

Drain

Sodium hydroxide

Hydrochloric acid

8-Port Valves 8-Port Valve

Syringe pump

Sample Pretreatment Equipment (Optional)

Sample distribution

Addition of reagent

Chemical decomposition

Distribution of reactant

Addition of reagents

880 nm absorption measurement

TP concentration output

zero calibration

Total Nitrogen Total Phosphorus

Sample distribution

Thermal decomposition (with platinum catalyst)

Dehumidification

Chemiluminescence measurement

TN concentration output

Drain

Drain

Rinse water

Samplingwater tube

Strainer

Homogenizer

Backflow rinseDrain valve

Sample (to syringe pump)

SampleRinse water

dilution if necessary dilution if necessary

sulphuric acid

UV irradiation

sodium hydroxide

dark calibration

Ammonium molybdate, antimony potassium tartrate

heatingOzone atmosphere

L-ascorbic acid

Analysis System Flow Diagram

Items marked with an * are options.

L-ascorbic acid

Antimony potassium

tartrate A

mm

onium m

olybdate

Sulphuric acid

Hydrochloric acid

Sodium

hydroxide

Standard

solution

Off-line sam

pleTransmission output

Display (LCD)Printer

Sample injector

Combustion tube

Furnace

Contact point output

Contact point input

Distribution signal input

Serial output*RS422/RS232C

Discharge pump

M

Measurementinstrument

CPU

Rinse water (tap water)

Air

Multi-stream suspended particle sample pretreatment unit*

Dilution tank

Span solution

Reaction

tank

M

Sample water

Compressed air

Strainer

Homogenizer

Drain

Waste liquid

Drain switch

Chemiluminescencegas analyzer

Exhausttreatmentsection

NDIRdetector

Dehumidifier, gastreatmentsection

(only for TNPC-4110C)

Gas purifier,flow ratecontroller

Note 1) Discuss separately regarding sample properties.Note 2) Refer to the "Installation Manual" published by Shimadzu for details on installation utilities.

The contents of this brochure are subject to change without notice.

Printed in Japan 7295-02801-10A-IK

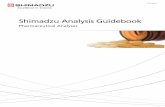

Specif ications External dimensions

Special Accessories

Equipped with multi-stream suspended particlesample pretreatment unit (optional)

TNPC-4110/4110C

1560 12

3029

0

380

980

665 490160

Multi-stream suspended particle sample pretreatment unit Note 1) (638-93129-01 to 03: maximum 3 streams)

Single-stream suspended particle sample pretreatment unit Note 1) (638-93163)

Backwash strainer sample pretreatment unit Note 1) (638-41507-03)

Transmission output board set (638-72496)Analogue output expansion, 2 outputs/board, maximum 4 boards. The optional board case (638-52518) is required when adding the board set to the TNPC-4110.In addition, the optional terminal set (638-72598-01) is required for 4-board expansion.Note 1) Select only one of the sample pretreatment units.

TN/TP measurement unit

Total nitrogen (TN), total phosphorus (TP)TN: Contact thermal decomposition – chemiluminescence methodTP: Ultraviolet oxidative decomposition – molybdenum blue absorptionSelect from the following on the screen:TN: 0 - 2/5/10/20/50/100/200/500/

1000/2000/4000 mgN/LTP: 0 - 0.5/1/2/5/10/20/50/100 mgP/LSelect from 1/2/3/4/6/12/24 hoursMaximum 3 streams (standard 1 stream)TN: Within ±2% FS

(5 mgN/L full scale or higher)Within ±4% FS (2 mgN/L full scale)

TP: Within ±3% FS (up to 20 mgP/L full scale)Within ±5% FS (50 mgP/L full scale or higher)

With the syringe pump, dilution within the syringe

Automatically calibrated for each time and cycle that has been set

Convertible to COD concentration

Load can be calculated by multiplying by flow input signal1 month supply of reagents

Selected for each signal from 4 to 20 mA, 0 to 16 mA, 0 to 1V DC(Standard: 2 outputs, Maximum: 10 outputs)

4 to 20 mA DC as the flow rate input signal, 1 inputWarning signal, event signal (“Normal Open”, “Normal Close” can be set)Signal from the flow meter, remote signal (fixed to “Normal Open”)RS-422 or RS-232C output possible (option)Backlit LCD display, 40 characters x 14 linesThermal paper, 42 characters per line, chart width 110 mmAC 100V ± 10V, 8A (breaker capacity)Maximum 650VAWater temperature: 0 – 40°C (no freezing)Flow rate: Multi-flow path suspended sample pretreatment unit:

10 L/min.Single-flow path suspended sample pretreatment unit: 1 L/min.Other sample pretreatment unit: 2 L/min.

For suspended sample pretreatment unit (option)Pressure: 300 – 500kPa; use tap water

Pressure: 250 – 300 kPaDust, oil mist, water droplets, etc. shall not be contained* Compressor air, instrumentation air, etc.

Indoor installation model1 – 40°C Approx. 100 kg

Measurement methodModel

Measurement item

Measurement principle

Measurement range

Measurement cycleNo. of Streams

Repeatability(with standard solution)

Measurement /delivery ofsamples and reagentsAutomaticcalibration capabilityConcentration ConversionFunctionLoad Calculator FunctionReagent storage capacity

Analog output signal

Analog input signal

Contact output signal

Contact input signalSerial outputDisplayPrinterPower sourcePower consumption

Sample water conditions

Rinse water conditions

Air source

Installation conditionsAmbient temperatureWeight

TOC measurement unit (TNPC-4110C only)

Total organic carbon (TOC)

Combustion catalyticoxidation – CO2 detection (NDIR)

Select from the followingon the screen:0-2/5/10/20/50/100/200/500/1000/2000/5000/10000/20000 mgC/L

Within ±2% FS

Chemiluminescence / UV oxidationTNPC-4110 / TNPC-4110C

Service area

1500

140 665 300

400

675

1400

Multi-stream suspended particle sample pretreatment equipment (Optional)

Tubing space(The required space will need to be changed depending on the tubing procedure.)

Multi-stream suspended particle sample pretreatment unit (optional)