Title · Web viewConcerning the commentary to the Load and Resistance Factor Design Criteria (LRFD)...

Transcript of Title · Web viewConcerning the commentary to the Load and Resistance Factor Design Criteria (LRFD)...

4th International Congress of Croatian Society of MechanicsSeptember, 18-20, 2003Bizovac, Croatia

THEORETICAL AND PRACTICAL PROBLEMS OF UP-TO-DATE STABILITY ANALYSIS OF STEEL STRUCTURES

Prof.dr.sc. Marta Sulyok

Keywords: load and resistance factor design criteria, the general principles of Eurocode 3 and 4, flexural members, bending, shear, combined bending and shear, lateral torsional buckling, calibration, target reliability

Abstract

Concerning the commentary to the Load and Resistance Factor Design Criteria (LRFD) of AISC Specification as an improved approach to the design of structural steel for buildings, the gen-eral principles of Eurocodes 3 and 4 (EC-3 and EC-4) are compared with theirs theoretical and practical background. The analysis of steel beams and other flexural members in bending, shear and combined bending and shear is researched with theirs stability problems in connection with the development of LRFD criteria and Eurocode 3 for structural steel members.

1. Introduction

The method of the First-order probabilistic basis will be illustrated by the examples of the sta -bility of steel beams with the selection of the load and resistance factors under dead and live load -ing for both mentioned design criteria.New research work, done in connection with the application of EC-3 and EC-4 in our National standards, is analysed due to our design meteorological loads such as snow and wind loading on steel structures in Croatia in the procedure of calibration. The verification of the stability of steel structures is evaluated by FOSM comparing by test results in connection with the limit state design.

2. Design requirements

It is evident that there are the differences in the design requirements for various specifications. The differences and similarities are compared for two code-rules which are based on the essentially the same theoretical background and the purpose of this section is to compare these methods and to draw the conclusions about the impact of the differences between them. These divergences are due to the different perceptions of the effects of initial imperfections. For specifications ECCS and AISC many variability arise especially in the inelastic range and for the laterally unsupported beams under moment gradient.

2.1 Ultimate capacity of the laterally unsupported rolled and welded beamsThe following general treatments are used beam design rules:

Use of the columns formula with the “equivalent” slenderness parameter: , here Mp is

the plastic moment of the cross section and ME is the elastic lateral-torsional buckling moment of the beam with the coefficient of initial imperfection coefficients a for rolled (0.21) and welled (0.49) beams, such as specified in EC3.

Use of the analytically exact lateral-torsional buckling solutions for the cross section, loading 1

and end condition, empirically modified to account for bucking in the inelastic range, such as in AISC Specification, with the linear interaction in the inelastic range, which can accommodate idealized conservative simplifications.

The most general equation is the one adopted in Western Europe: , with

the exponent, which takes on values 2.5 for rolled, and 2.0 for welded beams. The variation of the buckling strength with for the various values of “n” and “a“ is shown in Fig. 1. The advantage of this method is its simplicity and generality. Its disadvantage is that the implied reduction in flex-ural and torsional stiffness due to the partial plastification of the cross section is the same regard-less of the magnitude of the compressive residual stress, and it does not differentiate between cases where all or most of the unbraced segment is yielded and where only a small part of the length is plastified. This equation is conservative for beams with low residual stress and steep moment gradient.

2.1.1 Limit state lateral-torsional buckling of the AISCGenerality of the LRFD criteria of the AISC is comprised in the elastic solution which is ex-

pressed in the form: ME= CbMr , where Mr is the buckling solution for the case of uniform bending and Cb is the coefficient which accounts for the effect of loading. The inelastic buckling solution is approximated by the straight line (Fig. 2). The ultimate moment is determined as follows:

(1)

In these equations are:E = modulus of elasticityFy = yield stressMr = S(Fy - Fr ), yield momentMp = maximum moment capacityS = elastic section modulusFr = maximum compressive residual stressLr = unbraced length corresponding to Mr

Lp = spacing of the braces necessary to reach Mp without rotation capacity

Figure 1. Variation of Mu with slenderness parameters by AISC Specification

Since for beams where plastic moments are assumed to develop, the distances between lateral support points will be relatively short (Lp), with extreme fibre strain approaching into the strain hardening range. Studies of inelastic lateral buckling have made by Galambos, Lay, Massey and Pittman, Bansal and Hartmann. The unbraced length corresponding to the elastic limit, L r, can be

2

obtained by setting ME=Mr, where corresponding buckling moment Mr, is determined including re-sidual stresses.

2.1.2 Theoretical model for lateral-torsional buckling in use of EC-32.1.1 Limit state lateral-torsional buckling of the AISC

The selected model is based on the buckling curves of the compression members with five dif -ferent parameters of the initial imperfections, which are now in the use of Eurocode-3 (Rondal&Maqui) as follows:

(2)

where is cr/y= for all five buckling curves.The test results of the ultimate strength under lateral-torsional buckling are selected for rolled

and welded beams of symmetrical cross sections for the same boundary and loading conditions.

The results are non-dimensional in the form of over interval of 0.1 for slenderness ratio .

Figure 2. Buckling curves by ECCS with imperfection coefficients a and system factor n=2.5

2.2 Evaluation of web buckling test results for welded beams and plate girders in shear and combine bending and shear

The limit state design requirements for welded beams and plate girders in shear, and combined bending and shear, are analyzed and criteria for two codes (AISC and Eurocode 3) are compared. As the differences in the design requirements are substantial, the comparison of the achieved reli -ability indices is made in order to find out the model, which is closer to the target reliability level. The statistical parameters of the experimental results are evaluated and the FOSM method is used for the procedure of the calibration. The results vary for two examined models and it is necessary to achieve target values of reliability by correction of the models by the resistance factors.

2.2.1 Models of ultimate design shear strength including post- buckling strengthThe welded beams and plate girders under the shear are buckling both elastically and inelastic-

ally. The critical shear stress in the inelastic range is for the ratio where y is the yield

stress in shear, and strain hardening begins at . The web plate

stiffened by flanges and stiffeners has considerable post-buckling strength. On the principle adop-ted for the truss model, the tension forces are carried by the membrane action of the web, which

3

acts as a tension-field. The transverse stiffeners support the compression forces, with or without the additional field anchored into the flanges, depending on the examined models with the different as-sumptions defining the width of the tension field.

Basler’s model is the first one actually used in the design of using tension-field-action in de -termining the shear strength Vtf, without considering flange contribution, after the web has buckled under diagonal compression. Baslers model is prescribed for the ultimate shear strength in the AISC specifications with the transverse forces due to the anchorage of the tension field and the par -tial shear force Vtf over the band width s, developed by compression in the stiffener depending upon the stiffener spacing (a) and the angle () of the maximum shear component from the partial tension -field, where d(Vtf)/d=0.

Figure 3. Force in stiffener resulting from tension-field action

2.2.2 Ultimate shear capacity adopted in EC-3This method has similar arrangement for the central part of the tension field, but with two addi-

tional fields anchored to the flanges ( Mfpl). When the corresponding flange mechanism is formed, it works under the assumption that a part of the central tension field is also anchored to the flanges and the remaining small part, will probably induce transverse forces similar to those assumed in Baslers theory but neglected in the Cardiff model.

The ultimate shear capacity (Vu) of a plate girder may be computed by summing up three com-ponents:

1. The elastic critical load on the web.2. The load carried by the post-critical membrane tension developed in the web.3. The load carried by the flanges at the instant of formation of the plastic hinges.

The unknown value in Eq (14) is the angle and may be estimated as 0.67 d in order to max-imize Vu.. So defined Vu gives the significant post-buckling reserve of strength in the girders of high web slenderness. Baslers and Cardiff method are not applicable for unstiffened girders and for high ratios of a/h since these procedures lead to Vtf®0.

Figure 4. Shear panel collapse mechanism

On Fig.4. it is evident from which mechanism the shear capacity is defined by the Cardiff method from the authors: Rockey, K. C., Evans, H.R., Porter, D.M. and Škaloud, M.

2.3 Simplified model for the ultimate capacity in interaction of bending and shear4

The selected model is based on an empirical interaction equation, which agrees reasonably well with the test results (Basler-Thürlimanns tests are used in this work), which is noticeable from test-to-prediction ratios. The theory of the tension-field-action is proposed for shear capacity with the reduced ultimate moment capacity using the flanges and part of the web with or without flange local buckling for I shaped plate girders. The graphical presentation of the model is shown on Fig.5. with the loading path denoted by the coordinates which are the ratios of the experimental res-ults and the ultimate theoretical capacity spread over three regions of the dominant stress range.

Figure 5. Nominal and ultimate values for bending and shear with loading paths

3. Loading conditions

The design value of the effects of actions in the codes of AISC and EC-3 are define differently, although both codes have adopted modern principle in matter of structural safety based on probab-ilistic concepts of safety by use of partial safety factors applied to the load effects derived from the adequate structural analysis and to the design resistance.

3.1 Design value of the effects of the actions in EC-3The use of the partial safety factors applied to the effects of actions is given by:

(3)where F is the partial safety factor for the action consideredand Fk the characteristic value of the actionIn the Eurocodes for the ultimate limit state, the following combination of actions is considered:

ikioiqklqlkGd QQGS ,,, (4)

with Gk : characteristic values of the permanent actions Qkl : characteristic values of one (leading) of the variable action Qki : characteristic values of the other (accompanying variable actions) G, Q: partial safety factor for the permanent and variable actions o : combination factorIn document ENV-EC 1, Part 2.1 the proposed values for partial safety factors on the actions are secificated. In concern with partial resistance factors defined by EC-3, the target reliability level which has to be achieved, recommended by reliability index =3.8, for uniform reliability.

3.2 Design value of loadings in LRFD criteria of AISCThe design requirements for load and resistance factor design criteria are based upon the semi-probabilistic approach for the safety of the structures. This design requirement anticipate target value of reliability index =3.0. General equation for this design requirement is:

(5)where =0.9 is resistance factor for flexural members in AISC LRFD Specification Rn nominal resistance QDn nominal dead load effect

5

D=1.2 dead load factor QLn nominal live load effect L=1.6 live load factor

3.2.1Load statistics in LRFD criteriaThe mean load effect is define as:

(6)

where is mean dead load effect is mean live load effect QDn is nominal value for dead load L/D is live-to-dead load ratio The coefficient of variation of the load effect is:

(7)

where VD=0.10 is coefficient of variation of the dead load VL=0.25 is coefficient of variation of the live load

3.2.2 The statistical evaluation of the meteorological loads dataThe meteorological measurements, which have to be examined and taken as dominant are snow measurements, converted to the snow loads on the flat roofs and wind loading actions on towers and chimneys. The example in this paper is dealing with the calibration of the main roof beams, which are laterally unsupported on the distances between secondary beams. The snow load is taken as dominant load during 30 years of measurements of meteorological data with the characteristic values as 95% fractiles with return period of 30 years. The snow measurements, which are conver-ted to the snow loads on the flat roofs, are analysed and compared with extreme probability distri-bution function type I of Gumbel. This function of the extreme probability distribution during the period of n years is:

(8)

The general expression for the snow loads on the flat roofs with the reduction factor 0.8, concern-ing the thermal characteristics of the building and the exposure, and with probability density func-tion of Gumbel, is defined as:

(9)

where and are mean value and standard deviation of the calculate snow loads.Using the design equations for the predicted strengths for beam fail by either lateral-torsional buck-ling (LTB), flange or web local buckling (FLB or WLB), the “professional” factors are evaluated as tested-to-predicted ratios concerning the statistical properties of the same experimental results and the adequate theoretical models.

4. Reliability analysis of laterally unsupported steel beams and plate girders

The reliability index is derived from the equation of the ultimate limit state with two basic vari -ables, which are statistically independent, g(x) =R-Q, with the probability of the failure:

(10)

where is:FR - cumulative distribution function of resistance R

6

fQ - probability density function of load QThe basic variable are not distributed by the normal probability distribution function, so the FOSM method is not applicable and the Rackwitz & Fiessler-method is used with the transformation of the basic variables into the equivalent of normal distribution and the parameters under that the cumulative distribution and probability density functions are the same for the original and the ap-proximated variables, in the respective points on the ultimate limit state plane:

. The equivalent mean value and standard deviation of the basic variable is:

(11)

where is:F,f - distribution and density function of basic variable xi

, - cumulative distribution and density function of standard normal variableThe iterative procedure for approaching to minimum value of , is obtained by the equation sys-tem:

(12)

The partial derivations are evaluated for , and ai of the basic variables xi . After the con-

vergence of this algorithm, the reliability index is evaluated, and approximate value of the prob-ability of failure .

(13)

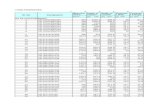

4.1 Results of calibration for the flexure (ECCS and AISC) and shear (by two models)The analysis of laterally unsupported steel beams for various design models is obtained, by which the ultimate limit state of the lateral-torsional buckling strength is evaluated for the purpose of the calibration of the rolled beams under the snow loads from the measured data in Croatia. The results of the calibration varies with applied snow loads and slenderness ratio for three examined designed models, and for ECCS criteria they are in the range from realised reliability indices = 3.20 to 5.19, for AISC Specifications indices are lower, such as =3.10 to 4.80, and for the model of proposed system factor “n” is quite on the target safety side with =4.20 and 6.20. The results of the calibra-tion for beams and plate girders in lateral-torsional or in local buckling under flexure or in shear are tabulated for various models (Tab.1.,2.,3.). For the combined bending and shear the resulting reli-ability index from the applicable tests is evaluated as =2.50 , which is not the desired target value and the single value of the resistance factor =0.90 is inadequate to insure uniform reliability.

Table 1. Ultimate strength and calibration for the snow load data in Ogulin

Theoretical results Mteo [kNm] for models: 0.918 ECCS AISC (m-2s) curve Mexp [kNm]

18.40 18.10 15.07 47.27Mmax 4.14 4.07 3.40 5.69

7

3.21 3.10 3.81

The design equations for web shear by Baslers method, which is used in the AISC specification, as well as the Cardiff method from Eurocode 3, are taken to be the predictive models when actual ma-terial properties are used to find the realized reliability indices and the model factors with target re -liability, are evaluated and specified in Tab. 2 and 3.

Table 2. Welded beams and plate girders in shear designed by Baslers method

Type of Member Number of Tests

VP VM VF for=0.9

N for=3.0

Welded beam 8 1.31 0.16 1.10 0.10 1.00 0.05 3.34 0.97Plate girder 14 1.00 0.11 1.10 0.10 1.00 0.05 2.52 0.81

Table 3. Plate girders in shear designed by Cardiff method

Type of Member

Number of Tests

VP VM VF for=0.9

N (M) for=3.0

Plate girder 11 1.03 0.07 1.10 0.10 1.00 0.05 2.93 0.895 (1.12)Concerning the results specified in Tab. 2., for the welded beams it is obvious that they are conser-vative as the post-buckling strength is taken partially into consideration and the reliability index is relatively high (=3.34) comparing with target reliability of AISC (T=3.0).

5. Conclusion

The calibration is performed with the designed models by global and by partial safety factors and the differences are the result of the basic formulations of the buckling curves. It is evident that there is the necessity to change the system factor “n” or “a” of buckling curves, or to correct the evaluation model by model and resistance factors with the target reliability level in order to achieve uniform reliability with the proposed loads factors, concerning the applied loads in certain cases. The reliability indices are not uniform, nor are they always close to the desired target value of =3.8 for EC-3 or =3.0 for LRFD of AISC. The reason for this disparity is that the single value of the resistance factor is inadequate to insure the uniform reliability. In order to adjust the curve from Eq.(2) with the experimental results, non-linear regression analysis is performed with new coeffi-cient of imperfection a=0.247 for 95% fractile, and reliability index will be close to the target reli-ability level. If the selection of the proposed models for shear has to be made, Cardiff method is more suitable concerning the reliability level, which has to be achieved with the needed uniformity. For the interaction range of bending and shear, new experimental results have to be examined.

References[1] American Institute of Steel Construction, Load and Resistance Factor Design, AISC, 1986[2] Eurocode 3. Design of Steel Structures-Part 1-1: General rules and rules for buildings, 1987[3] Sulyok, M. and Galambos, T.V.: The Evaluation of Resistance Factors for the Laterally Unsupported

Rolled and Welded Beams and Plate Girders Designed by LRFD of the AISC, Steel Structures: Advances Design and Construction, Elsevier Applied Science, London and New York, 1987, ISBN 1-85166-120-4

Prof.dr.sc. Marta SulyokUniversity of Zagreb, Faculty of Architecture, Kačićeva 26, 10000 Zagreb, Croatia, Tel. +385/1/463 93 48Fax:+385/1/482 80 79, e-mail: [email protected]

8