Timber Design & Technology - February 2012

-

Upload

andy-macgregor -

Category

Documents

-

view

218 -

download

0

description

Transcript of Timber Design & Technology - February 2012

www.timberdesignandtechnology.com

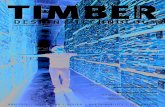

A N A L Y S I S | I N T E R V I E W S | D E S I G N | S U S T A I N A B I L I T Y | T E C H N O L O G Y

Is this the year of turnaround for the industry?

Interview with Dawood Al Shezawi

Hakkasan Abu Dhabi case study

Cross-laminated timber explored

How to manage your machines

Issue 01 | February 2012

PLUS Timber industry news, new products, exhibition previews and listings and more

Keeping carbon out of the atmosphere.Naturally.

American hardwood.

Each kilogram of U.S. hardwood product stores the equivalent of 1.835 kilograms of CO2 for as long as it remains in use.

For more information visit: www.americanhardwood.org

Follow us on TwitterAm

eric

an b

lack

wal

nut

the li

bra

ry a

t Z

ayed

Univ

ers

ity,

A

bu D

hab

i, U

AE

Editor’s WordFor a country that until very recently claimed to be home

to 90 percent of the world’s cranes, a quality publication dedicated to one of construction’s most major mainstays has been long overdue.

And hence, you hold in your hand the inaugural issue of Timber Design & Technology – a bi-monthly magazine catering exclusively to the GCC’s buyers of wood and related machinery and products. We will focus on sourcing, design, sustainability, technology, innovation, legality and other pertinent industry issues and cater to both the wood processing and design community.

We aim to bring you the latest and most relevant news, analysis and in-depth features examining all aspects of the regional timber industry. We hope to stay unbiased and accurate in our representation of the wood industry in the Middle East, and starting with this issue, you can tell us if we’re on the ball.

We’ve tried to achieve a balance in our content that will appeal equally to professionals across all areas of the industry: from importers and manufacturers to designers and architects.

In this issue, we bring you the latest industry news, trends, technologies and products, rounded off with your own little black book: a guide to the major industry trade fairs coming up over the next couple of months. We’ve taken an in-depth look at a hand-picked few - headed by the UAE’s own Dubai International Wood and Wood Machinery Show.

Dawood Al Shezawi, CEO, Strategic Marketing and Exhibitions – the man behind the show – told us what to expect in this year’s edition of the show. It’s heartening to note that the show – which reported sales volume over AED 100 million last year, and attracted 194 exhibitors and 5,940 visitors – has garnered the interest of 230 exhibitors this year.

That’s exciting news for the region: the fact that new markets such as Indonesia, Brunei, Cameroon, Gabon, Argentina are taking an interest in doing business in this region.

Business which there is no shortage of, by the way. Between the covers of this magazine, you will find news about the rapid expansion of companies, such as Danube, and of exciting new product launches, such as those we cover from Jotun’s side.

News and updates aside, education is one of the most important elements of our magazine. No matter who we’ve spoken to during the making of this magazine, we have always gotten the same answer regarding education about timber: there is a real need for more.

In addition to the newest techniques and developments, we have covered a couple of very fundamental and very critical subjects.

Keeping our finger on the pulse of what’s most recent and most relevant, we bring you information about Cross-Laminated Timber (a building material that could possibly change the way we build) and thermo-treated wood (a new generation of wood material that is gaining repute as being superior to non-treated wood).

We’ve also covered basic topics like what you should keep in mind when purchasing new machinery, and how to care for the machinery you already have. Woodworking machinery is a huge investment and protecting that investment so that it gives you maximum returns can make or break your business.

Lending his expert opinion to this issue is Lesly Lobo, Managing Director of Woodfloors Middle East. He tells us all about wood floors. As the man heading the company that has installed the wood flooring for Burj Khalifa, we heed his advice.

We hope you find this issue engaging and informative. Don’t forget to write to us and let us know what you would like to see in the next issue!

Regards,

ISSUE 01 | FEBRUARy 2012

Timber Design & Technology Magazine

PublisherAndy [email protected]+971 55 9199 783

Marketing ManagerEric [email protected]+971 4 455 8400

EditorUjala Ali [email protected]

DesignCreative Pocket+971 50 427 9688

International RepresentativesRabia AlgaAntExpo Org. | Turkey+90 216 541 [email protected]

Timber Design & Technology is published 6 times a year

by Citrus Media Group (powered by WillyMac Associates FZ LLC)Level 14, Boulevard Plaza - Tower One, Emaar Boulevard, Downtown Dubai, PO Box 334155, Dubai, UAE

and is printed by Masar Printing Press Great care is taken to ensure the accuracy of the contents of Timber Design & Technology but the publishers accept no responsibility for any errors or omissions. All contents are © 2012 Citrus Media Group and may not be reproduced in any form without prior consent.

Letters and readers’ contributions may be edited at our discretion.

A decade of regional cooperation to fight

illegal logging in Asia

Dubai WoodShow 2012 highlights challenges

and opportunities within regional timber market

ACIMALL: Woodworking Technology

to remain ‘stable’ in 2012

Sustainability: China’s appetite for wood takes

heavy toll on forests

Issue 1 | February 2012

www.timberdesignandtechnology.com

Cover photo:Private dining room Hakkasan Abu Dhabi

3February 2012 | www.timberdesignandtechnology.com

Editor’s word

Contents

PLUS

p7 Latest News

P12

P20

P26

p50 Calendar

Why Wood Floors?

Bringing back the Dragon

Hello, Yellow!

12 FeatureHello, Yellow!

Southern yellow pine comes out on top in a recent study by TRADA comparing the hardness and strength of five

species of softwood

14 FeatureTo Kiln or not to Kiln

Weighing Kiln-drying of wood against Air-drying

19 analysisAfter the collapse of the construction market in 2008,

2011 has been the year where the timber industry started its upward climb. Will 2012 be the year of turnaround?

20 Design anD DécorBringing back the Dragon

Hakkasan - a modern Chinese restaurant at the opulent Emirates Palace in Abu Dhabi

26 FlooringWhy Wood Floors?

Lesly Lobo, Managing Director of Woodfloors Middle East – talks about bringing the warmth and beauty of natural

wood into any room with wood flooring

30 sustainabilityAll Wood, All Good

‘Cross-Laminated Timber’ - the new buzzword in the dialogue for green building

35 What’s neWFeel The Heat:

Thermo-treated wood Jotun’s ‘Era-Coat MDF’ and ‘Woodshield’

40 tech talkManage Your Machines

Machine management and purchase tips from Stiles Machinery Inc.

43 shoWtimeDawood Al Shezawi, CEO, Strategic Marketing and

Exhibitions – talks about the upcoming 2012 edition of Dubai International Wood and Wood Machinery Show

5February 2012 | www.timberdesignandtechnology.com

In this issue

Illegal harvesting amps up reforestation

AROUND THREE million trees are harvested every year in the

Amazon - much of which done by the informal sector without the

necessary approvals and hence, illegally. Only a small part of this

overall harvest is undertaken by the timber industry which has the

necessary approvals for logging.

In light of this dilemma, reforestation with native species is

now being given serious consideration. One of these is the Paricá

(Shizolobium amazonicum) - the most widely cultivated tree

species native to the Amazon forest that grows fast and produces

high quality wood.

Parica timber is used in civil construction and furniture

manufacturing. It is also widely used for plywood production

because the logs are clear of defects and are cylindrical. The

Brazilian Agricultural Research Corporation (Embrapa) is

currently conducting research on genetic improvement of this

species as well.

More chips to China

AS IMPORT figures for 2011 roll in, China reports record import of wood chips in the last year, owing

largely to lack of domestic wood fiber sources coupled with increased pulp production. Wood chip

imports in the first ten months alone equaled more than the total volume of imports in all of 2010.

Total imports for 2011 reached around seven million tons, or 37 percent higher than in 2010. This

upward trend is expected to continue this year and 2013 because the Chinese pulp industry is in an

expansion mode.

Chinese pulp mills increasingly have to rely on imported wood chips for their wood fiber needs.

In 2011, record volumes were imported mainly from hardwood plantations in Vietnam, Thailand

and Indonesia.

With the lack of sufficient quality and quantity of domestic wood fiber supply, new pulp mills in

China are looking to expand importation of wood chips from plantation-rich countries in South East

Asia to meet their growing fiber needs. Vietnam, Thailand and Indonesia were the major suppliers to

China, together accounting for about 88 percent of all imports of hardwood chips, as reported in the

Wood Resource Quarterly.

News

7February 2012 | www.timberdesignandtechnology.com

News

DANUBE OPENED two new

state-of-the-art facilities in

Ajman and Al Quoz, wherein

the company invested a total

of AED 55 million as part of

its regional expansion plans to

address the demand for top-

quality materials in the region.

The new operations hubs will

conveniently bring the widest

range of products including

wood, steel, glass, aluminium,

hardware, sanitary, ceiling and

flooring closer to local and

regional customers.

The AED 30 million facility

in Ajman will have a total area

of 58,000 square feet. With

investments amounting to

over US $93 billion already

Danube spreads its wings

Bamboo for bio-energy

channeled into the Ajman real

estate market in the past two

years, Danube has identified

the potential of the emirate

to become one of the UAE’s

construction hotspots.

Amidst the strong efforts

of the Dubai Municipality

towards developing Al Quoz

as a world-class industrial

destination, the manufacturer

has made a decision to

invest in a new factory in

the area. Spanning a total of

30,000 square feet, the AED

25 million Al Quoz facility

underlines the company’s

deep resolve to increase

its production and further

expand across the emirates.

A PARTNERSHIP among African nations and communities, the International Network for bamboo

and Rattan (INBAR) and China are working to substitute bamboo charcoal and firewood for forest

wood on which 80 percent of the rural population in sub-Saharan Africa depend for their fuel needs.

Initial successes with bamboo charcoal in Ghana and Ethiopia, which have put bamboo biomass at

the centre of renewable energy policies, are spurring interest in countries across the continent and

prompting calls for greater investment in bamboo-based charcoal production as a ‘green biofuel’ that

could fight deforestation and mitigate climate change.

INBAR’s bamboo as sustainable biomass energy initiative is the first to transfer bamboo charcoal

technologies from China to sub-Saharan Africa to produce sustainable ‘green biofuels’ using locally

available bamboo resources.

Driven by growing concerns about energy, health and food security and climate change, the initiative

is funded by the European Union (EU) and the Common Fund for Commodities (CFC).

Designs on you

A NEW drawer system from ArciTech has now attracted two

coveted awards: the IF Product Design Award 2012 and the OWL

Innovation Prize 2011. Both accolades acknowledge the product’s

outstanding qualities, its design as well as the overall concept,

including the newly constructed production facility at company

headquarters in Kirchlengern/Bünde.

In the IF Product Design Award 2012, ArciTech came through

against a competent international field of competitors. The award

honours outstanding design achievements for volume products

that have not been on the market for more than three years or will

go into mass production in the award year. The IF Design Award

is regarded worldwide as a seal of quality for design excellence.

The OWL Innovation Prize goes to innovative products, services

and processes from the Ostwestfalen Lippe region. Hettich

received a special prize for the new ArciTech drawer system. The

jury felt that in a bold process and with the biggest investment

in company history, a completely new drawer system had been

developed that sets new standards with its incredibly smooth

running action, high stability and broad product line-up based on a

single platform, while also revolutionizing previous developments.

8 www.timberdesignandtechnology.com | February 2012

News

US and Indonesia collaborate for conservation

THE UNITED States has reportedly pledged US $450 million for

an environmental and climate change cooperation programme

with Indonesia. The money will be utilized to fund projects for

the promotion of environmentally sustainable economic growth,

strengthening climate change policies, conservation of tropical

forests, protecting coastal communities and fisheries as well as

the Low Emission Development Strategies (SOLUSI) project to

improve air quality.

The US will, reportedly, assist Indonesia to implement a ‘Green

Prosperity Project’ at a cost of US $332.5 million, which will

support environmentally sustainable economic growth through

the enhancement and management of Indonesian forests, peat

lands and other natural resources as well as the development

of renewable energy. In addition, the US will provide US $6.9

million to match funding from Norway for the new Indonesian

Climate Change Centre (ICCC), which will deploy and provide

the mapping and monitoring of carbon-rich peat lands and tropical

forests, with expertise to be provided by the US Forestry Service.

The aim is to provide Indonesia with the best available scientists

and policy analysts on key strategies and decision making from the

US to mitigate and adapt to climate change.

Rwanda reigns supreme

EACH yEAR the World Future Council (WFC) spotlights

exemplary policies that bring the interest of future generations to

the forefront of policy-making. In connection with the UN-declared

International year of Forests 2011, the WFC collaborated with

the United Nations Forum on Forests Secretariat, the Food and

Agriculture Organization and the Secretariat of the Convention on

Biological Diversity to honour the best in forest policy for the 2011

Future Policy Award.

2011’s winners represented the most inspiring, innovative

and influential forest policies. An international panel awarded

Rwanda’s National Forest Policy the gold medal, honouring its

work in biodiversity conservation, ecotourism and green jobs

which increased forest cover by 37 percent since 1990. Silver

medals were awarded jointly to USA’s Lacey Act for tackling the

problem of illegal timber trade, and Gambia’s Community Forest

Policy for providing local communities with secure and permanent

forest ownership rights. Winners were announced at a press

conference in New york at UN Headquarters, followed by an

awards ceremony that evening.

IDdesign’s third store in Saudi

IDDESIGN - an international

furniture store with an emphasis

on Scandinavian form and

simplicity – is set to open its third

store in Saudi Arabia.

Opening late 2012 in the

center of Al-Khobar, the new

store will be located in the

prestigious Al-Dhahran Street.

This new store will be the anchor

store in Al-Khobar with a floor size of app. 4,500 sqm that incorporates and reflects the newest

development in retail design, merchandising and customer focus.

The unique international furniture and interior design collection will ensure customers an extra-

ordinary shopping experience when visiting the new store. The product range will include everything

from furniture to lighting and accessories, and interior solutions for every room and purpose in your

home of the highest quality.

9February 2012 | www.timberdesignandtechnology.com

News

The report also predicts that ‘a lack of skilled labour and technical

and managerial proficiency will force the GCC construction

companies to leverage close tie-ups or joint execution for major

construction and infrastructure projects’ in Qatar and Saudi. Some

US $700bn worth of new investment projects are predicted in

Qatar by 2020, and around US $86bn alone will be spent on

infrastructure projects for the World Cup in the next decade.

Major projects include the New Doha International Airport,

the Qatar national railway endeavour, a multitude of new stadia,

the Lusail mixed-use development, the Doha port and the long

proposed Qatar-Bahrain causeway.

It was reported earlier that a total of 80-90 consortia have been

identified as qualified to bid for Qatar Railways Company (QRail)

Doha Metro phase 1 projects, tenders for which are set to be

issued in the second quarter of 2012.

Qatar and Saudi lead building material consumption in GCC

Steel yourself

CANADA’S PULP and paper sector’s revenues have dropped 38 percent over the past decade, and

they are now counting on nanocrystalline cellulose to up their bottom line.

Nanocrystalline cellulose (NCC) - pine needle-shaped crystals that measure less than 10

nanometres in length - is extracted from dried and bleached woody biomass. Together, the crystals

display some remarkable properties. Stronger than steel, but many times less dense, NCC is an

attractive additive for materials that need to be tough, rigid and lightweight, such as auto and airplane

parts. When formed into a film, the crystals can reflect ultraviolet and infrared light (good for energy-

efficient window films), and respond to magnetic and electrical fields (ideal for encryption inks). NCC

is currently being tested for dozens of applications and might one day find its way into consumer

products as diverse as golf clubs and nail polish.

Starting in early 2012, CelluForce - a joint venture between Domtar and the non-profit research

institute FPInnovations - will begin transforming wood pulp into NCC at its newly constructed

commercial demonstration plant in Windsor, Quebec. At peak production, the facility should produce

about a tonne of NCC daily from two tonnes of pulp.

QATAR AND Saudi Arabia have been tipped to consume some

50 percent of the GCC region’s building materials over the next

decade or so, according to analyst Frost and Sullivan.

Both countries have ‘ramped up’ construction activities due to

the growth in economic activities in Saudi Arabia and the run-up

towards the FIFA World Cup 2022 in Qatar.

Qatar and Saudi have increased their manufacturing activity,

especially in building materials so as to help the domestic

construction industry achieve a level of self-sufficiency.

However, phasing the different projects correctly will be

crucial, Frost and Sullivan has warned while highlighting what it

terms sequential key factors (SKF) crucial to a phased approach of

the project pipeline. These are availability of financial investment,

skilled labour for construction, building construction materials,

construction equipment, technological and managerial workforce.

10 www.timberdesignandtechnology.com | February 2012

News

Interested in quality hardwood lumber ?all species of hardwood

ABALON HARDWOODwww.abalon-hardwood.com

Contact: Benoit Moreau, Phone: + 973.39.710.630, [email protected]

INTERHOLCO AGwww.interholco.ch

please visit us at:

April 3-5, 2012

Central Hall | Booth: i - 1b

timber_magazine.indd 2 24.01.2012 14:59:48 Uhr

Hello, Yellow!

once felled, are virtually indistinguishable from each other. Four principal species make up the Southern yellow pine family: loblolly, longleaf, shortleaf and slash pine. All are native to America and grow mainly in a broad geographic region from eastern Texas to Virginia. Lumber from all four species is marketed as Southern yellow pine and graded in accordance with the grading rules of the Southern pine Inspection Bureau (SPIB), approved by the American Softwood Lumber Standard Committee.

The natural advantages of Southern yellow pine are its density, high resistance to decay, superior ability to hold fastenings, and ease of treatment with preservatives.

The Southern Forest Products Association contracted the internationally recognised Timber Research and Development Association (TRADA) to conduct a study to test the comparative hardness and strength of several softwood species: Southern yellow pine, Radiata pine sourced from both Chile and New Zealand, Brazilian Elliotis pine, European Redwood, and European Whitewood.

The purpose of the study was to obtain evidence from an objective, third-party source on which softwood is better suited for flooring, furniture, and other applications where durability is of paramount importance.

Testing was conducted for each of the species in one central location to ensure more reliable and objective

As America’s most abundant and sustainably harvested wood

resource, Southern Yellow pine has been an integral part of

American historyAS AMeRICA’S most abundant and sustainably harvested wood resource, Southern Yellow pine has been an integral part of American history. 199 Million acres of forest is replanted with Southern Yellow pine in the South east US every year, ensuring a steady and sustainable supply. Over time, though, lower-priced softwoods have encroached on its market share around the world. A recent study by the Timber Research and Development Association confirms the superiority of Southern Yellow pine over other softwood species, and aims to raise its profile.

Southern yellow pine - one of the strongest structural timbers in the world - is not a single tree species, but a collective term used to describe a range of species that,

12 www.timberdesignandtechnology.com | February 2012

Southern Yellow Pine

Even though 97 percent of American homes are

of timber frame construction and more wood is

consumed per head of population in the US than

anywhere else in the world, the forests of North

America cover the same land area as they did 100

years ago because more trees are planted every

year than are harvested, these forests are growing in

size. While about 4 million tree seedlings are planted

every day in the US, over 3 million of these are

Southern yellow pine. That’s over 1 billion of these

seedlings planted every year in the US.

results. Selection and conditioning of the samples was done following internationally accepted methodology. Testing methods included the Janka hardness test (e.g., resistance to indentation) and a modified Hatt-Turner test to determine impact bending. Both tests involve applying a load to wood specimens in a controlled environment.

Test results show that Southern yellow pine is significantly more resistant to indentation than Chilean Radiata pine, Brazilian Elliotis pine, European Redwood, and European Whitewood. Southern yellow pine also tested significantly stronger in impact bending than all the other species. In addition, it was considerably denser than the other species, which indicates that furniture, cabinets, doors, and flooring made of Southern Yellow pine are less susceptible to dents, scratches, and other signs of wear.

It is due to these very attributes that Southern yellow pine is regaining popularity with flooring and furniture-makers. Aesthetically, it has a beautiful butterscotch color and grain that appeals to many consumers. On a professional level, Southern yellow pine provides construction professionals with not only proven high performance timber, but also with third-party quality assurance of fitness for purpose. Every piece of Southern yellow pine is clearly marked with its grade and other information relating to its production, such as the manufacturer and moisture content at time of grading.

Southern yellow pine is one of the easiest softwoods to pressure-treat with preservatives. The wood’s unique cellular structure permits deep and uniform penetration

ApplicATionsSouthern yellow pine can be used for a wide range of applications:• Raised floor foundations • Outdoor living • Structural components • Post-frame construction • Aquatic and wetland structures• Vehicular bridges • Highway noise barriers • Permanent wood foundations

of preservatives, rendering the wood useless as a food source for fungi, termites and micro-organisms, and hence makes it the preferred species when pressure treated with wood preservatives. Each piece carries a treatment quality mark which provides

assurance that it has been produced by a qualified treater under a quality scheme audited by an independent inspection body accredited by the American Lumber Standards

Committee (ALSC).Southern yellow pine is also one of the stiffest, strongest

structural timbers in the world, making it ideal for flooring in areas of heavy traffic. It is equivalent to C22 in the UK strength class grading scheme, a structural timber classification. It is heavy (between 537 and 626 kg/m3) and dense (Janka hardness rating 690).

Applications for pressure-treated Southern yellow pine include flooring, external cladding, truss rafters, outdoor decking and boardwalks, pergolas, harbours, gazebos, screening, fencing, outdoor furniture, path and border edges, earth retaining walls, bridges, freshwater piers and pontoons, and post and frame structures.

The solid evidence provided by the TRADA study on the superior properties of Southern pine may well contribute to winning back market share lost to lower-cost products.

Southern Yellow pine is harder than the other types of pine, but not as hard as oak or bamboo, and its distinctive grain pattern

appeals to many consumers

“Southern Yellow pine provides construction

professionals with not only proven

high performance timber, but also with third-party

quality assurance of fitness for purpose”

13February 2012 | www.timberdesignandtechnology.com

Southern Yellow Pine

FReShlY FelleD timber contains a large quantity of moisture, most of which has to be removed in order to obtain satisfactory performance from the wood and to avoid unequal shrinkage during the equilibration process. While no one argues against the need to dry wood, there is a debate about the preferred method: kiln-drying or air-drying.

Air-drying is the drying of timber by exposing it to the air. The rate of drying largely depends on climatic conditions, and on the air movement (exposure to the wind). Kiln-drying is an industrial unit operation used to accelerate the drying of wood, in an enclosed space where air speed, temperature and humidity are controlled.

Both methods bring their own advantages and challenges for importers and sawmills. For manufacturers, they hold appeal for various reasons. Leading regional importers of timber confirm the benefits –and the demand - of kiln-dried timber.

“Kiln-dried lumber is of higher quality because - after drying - it will be graded again and any physical deformities or drying defects will be removed before shipment,” says Danube Group’s Founder and Chairman, Rizwan Sajan.

Natural air-drying of wood can take a very long time, while kiln-drying takes far

less time in comparison

To KILN or NoT To KILN

“Of course, most markets prefer kiln-dried wood,” states Mohamad Maulana, CEO, Al Nibras General Trading Company. “The main reason behind this is that kiln-drying lowers the moisture level significantly and gives you very stable timber.”

Kiln-dried timber can be machined to a finish superior to air-dried timber and therefore problems such as raised grain are virtually eliminated. Kiln-dried timber can usually be installed immediately upon delivery to site, which means that you don’t need to have expensive timber lying around acclimatizing. Such timber is also suitable for finishing immediately with a paint or stain, which means that the wood can be protected without delay.

Sajan tells us that the demand for kiln-dried wood exceeds the demand for air-dried wood in the markets Danube deals with. United Agencies’ General Manager Venu Gopal verifies that, in 2011, kiln-dried timber moved faster than air-dried timber, due to its superior properties.

The benefit of kiln-drying timber is that it is dried in a

14 www.timberdesignandtechnology.com | February 2012

Kiln-drying Technology

controlled environment, has rigorous testing, and is extremely quick - giving a higher quality end product. Bugs and insects are also killed during the drying process. Therefore it can be more cost effective and is less likely to have distortion, staining or drying stresses (i.e. warping or bowing).

Because it offers benefits with respect to ensuring consistent quality and preventing lumber

degrade, kiln-dried lumber is pretty much a standard in the global lumber industry nowadays.

For large sawmills, an important benefit of kiln-drying is the short lead time required to move the lumber, which reduces inventory costs and saves space in the yard. However, the cost of installing and maintaining kilns may often be prohibitive unless throughput of timber is high. The obvious advantage of air-drying is its low capital cost in comparison to kiln drying procedures.

Kiln operators often find that it is more economical to air-dry timber to 25 to 30 percent moisture content if the material is likely to take more than 5 weeks to kiln from green, due to its size or the drying characteristics of the timber. However, it is important to remember that air-drying can only be used to reduce the moisture content of timber to around 14 to 20 percent. Therefore, for many applications, kiln-drying - which reduces the moisture content down much further - is a necessary final step in the drying process.

The benefit of kiln drying timber is that it is dried in a controlled

environment, has rigorous testing, and is extremely quick - giving a higher

quality end product

“Compared to air-drying , kiln-drying results in lower and more uniform moisture levels,” adds Sajan. “For example, with kiln-drying it is possible to go down to a moisture content of 8 percent which is not at all possible in air drying. Compared to air-drying, the drying time is quicker with kiln-drying so the timber will be ready for use earlier than air dried timber and there is no dependency on weather. Also, while kiln-drying, all possible insects will be killed and we will get insect-free timber.”

Modern kilns allow tight control of air-flow, temperature and humidity so that all the timber dries uniformly and to the precise moisture content required. This results in a more uniform product and the problems often associated with poorly air-dried timber are avoided.

B M Ashraf, Managing Director of Mohiudeen Wood LLC concurs with his peers but also explains why air-dried timber is still selling and continues to be in stock. “The kind of timber required depends on the end use. If the use demands a very stable timber, then the timber has to be kiln-dried. Generally, when engineers have a fixed budget to work with and the end use allows a little flexibility, air-dried timber can be specified after careful thought.”

The main disadvantage of air-drying is that all pieces of a given bundle of lumber will not

Rizwan Sajan

Danube Group’s

Founder and Chairman

15February 2012 | www.timberdesignandtechnology.com

Kiln-drying Technology

• Kiln-drying lumber allows for uniform drying in a carefully controlled environment

• Careful drying in a controlled environment minimizes checking (cracking), warping and bowing, creating a stable product, which is ready for shipment and further processing

• Grading after kiln-drying ensures delivery of a quality-controlled product, which minimizes wastage

• The heat and steam used in kiln-drying serve to eliminate pests and disease in the green lumber

• Finishes can be applied to kiln-dried lumber without the need for further drying

• Once the moisture content is sufficiently reduced through the process of kiln-drying, the wood will remain dimensionally stable and allow for a longer lasting performance product.

soMe oF THe BeneFiTs AssociATeD WiTH Kiln-DrYinG:

necessarily dry to the same moisture content. Boards on the inside of the stack may have a completely different moisture content to those on the outside. In other words, when air-drying timber you don’t have the same control that kiln-drying offers.

Another disadvantage is that air-dried timber usually needs acclimatizing when delivered to site to prevent further shrinkage once installed. Furthermore, air-dried wood may not be sufficiently dry for a coating to be applied whereas kiln-dried wood can be coated with a wood finish immediately. There are dangers in air-drying timber as well. If allowed to dry out too quickly, case-hardening or honeycombing may ruin the structure of the wood.

“Wherever the final destination of sawn timber (lumber) in temperate species, it is always advisable that the wood is kiln-dried before shipment,” explains Rod Wiles, AHEC Director for Africa, Middle East, India and Oceania. “The process is a fine art and those who produce the wood in North America or Europe, for example, have perfected it over many, many years. It is a genuine value-addition to the product and should ensure that what is delivered to the customer is higher yielding, pest and fungus free, ready to use and dimensionally stable. In effect, when you buy kiln-dried lumber, you have more chance of knowing what you are going to get and there will be much fewer unwanted surprises.”

Rod Wiles, AheC Director for

Africa, Middle east, India and

Oceania

“Kiln operators often find that it is more economical to air dry timber

to 25 percent to 30 percent

moisture content if the material

is likely to take more than 5

weeks to kiln from green”

16 www.timberdesignandtechnology.com | February 2012

Kiln-drying Technology

C

M

Y

CM

MY

CY

CMY

K

interzum guangzhou_ad_210x297(NSP).pdf 2011-11-8 18:02:47

Doors, kitchen Doors, furniture, hotel furniture, Yatch furniture, frames, glass, plastic…

for this anD much more, cefla is here With his 80 Years of historY

the finishing experience

cefla miDDle east fZe.P.O Box: 261 633Warehouse No. FZS2AB02Jebel Ali Free Zone - Dubai - UAE Tel: +971 4 8862 722 - Fax:+971 4 8862 [email protected] - www.ceflafinishinggroup.com

cefla: since 20 years the finishing experience in the middle east.

Doors, kitchen Doors, furniture, hotel furniture, Yatch furniture, frames, glass, plastic…

for this anD much more, cefla is here With his 80 Years of historY

the finishing experience

cefla miDDle east fZe.P.O Box: 261 633Warehouse No. FZS2AB02Jebel Ali Free Zone - Dubai - UAE Tel: +971 4 8862 722 - Fax:+971 4 8862 [email protected] - www.ceflafinishinggroup.com

cefla: since 20 years the finishing experience in the middle east.

2012:Is it the year of

the turn-around?

FOR The timber industry, the recession hit bottom in late 2008 and early 2009, and demand for wood products began increasing slightly in 2010. 2011 was a marginally better year and all the industry people we spoke with agree that - though growth in 2012 is going to be sluggish - it’s not going to get any worse.

The collapse of the construction market in 2008 has been responsible for much of the timber industry’s ensuing woes. 2011 has been the year where the timber industry has climbed slowly out of its recession and has started its upward climb. Recent construction data for the region suggests that 2012 may well be the year of turnaround.

A lot of strong trends emerged towards the end of 2011. North American and European hardwood exporters and international buyers reported reduced trade in December. Sellers noted intense competition for orders in almost every market, although many held prices firm in the belief that they have reached bottom and will soon be rising. Supplies appeared to be tightening, with several exporters reporting that lower production and slower kiln turns had started to limit sales. US hardwood lumber exports reached a five-month high of 105.6 million board feet (MMBF) in October 2011, the latest month for which data is available.

Also towards the end of 2011, with weaker demand for lumber around the world, sawlog prices fell in a majority of the 21 markets tracked by the Wood Resource Quarterly. The Global Conifer Sawlog Price Index (GSPI) declined in the the third quarter of 2011, for the first time since the first quarter of 2009.

The outlook for the next two years is moderately positive. Log export markets look favorable, but with substantial risk deriving from Europe’s financial crisis. The bottom line is that timber industry executives must plan for moderate growth while protecting themselves from a possible recession.

While total recovery for the markets still seems far away, prices are now bottoming out. As a result of improving sentiment, construction companies are picking up where they left off, and bringing business to the timber market: a view that has been confirmed by our industry experts.

We spoke with several timber industry experts to get their take on 2011 and their outlook for 2012

19February 2012 | www.timberdesignandtechnology.com

Analysis

The international timber market has some encouraging statistics to report. In the first 11 months of last year, the district of British Columbia shipped 4.2 billion board feet of lumber to China, exceeding a goal of 4 billion set four years ago. Exports are up 200 percent from 2009, and their value has hit more than US $1 billion. China now takes about 29 percent of all B.C. lumber exports, second only to the US, which accounts for 42 percent of exports.

Speaking about things closer to home, Venu Gopal, General Manager, United Agencies reiterates that the effects of the recession hold strong and not much construction is going on. “We feel that there is going to be a decline in general demand for timber in 2012,” he says.

Rizwan Sajan, Founder and Chairman of Danube Group, says that he expects demand to remain more or less the same in the coming months.

“We always maintain a positive outlook, with a conservative approach to achieve sustainable levels of growth,” says B M Ashraf, Managing Director of Mohiudeen Wood LLC. “The signs are all there and we are certain the market is slowly moving on a stable upward trajectory. The year ahead looks promising indeed.”

Al Nibras General Trading Company’s CEO Mohamad Maulana explains that while the market is definitely evolving, there are still a couple of challenges. “One major challenge is cash-flow, which is not just a local issue, but a global one. Most of the projects that are unfinished belong partially to international investors – who have cash-flow problems. There are minor indications which show that the market has picked up, but it’s more a matter of ‘let’s get started on the project and move it along slowly, rather than stop it altogether’. A project that could easily be completed in 6 months, is being scheduled for completion in a period of one year. This makes demand go down.”

Maulana feels that if construction speeds up, then the demand for timber will go up.

“So the market depends not just on whether or not owners decide to complete projects, but also the speed at which they decide to do it,” explains Maulana. He adds that that the market situation in the UAE is excellent compared to other GCC countries, because it is positioned in to take up not just local, but regional and international projects as well – which is why factories are still working and businesses are still in operation in the UAE, while they are closing down elsewhere.

When asked about the specifics of what kind of wood has been in demand over 2011, Gopal, Sajan and Maulana all confirm a high demand for red oak on the higher-priced end and meranti on the lower-priced.

United Agencies deal primarily in European and American hardwood and Gopal reports that there has been ample demand for both, American red oak and ash in particular.

Danube’s Sajan says red oak, beech and meranti have been the most sought-after hardwoods, and amongst the softwoods, it has been spruce and pine.

Both Sajan and Gopal have seen hardwood being procured for interiors and softwood for construction purposes.

Maulana from Nibras comes forward with a very interesting observation on the duality of demand in the market: very expensive species such as walnut and

red oak have moved very fast, as has the more humble meranti - the former for luxury projects and the latter for commercial projects.

“Since most of the projects have gone into cost-saving mode, meranti has been specified for a lot of commercial projects to keep the costs low,” explains Maulana.

Mohiudeen’s Ashraf is keen to point out that demand for certain species never fades, such as Malaysian red meranti, West African okume and Burmese teak, which are predominantly sought after in this market because of their ready availability and their ability to be used for a variety of internal and external applications.

“European and American hardwood species such as beech and ash are also in high demand,” adds Ashraf. “North American and European suppliers have had to

20 www.timberdesignandtechnology.com | February 2012

Analysis

look at burgeoning international markets such as China, South East Asia and the Middle East to fill demand, as their local markets and client base have shrunk in the past year. This is an added advantage for buyers here and - coupled with the depreciating Euro - has worked in our favor.”

Talking about the reasons why certain species are more popular in this region, all experts agree that two major factors are at play: aesthetics, and cost.

Walnut and red oak are very popular in this region because of their aesthetic appeal and luxury element , and meranti due to its price.

“The wood selected depends largely on the specifications of the consultants. We hardly ever dictate or influence decision,” says Gopal. “A lot depends on the

tastes of people too, be it the consultant, the architect or the client.”

“Technically speaking, most of the species can work in any project ,” says Maulana. “There are lower-priced species that you can stain and get the look of walnut. But people here specify walnut mainly for the luxury aspect. From a durability and technical suitability point of view, there are rarely very strict technical considerations that dictate what kind of timber is specified. It is mostly the aesthetic and cost factor on which the decision is made. There are a lot of luxury projects in the region – such as five-star hotels from international hotel chains – which follow strict international specifications, such as the use of walnut. We also have a lot of palaces and luxury residences in the UAE, and hence more expensive ‘luxury’ wood moves fast.”

Ashraf highlights that technical specification should not be overlooked when specifying timber.

“For most applications apart from industrial uses, it is important to specify a timber that is stable, which doesn’t split, crack, cup, warp, twist or bend after installation,” says Ashraf. “For example West Malaysian red hard meranti is a naturally stable timber, that doesn’t necessarily require careful curing cycles and remains relatively stable as it dries out naturally. Cost and availability are also major factors. meranti is both cost effective and readily available, so this makes meranti one of the most commonly used timbers in this region. Burmese teak, which is also a naturally stable timber, is sought after for use in prestigious installations, such as yacht decks, interior paneling and fine furniture, but is sparingly used when compared with other species due to its relatively high cost.”

Regional timber importers and suppliers are well prepared for the most highly demanded species, but what happens when an order comes in for something not in stock?

Danube’s Sajan refers to his regular supply base who have flexible manufacturing facilities and can accommodate such requests.

Mohiudeen – as the oldest sawmilling company in the Middle East with two dedicated sawmills that mill and process various species of hard and softwood logs into various special and standard dimensions upon demand – proudly profess that they can execute special orders within very short time frames.

“We were the first to import round logs into the UAE and we have certainly come a long way since then,” says Ashraf. Maulana expresses that Nibras is well-placed when it comes to sourcing orders, as their global network of suppliers is wide and varied.

“We already have good knowledge about the different species used all over the world, and have a network of producers as well,” Maulana explains. “It’s a little bit faster and easier for us to get any new species that may come to be in demand. We also have a huge variety in our stocks, which gives the manufacturer or consultant a chance to choose. If the quantity they require is higher, or if they need a new species, then it is just a matter of how long it takes us to ship it. In my opinion there are not many species available in the world - or that are demanded in this market - that we don’t have. We have 45 species in our stocks today, where 65-70 species are used worldwide. So you can say we cover almost all of the species. “

21February 2012 | www.timberdesignandtechnology.com

Analysis

‘Brin

ging back the Dragon’

We explore this Chinese restaurant which combines Oriental charm, Arabian mystique and American hardwoods

22 www.timberdesignandtechnology.com | February 201222 www.timberdesignandtechnology.com | February 2012

Design and Decor

‘Brin

ging back the Dragon’

DIneRS WhO flocked to the opening of modern Chinese restaurant - hakkasan - at the opulent emirates Palace in Abu Dhabi in 2010 were ushered into a magical world where haute Chinois culture and cuisine effortlessly blends with Arabian mystique.

Backed by the famed Michelin stars from Michelin Guides, the global authority on restaurant and hotel evaluations, Hakkasan brings the grandeur of Chinese fine dining right at the heart of the capital. Hakkasan Abu Dhabi’s expansive 16,000 square feet of space includes a dining area, a bar, a lounge and four private dining rooms. All sections are separated by carved wooden lattice screens made of American red oak, adding luster to the luxurious interior of the high-class restaurant.

Alan yau, the man behind the Hakkasan concept of offering modern Chinese dishes with chic Chinese décor, aimed to reproduce the same ambience of the restaurant’s London branch in the UAE and complement it with Arabian touches. To achieve this, he contracted the services of long-time design partner Gilles and Boissier. The Paris-based design firm maintained trademark modern-ethnic Hakkasan elements and accentuated the facility with embroidered finished furniture and marbled Chinese forms to add body to key spaces. The main dining area was crafted into a wooden cage-like structure surrounded by blue glass nested in a stainless steel frame.

Woods Bagot, a global design studio specialising in the design and planning of facilities, was also brought onboard as the Executive Architect for Hakkasan Abu Dhabi. The leading firm managed key functions including the liason work between project consultants and the client in addition to handling approvals on material selections. Woods Bagot also had an influence on the design in the ‘Front of House’ areas, but more importantly as and when required during resolution of design issues. In addition, the firm designed the entire ‘Back of House’ area excluding the kitchen.

The design of the restaurant pays tribute to the emotional aspects of the venue, considering important factors such as the aura of each space, the emotion it provokes and nurtures, and the logistics behind its aesthetics, functions and form. Further, Hakkasan Abu Dhabi’s unique feel is achieved by employing the Chinese art of Feng Shui and tuning the layout and design in harmony with the social dynamics within the space, all of which involved careful consideration of how people would interact in the designed environment.

The design ethos for Hakkasan was based on the theme ‘Bringing back the Dragon’ in honor of the colorful cultural roots of Chinese restaurants from days of yore. Woods Bagot sought to imbibe a distinctive Chinese feel coupled with rich, sensuous overtones with the use of American red oak across different parts of Hakkasan. Space planning was also a major consideration in designing the layout. The methods and elements employed focused on the spatial relationship of the furniture; the size and dimensions of the tables and chairs; scene setting of lighting; music and sound; fire; and scent. The end result is a comfortable setting that dispenses with the hows and whys and says ‘it just is’.

“To implement the design by Gilles and Boissier, which intended to impart a strong Oriental feel to the place for the patrons, Woods Bagot and the contractor, Decovision,

Bird’s eye View of lounge

ling ling lounge

adopted the use of red oak along the various parts of the restaurant. If you look around, you will find that the internal columns, screens, ceilings, some of the walls and the loose furniture are made of red oak. The wood magnifies the Chinois ambience while giving off a relaxing vibe,” said Bruno Veninga, Associate, Woods Bagot.

Hakkasan Abu Dhabi integrates design cues from the orignal Hakkasan restaurant in London and the collaboration between Woods Bagot and Giles and Boissier has ulitmately resulted in achieving the signature aesthetic feel that has now become embedded as a fundamental principle of the Hakkasan concept. The style exudes a cool charm that bestows calm, tranquillity and modesty to a luxurious and modern environment. Signature elements such as the use of blue glass, the ‘caged’ dining area, the contemporary European interpretation of Orientalism in the design of the furniture, fittings and equipment, and the permeating scent of Bindi candles point to the Hakkasan legacy.

hakkasan Abu Dhabi’s unique feel is achieved by employing the Chinese art of Feng Shui and tuning the layout and design in harmony with the social

dynamics within the space

23February 2012 | www.timberdesignandtechnology.com 23February 2012 | www.timberdesignandtechnology.com

Design and Decor

Private dining room

We are very proud of our work with hakkasan Abu Dhabi as it elicits both excitement and intrigue,” Bruno Veninga, Associate, Woods Bagot

Upon entering Hakkasan Abu Dhabi, visitors are greeted by an entrance desk made of stainless steel, mirror polished consoles and a marble top. This visual delight is punctuated by a hanging rectangular white silk pendant. The dining area’s cocoon-like atmosphere is

generated by a surrounding woodwork structure infused with the restaurant’s signature blue glass and backlit stainless steel frames. The woodwork, primarily made of American red oak, gives patrons their first feel of Chinese design, which comes in the form of traditional patterns - visions of Chinese forms recreated in marble and wood, handcrafted and moulded Chinese pottery, and furniture in fish-skin embroidery.

“All wood used in this project were stained a very dark ‘Wengue’ tone, with none of the original color or variation in color visible. Some features of American red oak that we took great advantage of were the excellent

24 www.timberdesignandtechnology.com | February 201224 www.timberdesignandtechnology.com | February 2012

Design and Decor

ProjectParticulars

Project Name: Hakkasan, Emirates Palace Hotel, Abu

Dhabi

clieNt:Emirates Palace Hotel (Owner-

Operator) / Hakkasan (Management)

executive architect:

Woods Bagot

iNterior DesigNer:

Giles and Boissier

lightiNg DesigN:

Firefly Lighting Design

DimeNsioN:1,500 sq.ft split over

ground and mezzanine Levels

WooD sPecies:American red oak

PhotograPher: Victor Romero

geNeral coNtractor:

Decovision LLC

Project maNager:Woods Bagot

depth of grain that occurs naturally without sacrificing structural integrity and its easy adaptability in carvings and structural elements,” added Veninga.

The kitchen can be seen through the blue glass surrounding the dining area. This concept allows activity in the kitchen to be part of the whole dining experience, with diners treated to a live show on how their food is prepared. A long blue-toned glass rectangular bar with a retro-lit top accompanied with a back bar with blue, retro-lit acrylic shelves also forms part of the dining space. Hanging overhead are custom-made conical steel pendant lights while surrounding walls are fitted with ripple lighting to create an atmospheric night-time effect.

Hakkasan Abu Dhabi also boasts of a Ling Ling Lounge and Bar, which plays on architectural space with its American red oak -accented seats separated by white marble elements and heightened with red leather and dark blue pillows. In addition, Chinese red pendants hang

on the ceiling like traditional Asian lanterns.The four private dining rooms are ably separated by

vertical pinewood shutters, with the walls of each room adorned with hand-carved panels of grey-tinted American red oak depicting Chinese scenery. Another part of the restaurant that makes full use of the aesthetic beauty of American red oak are the toilets, which seek

to capture an endearing sense of calm and a spa-like feel. Inside, white marble is set against dark wood and steel-framed mirrors and sinks are accented with a touch of teak. Asian-fragranced soap is further evidence of the high level of attention to detail inherent in this interior.

A key challenge faced by the design team was the restaurant’s interior lighting. The designers wanted a lighting concept that highlighted the patterns coming from the claustra and created contrast to the dark wood and other elements. The solution was to create a filter that diffused the UAE’s extraordinary sunlight. The wood color was highlighted by using lighter-toned leather while the

windows were covered with dense Chinese woodwork that acted as a filter. The mood-enhancing set-up is made more sophisticated by strategic seating dimensions and spacing between tables and the infusion of local design elements. The end-result is a venue that successfully captures the essence of the original London restaurant while being anchored on its Middle East setting.

“We are very proud of our work with Hakkasan Abu Dhabi as it elicits both excitement and intrigue. What creates the identity of this space is the way that your eye can move, play everywhere and never rest. Each visit feels like the first time because each seat has a totally different view. We are particularly pleased with the ease of use of American red oak, which gave the interior contractor the opportunity of rendering the design and desired ‘Chinois’ feel to a successful reality. The timber depicts strength, shape and color, while not being too susceptible to damage from everyday use. The wood being seen all over the place is synonymous to constantly greeting visitors with a warm ‘Welcome to Hakkasan’” concluded Veninga.

The design ethos for hakkasan was based on the

theme ‘Bringing back the Dragon’ in honor of the colorful cultural

roots of Chinese restaurants from days of yore

25February 2012 | www.timberdesignandtechnology.com 25February 2012 | www.timberdesignandtechnology.com

Design and Decor

Why

An UnBelIeVABle range of natural wood patterns and colors means you can find a fit for any taste and any interior. A little help along the way never hurts, and that’s why we spoke with Lesly Lobo. As Managing Director of Woodfloors Middle East – a company with over three decades of wood flooring expertise, including projects such as Rihan Heights, one of the largest wood flooring projects in the Middle East, and through their subsidiary, Zoralco International, the wood flooring on the Burj Khalifa Tower – he is certainly the man in the know.

Wood floors have come a long way in the past few years. Nature has gifted us with an unbelievable range of natural wood patterns and colors, that enhance the beauty of any interior. Today, there are more styles, colors and species of wood flooring available than ever before. Whether you’re looking for traditional oak, rustic pine, exotic wenge or trendy bamboo, you’re sure to find a color and style to fit your décor.

We offer you ways of using this bounty of nature to make it convenient to utilise in various decors and interior/exterior finishes. Our range of wood flooring comes to you in unfinished and pre-finished wood flooring.

If class, elegance, timelessness and longevity is what you are looking for to enhance your interiors, then wood flooring is the answer.

There are many reasons to choose wood floors. Over time, they maintain their value and their integrity. When other flooring options are looking tired and worn out, wood

Wood flooring brings the warmth and beauty of natural wood into any room, enhancing the décor

Wood Floors?

26 www.timberdesignandtechnology.com | February 2012

Surface and flooring

floors will still look beautiful and timeless.Wood floors are ecologically friendly. Since it is a

natural resource, wood is both renewable and recyclable. And, because wood does not collect dust and other allergens, many leading health associations agree that wood floors are the perfect choice for a healthy home.

Maintenance of today’s wood floors is easy. With advanced technology in stains and finishes, regular maintenance requirement is reduced to just sweeping and/or vacuuming, with occasional use of a professional wood floor cleaning product.

Wood floors come in a variety of styles to meet the demands of today’s busy lifestyles - factory finished, unfinished, solid, engineered, strip, plank, parquet, and acrylic impregnated. Choosing the style that is best for you is an important decision, and will be based on a variety of issues including your lifestyle, your decorating style, and the area in which you live.

ColorsWood floors come in a rainbow of colors to fit any décor. you can achieve unique, one-of-a-kind looks with custom stains and finishes. And even if your floor is old, you can achieve an entirely new look with new stain and finishes. The possibilities are endless.

SpeciesToday’s wood floors come in more than 50 species, both common and exotic, spanning the spectrum of color options, hardness, and price ranges. No matter what the look you want to achieve, there are a variety of species to meet your needs.

Care and attention to installation and maintenance of wood floors goes a long way to increase the life of your wood floors.

Before beginning the installation you should consider few things in order to make the floor installation quick and effortless. A well-made plan will help you to install well -functioning floor that will last for years to come. you should thoroughly consult with a reputed installation expert before acquiring a wooden floor.

Caring for wood floors is fairly easy and simple. Natural oil waxes that are hardened with UV light are more durable and more manageable than traditional oil waxes, so regular oil waxing is not needed in normal wear. Vacuum cleaning and wiping with a damp mop is sufficient. Try to maintain appropriate humidity (RH 40-60 percent) and temperature conditions (+18-24°C), necessary protection of the parquet surface (doormats, felt patches etc.) and regular vacuum cleaning and wiping with a damp mop.

27February 2012 | www.timberdesignandtechnology.com

Floorings

Wood Floors Middle East has just launched an exclusive flooring product from Finland: Timberwise. The range features the following collections:

Original CollectionOriginal Collection is a good choice for lovers of traditional wooden floors. You can choose from pine, Siberian larch, oak and ash. Besides wood in natural color tones, we also offer white varnished and white wax oiled products. The following spreads show examples of different surface treatment combinations. Your floor can be brushed and varnished, sanded and wax oiled - or vice versa. Varnish and wax oil finishes are available in clear or matt, so there is plenty to choose from.

Color Collection wax oiledWax oiled Color Collection products use colored wax oil to emphasize the wood’s natural tones. Depending on the selected wood species and colors, the end result varies from nearly white to dark ebony wood tones. you can choose from Siberian larch, oak and ash. Ideal finishes are silky gloss or matt wax oils.

Color Collection lacqueredIn the lacquered Color Collection, varnishes and stains are used to create an attractive floor color. The surface is brushed or sanded, after which it is coated with a suitably colored varnish or stain. Even stained products receive a varnish coating, which ensures the floor is durable. Available wood types are oak and ash.

Handwashed CollectionThe inspiration for the Handwashed Collection was sourced from nature and its harmonious colors and lively surfaces. Every wood and floor is unique reflecting nature’s own diversity. Handwashed Collection’s color range gives you endless opportunities to create fascinating and cutting edge interiors.

28 www.timberdesignandtechnology.com | February 2012

Flooring

WOOD hAS always been a desirable construction material for a multitude of reasons. however, due to the relative weakness of existing construction methods utilizing just wood, it has not been possible to build tall wooden structures. Until recently.

‘Cross-laminated timber’ is the new buzzword in the dialogue for green building, and is changing how we will be using wood.

Cross-laminated timber, or CLT, is a new method of fabricating wood panels that is – amongst other applications - enabling mid-rise construction with wood.

This highly pre-fabricated building material is essentially a panel made of wood planks that are fastened together using interlocking profiles (i.e. dovetail connections) instead of glue or fasteners, and can be used for long spans, such as roofs, floors and walls.

Work with CLT was first done in Switzerland and

ALL WooDALL GooD

Cross-laminated timber promises faster and cheaper construction, lower carbon footprint, easy deconstruction

and prevention of resource depletion

Austria in the early to mid 1990s, and since then CLT has proven to be a boon on many counts:

Faster and cheaper construction:Because the panels are lighter than masonry and hollow-core concrete plank, and since the panels can be lifted with lighter equipment, construction can be faster and thereby less expensive. It also requires a smaller crew to install and connect the panels at the job site, which allows for rapid and efficient construction. CLT also reduces labor and construction site waste because of its pre-fabrication.

Low Carbon footprint: Since CLT is all wood, it is a carbon sink: it traps the carbon in solid form and keeps it from entering the atmosphere. Because wood products are responsible for less air and water pollution and fewer greenhouse gas emissions than other materials, and because of its capacity to stores more carbon than other non-wood building materials, CLT could perhaps even be accredited with a negative carbon footprint.

Easy deconstruction and prevention of resource depletion: As CLT panels can be constructed with dovetail joints or other joints, without the use of glue or fasteners, deconstruction becomes easier – meaning CLT panels can easily be reused in other building applications. This, in turn, reduces environmental impact caused by resource depletion.

The only catch here is that CLT is a relatively new technology that has only started gaining traction a decade or so ago. As a building material CLT is commercially available in Europe, but isn’t widely or readily available in other parts of the world.

Attention on green building in the region will no doubt create a demand for CLT regionally, and hopefully - supply will follow. UBC earth Sciences Building

30 www.timberdesignandtechnology.com | February 2012

TitleSustainability

While we’re waiting for this product to reach our shores, it has already made a huge impact in the West. Innovative Timber Solutions LLC - the first CLT Service firm in the US – share some of the advantages of CLT for the various segments of users:

CLT is extremely versatile and is perfectly combinable with other construction materials. As a result of its extreme load distribution properties in both directions, CLT presents few limitations for architectural, residential or utility building projects. This is a significant reason for its increasing use in the construction of detached and multi-tenant residential properties or in the construction of commercial and industrial premises.

In addition, the enormous load-bearing and rugged properties of CLT ensure the increasing popularity of this high-quality construction product in the construction of bridges, carports, ancillary buildings, wood/concrete composite ceilings and in many other fields.

ArchitectsArchitects have been eagerly and proudly designing and specifying CLT in Europe for over twenty years. Design freedom and opportunities with CLT are limitless. The stunning success of architect Andrew Waugh’s nine-storey Stadthaus CLT apartment building in London are a testament to what the future holds for this system. Flawless in its life cycle assessment, carbon footprint, sustainability, ease and speed of installation, architects have new and previously unattainable opportunities to design unique, innovative high performance buildings across all categories that will last for generations.

BuildersMost builders will agree that little has changed in our method of construction over the last 150 years. Why is that we have been building cars in factories since the turn of the century yet we continue the slow, wasteful, stressful, inefficient method of site built construction? Would you buy a car built in the parking lot? Smart builders, those looking ahead, those that recognize advances in technology can improve their bottom line and deliver higher quality, faster, better buildings. If you want to operate with less labor, less risk, less waste and accelerate the number of projects you can accomplish, CLT has a long list of tangible assets for your business.

Work with ClT was first done in Switzerland and

Austria in the early to mid 1990s

Cross-laminated timber

Residential Anyone who has lived in a “modern home” that was built to today’s “standards” has experienced the realities of our archaic methods and materials. Homes that won’t outlive most mortgages with low performance, often toxic materials thrown together on-site, exposed to all the elements for months while dumpsters are filled with construction waste (much of it wood) and hauled to the dump. Stud framed walls are loud, have thermal bridging at every stud (that can add up to as much as 20 percent of your home being uninsulated) and trap moisture in the walls causing mould.

31February 2012 | www.timberdesignandtechnology.com

Sustainability

CLT homes are like living, breathing buildings. CLT wall assemblies are engineered to be a Vapor-Open system. This means the walls can eliminate internal water vapor (think of your kitchen, bathrooms, people, animals, fish tanks all pumping significant volumes of water vapor into your walls) just by letting the wood do what is does naturally. It breathes. CommercialThis is the real prize for CLT in North America because CLT can replace high embodied energy materials like concrete and steel in low and mid-rise buildings and do it faster and cost competitively. In commercial applications, CLT panels can be installed in a platform frame method in buildings that would otherwise be

Cross-laminated timber process

ClT could perhaps even be accredited with a negative

carbon footprint

32 www.timberdesignandtechnology.com | February 2012

Sustainability

ContaCtTel: +971 (0)4 447 1788 | email: [email protected]

Stadthaus ClT apartment building

in london

using concrete. CLT can also be used to compliment any post and beam structure and is particularly well suited as a vertical application in any timber frame project. For instance, the CLT panel would vertically enclose the building, while horizontal oriented panels then create the floors by spanning the beams. CLT can even handle a more industrial configuration where the larger panels are erected in multi story balloon frame and the floor panels are hung from vertical CLT panels.

The recent nine storey Stadthaus CLT apartment building in London was erected in 27 days with four carpenters. The dramatic weight reduction of the structure drove cost reductions by reducing foundation requirements, less labor, shorter construction loan and no waste removal expenses. They even built the elevator shaft and stairwells using thick CLT elements.

DeveloperToday’s sharp developers recognize the fundamental need to differentiate their product from their competitors in a manner that matches the expectation of the demanding customers. No small challenge on the heels of the recession. Many developers shelved projects and find themselves behind schedule on long term strategies. Accelerating delivery of projects, reducing labor and associated risks and creating a sustainable strategy for expediting sales and occupancy dates are all critical to success, and CLT makes all of this more achievable.

33February 2012 | www.timberdesignandtechnology.com

Sustainability

TheRMO-TReATeD wood is a new generation of building material that is gaining repute as being superior to non-treated wood. The experts at Chabros International Group – one of the region’s leading distributors of this exciting product – tell us more.

Increased weather durability and dimensional stability. Moisture repellence at the molecular level. An even brown color, consistent to the core, with beautifully accented grain structure. 100 percent chemically free.

Just a few of the reasons to choose thermo-treated wood

The versatility of this material makes it a widely used material for both interior and exterior applications, such as siding, roofing, decking, garden furniture, hardwood flooring, doors, windows, fences, musical instruments and highway acoustic barriers. Other applications ideal for thermo-treated wood are high moisture environments such as, boardwalks, areas around swimming pools, trim of yachts, sinks, bathtubs, floors and facing tiles in bathrooms.

The list is really only limited by a person’s imagination. The natural elegance of thermo-treated wood and its distinguishing features make it quite

easy to integrate into the most stunning and innovative designer solutions.

Thermo-treated wood DurabilityThe reason for thermo-treated wood being so durable and stable is the molecular changes in thermo-treated wood compared to untreated wood. 95 percent of the polysacharide are removed during the high-temperature processing, and for this reason, thermo-treated wood is so durable.

The thermo-treated wood assumes its minimal size, which substantially reduce moisture related swelling and shrinkage and increase hardness. Wooden floors and furniture for bathrooms and other high humidity areas are now acceptable.

The thermo-treatment process enhances the woods color, creating an even brown tint that is consistent beyond the surface (making scratches invisible, which is important to design the high-traffic areas furniture and flooring, as an example). The natural wooden grain is accentuated, giving the appearance of exotic wood for a fraction of the cost.

Chemicals are never used during the thermo-treatment process, so the material remains environmentally safe.

Chemicals are never used during the thermo-treatment process, so the material remains environmentally safe. You and your

children can walk barefoot across a thermo-treated wooden deck with certainty and

piece of mind

FEEL THE HEAT

ChABROS InTeRnATIOnAl Group is a well known name in wood and veneer supplying since its foundation in 1960. Product lines range from the standard to the exotic from different origins around the globe. Through its affiliates all over the world, Chabros procures raw material of high standards and qualities to meet the demands of the different markets in Africa, Asia, and Australia. Due to its strategic alliances with mills in Africa, north/south America and europe, as well as its own mills in Ukraine and Serbia, which are responsible for sourcing, cooking, cutting/slicing, drying, grading and supplying the various wood products, the group has expanded its chain of supply to incorporate all wood related activities from a to z, and from the source directly to the consumer without any mediators.

Because of its cognition of the different markets and its keen interest in growth and development, Chabros group has extended its services to include production and not just the supply of raw material. In its different locations, Chabros facilities are equipped with cutting, slicing, pressing and laser machines for the production of layons, veneered boards, and marquetry/parquetry designs.

Being at the forefront of this field, Chabros has established itself, not only in the UAe market, but in the Middle east area and especially in the Gulf region. With a record of consistent clients, its name has been attached to myriads of projects, ranging from residential and commercial towers to hotels, shopping malls, villas and palaces.

35February 2012 | www.timberdesignandtechnology.com 35February 2012 | www.timberdesignandtechnology.com

What’s New?

WHY THerMo-TreATeD WooD• Thermo-treated wood is ‘Green’ (chemical free)• Increased weather durability by 25 years for outdoor applications• lightweight• Safe for contractors and homeowners• Fasteners are not corrosive• exotic wood appearance and color• Thermo-treated wood costs less to maintain (finish doesn’t crack due

to the increased dimension stability of the wood)• Does not get extremely hot like composite’s and plastics do in the sun• Does not accelerate the dulling of tools such as blades and bits• Thermo-treated wood has better grain structure hence greater

stability and lesser splitting• Increased dimensional stability (swelling and shrinkage is reduced

by 5-15 times)• Repels moisture at the molecular level (the equilibrium moisture

content is lowered by 50-90 percent)• An even brown color, consistent to the core, with beautifully accented

grain structure.

you and your children can walk barefoot across a thermo-treated wooden deck with certainty and peace of mind.

Is it environmentally safe? Thermo-treatment process uses only water and electricity to create the desired results, minimally impacting the environment. When you consider this along with the fact that chemicals are never introduced, you realize this is real wood material that is 100 percent environmentally safe and people friendly.

Does TTW shrink or swell?The dimensional stability is dramatically improved, compared to non-treated wood (by 5-15 times). The darker the color, the better the stability. But, thermo-treated wood is still wood and cant be considered as absolutely stable material, like stone. Some dimensional movements have to be taken into consideration.

Can it be used when constant ground contact is unavoidable? Research has shown that when thermo-treated wood is kept in constant contact with the ground it does not decay. However, due to the chemical processes that occur in wood kept in constant contact with the ground, there is some loss of strength. For the time being, it is not recommended to maintain constant ground contact when using thermo-treated wood.

Is the color of TTW consistent throught the wood?The color is consistent to the very center of the board.

Can it be glued?Thermo-treated wood is suitable for jobs involving glue or paint. If water-based glue or paints are used, a longer penetrating time is required (mostly for softwoods). This is due to the diminished absorption of water and must be taken into consideration.