Theories of Failure Under Static Load

Transcript of Theories of Failure Under Static Load

18/10/2014 1

University of Al-Qadisiya

Collage of Engineering

Mechanical Engineering

By

Mr. HUSAM K. MOHSIN

Introduction

• Strength is a property or characteristic of a mechanical element.

• This property results from the material identity, the treatment

and processing incidental to creating its geometry, and the

loading, and it is at the controlling or critical location.

2 18/10/2014

• Static load– a stationary load that is gradually applied

having an unchanging magnitude and direction.

• A static load can produce axial tension or compression, a shear

load, a bending load, a torsional load, or any combination of

these.

• Failure– a part is permanently distorted and will not

function properly. Thus it has had reliability downgraded.

• A part has been separated into two or more pieces.

3 18/10/2014

• Under any load combination, there is always a combination of

normal and shearing stresses in the material.

• Generally, mechanical components fail because the applied

stresses exceeds the material’s strength.

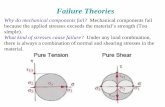

Ductile and Brittle Materials

• A ductile material deforms significantly before fracturing.

• Ductility is measured by % elongation at the fracture point.

• Materials with 5% or more elongation are considered ductile.

4 18/10/2014

• The limiting strength of ductile materials is the stress at yield

point.

• A brittle material yields very little before fracturing, the yield

strength is approximately the same as the ultimate strength in

tension.

• The ultimate strength in compression is much larger than the

ultimate strength in tension.

• The limiting strength of brittle materials is the ultimate stress.

5 18/10/2014

Tensile test diagrams of ductile and brittle materials

6 18/10/2014

F.S.= failure stress/allowable stress

or F.S.= failure load/working load

The allowable stress is the stress value which is used in design

to determine the dimensions of the component. It is considered

as a stress which will not reach or exceed the limiting stress

under normal operating conditions.

For ductile materials

Allowable stress = yield stress/F.S.

For brittle materials

Allowable stress = ultimate stress/F.S.

F.S ≥ 1

7 18/10/2014

Static failure theories

• Predicting failure in members subjected to uni-axial stress is

both simple and straight-forward. But, predicating the failure

stresses for members subjected to bi-axial or tri-axial stresses is

much more complicated.

• A large numbers of different theories have been formulated.

The principal theories of failure for a member subjected to bi-

axial stress are as follows:

I. Maximum principal (or normal) stress theory (Rankine’s th.)

II. Maximum shear stress theory (Guest’s theory)

III. Maximum principal (or normal) strain theory (Saint’s theory)

IV. Maximum strain energy theory (Haigh’s theory)

V. Maximum distortion energy theory (Hencky&Von Mises th.)

8 18/10/2014

Maximum shear stress theory (Guest’s theory)

According to this theory, the failure or yielding of mechanical

component subjected to bi-axial or tri-axial stress occurs when

the maximum shear stress at any point in the component becomes

equal to the shear stress at yield point in a simple tension test.

Mathematically,

Where, : Maximum shear stress in an axial stress system.

: Shear stress at yield point from simple tension test.

F.S: Factor of safety.

Since, = 0.5 →

SF

yt

Max .

Max

yt

yt yt SF

yt

Max .2

9 18/10/2014

For a general state of stress, three principal stresses can

be determined and ordered such that .

The maximum shear stress is then .

Thus, for a general state of stress, the maximum-shear-

stress theory predicts yielding when,

≥ or

Assuming that ,there are three cases to consider

when using equation above for plane stress:

321

2

31

Max

2

31

Max yt y

31

BA

10 18/10/2014

Case 1: . For this case, and . it

reduces to a yield condition of,

Case 2: . Here, and , let to

Case 3: . For this case, and ,

and it gives,

0 BA

BA 0

BA0

yA

yBA

yB

A

10

3

A

1 B

3

01 B

3

11 18/10/2014

Note , is same .

The maximum-shear-stress (MSS) theory yield envelope for plane stress, where

σA and σB are the two nonzero principal stresses.

y S y

12 18/10/2014

Example 1: The load on a bolt consists of an axial pull of 10 kN

together with a transverse shear force of 5 kN. Find the diameter

of bolt required according to Maximum shear stress theory

(MSS). Take permissible tensile stress at elastic limit = 100 MPa.

Solution. Given : Pt1 = 10 kN ; PS = 5 kN ; σt(el) = 100 MPa = 100

N/mm2.

Let d = Diameter of the bolt in mm.

∴ Cross-sectional area of the bolt,

We know that axial tensile stress,

mmddA

22

2

7854.04

mmdd

P kNA

t 2

22

1

1

73.12

7854.0

10

13 18/10/2014

and transverse shear stress,

We know that maximum shear stress,

,

mmdd

P kNA

s 2

22

365.6

7854.0

5

22

4312

1)(Max

02

22

412

1)(Max

)365.6

()73.12

(2

422

122

dd

44365.6

*2

12

d14 18/10/2014

According to maximum shear stress theory,

mmdmmd

d

ely

Max

42.1318050

9000

502

1009000

2

22

2

)(

mmd

kN2

2

9

mmd

NMax

2

2

9000

15 18/10/2014

The distortion-energy theory or (Von Mises theory) predicts that yielding occurs when the distortion strain energy per unit volume reaches or exceeds the distortion strain energy per unit volume for yield in simple tension or compression of the same material.

The total strain energy per unit volume (u) is the distortive strain energy + the volumetric strain energy

U = 1/2[σ1ε1 + σ2ε2 + σ3ε3]

U = 1/2E [σ1^2+ σ2^2+ σ3^2− 2ν(σ1σ2+ σ2σ3+ σ3σ1)]

16 18/10/2014

: the distortive strain energy (pure angular distortion

of element, that is no volume change).

: the volumetric strain energy (pure volume change of

element, that is no angular distortion).

0321 ddd

uv

ud

3

321

av

17 18/10/2014

Since,

∴

Note that the distortion energy is zero if .

For the simple tensile test at yield, & ,

the distortion energy is

3

321

av

321

S y 1

032

18 18/10/2014

So for the general state of stress is given, yield is predicted if,

If we had a simple case of tension σ , then yield would occur

when . Thus, the left of above equation can be thought

of as a single, equivalent, or effective stress for the entire

general state of stress given by , and .

This effective stress is usually called the Von Mises stress (σˊ ).

for yield, can be written as ,

→

sy

1 2 3

19 18/10/2014

For plane stress, the von Mises stress can be represented

by the principal stresses , , and zero.

∴

A B

20 18/10/2014

Using xyz components of three-dimensional stress, the

von Mises stress can be written as

and for plane stress,

Considering the factor of safety (F.S), we get

′ SF

S y

.

'

21 18/10/2014

Example 2: A hot-rolled steel has a yield strength

kpsi and a true strain at fracture of ε = 0.55.

Estimate the factor of safety (F.S) for the following

principal stress states:

(a)

(b)

(c)

(d)

100 ss ycyt

kpsiKpsiKpsixyyx

0,70,70 kpsiKpsiKpsi

xyyx15,40,60 kpsiKpsiKpsi

xyyx45,40,0

kpsiKpsiKpsixyyx

15,60,40

22 18/10/2014

Solution:

Since ε > 0.05 and Syt and Syc are equal, the material is

ductile and both the distortion-energy (DE) theory and

maximum-shear-stress (MSS) theory apply. Both will

be used for comparison. Note that cases a to d are plane

stress states.

(a) Since there is no shear stress on this stress element,

the normal stresses are equal to the principal stresses.

The ordered principal stresses are σA = σ1 = 70, σB = σ2

= 70, σ3 = 0 kpsi.

23 18/10/2014

DE

σ′ = [702 − 70(70) + 702]1/2

= 70 kpsi

F.S = Sy/σ′

= 100/70= 1.43

MSS

Noting that the two nonzero principal stresses are equal, τmax will be from the largest Mohr’s circle, which will incorporate the third principal stress at zero.

τmax = (σ1 − σ3)/2

= (70 − 0)/2

= 35 kpsi

F.S = (Sy/2τmax)

= 100/70= 1.43 24 18/10/2014

(b) the nonzero principal stresses are

σA, σB = (60 + 40)/2 ± [((60 − 40)/2)2+ (−15)2 ]0.5

= 68.0, 32.0 kpsi

DE

σ′ = (682 − 68(32) + 322)1/2

= 59.0 kpsi

F.S = Sy/σ′

= 100/59.0

= 1.70

25 18/10/2014

MSS

Noting that the two nonzero principal stresses are both

positive, τmax will be from the largest Mohr’s circle

which will incorporate the third principle stress at zero.

τmax = (σ1 − σ3)/2

= (68.0 − 0)/2

= 34.0 kpsi

F.S = Sy/2τmax

= 100/68

= 1.47

26 18/10/2014

(c) This time, we will obtain the factors of safety directly

from the xy components of stress.

DE

σ′= [σx2− σxσy + σy

2+ 3τxy2]1/2

= [(40)2 + 3(45)2]1/2

= 87.6 kpsi

F.S = Sy/σ′

= 100/87.6

= 1.14

NOTE. For comparison purposes later in this problem, the nonzero

principal stresses can be obtained to be 70.0 kpsi and −30 kpsi.

27 18/10/2014

MSS

Taking care to note from a quick sketch of Mohr’s

circle that one nonzero principal stress will be positive

while the other one will be negative, τmax can be

obtained from the extreme-value shear stress without

finding the principal stresses.

τmax=[(σx − σy/2)2+ τxy2]0.5

=[(0 − 40/2)2+ 452]0.5

= 49.2 kpsi

F.s = Sy/2τmax

= 100/98.4

= 1.02

28 18/10/2014

(d) the nonzero principal stresses are

σA, σB = (-40 + -60)/2 ± [((-40 +60)/2)2+ (15)2 ]0.5

= −32.0,−68.0 kpsi

The ordered principal stresses are σ1 = 0, σA = σ2 =−32.0,

σB = σ3 = −68.0 kpsi.

DE

σ′= [(−32)2 − (−32)(−68) + (−68)2]1/2

= 59.0 kpsi

n = Sy/σ′

= 10059.0

= 1.70

29 18/10/2014

MSS

τmax = (σ1 − σ3)/2

= (0 +68.0)/2

= 34.0 kpsi

F.S = Sy/2τmax

= 100/68.0

= 1.47

A tabular summary of the factors of safety is included for comparisons.

30 18/10/2014

Since the MSS theory is on or within the boundary of

the DE theory, it will always predict a factor of safety

equal to or less than the DE theory, as can be seen in

the table.

For each case, the coordinates and load lines in the σA,

σB plane are shown in figure below.

Note that the load line for case (a) is the only plane

stress case given in which the two theories agree, thus

giving the same factor of safety.

31 18/10/2014

32 18/10/2014

Maximum principal (or normal) stress theory

The maximum-normal-stress (MNS) theory states that failure

occurs whenever one of the three principal stresses equals or

exceeds the strength.

Again we arrange the principal stresses for a general stress

state in the ordered form . This theory then

predicts that failure occurs whenever

321

33 18/10/2014

where and are the ultimate tensile and compressive

strengths, respectively, given as positive quantities.

For plane stress, with , the equations can be written as

which is plotted in below figure.

S ut S uc

BA

34 18/10/2014

As before, the failure criteria equations can be converted

to design equations. We can consider two sets of equations

where as

or

Example 3:The load on a bolt consists of an axial pull of 10

kN together with a transverse shear force of 5 kN. Find the

diameter of bolt required according to Maximum principal

stress (MPS) theory. Take permissible tensile stress at

elastic limit equals 100 MPa and poisson’s ratio equals

0.3.

BA

SF

S ut

A .

SF

S uc

B .

35 18/10/2014

Solution:

d = Diameter of the bolt in mm.

∴ Cross-sectional area of the bolt,

We know that axial tensile stress,

and transverse shear stress,

We know that maximum principal stress,

σt1 = (σx + σy )/2 + [((σx - σy )/2)2+ (τ)2 ]0.5

mmddA

22

2

7854.04

mmdd

P kNA

t 2

22

1

1

73.12

7854.0

10

mmdd

P kNA

s 2

22

365.6

7854.0

5

36 18/10/2014

= (12.73/d2+ 0)/2 + [((12.73/d2 - 0)/2)2+ (6.365/d2 )2 ]0.5

= (6.365/d2)[1+0.5(4+4)0.5]

σt1 = (15.365/d2) kN/mm2

According to maximum principal stress theory,

σt1 = σt(el) = (15.365/d2) = 100

→ d2 = 153.65 mm2

∴ d= 12.4 mm

37 18/10/2014

Mathematical analysis and

experimental measurement

show that in a loaded structural

member, near changes in the

section, distributions of stress

occur in which the peak stress

reaches much larger magnitudes

than does the average stress

over the section. This increase

in peak stress near holes, grooves,

notches, sharp corners, cracks,

and other changes in section is called stress concentration.

38 18/10/2014

A theoretical, or geometric, stress-concentration factor Kt or

Kts is used to relate the actual maximum stress at the

discontinuity to the nominal stress. The factors are defined by

the equations

where Kt is used for normal stresses and Kts for shear stresses.

The nominal stress σ0 or τ0 is the stress calculated by using

the elementary stress equations and the net area, or net cross

section.

Max

tK

Max

tsK

39 18/10/2014

The stress-concentration factor depends for its value only on the

geometry of the part.

Most stress-concentration factors are found by using experimental

techniques.

In static loading, stress-concentration factors are applied as

follows:

In ductile materials (εf ≥ 0.05), the stress-concentration factor is

not usually applied to predict the critical stress.

In brittle materials (εf < 0.05), the geometric stress-concentration

factor is applied to the nominal stress before comparing it with

strength.

40 18/10/2014

Chart of Thin plate in tension or simple compression with a

transverse central hole. The net tensile force is F = σwt.

Where,

t is the thickness of the plate.

The nominal stress is given

by

41 18/10/2014

Example 4: The 2-mm-thick bar shown in figure below

is loaded axially with a constant force of 10 kN. The

bar material has been heat treated and quenched to raise

its strength, but as a consequence it has lost most of its

ductility. It is desired to drill a hole through the center

of the 40-mm face of the plate to allow a cable to pass

through it. A 4-mm hole is sufficient for the cable to fit,

but an 8-mm drill is readily available. Will a crack be

more likely to initiate at the larger hole or the smaller

hole?

42 18/10/2014

Solution:

A. For a 4-mm hole,

The theoretical stress concentration factor, from

previous chart, with d/w= 4/40= 0.1, is Kt= 2.7. The

maximum stress is

Mpatdw

F

A

F139

2)440(

10000

)(

MpaK tMax380)139(7.2

43 18/10/2014

A. Similarly, for an 8-mm hole,

The theoretical stress concentration factor, from

previous chart, with d/w= 8/40= 0.2, is Kt= 2.5. The

maximum stress is

∴ The crack will most likely occur with the 8-mm hole

and next likely would be the 4-mm hole.

Mpatdw

F

A

F156

2)840(

10000

)(

MpaK tMax390)156(5.2

44 18/10/2014