THE WABASH RIVER IGCC PROJECT … · Repowering Unit 1 (90 MW) of Six Unit 888 MW PC plant...

Transcript of THE WABASH RIVER IGCC PROJECT … · Repowering Unit 1 (90 MW) of Six Unit 888 MW PC plant...

March 14, 2001

GTC Gasification Workshop for Environmental Regulators

1

The Wabash River IGCC Project

THE WABASH RIVER IGCC PROJECT

REPOWERING COAL FIRED POWER PLANTS

PHIL AMICK

VICE PRESIDENT, COMMERCIAL DEVELOPMENT

GLOBAL ENERGY, INC.

March 14, 2001

GTC Gasification Workshop for Environmental Regulators

2

The Wabash River IGCC Project

March 14, 2001

GTC Gasification Workshop for Environmental Regulators

3

The Wabash River IGCC Project

Our company:

• Project Developer for Gasification Facilities

• Environmentally Driven

• A Founder of Gasification Technologies Council

• Develop, Build, Own & Operate Strategy

• Two Technologies

• British Gas Lurgi (BGL)

• E-Gas (Dow / Destec Gasification Process)

DOWDeveloped Technology, Proto Plants & LGTI

1973 - 1989

Spun off from Dow in 1989, 80% Dow Ownership

Wabash River 1989-1997

NGC Corporation

Purchased Destec from Dowin June 1997

NGC changed its name toDynegy in June 98

“E-GAS” GASIFICATION PROCESS HERITAGE

2000

March 14, 2001

GTC Gasification Workshop for Environmental Regulators

5

The Wabash River IGCC Project

TECHNOLOGY COMPARISONE-Gas “Destec” BGL

Type Entrained Flow Fixed BedSlagging SlaggingSlurry Fed, O2 Dry Feed, O2

Feedstocks Tested Coal, Lignite Coal, Pet CokePet Coke AFT Fuel Briquette

w/ biomass, sludge

Module Size 120/250/500 MW 120/400 MW

Products Power, Steam, H2 Power, GasChemical Feedstock Transportation Fuel

March 14, 2001

GTC Gasification Workshop for Environmental Regulators

6

The Wabash River IGCC Project

March 14, 2001

GTC Gasification Workshop for Environmental Regulators

7

The Wabash River IGCC Project

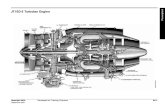

E-GAS GASIFIER

March 14, 2001

GTC Gasification Workshop for Environmental Regulators

8

The Wabash River IGCC Project

EGAS TECHNOLOGY HISTORY

PILOT PLANT 36 TPD 1975

PROTO 1 400 TPD 1979

PROTO 2 1600 TPD 1983

LGTI 2400 TPD 1987

WABASH 2550 TPD 1995

March 14, 2001

GTC Gasification Workshop for Environmental Regulators

9

The Wabash River IGCC Project

March 14, 2001

GTC Gasification Workshop for Environmental Regulators

10

The Wabash River IGCC Project

Wabash River Project Overview• E- Gas Technology Gasification Process• Coal Gasification Combined Cycle Repowering

• Operational since 1995

• 262 MWe Net Output

• Bituminous Coal and Petcoke, up to 7 % S

• Cleanest Coal/Coke Fired Power Plant in the World

• Greatest Petcoke Throughput Demonstrated in Single Gasifier

March 14, 2001

GTC Gasification Workshop for Environmental Regulators

11

The Wabash River IGCC Project

Wabash River Project Overview• E- Gas Technology Gasification Process

– Oxygen Blown, Slurry Fed– Continuous Slag Removal ( No lock hoppers)

• High Temperature Heat Recovery (~ 1000 DegC)• Medium Temperature Char Filtration (~ 450 DegC)

– Metallic Elements, Dry Filtration

• COS Catalyst, MDEA Acid Gas Removal• Claus based Sulfur Recovery• Recycle of SRU Tailgas and Char to gasifier• General Electric 7FA Gas Turbine, Dual Fuel (Oil/Syngas)

March 14, 2001

GTC Gasification Workshop for Environmental Regulators

12

The Wabash River IGCC Project

WABASH REPOWERING

SlurryPrep

ASU

Slag / Frit

Handling

Gasifier

HTHR

Filtration

Sulfur

Recovery

Sulfur

Removal

GT

HRSG

Water

Treatment

Switch

Yard

Fuel

Handling

STG &

Aux

Existing

March 14, 2001

GTC Gasification Workshop for Environmental Regulators

13

The Wabash River IGCC Project

WABASH RIVER ENERGY LTD.

March 14, 2001

GTC Gasification Workshop for Environmental Regulators

14

The Wabash River IGCC Project

WABASH RIVER ENERGY LTD.

March 14, 2001

GTC Gasification Workshop for Environmental Regulators

15

The Wabash River IGCC Project

PROJECT SITE

Repowering Unit 1 (90 MW) of Six Unit 888 MW PC plant

Approximately 40 Acres on existing powerplant and coal mine property

Site located on reclaimed mine entrance area

Viking and Saxton coal mines (abandoned) underly the site

Nearest residence one half mile away (nearer existing plant)

March 14, 2001

GTC Gasification Workshop for Environmental Regulators

16

The Wabash River IGCC Project

WABASH RIVER PROJECT SCHEDULE91 92 93 94 95

MILESTONESProposal for Clean Coal IVDOE SelectionIURC Approval

ENVIRONMENTAL PERMITSEnvironmental Information VolNEPA Process

MAJOR EQUIPMENT FABRICATION

CONSTRUCTION

START-UP

March 14, 2001

GTC Gasification Workshop for Environmental Regulators

17

The Wabash River IGCC Project

March 14, 2001

GTC Gasification Workshop for Environmental Regulators

18

The Wabash River IGCC Project

AIR EMISSION POINTS

Gas Turbine/HRSG Stack 225 Ft. Elevation

Auxiliary Boiler Stack 50 Ft.

Tail Gas Incinerator Stack 310 Ft.

Flare 180 Ft.

Cooling Tower 30 Ft.

March 14, 2001

GTC Gasification Workshop for Environmental Regulators

19

The Wabash River IGCC Project

March 14, 2001

GTC Gasification Workshop for Environmental Regulators

20

The Wabash River IGCC Project

EMISSIONS COMPARISON

Emissions, lb/MWh

SO2 NO x CO PM-10 VOC

Unit 1 before Repower 38.2 9.3 0.64 0.85 0.03

IGCC 1.35 1.1 1.37 nil 0.02

March 14, 2001

GTC Gasification Workshop for Environmental Regulators

21

The Wabash River IGCC Project

SO x Control

IGCC is permitted for 0.25 lb SO2/MMBtu (split between GT and TGI stacks)

Sour syngas goes through a COS catalyst and then an amine based acid gasremoval stage.

Normally running at 0.10 lb SO2/MMBtu

As low as 0.03 lb SO2/MMBtu has been achieved

March 14, 2001

GTC Gasification Workshop for Environmental Regulators

22

The Wabash River IGCC Project

SO2 EMISSIONS

E x is tin g 1 9 5 3S ta tio n

N e w S o u rc eP e rfo rm a n c e

S ta n d a rd s

W a b a s h0

0 .5

1

1 .5

2

2 .5

3

3 .5

4

4 .5

LBS.

SO

2 / M

MB

tu o

f Coa

l Fee

d

E x is tin g 1 9 5 3S ta tio n

N e w S o u rc eP e rfo rm a n c e

S ta n d a rd s

W a b a s h

March 14, 2001

GTC Gasification Workshop for Environmental Regulators

23

The Wabash River IGCC Project

NO x Control

GE 7FA combustion turbine with steam injection (1992 purchase order)

Guaranteed for 25 ppm NO x

Has run as low as 18 ppm

March 14, 2001

GTC Gasification Workshop for Environmental Regulators

24

The Wabash River IGCC Project

�������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������

�������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������

�������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������

�������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������

�������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������

�������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������EXISTINGEXISTINGEXISTINGEXISTINGIGCCIGCCIGCCIGCC

00000.10.10.10.10.20.20.20.20.30.30.30.30.40.40.40.40.50.50.50.50.60.60.60.60.70.70.70.70.80.80.80.80.90.90.90.9

LBS.

NOX

/ M

MBt

u of

Coa

l Fee

dLB

S. N

OX /

MM

Btu

of C

oal F

eed

LBS.

NOX

/ M

MBt

u of

Coa

l Fee

dLB

S. N

OX /

MM

Btu

of C

oal F

eed

NOX EMISSIONSNOX EMISSIONSNOX EMISSIONSNOX EMISSIONS

March 14, 2001

GTC Gasification Workshop for Environmental Regulators

25

The Wabash River IGCC Project

PARTICULATE EMISSIONS

NONE MEASURABLE IN HRSG STACK

ZERO OPACITY

March 14, 2001

GTC Gasification Workshop for Environmental Regulators

26

The Wabash River IGCC Project

March 14, 2001

GTC Gasification Workshop for Environmental Regulators

27

The Wabash River IGCC Project

Steam TurbineCondenser

Gasification Island, ASU, CWT

Power Block

Old Power Plant

New WW Pond

Ash PondOutfall 002

Metering Point

March 14, 2001

GTC Gasification Workshop for Environmental Regulators

28

The Wabash River IGCC Project

WATER BALANCE – NEW USERSCooling Tower BD 0.144 mgd

Flushes & Purges 0.144

Unrecycled slurry water 0.101

Demineralizer Rinse 0.086

Steam Losses 0.072

Filter Backwash 0.065

Clarifier Sludge 0.058

Coal Pile Runoff 0.014

Boiler Blowdown 0.014

Domestic Sewage 0.022

March 14, 2001

GTC Gasification Workshop for Environmental Regulators

29

The Wabash River IGCC Project

WATER BALANCE – OUTFALL 002

Added Discharge from new project 0.72 mgd

Savings from PC Boiler Decommissioning (0.57)

-------

Net Increase to Outfall 002 0.15 mgd

( 2.8 % increase for overall station)

March 14, 2001

GTC Gasification Workshop for Environmental Regulators

30

The Wabash River IGCC Project

March 14, 2001

GTC Gasification Workshop for Environmental Regulators

31

The Wabash River IGCC Project

Slag

Sulfur

Black, glassy sandlike material

Inert, passes TCLP

Generally 3-10% Carbon

Marketed for asphalt, construction backfill, roofing shingle applications

Production is proportional to ash & flux content in feed

Produced as 99.99% pure elemental sulfur

Leaves plant in railcars

Sold to Broker for agricultural applications, over 40,000 tons to date

March 14, 2001

GTC Gasification Workshop for Environmental Regulators

32

The Wabash River IGCC Project

March 14, 2001

GTC Gasification Workshop for Environmental Regulators

33

The Wabash River IGCC Project

Annual output constrained by 100 day combustion turbine outage Reflects restructuring (no contract and no sales for three months)

SYNGAS FACILITY OPERATING STATISTICS

Time PeriodOn Coal(Hrs)

Coal/CokeProcessed(Tons)

On Spec. Gas(MMBtu)

SteamProduced(Mlbs)

ProductSyngasAvailability(%)

1998 5,279 561,495 8,844,902 2,190,393 70

1999 3,496 369,862 5,813,151 1,480,908 69

2000 386,630 6,430,446 1,082,254 75

Overall11/18/1995–12/31/2000

1,936,191

30,321,513

8,010,727 1998-2000

71%

4,191

19,260

March 14, 2001

GTC Gasification Workshop for Environmental Regulators

34

The Wabash River IGCC Project

Syngas Production

0

1

2

3

4

5

6

7

8

9

10

Tri

llio

n B

tu o

f S

yng

as P

rod

u

1996 1997 1998 1999 Adjusted 2000 Adjusted

March 14, 2001

GTC Gasification Workshop for Environmental Regulators

35

The Wabash River IGCC Project

Syngas Availability

0

10

20

30

40

50

60

70

80

Ava

ilab

ilit

y of

Syn

gas

Del

iver

1996 1997 1998 1999 2000

March 14, 2001

GTC Gasification Workshop for Environmental Regulators

36

The Wabash River IGCC Project

• Gasifier Second Stage at LGTI ~ 1990

• Wabash River 1997 - 20,000 tons from Midwest Refinery

• Wabash River 1999 - 10,000 tons from Gulf Coast Refinery

• 2000 & 2001 - Over 1,000,000 tons from another MidwestRefinery

E-GAS PETCOKE CAPABILTY DEVELOPMENTPROGRAM

March 14, 2001

GTC Gasification Workshop for Environmental Regulators

37

The Wabash River IGCC Project

Petroleum Coke Test Results - 1997 & 1999

• Demonstrated plant efficiency, 40.2% (HHV)

• Produced 100% rated output at normal environmental standards

• 99% Carbon Conversion

• No slag tapping problems

• Nickel (80%) and Vanadium (99%) were captured in slag, non-leaching

• No negative impact on equipment

• Refractory wear rates similar to coal operations

March 14, 2001

GTC Gasification Workshop for Environmental Regulators

38

The Wabash River IGCC Project

P E T R O L E U M C O K EA N A L Y S I S T Y P I C A LC O A L 1 9 9 7 1 9 9 9 2 0 0 0

M o istu re , % 1 5 .2 7 .0 1 2 .0 7 .8A sh , % 1 2 .0 0 .3 0 .4 0 .6V o la t i le , % 3 2 .8 1 2 .4 1 1 .2 1 0 .5F ix e d C a rb o n , % 3 9 .9 8 0 .4 7 7 .7 8 1 .1S u lfu r , % 1 .9 5 .2 5 .6 5 .7

M e ta ls in F u e l :N i, p p m , d ry b a s is T ra c e 2 1 0 2 9 0 3 7 0V , p p m , d ry b a s is T ra c e 4 3 0 1 5 0 0 8 9 0

H e a t in g V a lu e , a s re c ’d ,B tu /lb

1 0 ,5 3 6 1 4 ,2 8 2 1 3 ,3 8 0 1 4 ,0 2 6

FEEDSTOCK SPECIFICATIONS

March 14, 2001

GTC Gasification Workshop for Environmental Regulators

39

The Wabash River IGCC Project

PRODUCT SYNGAS ANALYSIS

TypicalCoal

PetroleumCoke

N2, % 1.9 1.9Ar, % 0.6 0.6CO2, % 15.8 15.4CO, % 45.3 48.6H2 % 34.4 33.2CH4, % 1.9 0.5Total S, ppmv 68 69HHV, Btu/Scf 277 268

March 14, 2001

GTC Gasification Workshop for Environmental Regulators

40

The Wabash River IGCC Project

Performance Variable Typical Coal

Petroleum CokeTest #1

Petroleum CokeTest #2

SO2 Emission, lbs/MMBtu <0.1 <0.1 <0.1

Sulfur Removal Eff., % >99 >99 >99

Carbon in Slag, % <5 <10 <5

Carbon Conversion, % >99 >99 >99

Cold Gas Efficiency, % 71 - 76 71 - 73 72 - 74

Projected Heat Rate, HHV,Btu/kWh

8910 8790 8600 (est.)

Table 3: Petroleum Coke Performance Summary