THE ULTIMATE SOLUTION FOR ALL (EXISTING) … › pdf › RISWAT.pdfRISWAT® multi-cable transits are...

Transcript of THE ULTIMATE SOLUTION FOR ALL (EXISTING) … › pdf › RISWAT.pdfRISWAT® multi-cable transits are...

THE ULTIMATE SOLUTION FOR ALL (EXISTING) WATER AND GAS TIGHT

MULTI-CABLE TRANSITS

Websites: http://www.actifoam.com, www.beele.com, www.csdplugs.com, www.firsto.com,www.nofirno.com, www.rise-systems.com, www.riswat.com and www.slipsil.com

Copyright :BEELEEngineeringBV/CSDInternationalBV,Aalten,theNetherlands. Proprietaryrightsonalldrawingsandtechnicaldatareleasedinthisbrochure. © 1997-2007

Edition :May2007

Note :Nopartofthispublicationmaybereproducedwithoutexplicitwrittenapprovalof BEELEEngineeringBV.

Research & Development :BEELEEngineeringBV,Aalten,theNetherlands.

Note :Themanufacturerreservestherighttomakedimensionalanddesignmodifications withoutpriornotification.

® :ACTIFIRE, ACTIFOAM, AQUASTOP, BEEBLOCK, BEELE, BEESEAL, CONDUCTON, CRUSHER, CSD, CSD THE SIMPLE SEAL SYSTEM, DRIFIL, DYNATITE, FIRSTO, FIRUB/NOHAL, FITEFIRE, FIWA, LEAXEAL, LUMIREFLEC, NOFIRNO, RAPID TRANSIT SYSTEM, RISE,RISWAT, S, SLIPSIL, ULEPSI andYFESTOS are registeredtrademarksofBEELEEngineeringBV.

brochure code : riswat/hb/en/con

BEELE ENGINEERING BVCSD INTERNATIONAL BV

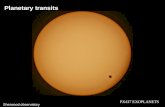

Above an impression of the research and develop-ment centre with a training and schooling insti-tute for passive fire prevention products and sys-tems and for the improvement of evacuation sign-posting systems in buildings and on board ships.Thecentreconsistsofapresentation theatreseatingupto45persons,andamock-upcoveringabout500squaremetresinwhichvariousevacuationsignpostingsystemsareinstalledtoenabletheireffectivenesstobe

determinedinthedark.Thebehaviourofescapingpersonsinsidethetestfacilityare recorded fromaseparate technicalarea(withanassociatedshowroom)bymeansofinfra-redcamerasandanaudio-videosystem.Inadditionthecentrecomprisesthreelaboratorieswithatotalsurfaceareaofabout300squaremetresinwhich,respectively,large-scalefiretests,mechanicaltests,andlightemissioninvestigationsareperformed.

1

The R&D department of BEELE Engineering is constantly working in the field of rubber and systems tech-niques to optimize the existing systems and to develop new concepts for cable and pipe conduits on board of vessels and offshore installations. Although installation of the CSD sealing systems is in fact an easy matter, a full training programme can be given in-house by our engineers. Because the advantages and possibilities of passive fire prevention and evacuation signposting can most effectively be discovered in an environment that matches the practical situation as closely as possible, work is currently proceeding on the construction of a unique research and development centre. As far is known, this R&D centre is the only institute world-wide where visitors can experience for themselves all the aspects of fire prevention and evacuation signposting systems.

BEELEEngineeringandCSDInternationalhavebeenworkinginthefieldofwaterandgastightandfireproofsealingofconduitsforpipesandcablesformorethan30years.Inthefieldofpassivefireprevention,wehaveinvestedsubstantialamountsofmoneyinthedevelopmentofsystemswhicharecapablewithstandingfiresforextendedperiodsoftime.Passivefirepreventionisaverycomplicatedmatterduetothefactthatcableandpipepenetra-tionshavetobedesignedtotheactualcircumstan-cesatsiteandnotforalaboratorytest.Incaseofacatastrophepenetrationsaresubjectnotonlytoflameerosionandveryhightemperatures,butalso

tomechanicalloadsduetocollapsingcablewaysandpossiblyajetoffire-fightingwater.Thismeansthattheperformanceinactualsituationscandifferdramaticallyfromthatinaregularfiretest.Infact,the systems could only be applied as tested toguaranteetherequiredfiresafety.And this means discussions and limitations! We have ensured that our systems will functionunderallcircumstances,andtheclassificationsoci-etieshaveawardedussignedandstampedinstalla-tiondrawingsofoursealingsystems.Approvedforsteelandaluminiumpartitions.Guaranteedsafetyinyourinstallationwillbetheresult.

RISWAT® MULTI-CABLE TRANSITS:THE RAPID® SEALING SYSTEM

RISWAT® cable conduits offer the following advantages:HIGH LEVELS OF

GAS AND WATER TIGHTNESS

HIGHLY ELASTIC COMPOUND LAYER READILY ABSORBING SETTLEMENTS AND MOVEMENTS OF THE CABLE/PIPE BUNCH

DRIFIL® SEALANT:SUPER-ADHESIVE AND FAST-DRYING

THE PERFECT SOLUTION FOR SUBSEQUENT SEALING OF LEAKING RUN-INS

NO PRE-ENGINEERING REQUIRED

NO CONDUIT FRAMES NEEDED

EXTREMELY LIMITED NUMBER OF COMPONENT PARTS

VERY COMPACT ASSEMBLY

SUITABLE FOR CABLES AND PLASTIC AND METALLIC PIPES

SIMPLE INSTALLATION

CAPABLE OF WITHSTANDING MECHANICAL LOADING

RISWAT® multi-cable penetrations areanalternativeforthecastingcompoundsand block systems in watertight wallsandfloors.Veryeasytoinstall.Theverylimitedamountofdifferentpartsmakesthissystemeasytohandleonsite.UseismadeofRISWAT®thermoplasticinsertsleeves,splitlenghtwise(placedaroundthecables)andRISWAT®fillersleeves.Thethermoplasticinsertsleevesactasaspacertoseparatethecablesandthefillersleevesareusedtocreateacarrierforthesealant.TheRISWAT®sleevesaresupplied in lengthsof60,80,110,160and210mm.Theyarealsoavailableinlengthsof500and1000mm.Theycanbeeasilycuttosize.Thesleevesshouldfitsnuglyintheconduitopening.AlayerofDRIFIL®sealantabout2cm thick isappliedontheresultantcarrier.Temperaturerange-40°Cto+110°C.

TheRISWAT®sealingsystemallowscablestobeductedthroughconduitopeningsinabent,curvedorobliquewaywithoutanyadverseimpactonsealingperformance.

2

RISWAT®multi-cabletransitsareparticularlysuitableforuseinexistinginstallations.ThegoodadhesionandlargeflexibilityofthelayerofDRIFIL®sealantappliedyieldsaperfectseal.Theverysmallnumberofdifferentcomponentpartsmakesthissystemsimpletouseontheconstructionsite.ItincorporatesRISWATsleeves(whicharefittedaroundthecables)andfillersleeves.Thesearemadefromaspeciallydevelopedextrudablethermoplasticwithsufficientstiffnesstoenableeaseofinsertion.AlayerofDRIFIL®sealantabout2cmthickisthenappliedontheresultantcarrier.ItisadvisabletoinstalltheDRIFIL®sealantatbothsidesoftheconduitopening.

TheRISWAT®systemcanalsobeusedfor(existing)pipepenetrations.InsuchcasesCSD®sealingplugscannotgenerallybeused,becausetheyrequiretheductedpipetobelocatedcentrallyintheconduit.ForRISWAT®pipepenetrations,theentirespacearoundthepipeintheconduitisfilledupwithRISWATfillersleeveswithalength40mmshorterthanthedepthoftheconduitopening.Thesecanbedeliverednon-splitandaremadefromaspeciallydevelopedextrudablethermoplasticwithanoptimizedstiffness.AlayerofDRIFIL®sealantabout2cmthickisthenappliedontheresultantcarrier.ItisadvisabletoinstalltheDRIFIL®sealantatbothsidesoftheconduitopening.

Inthesameway,theRISWAT®systemcanbe used for sealing existing penetrationscarryingmultiplecablesandmetallicandplasticpipes.

3

RISWAT® MULTI-CABLE TRANSITS:THE RAPID® SEALING SYSTEM

4

RISWAT® MULTI-CABLE TRANSITS:THE RAPID® SEALING SYSTEM

RISWAT® multi-cable transits: non-toxic, halogen free components

only two different components for a RISWAT® multi-cable transit: sleeves and sealant

dimensions in mm* filler sleeves are supplied non-split for ease of filling

RISWAT®sleevesaremadefromaspeciallydevel-opedextrudablethermoplasticwhichofferssuffi-cientstiffnesstoenableeaseofinsertion.RISWAT®sleeveshaveaclearlyrecognizablebluecolourtoensure that they are easily distinguishable fromtheRISE®sleeveswhichareusedforfire-resistantconduits.RISWAT®sleevesaresuppliedinlengthsof60,80,110,160and210mm.Theyarealsoavailableinlengthsof500and1000mm.Theycanbecuttolengthasrequiredontheconstructionsite.RISWAT®sleevesaresplitlengthwisetofacilitatefit-tingthemaroundcableswhicharealreadyinplace.Thewallthicknessofsleevesissochosentoen-suresufficientseparationofthecablestofacilitateapplicationoftheDRIFIL®compound.Fillersleevestype18/12and27/19arenon-splitforeaseoffillingandtocreateaverytightfit.Thisim-provesthefinaltightnessofthesealingsystem.

sleeve cable sleeve wall type diameter lengths thickness (standard)

12/6 5 - 7 60-80-110-160-210 3 14/8 7 - 9 60-80-110-160-210 3 16/10 9 - 11 60-80-110-160-210 3 18/12* 11 - 13 60-80-110-160-210 3 20/14 13 - 15 60-80-110-160-210 3 22/16 15 - 17 60-80-110-160-210 3 27/19* 17 - 21 60-80-110-160-210 4 31/23 21 - 25 60-80-110-160-210 4 35/27 25 - 29 60-80-110-160-210 4 39/31 29 - 33 60-80-110-160-210 4 46/36 33 - 39 60-80-110-160-210 5 52/42 39 - 45 60-80-110-160-210 5 58/48 45 - 51 60-80-110-160-210 5 64/54 51 - 57 60-80-110-160-210 5 70/60 57 - 63 60-80-110-160-210 5

5

PRODUCT INFORMATION01) colour dark blue

02) specific gravity 1.40 ± 0.03 g/cm3

03) curing of top layer 60 minutes

04) service temperature -50 °C up to +180 °C

05) tensile strength 0.95 MPa

06) elongation at break 375%

07) hardness 35 Shore A

08) elastic defromation approx. 75%

09) resilience 95%

10) good adhesion to glass, tiles, concrete, wood, metals and a wide range of plastics

11) supplied in cartridges, containing 310 ml

12) storage to be stored cool and dry min/max temperature = +5/+30° C

13) storage life approx. 12 months

DRIFIL®isapaste-likecompoundwhichissimpletouse.Afterapplyingthecompoundwithagun,itcanbesmoothedbymeansofawetclothandasmallspatula.Becausethecompoundadheresverytightlytheclothandspatulashouldbewettedwithwaterbeforeusetopreventcompoundfromstickingtothem.

DRIFIL® isawater-repellentsealantbasedonasingle-componentsiliconematerial.IndevelopingDRIFIL®sealant,highprioritywasfocusedonitspowerofadhesiontosubsurfacessuchassteel,stainlesssteelandaluminium,andtoplasticcablesheathings.Inaddition,specialattentionwasgiventothepermanentflexibilityofthesealantinordertopermitmovementsofthepenetrationafterthesealanthasset.Thepurposeofthisistoensurethatthesealremainsintactinthelongertermeveninspiteofpossiblemechanicalloading.DRIFIL® is water-repellent High bonding strength UV and Ozone resistantNon-ageingDRIFIL®sealanthasaveryshortsettingtime.Thetoplayerisrapidlytack-free.LRS certificate APE 0009060/1 (1.5 bar)

RISWAT® MULTI-CABLE TRANSITS:THE RAPID® SEALING SYSTEM

optimum combination of viscosity, flow and bonding capacity of DRIFIL ® sealant

only two different components for a RISWAT® multi-cable transit: sleeves and sealant

6

no special conduit frames needed for a RISWAT ® multi-cable penetration

no pre-engineering needed for a RISE ® multi-cable penetration

whatever conduit sleeve you have around will do for a RISWAT ® multi-cable penetration

Sincethecablescanbeductedinran-domorderthroughtheconduit frameorsleeveitisnotnecessarytocreatelay-outsfortheinstallerstobesurethatthecablesareductedattherightspotintheconduit.Wehaveasoftwarepro-gramavailableforcalculatingthesizeoftheconduitopeningandtheamountofinsertsleevesandsealantforeachRISWAT®penetration.Allpenetrationscanbeputinadatabasetocalculatethetotalamountforaproject.Coulditbeeasier?

no time-consuming lay-outs for a RISWAT ® multi-cable penetration

RISWAT® MULTI-CABLE TRANSITS:THE RAPID® SEALING SYSTEM

7

space and weight saving properties of RISWAT ® multi-cable penetrations

time-saving installation ofRISWAT ® multi-cable penetrations

substantial overall time-savings withRISWAT ® multi-cable penetrations

no bolts, no nuts, no precise fitting workwith RISWAT ® cable penetrations

RISWAT® MULTI-CABLE TRANSITS:THE RAPID® SEALING SYSTEM

It’ssosimple.Justplacethelength-wisesplit insertsleevesaroundthecables,fillupanysparespacewithemptysleevesandsealitoffonbothsides.Noworkforspecialists.Whatcouldbeeasier!Calculate the right way, save timeandmoney.Ask for the installationvideoshow-ingthatatransitmeasuring450x130mmwith63cables issealedwithin40minutes.Substantial cost-savings.

same amount of cables in less than half the conduit size with RISWAT®

���

���

���

���

Prefabricated sealing systems aresealedwithsolid rubberparts.Dueto the block sizes a substantialseparationofthecablesmightoccur.TotallydifferentwithRISWAT®.Theconduitopeningcanbesubstantiallyreduced when compared to blocksystems,due to thehighfillcapac-ityofRISWAT®.Anysparespaceintheconduitisfilledwithhollowfillersleeves enabling ducting of morecablesinalaterstageaneasymatter.Nototaldisassemblingneeded.

8

1) The cables can be ducted through the conduit opening in random order. It is most important that they are not pulled too tight in order not to hamper their separation at a later stage.

RISWAT® MULTI-CABLE TRANSITS:THE RAPID® SEALING SYSTEM

2) After the cables have been ducted, a RISWAT® insert sleeve is applied around each cable. The insert sleeves are split length-wise and can therefore be fitted around the cables in front of the conduit.

9

3) Apply insert sleeves which match the OD of the ducted cable.The insert sleeve(s)can be pushed into the conduit opening.

4) The remaining free space in the conduit is filled with RISWAT® filler sleeves type 27/19 and 18/12.

Before applying the sealant it is advisable to check the status of the filling with insert and filler sleeves.

RISWAT® MULTI-CABLE TRANSITS:THE RAPID® SEALING SYSTEM

10

6) A 20 mm thick layer of DRIFIL® sealant is applied at each side of the conduit. Clean and dry the conduit opening and the pipe thoroughly and remove any dirt, rust or oil residues before applying the sealant.

Look for our professional sealant dispensers. Hand fatigue is prevented and optimum flow of the sealant is obtained.

RISWAT® MULTI-CABLE TRANSITS:THE RAPID® SEALING SYSTEM

5) Push the sleeves into the conduit in such a way as to leave about 20 mm free space at the front. The whole set of insert and filler sleeves should tightly fit into the conduit to offer sufficient mechanical stability.

11

8) To smooth the surface of the DRIFIL® sealant layer, a cloth is sprayed with water. This prevents the sealant from sticking to the cloth.Note: do not use soapwater!

RISWAT® MULTI-CABLE TRANSITS:THE RAPID® SEALING SYSTEM

7) The conduit should be overfilled with DRIFIL® sealant, because some sealant will be pushed between and into the empty filler sleeves during further finishing.This will contribute to obtain higher tightness ratings.

12

10) The surface can further be smoothed by hand. Just wet the hand thoroughly with soap and water. No dirty hands when working with DRIFIL® sealant. People with sensitive skin should use gloves when wor-king with DRIFIL® sealant.

RISWAT® MULTI-CABLE TRANSITS:THE RAPID® SEALING SYSTEM

9) The cloth is then used to press down the sealant layer. The DRIFIL® sealant should be carefully pressed down and smoothed in between the cables. This is essential to obtain an effective gas- and water tightness.

13

12) For optimum gas- and water tightness it is advisable to apply at both sides of the penetration a 20 mm thick layer of the DRIFIL® sealant.Note: the cables have to be fixed directly after installation.

RISWAT® MULTI-CABLE TRANSITS:THE RAPID® SEALING SYSTEM

11) After smoothing is finished a last check should be taken if sufficient sealant is applied in between the cables especially at penetrations with larger amounts of cables.

14

13) Vertical transits are aesy to install as well.The insert sleeves cling to the ducted cables.To prevent the filler sleeves from falling out of larger conduit openings, they should be bundled together to form a compact bundle.

14) A 20 mm thick layer of DRIFIL® sealant is applied at each side of the conduit. Clean and dry the conduit opening and the pipe thoroughly and remove any dirt, rust or oil residues before applying the sealant.

RISWAT® MULTI-CABLE TRANSITS:THE RAPID® SEALING SYSTEM

15

15) For optimized me-chanical stability and to obtain higher pres-sure ratings instead of DRIFIL® sealant, FIWA® sealant can be used. The FIWA® sealant cu-res to a harder rubber mass then DRIFIL®.

RISWAT® MULTI-CABLE TRANSITS:THE RAPID® SEALING SYSTEM

PRODUCT INFORMATION01) colour dark grey

02) specific gravity 1.30 ± 0.03 g/cm3

03) curing of top layer 1 - 2 hours

04) service temperature -50 °C up to +160 °C

05) tensile strength 1.15 MPa

06) elongation at break 160%

07) hardness 45 Shore A

08) elastic deformatiom approx. 25%

09) fire class IMO Res. A.653(16)

10) ageing up to 50 years service life

11) supplied in cartridges, containing 310 ml

12) storage to be stored cool and dry min/max temperature = +5/+30° C

13) storage life approx. 12 months

FIWA is absolutely HALOGEN FREE (tested according to Naval Engineering Standard NES 713: Issue 3).

Furthermore FIWA has a low smoke in-dex (NES 711: Issue 2: 1981) and a high oxygen index (ISO 4589-2: 1996),

and low flame spread characteristics accor-ding to IMO Resolu-tion A.653(16).

optimum combination of viscosity, flow and bonding capacity of FIWA ® sealant

16

Adding extra cables is an easy job. Cut away the sealant layer at both sides of the penetration with a knife or a hollow punch in a tapering shape as shown above. This creates a good foundation for the sealant mass to be applied later.

Pull the cable through one of the empty fillersleeves with an inner diameter more or less corresponding to the outer diameter of the cable.Refill the opening in the sealant layer at both sides of the penetration with sufficient DRIFIL® sealant.

RISWAT® MULTI-CABLE TRANSITS:THE RAPID® SEALING SYSTEM

17

If the empty filler sleeves are not fitting to the size of the cable to be ducted, a number of these insert sleeves must be removed from the penetration.Install a fitting insert sleeve (with some filler sleeves if necessary) in the open space in the penetration.

Pull the cable through the fitting insert sleeve that has now been installed. Refill the openings cut in the sealant layer at both sides of the penetration with sufficient DRIFIL® sealant. The DRIFIL® sealant is pressed down firmly and smoothed with a damped cloth.

RISWAT® MULTI-CABLE TRANSITS:THE RAPID® SEALING SYSTEM

Easington Gas Storage Plant/Engeland

130.000 RISWAT® sleeves in 180 concrete pits

RISWAT® MULTI-CABLE TRANSITS:THE RAPID® SEALING SYSTEM

The RISWAT® conduit and sealing system is extremely flexible in its composition. The system is used in particular for the purpose of rendering conduits in existing installa-tions gas and watertight subsequent to completion (retrofitting).Cables may have been ducted through the conduit in random sequence. The excellent adhesive properties of the sealing compound used makes the RISWAT® system suitable for cables and metal and plastic pipes. Assembly of the component parts needed is an extremely simple job. A very limited number of different components are needed to seal the conduit. Only seven different types of sleeves are used.To finish the conduit, a layer of DRIFIL® or FIWA® sealant is applied at one or both sides. DRIFIL® sealant allows movements or settlements of the cables and/or pipes, but at the same time the RISWAT ® sleeves restrict the amount of allowable movement in such a way that the 25% limit of elasticity is not exceeded.

Thisautumnsawtheofficialopen-ingoftheworld’slargestsubseapipeline,whichhas thecapacityto transport approximately 20%of the UK’s gas requirements.Thefirstvolumeofgaswaspipedashoreon1October2006atEas-ington(onthenorth-eastcoastofEngland),andinduecoursesup-pliesthroughthepipelinewillto-tal20billioncubicmetresayear.Thegasisproducedatadepthof900metres intheOrmenLangefield, which lies 120 kilometresto the north-west offshore theNorwegian coast; Ormen LangeranksasthelargestgasfieldontheNorwegiancontinentalshelf.

Anew large-scalegas receivingstation was constructed at Eas-ingtontoprovidethelandfallsiteforthegassupplied.TheRISWATsystem by Beele Engineeringwas chosen to provide gas andwatertightsealsforallthecableconduitsinthegasreceivingsta-tion. This represents one of thebiggest RISWAT orders in his-tory:altogetheratotalof130,000sleeves were supplied within afortnight.KeyfactorsthatdecidedthechoiceoftheRISWATsystemwere the simplicity of construct-ingtheseal,theshortinstallationtime,andthecomparativelysmallspacerequiredinordertoductagivenamountofcabling.

FIWA® sealant used for ultimate mechanical properties

20

ease of calculation withRISE ®/RISWAT ® cable and pipe penetrations

RISWAT® MULTI-CABLE TRANSITS:THE RAPID® SEALING SYSTEM

we are there with full support forRISE ®/RISWAT ® cable and pipe penetrations

Aftertheentryofthedimensionsoftheconduitopeningandtheamountandouterdiametersoftheductedcablesorpipes,thesoftwarecalculatestheamountofRISE®/RISWAT®sleevesandDRIFIL®/FIWA®sealant.Adrawingappearsonthescreenshowingalsotheremainingfreespaceintheconduitopening.Allcalculatedtransitscanbestoredinadatabase.Printsorder/calculationforms.

Canbedownloadedfromourwebsitehttp://www.beele.com.

CallusforafreeCDand/oryourregistrationnumber!

Featureforautomaticupdateviaourwebsiteeverytimetheprogramisstarted.

21

22

ARTIST IMPRESSION OF THE FIRST PHASE OF THE NEW FACTORY NEXT TO OUR R&D CENTRE

ENGINEERING

YOUR RELIABLE PARTNERS

1) machines specially developed for compounding and processing of rubbers under controlled conditions to obtain optimum quality2) machines specially developed for compounding and manufacturing of all types of sealants under controlled processing3) moisture treatment installation and processing equipment for manufacturing of electrically conductive sealants and rubbers 4) a complete line of injection moulding presses ranging from 40 tons up to 400 tons for manufacturing sealing plugs and other rubber components5) a complete line of compression moulding presses up to 300 tons for manufacturing larger type sealing plugs and ULEPSI rubber plates6) processing installation for after-curing of rubber products to obtain the required compression set (long term behaviour) 7) extruder line including cooling system and cutting and slitting installation for manufacturing insert and filler sleeves for the RISWAT system8) fully automatic extruder lines with a length of 20 meters, including cooling system and automatic cutting, slitting and sorting installation for manufacturing rubber insert and filler sleeves and rubber strips of the RISE system9) extruder line for manufacturing luminescent profiles and hoses10) line of injection moulding machines ranging from 50 up to 200 tons for manufacturing plates of the ULEPSI tank supports and luminescent YFESTOS floor coverings11) completely equipped die-making shop for the in-house production of all tooling for rubber and plastics manufacturing12) modern laser equipment for engraving the type codes in the dyes for rubber manufacturing and for marking products with bar and 2D-matrix codes13) mixing and airless spraying facilities for the NOFIRNO boards

Together with highly advanced systems and technologies we offer highest quality products.

Websites: http://www.actifoam.com, www.beele.com, www.csdplugs.com, www.firsto.com,www.nofirno.com, www.rise-systems.com, www.riswat.com and www.slipsil.com

ASK FOR THE SEPARATE BROCHURES ON OUR PRODUCT RANGES:

* RISE® MULTI-CABLE TRANSIT SYSTEM* RISE® SEALING SYSTEM FOR SINGLE AND MULTI-PENETRATIONS FOR PLASTIC AND METALLIC PIPES* RISWAT® GAS AND WATERTIGHT CABLE AND PIPE DUCTS* CSD® SEALING PLUGS FOR METALLIC AND PLASTIC PIPE ENTRIES* SLIPSIL® SEALING PLUGS FOR PIPE ENTRIES* DYNATITE® DYNAMIC HIGH PRESSURE SEALS * BEESEAL® MULTI-PIPE AND CABLE PENETRATIONS* CSD®-SQ MULTI-CABLE TRANSITS* LEAXEAL® HIGH PRESSURE GRIP SEALS* ACTIFOAM® TEMPORARY SEALS AND CAVITY SEALS* FIRSTO® FIRESTOPS FOR CABLE TRAY PENETRATIONS* NOFIRN0® CAVITY SEALS, COATINGS AND SEALANTS* ULEPSI® TANK SUPPORTS FOR BITUMEN TANKERS

CONDUIT SEALING DEVICES OF AN AMAZING SIMPLICITY WITH AN OUTSTANDING PERFORMANCE

distributed by:

BEELE Engineering and CSD International have been involved with fire, water and gas tight sealing for more than 30 years. We have developed and tested products proven to provide the utmost in sealing protection around the world. To receive our complete civil construction and/or marine products catalogues, please contact your distributor or local representative.

BEELE Engineering bv - CSD International bvBeunkdijk 11 - 7122 NZ AALTEN - THE NETHERLANDS

Tel. +31 543 461629 - Fax +31 543 461786 - E-mail: [email protected]: http://www.actifoam.com, www.beele.com, www.csdplugs.com, www.firsto.com,

www.rise-systems.com, www.riswat.com and www.slipsil.com

���������������

®