The Story of Cannon Power Group’s Windy Point Windy Flats...

Transcript of The Story of Cannon Power Group’s Windy Point Windy Flats...

The Story of Cannon Power Group’s Windy Point /Windy Flats Project

SUNRISEPROSPECTINGCULTIVATING THE LANDPLANTINGTHE HARVESTTENDING THE LANDSUNSET

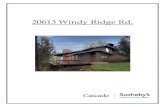

Windy Point at dawn.

SUNRISEThe two-lane highway that winds along the northern bank of the Columbia River outside

of Goldendale, Washington is a living documentary of rural America. A modern day

patchwork of the family farms and ranches that have forged the country’s economic and

cultural identity since the seed of America was first planted. But upon closer observation,

stretching for miles of ridgeline along the Columbia River Gorge, a different kind of farm

can be seen. Like its neighbors, this farm plays a key role in providing the country with the

necessities of life and supporting the local economy with jobs. But this farm is different.

Instead of harvesting wheat or wool, this farm harvests the wind.

Spanning 26 miles and offering a capacity of 500 megawatts, Cannon Power Group’s

Windy Point/Windy Flats development represents one of the largest wind energy projects

in the United States. While the promise of the clean, renewable energy this type of wind

farm provides contributes directly to cleaner air, reducing harmful emissions from energy

production and reversing the effects of climate change, the environment is hardly the

only beneficiary. From infusing jobs, tax revenue and improved infrastructure into local

economies, to helping provide energy security and new economic opportunities for the

country as a whole, it is clear Windy Point/Windy Flats cultivates much more than wind.

The driving force behind this vision of The New American Farm is San Diego-based

Cannon Power Group. As an independent leader and pioneer in the renewable energy

industry since 1979, the team at Cannon has cultivated success in the United States

and around the globe. Cannon Power Group is dedicated to developing, constructing,

operating, and maintaining utility-scale wind and solar energy projects to generate

plentiful, affordable, and environmentally responsible power. Driven by a knowledgeable,

agile team of professionals, Cannon’s dedication to the renewable energy industry has

yielded more than 30 major projects with a capacity of 4,150 megawatts around the world.

THE NEW AMERICAN FARM

PROSPECTINGIn all types of farming, finding the right soil makes all the difference. Wind farming is

no different. While the ridgeline along the Columbia River Gorge that would ultimately

become home to the Windy Point/Windy Flats project has long been recognized as

potentially fertile ground for wind energy, Cannon Power Group was one of the first to truly

realize that potential.

Interestingly, when developing a wind farm, windiness isn’t enough. In fact windiness is

only one of a group of factors that determine the potential and yield of a site. These factors

include the availability of transmission lines, accessibility to markets with demand for

renewable energy, ability to obtain the necessary permits, willing landowners and the

acreage needed to make it all work. Of course without the wind, nothing else matters.

THE NEW AMERICAN FARM

EVALUATION Evaluating a potential wind project site begins with measuring the

inherent natural factors of the area. First, the wind. In order to determine

the ultimate megawatt hour potential of the Windy Point/Windy Flats

site, Cannon Power Group first accumulated and studied wind data taken

over a 20-year period from more than 100 on-site wind measurement towers

as well as from a new, state-of-the-art Sonic Detection and Ranging

(SODAR) unit – the first of its kind in the United States.

Cannon Power Group’s Windy Point/Windy Flats project spans over 26 miles from end to end. Each square on the map represents one square mile.

Using sonar technology, the SODAR unit is capable of measuring

wind strengths and variations at heights up to 200 meters. From these

measurements, Cannon determined that the wind characteristics

found along this stretch of the Columbia River Gorge were well-suited

to support a viable wind farm project. Once the natural factors were

proven viable, ensuring the ability to deliver the cultivated wind energy

to consumers became the focus.

THE NEW AMERICAN FARM

SURVEYING THE LAND The next question was whether there was enough space for the number of turbines required to yield the energy necessary to make the project worthwhile. While the

actual footprint of a wind turbine tower is only 16 feet in diameter – a fact that makes wind farming uniquely complimentary to other types of farming and ranching

– the turbines themselves need to be spaced a substantial distance apart to avoid wind interference. In fact, each turbine needed roughly one-half acre to work at

maximum capacity. In the case of Windy Point/Windy Flats, the vast open land offered by the surrounding farmland, coupled with optimal wind conditions, provides

a near ideal site for a wind farm. Ridgeline view of the bluffs which are home to the Windy Flats project.

Mike Canon, Klickitat County Economic Development Director

and Curt Dreyer, Klickitat County Planning Director

“[In Klickitat County] wind development is regarded as just another form of farming in the county. It’s harvesting a wind resource, just as you would harvest wheat or corn. And instead of replacing any type of current or existing agricultural activities, it works in addition to what’s going on already.

As well, the tax revenue benefits the local districts, the local hospitals, schools, and county goverment. It’s a significant impact in regard to what we had before, which was very little.”

- Curt Dreyer Klickitat County Planning Director

WORKING WITH THE COMMUNITY With the natural potential and means of delivery in place, the final aspects of determining the

viability of a wind project are found in the ability to obtain the multitude of necessary permits

and, ultimately, to actually build it. For Windy Point/Windy Flats, the list of required permits

was a long one including land use permits, Federal Aviation Administration lighting permits,

and more. Additionally, the success of any wind farm depends on the amenability of local

landowners to the idea of the long-term leases involved – usually 20 to 40 years in length. At

Windy Point/Windy Flats, initial meetings and agreements with key landowners were followed

by a Letter of Intent laying out the basic terms of what the project would mean to them from a

financial and land usage standpoint.

County Commissioners Ray Thayer, Rex Johnston and Dave Sauter in front of the Klickitat County Court House

“Lucky” Hoffman and Kurt Humphrey discuss the construction at Windy Point.

THE NEW AMERICAN FARM

CULTIVATING THE LANDWhether the plan is to harvest corn or harvest wind the same is true: You can’t just put a

seed in the ground and expect it to grow. The land first has to be tilled, nourished and

prepared. At Windy Point/Windy Flats, the process of preparing the land played out over

many steps.

At the beginning, cultivating the site meant a procession of continuing and increasingly

detailed wind, transmission and environmental studies required for both planning and

permitting purposes. These studies were quickly followed by the conversion of the original

landowner Letters of Intent into finalized leases and beginning the exhaustive process

of applying for the over 20 different permits needed to bring Windy Point/Windy Flats to

fruition.

Preparing the site isn’t just about paperwork, however. The team of highly experienced

engineers and designers at Cannon Power Group concurrently set to work unraveling

the complex process of project layout and engineering, negotiating with turbine

manufacturers and lining up off-takers for the clean, renewable energy that would

ultimately be produced by Windy Point/Windy Flats.

Once the land was tilled and the plans were set, the final steps before the first seed could

be planted were creating the financing package, signing contracts, and finalizing project

details.

THE NEW AMERICAN FARM

KPUD Commissioners Ray Mosbrucker (left) and Dan Gunkel (right)

PREPARATION Even after the fertile potential of the site at Windy Point/Windy Flats was established, the next 12 to 18 months found

the Cannon Power Group team conducting a variety of in-depth studies and research on the area.

Along with the wind study, Cannon Power Group carried out a series of comprehensive interconnection and

transmission studies. Performed by the local utilities in possession of the transmission lines, these studies

determined if the existing lines had enough capacity to carry the electricity produced by Windy Point/Windy

Flats and how the energy produced by the turbines would be transported to the lines. These studies ultimately

revealed what improvements and additions needed to be made – such as upgrades to the transmission lines and

construction of new substations.

Studies were conducted by the local utilities to determine if the existing lines had the capacity to carry the electricity produced by the wind turbines.

“I certainly believe that there is a local pride in moving forward and being a provider of clean, renewable energy for west coast entities, whether it be in Seattleor Los Angeles.

As long as the turbines are spinning, it generates revenue for all those in the chain that we’ve established here.”

- Dan Gunkel

Klickitat County PUD Commissioner and Local Farmer

THE NEW AMERICAN FARM

RESEARCHAs the various studies were carried out, the leases signed and the permits

gathered, the Cannon Power Group designers and engineers began laying out

the entire project. An incredibly complex process, creating The New American

Farm at Windy Point/Windy Flats required bringing together a seemingly infinite

number of variables – including selecting the right turbines, the exact number

and spacing of those turbines to create the greatest efficiencies, and selecting the

ideal location for each one.

Ron Nierenberg determines turbine density for the Windy Point/Windy Flats Project.

THE NEW AMERICAN FARMAlthough the diameter of the base of a turbine measures only 16 feet, the blades measure 300 feet wide. Each turbine must be placed a minimum of 600 feet apart so as not to interfere with the wind of another turbine.

THE NEW AMERICAN FARM This part of the Windy Point project in the Juniper Point area has the highest elevations – and the highest winds – in the Pacific Northwest.

PLANTINGFinding the ideal, fertile land. Preparing the soil. The process is the same whether it is

traditional farming or The New American Farm. Every task up to this point is preparation

for the next step: Planting. At Windy Point/Windy Flats, the planting process took on a

grander scope than simply sowing seeds.

Beginning with the construction of nearly 50 miles of new roads and over 20 miles of high

capacity transmission lines, sowing the seeds of Windy Point/Windy Flats brought together

the expertise of Cannon Power Group and the hard work and dedication of the entire

Goldendale community. Along with the roads and transmission lines, the culmination

of the vision of the New American Farm saw the construction of multiple new project

substations, one large-scale regional substation and over 175 state-of-the-art wind

turbines.

THE NEW AMERICAN FARM

PHASE 1: ROADSSimilar to planting crop rows, construction began with creating access

both to and from the site. At Windy Point/Windy Flats more than 50

miles of new roads provided the necessary access for equipment,

crews and surveyors during construction and, afterward, access for

operations personnel. As an added benefit, these roads are completely

accessible to landowners, helping to improve their own operations.

PHASES OF WIND TURBINE CONSTRUCTION

PHASE 1: ROADS

PHASE 2: ELECTRICITY

PHASE 3: INSTALLATION

PHASE 4: TESTING AND INITIATION

More than 200 miles of underground cabling will be used to connect the turbines at Windy Point/Windy Flats to the four on-site project substations.

After the underground cabling is laid, crews carefully refill and compact the trenches.

The construction of roads and turbine foundations at Windy Point/Windy Flats took a year and a half to complete.

Electrical cabling being laid in trenches.Newly constructed roads being watered to supress dust.

The project utilized two on-site rock quarries.

Windy Point/Windy Flats created over 175 jobs – 75% from within the County. Newly constructed roads being watered to supress dust.

High voltage (500 kV) transmission lines carry the electricity from the Windy Point/Windy Flats Project to ultimate customers as far away as California.

PHASE 2: ELECTRICITYUnder, above and alongside the roads a dynamic system of

transmission lines and substations was built. This system serves as

both transportation and preparation for the electricity created by the

turbines. As it passes along the transmission lines, the electricity goes

through a progression of transformations at each substation to greater

voltages and larger lines. In the case of Windy Point/Windy Flats, the

electricity from each turbine is collected at 34.5 kilovolts by

underground lines. At its first stop at one of the substations, the

electricity is transformed up to 230 kilovolts and transferred to larger,

above-ground lines built for the journey to the Rock Creek substation.

At Rock Creek the voltage is again increased, this time to 500 kilovolts,

before making the 800-mile journey to off-takers in California. Funded

and built by Cannon Power Group, the 15 miles of 230 kilovolt lines and

the Rock Creek substation will ultimately be transferred to the Klickitat

Power & Utility District to help improve the local electrical system.

Electrical circuitry banks at substation.

Electrical connection equipment at the new regional Bonneville Power Administration Rock Creek Substation.

Work crews installing high voltage electrical transmission lines.

High voltage components being installed at the Willis project substation. Technician wiring one of the many relay panels that operate the substations. A 130 Kva transformer being moved into place at the Willis project substation.High voltage components being installed at the Willis project substation.

PHASE 3: INSTALLATIONOnce the conduits were in place, erection of the wind turbine towers

began. Rooted in foundations 32 feet deep with a 16-foot diameter,

the towers are held in place by more than 245 cubic yards of

concrete. Each individual turbine was transported to the site in three

segments and erected from the ground up. Perched atop the 220 foot

tall towers, the majority of turbine rotors at Windy Point/Windy Flats

measure 300 feet in length, but Windy Flats also saw the installation

of the first two 330 foot-long rotors in the US.

Workers and tools being lowered to the base of the foundation to begin the assembly of anchor bolts.

A corrugated metal cylinder is shown being lowered into the foundation hole. An outer ring of cement will then be poured to form an outer shell.

A crane lowers steel rods encased in PVC sleeves into the turbine foundation. These will be used to anchor the tower to the foundation. Workers install electrical grounding wire at the base of the turbine foundation.

Excavation of turbine foundation - 16 ft. in diameter and 32 ft. deep

A crane lowers steel rods encased in PVC sleeves into the turbine foundation. These will be used to anchor the tower to the foundation.

A completed foundation is ready for tower segments to be set.Workers removing lifting cables after installing inner foundation cylinder.

A concrete cap is shown being poured to provide a base for the turbine tower.

Steel reinforcement being cut in turbine foundation.

Close-up view of base tower being set in foundation grout pocket to ensure a level tower.Anchor bolts securing tower base to the foundation are carefully

tightened according to strict tensioning procedures.

Cranes setting tower segments.

Towers are delivered to the site in three segments.

Workers mounting a lifting device to a tower section that will be lifted into place by a crane. After tower segments are off-loaded from cargo vessels, they are prepared for shipment to the site.

Rotors being off-loaded at Port of Vancouver for transport by truck to the site – a distance of over 100 miles.

This assembled rotor will be lifted by a 650-ton crane and attached to the turbine nacelle.

Crane positioned next to turbine tower and ready to set turbine nacelle.Photo Caption Here: lorem ipsum. lorem ipsum

PHASE 4: TESTING AND INITIATIONWith the towers erected, the engine housing, known as the ‘nacelle’,

and rotors were carefully lifted into place and attached. At this point, it

was time for the finishing touches. Electrical wiring and transformers

were installed and the entire turbine was ready to be energized and

tested by teams of engineers from Cannon, the turbine manufacturer,

the off-takers and the financing institutions. After rounds of extensive

testing, the turbine was ready to be initiated and begin its role in the

creation of the 500 megawatts of clean, renewable energy produced at

Windy Point/Windy Flats.

One of the 147 foot-long rotors being transported to the turbine pad.

Turbine nacelle and rotor being staged at turbine pad. Inside of turbine nacelle.

“I’ve really enjoyed working with [Cannon Power Group].I think we definitely benefited. We’ve got a new office building. We’ve got more employees. And hopefully we’ll see this continue in the future. Working on their project also gives experience for the next project.”

- Dustin Conroy

Owner, Pioneer Survey and Engineering

Crane attaching rotor to turbine nacelle.

Dustin Conroy front row, third from left.

THE NEW AMERICAN FARM

Completed wind turbines harvest the wind at Windy Point/Windy Flats.

THE HARVESTThe harvest at The New American Farm lacks the drama found at traditional farms.

There are no threshers tearing along crop lines or tractors hauling the season’s yield to

be processed. There are just tall rows of turbines with their rotors spinning gracefully. But

while the harvest at Windy Point/Windy Flats may be more understated, the bounty is much

more profound. Generating 500 megawatts of clean, infinitely renewable energy, Cannon

Power Group’s project produces enough electricity to satisfy the annual energy needs

of more than 250,000 households and displace over 800 metric tons of carbon dioxide

from the atmosphere each year. These results play key roles in the drive to reverse global

warming and ensure energy security for the nation.

At the same time, the true benefits of the Windy Point/Windy Flats project extend well

beyond energy creation. They can be felt in every corner of the community surrounding

Goldendale, Washington. From the infusion of millions of dollars in property tax revenue

and creation of more than 150 local jobs, to helping preserve family farms and ranches

and provide economic opportunities that allow local citizens to stay rooted in their

hometown, the harvest at this farm results in much more than an ear of corn.

THE NEW AMERICAN FARM

WINDY POINT/WINDY FLATS: A 26-MILE CORRIDOR OF WIND POWER In farming, the size of a crop is a product of two factors: quality acreage and the ability to use every piece of that acreage to it utmost potential. Cannon Power Group’s

Windy Point/Windy Flats project stretches across more than 26 miles of the most fertile wind power land in the country. Spanning a total of more than 90 square

miles, and with the help of more than 50 miles of new roads and 200 miles of underground cables, the 175 turbines that make up Windy Point/Windy Flats promise

500 megawatts of clean energy.

“Farming was drying up. There were a lot of farmers going broke just a few years ago. There was no money in it. The wind might be the mortgage lifter on the whole outfit. You know, it really helps.

If we can get some debts lifted off of our shoulders – some long-term and short-term debts – then we’ll hopefully be able to purchase equipment a little easier rather than trying to do it strictly off the farm. The wind income will definitely help that way.”

- Bruce Davenport Fifth Generation Goldendale Farmer and Rancher

THE NEW AMERICAN FARMER The role that Windy Point/Windy Flats plays in the local community is

easy to measure in economic terms, but economic terms alone cannot

tell the whole story. Many of the benefits of the project are found on

a much more personal, intimate level. For many in the Goldendale

community, The New American Farm represents a chance to keep

family together. Driven by a lack of jobs and an economic environment

that makes it more and more difficult for family farms to survive, the

younger generations of Goldendale were often forced to leave home to

make their living. For these people, the increased opportunity brought

to the area by Cannon Power Group offers a means to hold on to the

way of the life and the people they love.

Milt Patterson shoeing a horse at Dave and Lauri Davenport’s Ranch.

Bruce Davenport

Bruce Davenport and brother David Davenport

“When Jack and I returned to the Davenport homestead in 1960, we were seeking a special way of life for our family. To me this wind project guarantees a crop which will assure financial security for continuing life in the country for my children and grandchildren for many generations. This is a dream come true.”

- Ruth Davenport Goldendale Resident and Great Grandmother

Larry Kelley, third-generation Klickitat County resident, rancher and retired teacher, with his dog Gabe.The Davenport Family. Ruth Davenport (second row, third from left)

“The more I thought about it, this is the best way for us to have homeland security because then we are not giving our money to the oil people over there [in the Middle East] and places like that. It adds up to me, and it adds up to a lot of other people too.”

- Jo VanHoy Goldendale Resident, Renewable Energy Activist and Windy Point Lessor

“A lot of guys have gone to work doing the turbine maintenance. Those are people who have lived here before and want to stay here. Now there’s a job that allows them to stay. The thing that I really like about the Cannon Power Group wind projects is that they work really hard to hire local people and put people to work in a high unemployment county.”

- J.P. Enderby Fourth Generation Goldendale ResidentRancher Lauri Davenport with new-born calf.

Lauri and her husband David lease a portion of their ranch to the Windy Point project.Ellen Willis, rancher and farmer, leases turbine and substation sites to the Windy Point project.

“Cannon Power has been really great. They have been good partners. Honest and forthright. But even more importantly for Maryhill, they have supported the institution in a variety of ways. The most recent of which was the donation of concrete for our new parking lot and walkways. It was a tremendous gift.”

- Colleen Schafroth Executive Director, Maryhill Museum Goldendale, WA

Maryhill Museum of Art Goldendale, Washington with Mt. Hood in the background.

CULTIVATING COMMUNITY For the people at Cannon Power Group, putting down roots in

the community extended beyond providing economic benefits

to their neighbors and the county. It meant getting involved

in local events and culture as well. The relationship between

Cannon Power Group and the Maryhill Museum of Art began

with a few tons of concrete. As the foundations for the turbines

at Windy Point/Windy Flats were being poured, Cannon decided

to donate the concrete Maryhill needed for the construction

of a new parking lot and pedestrian walkways throughout the

grounds. Cannon and its employees continue to support the

museum as members and through sponsoring various exhibits

and events.

TENDING THE LANDPerhaps more than any other endeavor in our modern world, farming keeps people rooted

to the earth – both literally and metaphorically. The intimate involvement with the soil and

the surrounding environment is a constant reminder that the key to a bountiful harvest lies

in our ability to strike a sustainable and respectful balance with the land that provides it.

For Cannon Power Group this understanding manifests itself in a long-standing dedication

to providing responsible, progressive stewardship of the natural environment at wind

project sites throughout the world. The tradition of cultivating a symbiotic relationship

with nature shared by Cannon Power Group and traditional farms everywhere continues at

Windy Point/Windy Flats. Working closely with key stakeholders and environmental experts,

the Windy Point/Windy Flats team helped preserve the natural beauty of the Columbia

River Gorge as well as important habitats for indigenous wildlife such as the Western Grey

Squirrel, among others.

This steadfast commitment to working in harmony with nature ensures that the project at

Windy Point/Windy Flats provides a progressive example of the potential for economic and

environmental objectives to go hand-in-hand.

THE NEW AMERICAN FARM

“Living here all my life, I really do appreciate this landscape and (Cannon’s) effort to leave it as undisturbed as possible. It’s open, free, and not crowded with a bunch of housing developments. It’s nice to be able to come up here and see all the wildlife running around. And it’s nice to know it’s going to stay that way”

- Dan Hoctor Goldendale Farmer and Rancher

PRESERVATION In addition to taking progressive steps to protect local wildlife and

habitats, Cannon also helped to ensure the preservation of the scenic

beauty of the Columbia River Gorge by committing over $1 million

to a Columbia River Gorge Habitat Preservation Fund. Administered

by a highly regarded non-profit organization dedicated to land and

habitat protection within the Gorge, this fund is used to obtain long-

term conservation easements to protect the local ecology. Cannon

also limited both the physical and visual impact of the project along

the 26-miles of ridgeline that encompass Windy Point/Windy Flats.

Through detailed planning and strategic placement of each turbine,

the team was able to avoid impacting the view from the Columbia

River Gorge National Scenic Area.

Wild deer roam the hills of Windy Point and Windy Flats.

SUNSETThe end of each day at The New American Farm brings a fresh reminder of the power

and potential of wind energy projects such as Windy Point/Windy Flats. As the sun sets, the

community in and around Goldendale, Washington lights up providing the perfect tableau

to display the energy, economic opportunity and environmental harmony that embody

Cannon Power Group’s vision of The New American Farm.

THE NEW AMERICAN FARM

Wayne Hoctor, a Windy Point/Windy Flats Lessor. Shay Davenport (right) and her daughter Chelsey.

Stanley Crocker, long-time rancher and horseman in Klickitat County.

Cannon Power Group Goldendale Team. Back Row (left to right): Kurt Humphrey, Gary Hardke and Gerry Monkhouse. Front Row (left to right): Keelie Olsen, Brandy Myers and Danielle Olsen.

Turbines located on land leased from the Washington Department of Natural Resources.

Pictured from left to right: Kurt Humphrey, Windy Point/Windy Flats Project Manager with Gary Hardke and Gerry Monkhouse, Co-owners of Cannon Power Group.

“Gary and I have been in this business for a long time. When we look at potential areas of development, we are very much influenced by the feeling we get from the community and if there are areas where we think we can contribute. For us, it’s not just about financial profit. It’s also about the overall benefits we feel we can bring to the local community. We saw that opportunity in this area.”

- Gerry Monkhouse, Chairman/Founder, & Co-Owner, Cannon Power Group

“There’s clearly a frontier mentality in this area with a committment both to the land and to mutual support. The entire community pulls together and looks out for each other because that’s how they’ve learned to survive all these years. If somebody’s barn burns down, everybody pitches in to rebuild it. If somebody has a health problem and can’t bring in their wheat, their neighbors lend a hand with the harvesting. That came through loud and clear to us. We felt this was the kind of place we wanted to invest our time and effort in because not only did it have a great wind resource, but it was a community with which we would be proud to be associated.”

- Gary Hardke. President & Co-Owner, Cannon Power Group CANNON POWER GROUP GRATEFULLY ACKNOWLEDGES:

PHASE I LESSORS

Wayne and Shirley Claussen; David and Lauri Davenport; Davenport Ranches, Inc.;Wayne and Dan Hoctor; JoAnn VanHoy; Kurt A. and Rebecca Humphrey; NSC Smelter, LLC.; Washington Department of Natural Resources (DNR); and Ellen Willis.

PHASE II LESSORS

Louis and Patricia Cosner; Davenport Ranches, Inc.; Eleanor Dooley; Robert Eshelman;Scott and Wendy Hall; Wayne and Dan Hoctor; Neil and Jill Kayser, Kayser & Sons, Inc.;The Linden Family, Calvin and Terry Linden; Maryhill Museum of Art; Martin andCheri Nye; Pyramid Land and Cattle Co.; James Sizemore; and theWashington Department of Natural Resources (DNR).

KLICKITAT COUNTY COMMISSIONERS

Rex F. Johnston - District 1, David Sauter - District 2, Ray Thayer - District 3

Klickitat County Planning Director: Curt Dreyer, Director and Staff

Klickitat Public Utility District (KPUD): Commissioners and Staff (Jim Smith)

Former KPUD General Manager: Tom Svensen

CANNON’S GOLDENDALE TEAM

Kurt A. Humphrey, Project Manager

Brandy Davenport-Myers, Administrative Manager

Danielle Olsen, Asset Manager

Keelie Olsen, Construction Administrator

PHOTOGRAPHY

Bruce Forster of Bruce Forster Photography

THE NEW AMERICAN FARM

CANNON’S CONSTRUCTION TEAM LEADS

Clare Lees

Lucky Hoffman

Chuck Dickerson

CHAPTER PHOTO SUBJECTS

Kayde Davenport - Planting Chapter

Jesse Davenport - Harvesting Chapter

Jack Mulrony - Prospecting Chapter

Windy Point/Windy Flats at sunset.

www.cannonpowergroup.com

For more than three decades, San Diego-based Cannon Power Group has developed, constructed, operated, and maintained

more than 30 utility-scale wind energy projects in the U.S., India, Switzerland, Spain, Italy, Turkey, Greece and Croatia. In

2007, Cannon Power Group established its solar project division, Cannon Solar Partners, LLC. In addition to Windy Point/

Windy Flats, Cannon Power Group’s current projects include the Aubanel wind and solar project in Baja California, Mexico

and the Lucerne Valley solar project in San Bernardino County, among other wind and solar projects in the United States and

Europe. Visit www.cannonpowergroup.com for additional information on Cannon and its current projects.

www.cannonpowergroup.com

Cannon Power Group12555 High Bluff Drive, Suite 385

San Diego, CA 92130858.461.1260

Th

e Sto

ry of C

an

no

n Po

we

r Gro

up

’s Win

dy Po

int/W

ind

y Fla

ts Proje

ct

INSI

DE

FRO

NT

FLA

P

INSI

DE

BA

CK

FLA

P

SPIN

E