The Oddy Test

-

Upload

dan-octavian-paul -

Category

Documents

-

view

217 -

download

0

Transcript of The Oddy Test

-

8/10/2019 The Oddy Test

1/5

1

The Oddy Test Possibilities and limits

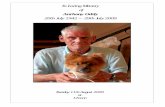

Prof. Univ.-Doz. Dipl.-Ing. Dr. Gerhard Banik,former head of the

"Restaurierung und Konservierung von Graphik-, Archiv- und Bibliotheksgut" at

the State Fine Art Academy, Stuttgart, comments after three years of in-depth

examination on the implementation of the ODDY Test.

The Oddy Test was first proposed in 1973 by Antony Werner and in 1975, the

conservation scientist Andrew Oddy, then at the British Museum, Scientific

Department, developed the test to evaluate the suitability of materials for use

in storage and display cases. The evaluation and identification of potential

damaging storage materials is accomplished by monitoring the tarnish of the

metal indicators (Oddy 1975). The procedure is basically a corrosion test at

100% relative humidity, where three indicator metals (silver, copper and lead)

when in contact with contaminants emit gas pollutants (VOCs). The evaluation

factor of the indicator metals out-gassing at 100% RH and 60C is reached

after a treatment period of 28 days.

A study by Lee and Thickett released in 1979 describes the test method, but

the authors strictly recommend to observe the research methodology: The

following recommended method should be followed exactly. Accordingly two

grams of the sample material in crushed form is placed at the bottom of a

clean glass vessel, for example an Erlenmayer test tube or any glass reactionvessel, the purified indicator metal is suspended from a nylon thread over the

sample material and then for the relative humidity adjustment a glass vessel

filled with distilled water is placed into the analysis container, which is then

hermetically sealed with either a suitable plastic or glass seal. The heat

treatment is then carried out over the prescribed test duration of 28 days in a

drying oven at constant 60C. An improved and simplified procedure can be

found in the recent publication by Robinet and Thickett (2003), which is

mediated in the HTW Berlin (see literature appendix) in ODDY Test training

workshops.

In order to be able to compare test results, the authors have suggested the

necessity of strict adherence of the research methodology, considering that

approximately twenty different types of testing methods are carried out -

mainly in museum laboratories or by restorers - and their results are really not

comparable.

The Oddy test as a corrosion test with indicator metals is fraught with a great

number of uncertainties, which are due mainly to the following facts:

-

8/10/2019 The Oddy Test

2/5

2

1) The corrosion of test metals at 100% RH is definitely different in comparison

to corrosion that takes place under normal humidity conditions. (50% rF)

2) The corrosion of test metals in direct contact with tested material is not the

same compared to the corrosion that takes place if in direct contact with the

outgassing emittants. (VOCs)

3) The corrosion of the test material decisively depends on the method how

the surface of the metals has been treated and prepared. This applies both to

the precision grinding of the metal surface as well as its subsequent

purification. For the comparability of the results and the interpretation of a

corrosive change of even one of the test metals, it is of utmost importance that

the grinding and purification the indicator metals is carried out with absolute

precision. In this context please refer to the evidences of Lee and Thickett, and

of other publications. (Zang et al. 1994, Robinet und Thickett 2003)

4) The corrosion of the three test metals copper, silver and lead in most cases

lead to the following outgassing substances: sulfide (silver), acetic acid

(copper) and acetic acid from lead, whereby the mechanisms of the respective

corrosion process due to the mixture and mingling of outgassing pollutants is

visually unassessed.

5) Additional intensive colour changes on the surfaces of copper and lead are

due to oxidization.

6) The comparison of the changes that have taken place on the metal surfaces

can be categorized into three levels: no corrosion slight corrosion severe

corrosion and are subject to the visual impressions of the person testing and

can therefore not be assessed or considered as reproducible for a clearly

interpretable scientific result.

7) The sample selection, handling and storage of the material to be examined

in either workshops or laboratories can have a significant influence on the test

result, especially the latter plays an important role because of the absorption

of contaminants present in the atmosphere during storage.

One of the main issues of the ODDY Test is that there is some subjectivity to

the interpretation of the results, since it is primarily a visual determination.

Accordingly, it is not a sufficiently precise analytical tool to interpret the causes

of the corrosion phenomena or of the discolouration of the indicator metals.

Despite the wide implementation of this testing method in the museum sector

it is still of great controversial discussion. (Grzywacz, 2006). The test is

basically only suitable to prove that under certain experimental conditions, test

-

8/10/2019 The Oddy Test

3/5

3

materials can emit harmful gases and are thus not suitable, but are not

meaningful to derive risks for other materials that have also been in contact

with the test material for long periods of time. A direct transfer of data is

subject only to the tested material and here again is basically only applicable

for silver (blackening effect due to the formation of silver sulfide in the

presence of sulphide and sulphuric pollutants) and in the case of lead(formation of white deposits due to alkaline lead carbonate or lead acetate

released by acetic acid). For more information about corrosion of lead in the

presence of acetic acid, please refer to Tetreault (1998).

Recent studies from the years 2003 and 2010, which are listed in the literature

appendix, allude more accurate testing methods, for example the optimized

ODDY Test (Robinet and Thickett, 2003) and a modified experimental set-up

with precise analysis (Strli 2011). The Strli Test is especially suitable with

precise statements with respect to the danger degree for cellulose-basedmaterials, however, this test demands a considerably higher analytical effort.

In the studies of Strli one finds evidence of the examination of paper an board

materials and cellulosic materials used for manufacturing ageing resistant

products, however further verification is necessary. It is well-known that

gaseous pollutants have an influence on the ageing resistance of paper,

however the degree of risk depends upon the composition of paper and the

respective pollutant compounds. One can formulate that gaseous acids have a

relatively significant effect, but also aldehydes after oxidization to acidic

compounds also cause the degradation of paper. Acetic acid is emitted during

the ageing process of paper with lignin content, but its presence, according to

current research (Di Pietro und Ligterink, 2012) has no or hardly any effect on

the stability of paper. Besides the formation of acetic acid also formic acid and

other compounds occur, but it is difficult to estimate their influence (Volland et

al., in print). Above all, it should definitely be noted that historical documents

stored in such containers also emit these kind of pollutants.

It is remarkable that the standard for wrapping materials (ISO 16245:2011-

04) has not considered materials emitting gaseous pollutants and their

accumulation in packaging's and storage containers. From a collector's point-

of-view it advisable to consider modifying these standards, because one can

estimate that not only the boxing and mounting material can emit acetic acid

to a certain extent but also the collectables stored within the containers could

emit these gases. It is difficult to estimate the extent of damage caused due to

the concentration of acetic acid, but it is probably insignificant, otherwise it

would obviously be seen on many collection items, especially with acid-

sensitive colourings.

-

8/10/2019 The Oddy Test

4/5

4

Likewise, from the museum point-of-view one should consider, whether the

current standard in force for wrapping materials of collections (ISO

11799:2003) is still up to the mark, and whether the limitations for acidic acid

concentration

-

8/10/2019 The Oddy Test

5/5

5

Robinet, L., Thickett, D.: A new methodology for accelerated corrosion testing.

Studies in Conservation 48 (2003): 263-268

Strli, M., Kralj Cigi, I., Moir;A.,de Bruin; G., Kolar, J., Cassar, M.: The

effect of volatile organic compounds and hypoxia on paper degradation.

Polymer Degradation and Stability 96 (2011): 608-615

Jean Tetreault, J., Jane Sirois, J., Stamatopoulou, E.: STUDIES OF LEAD

CORROSION IN ACETIC ACID. Studies in Conservation 43 (1998): 17-32

Volland, G., Hansen, D., Knjasev, V., Meyer ,F.: The Schinkels Legacy

Project at the Kupferstichkabinett / Schinkelmuseum Berlin. Subproject: Air

Quality in Warehouse Storage Cabinets Cause and Effect. Restaurator 34,

No.3, in Druck.

Zhang, J., Thickett, D., und Green L.: Two tests for the detection of volatile

organic acids and formaldehyde. Journal of the American Institute for

Conservation 33 (1994): 47-53