The Global Magazine of Leica Geosystems · Operational since January 2013, the topograph-ic...

Transcript of The Global Magazine of Leica Geosystems · Operational since January 2013, the topograph-ic...

2 | Reporter 69

Dear Readers,

Modern life is unthinkable without the geospatial

information that our industry generates and that

helps individuals, businesses and governments make

better informed decisions. We need reliable geo-

data to support sustainable growth; and processing

and interpreting the large amounts of data gener-

ated quickly and easily is vital.

In this issue of the Reporter you will discover why

3D data is essential. In China, geodesign and land-

scape architecture is now an established university

degree; and Leica Geosystems solutions are helping

students create 3D landscape visualizations. In the

Caspian Sea, Leica Geosystems geodynamic monitor-

ing systems are being used on an offshore oil rig to

ensure its safe operation and to protect its workers

on the high seas. In Frankfurt, Germany the fascinat-

ing history of St. Leonard's church is being brought

to light. During the renovation work the original col-

umns were discovered two meters below the current

floor. Using 3D laser scanning, an accurate 3D model

of the columns was created bringing this piece of

history to life.

The articles in this edition fit very well with the theme

at this year’s Intergeo in Essen, Germany. Our stand

shows how topography, construction, infrastructure,

cadastre, monitoring and geospatial imaging are all

interlinked and how Leica Geosystems solutions and

services help to improve the world we live in.

Juergen Dold

CEO Leica Geosystems

Editorial

Imprint

Reporter: Leica Geosystems customer magazine

Published by: Leica Geosystems AG, CH-9435 Heerbrugg

Editorial office: Leica Geosystems AG, 9435 Heerbrugg, Switzerland, Phone +41 71 727 34 08, [email protected]

Contents responsible: Agnes Zeiner (Director Communications)

Editors: Konrad Saal, Agnes Zeiner

Publication details: The Reporter is published in English,German, French, Spanish, and Russian, twice a year.

Reprints and translations, including excerpts, are subject tothe editor’s prior permission in writing.

© Leica Geosystems AG, Heerbrugg (Switzerland), September 2013. Printed in Switzerland

Cover: © Evgeniy Bogdanets

CO

NTEN

TS Monitoring Mother

Nature’s Forces

Bringing History to Life

Safety on the High Seas

From GeoDesign toLandscape Design

GNSS Live Trackingfor Cycling Fans

Preserving an African Legacy

Superstorm Sandy Recovery

Manual WorkMeans Top Quality

A New Constellation for Gold

Picture Contest:– when it has to be right

03

06

09

12

14

18

20

24

27

30

© D

uil

io G

uiz

zett

i

>>

The Global Magazine of Leica Geosystems | 3

by Elena Piantelli

The Messina region is considered one of Sicily’s

areas most vulnerable to natural disasters. As

such, the communities in this northeast region

have become all too familiar with “renewal” –

the recovery after violent earthquakes, flood-

ing, mudslides and landslides. Indeed, the

community of San Fratello, a small village 90

kilometers (56 miles) west of Messina, is still

trying to regain its footing three years after a

disastrous landslide forced almost half the pop-

ulation of 4,500 residents from their homes.

The implementation, however, of an advanced

surface monitoring system is providing authori-

ties with the ground intelligence they need to

not only help avoid the disastrous element of

surprise, it may help to stem the slide as well.

According to ISPRA (Italy’s Institute for Environmen-

tal Protection and Research), a significant contribut-

ing factor to the landslide was rainfall. About 105

mm of rain fell over the area in the eight days prior to

the destruction, overwhelming the existing drainage

system and putting the hillside village at serious risk.

On 13 February 2010, a landslide was triggered in

Riana, a district in San Fratello. The two-kilometer-

Monitoring Mother Nature’s Forces

Monitoring network with GPS baselines (red and yellow lines) and total station observations (pink lines).

© R

CP

4 | Reporter 69

wide (1.2 miles) phenomenon descended across the

area for about two days, swallowing homes, dam-

aging important monuments such as the San Nic-

ola church, destroying principal roads and causing

extensive damage to the districts of San Benedetto

and Stazzone.

The day after the landslide stopped, the authorities

with the Regional Civil Protection (RCP) of Sicily initi-

ated plans to take a proactive approach to disaster

preparedness. The plan would lead to a sophisti-

cated, real-time, surface monitoring system that not

only maintains a continual read on the stability of

the terrain, it may help authorities manage Mother

Nature’s forces.

Setting a New Preparedness Standard To adequately design a monitoring system, authori-

ties first needed to study and observe the region’s

terrain to truly understand its movements, and con-

sequently, its vulnerabilities. For two years, surveyors

and engineers recorded and analyzed measurements

from geotechnical and topographic instruments.

Based on this comprehensive study, they determined

an automated, integrated surface monitoring system

would be the most effective, first-alert approach for

its emergency preparedness plan.

In August 2012, the RCP issued a request for pro-

posal for such a system, and in September 2012, it

awarded Leica Geosystems with the design, develop-

ment and installation of the integrated monitoring

solution.

Operational since January 2013, the topograph-

ic monitoring system combines both GPS and TPS

technology, along with advanced software tools, to

provide a precise picture of the village’s surface in

near-real time.

Eight Leica GMX901 GPS receivers sit on buildings

and drainage wells located in the landslide area.

These compact, single frequency sensors monitor

the high risk zone, acquiring position data every sec-

ond, enabling them to record the smallest of move-

ments.

Completing the automated control network are two

double frequency GMX902 GPS stations, which are

specifically designed to provide precise correction

data to the single-frequency GPS receivers.

Each GPS station is powered by 220V and/or by a

solar panel, and is connected to a cabinet equipped

with protected electric cables and a buffer battery.

GPS Monitoring Station

© D

uil

io G

uiz

zett

i

The Global Magazine of Leica Geosystems | 5

structure, such as installing new drainage wells and

constructing other support structures, mitigating the

town’s risk of severe damage from future natural

disasters.

It is likely that landslides will descend on San Fratello

again, but by flooding the area with their own net-

work of technology, authorities may now have the

means to turn the event into an exercise in “pre-

paredness” rather than “disaster.” And that may give

comfort to both the residents and the authorities

charged with trying to protect them.

About the author:

Elena Piantelli has a degree in natural science and

works in Business Development for Monitoring Solu-

tions at Leica Geosystems S.p.A. based in Cornegliano

Laudense/Italy.

The communication among the stations and the mas-

ter unit station, which houses the management soft-

ware, is guaranteed by a wireless LAN 5 GHz device.

The continuous GPS readings are collected by the

Leica GNSS Spider software, which is installed on

a dedicated PC on site. The software manages the

individual GPS sensors, automatically calculates the

baseline and sends the information to the RCP.

The Deformation Data StreamThe automated management of the GPS receivers

and the data analysis tools are maintained by the

RCP’s control center, which is based in the city of

Palermo, about 140 km (87 mi) from San Fratello. The

centralized control center has a network of com-

puters to receive the GPS and other supplemental

data, and it has specialized data analysis software

to enable the RCP to study the data provided by the

different instruments.

Although the frequency of the baseline calculation

depends on the RCP’s specific needs, at present, the

automated monitoring system provides measure-

ment data every hour. RCP personnel can access the

system at any time to consult the measurements and

modify acquisition parameters, thanks to the remote

control features of the solution and an opportune

remote control software.

In addition to the automated GPS monitoring system,

50 prisms are permanently set on buildings for rou-

tine measurement by a Leica TS30 automatic total

station. Using a network of six measurement pillars,

a surveyor positions the total station to perform an

automatic measuring cycle, surveying each prism

point, and enabling users to produce a topographic

analysis of the measurement data.

Measurements and surveys are made on a monthly

basis but the frequency can change according to

specific requests based on the stability of the area

or changing environmental and climatic conditions,

which are considered hazardous.

Strategies to Stabilize SubsidenceAll of the information gathered by the system is

promptly delivered to the Office for Civil Protection

so the data can be validated and integrated into

the emergency plan. By having accurate, near-real

time data, authorities have been able to identify and

implement strategies to improve San Fratello’s infra-

6 | Reporter 69

Bringing History to Life

by Theo Drechsel

The recent restoration of St. Leonhard's Church

in Frankfurt, Germany drew much attention

around the world. Not only in the form of many

publications on the subject, but also by the con-

stant flow of fascinated visitors from around

the world who come to tour the church. The

excavations, which uncovered 70 skeletons and

a variety of burial objects, were documented

not least thanks to the critical role played by 3D

laser scanners from Leica Geosystems. The data

was even used to create a 3D model of the sup-

port structure on a scale of 1:20.

From 2004 through 2008 the external facade, roofs

and tower dormers were restored. Interior restora-

tion of the church finally began in 2011. The goal of

Frankfurt’s municipality was to revert St. Leonhard's

Church back to the late Gothic style due to the vari-

ety of different architectural styles used on the inte-

rior. The floor was also to be lowered, as the interior

was raised repeatedly over the centuries to protect

against flooding by the Main River.

An assessment of the current condition had to be

made before the restoration, so in 2009 Frankfurt's

Central Building Department commissioned local

engineering firm Steuernagel Ingenieure GmbH for

the job. “After testing, we realized right away that 3D

laser scanning would be the only option for measure-

ment due to the particularly complex nature of the

building,” recalls Managing Director Kai Steuernagel.

“This is why we used the HDS6200 laser scanner

and a ScanStation C10 from Leica Geosystems, which

guarantee the required accuracy of ± 10 mm (0.4 in).”

The goal of the project was to document the inter-

mediate results of construction as the restoration

progressed. In 15 days the surveyors fully scanned

each phase of the excavation down to a depth of

almost 3.5 meters (11 ft). The entire interior of the

church, including all auxiliary rooms, the ceiling arch-

es and both apses (towers) were captured in exact

detail. Great value was placed on the selection of

the laser scanning positions to minimize shadowing

during the scanning process. “We scanned one sup-

port structure from 16 different positions,” reported

Christof Kremer. “Our knowledge and experience as

Accurate 3D model of the support structure on a

scale of 1:20 based on the 3D laser scan

The Global Magazine of Leica Geosystems | 7

>>

surveyors ensured the high precision and quality of

the scans.”

The big challenge for the expert surveyors was the

accurate and thorough representation of the Gothic

architectural style with its frescoes and many details,

particularly with the intention of creating the floor

plan as a dimensional site plan. This was prepared in

detail, down to the benches and floor coverings; by

the end of the project roughly 17 billion points had

been scanned.

The software 3D Reshaper from Technodigit, a Leica

Geosystems sister company, proved itself brilliant-

ly during this project. It was used for modeling by

Steuernagel and offered the surveying experts many

options. In conjunction with the 3D laser scanner

from Leica Geosystems, it offers considerable add-

ed value thanks to its visualization options, which

also enthralled the Central Building Department.

The most impressive element, though, was the laser

scanner itself, which exhibited its strengths particu-

larly in close range applications thanks to its high

precision and resolution.

The advantages of laser scanning were highly evi-

dent in other areas as well. When the Central Building

Department asked Steuernagel for an additional rep-

resentation after the work was completed, it could

be created and submitted quickly without having to

© m

ne

um

an

n_1

00

- F

oto

lia.c

om

St. Leonhard's Church isn't just one of the sights to

see in Frankfurt. It is the most valuable church in

the Hessian metropolis. Located on the north bank

of the Main River in the old town it was erected

in 1219 as a late Romanesque basilica and subse-

quently remodeled in the neo-Gothic style. The first

ever Frankfurt book fair was held in the north nave

of the church in 1450. A hanging arch is found in the

integrated chapel of St. Salvator built from 1500 to

1515. Arches of this type consist of stone arch ribs

and are rare in Europe due to their complex design.

During the Second World War, St. Leonhard's Church

was the only one in Frankfurt to miraculously remain

almost entirely intact.

St. Leonhard's Church

8 | Reporter 69

return to the site to carry out more work. The archi-

tect, who is located in Fulda, about 100 km (62 mi)

away from the church, is also delighted. He used

to have to visit the property frequently to clear up

outstanding issues, but now he gets the informa-

tion he needs with much less effort thanks to the

Leica TruView freeware. With this software, he can

view extensive point clouds directly in a web browser

without the need for CAD experience.

The icing on the cake of a very successful project was

the “tangible” 3D model, accurate down to the mil-

limeter (including every joint), created by Steuernagel

and a partner at the end of the project. A 3D printer

was used to construct a complete support structure

around the excavation area in a scale of 1:20. The

three-dimensional workpiece was constructed by

computer control using the specified dimensions and

shapes from the CAD model.

“If nothing else, this museum-quality 3D presenta-

tion model confirms my opinion that laser scanning is

currently unbeatable where 3D data and 3D models

are needed,” stressed Kai Steuernagel.

About the author:

Theo Drechsel is the owner of the specialist metrol-

ogy and quality assurance PR agency 4marcom + PR!

based in Unterschleissheim near Munich.

Founded in 1992, the Steuernagel Ingenieure GmbH

engineering firm is located in Frankfurt am Main and

focuses on surveying, civil engineering and graphical

data processing. Since the beginning, Steuernagel has

used only Leica Geosystems measurement systems.

Regarding its latest purchase, two Leica HDS7000

Steuernagel Ingenieure GmbH

laser scanners, Managing Director Kai Steuernagel

had this to say: “We invested in the laser scanners

because we want to build a mainstay for the future,

expanding our portfolio as a large engineering firm

in Frankfurt.”

© E

vge

niy

Bo

gd

an

ets

>>

The Global Magazine of Leica Geosystems | 9

Safety on the High Seasby Evgeniy Bogdanets and Anton Ivanov

Government awareness of the need for

increased safety on offshore works is increas-

ing worldwide. Russia has a strong interest in

offshore safety and is in the process of prepar-

ing a bill concerning “protecting the seas of the

Russian Federation against oil pollution”. There

are currently two oil-drilling rigs in operation,

both belonging to “Lukoil” Ltd. The bill is not yet

ready or obligatory, but Lukoil’s directors have

already initiated geodynamic monitoring sys-

tems on a maritime, ice-resistant platform over

the Yuri Korchagin oil deposit to ensure safe

operation and to protect workers from unex-

pected occurrences on the high seas.

The Yuri Korchagin oil deposit was discovered in

2000 and is located 180 km (110 mi) from Astrakhan

in the northern part of the Caspian sea, at an aver-

age sea depth of 11 – 13 m (36 – 43 ft). The rig began

working in spring 2010 and consists of two blocks:

the production and the accommodation facility.

Preliminary Evaluation The owner and operator “Lukoil-Nizhnevolzhskneft”

Ltd. put on a competition for the monitoring project,

which was won by the Perm State Technical Universi-

© E

vge

niy

Bo

gd

an

ets

Leica AR25 Reference Station

10 | Reporter 69

infrastructure. Natural seismic activity in the region

can aggravate the risk of man-made seismic events,

which is further proof that geodynamic monitoring of

facilities is essential.

Mathematical deformation modeling of the rock

mass and the earth surface during oil production at

the Yuri Korchagin field performed by experts from

the Perm State Technical University have shown that

maximum seabed subsidence is 100 mm (4 in). Pre-

liminary evaluation of the general rock stress level

during commingled oil and gas production indicates

that maximum pay zone compaction reaches 890 mm

(35 in). This means the development of gas reserves

at the field is the main driving force behind seabed

subsidence.

The Right Monitoring Approach The PSTU scientists proposed a two-segment moni-

toring system: the first segment is an automated

monitoring system using Leica GNSS Spider software

and the second is control monitoring performed

upon control reference points onshore. Both seg-

ments involve sea and onshore works.

The shore reference network uses a reference sta-

tion installed on the roof of a Lukoil-Nizhnevolzhs-

kneft Ltd. office and connected to a server running

Leica GNSS Spider, which is regularly checked by the

chief surveyor. In addition, raw measurements of the

four constantly operating sensors are saved on this

computer. The sea segment of the monitoring sys-

tem consists of three sets of GNSS equipment with

antennas set up permanently on the three edges of

the rig’s main deck.

A geodynamic polygon of ten control sites has been

created for the shore segment monitoring. Baseline

solutions to the rig are computed from a single mas-

ter site. All other sites are used to control the stabil-

ity of the master site. If the master is moved or lost

for any reason, its role transfers to another site.

The combination of sea and onshore segments

results in a collection of raw measurements of all

GNSS sensors combined on the computer of Lukoil-

Nizhnevolzhskneft’s chief surveyor. Leica GNSS Spi-

der allows gathering and archiving data automati-

cally. The system is configured to compute sensor

coordinates (points on the edges of the main deck)

in real-time every second, as well as with hourly and

twelve hour intervals in post-processing. The results

ty (PSTU). The Mining GIS and Surveying department

of PSTU had already had successes with projects in

the area of deposit extraction and considered pro-

fessional, quality equipment and software a crucial

part of successful project completion. The scientists

chose Leica Geosystems GNSS equipment to moni-

tor the vertical and horizontal displacements of the

oil rig.

The Caspian rig is permanently fixed to the seabed

on six carriers. During the extraction process, the de-

oiled rock is repacked so the terrain generally settles

down. However, if irregularities occur in the process,

the rig might lurch. Therefore platform position mon-

itoring is crucial to prevent dangers.

If subsidence processes develop gradually, produc-

tion-related subsidence should not impact the facili-

ties. However, local irregular seabed displacements

can occur, which may pose a threat to the oilfield

© E

vge

niy

Bo

gd

an

ets

A Leica AR10 antenna monitors movements of the oil rig.

The Global Magazine of Leica Geosystems | 11

Comparing the control monitoring results with a drill-

ing map leads PSTU to believe that smaller move-

ments of 20 mm (0.8 in) are mainly caused by engine

lowering and lifting. The Leica Geosystems monitor-

ing installation remains essential to keeping all rel-

evant parties informed.

About the authors:

Evgeniy Bogdanets is Mining GIS and Surveying chair

assistant at PSTU. [email protected]

Anton Ivanov is Public Relations Manager at Navgeo-

com, Leica Geosystems' Master Distributor in Russia.

of coordinate calculations are presented in a move-

ment diagram and are used to make a conclusion

about sensor stability – and therefore rig stability.

Section two of the system is controlling the monitor-

ing results by making long-term GNSS observations

on permanent onshore base stations. To ensure the

stability of the control network, first-order leveling

was performed before starting GNSS observations.

A Stable Oil Platform Since the installation of the monitoring system, the

results show that control measurements and auto-

mated monitoring data correlate: the nature of sub-

sidence and rises is completely identical, concluding

that the real-time monitoring gives correct results.

The sensor displacements are of non-permanent

nature; their values are small and for the most part

do not exceed measurement accuracy, which indi-

cates that their location is permanent and stable.

12 | Reporter 69

From GeoDesign to Landscape Design

Landscape Architects are not surveying profes-

sionals, but understanding how to apply differ-

ent surveying methods, as well as the workflow

and effort necessary to create the data they

use for their design concepts, is essential. In

June 2013, the Leica Geosystems team in Nan-

jing, China provided instruments, know-how and

manpower for the workshop “From GeoDesign

to Landscape Design”, taught by Prof. Dr. Li Pang

and Prof. Peter Petschek, to educate future

Landscape Architects on different surveying

methods.

by Dr. Li Pang and Prof. Peter Petschek

In the past years, the role of Landscape Architec-

ture in China has completely changed. The Chinese

government now considers it equal in importance

to Architecture and Planning. This is also reflected

in the university system. Landscape Architecture is

an established university degree equal to other dis-

ciplines in the planning and construction area. At

South East University (SEU) in Nanjing, one of the

top universities in this field, the subject is taught at

Bachelor, Master and PhD levels.

GNSS and laser scanning are new buzzwords in Land-

scape Architecture. But which surveying technolo-

gy is best suited for which project, how much time

does it take, what are the measurement principles

of these instruments and how do you collect land-

scape information and build landscape models? The

instructors of the “From GeoDesign to Landscape

Design” workshop teamed up with Leica Geosystems

to teach students at SEU how to solve these and

other surveying related questions.

During the first part of the workshop, the students

learned to use the Leica Geosystems laser scanning

technology on site in an area covered with abundant

trees and bushes and with a pond in the middle. The

advantages of measuring millions of points within a

very short time quickly became clear. But the stu-

dents also realized that laser scanning is not the

answer to every task in landscape architecture - for

even more precise landscape design/planning and

stake-out in the field the students were introduced

to the Leica Builder total station.

In the second part of the workshop the students

were taught how to create Digital Terrain Models

making the development of landscape design solu-

tions in China easier.

About the authors:

Li Pang received her PhD at ETH Zürich and teaches

Landscape Architecture at SEU.

Peter Petschek is a graduate landscape architect and

professor at HSR University of Applied Sciences Rap-

perswil/Switzerland.

The Global Magazine of Leica Geosystems | 13

(DTM) from the data observed with the Leica Builder.

AutoCAD Civil 3D with its many possibilities to ana-

lyze and manipulate the terrain was used for this

purpose. The DTM know-how was then applied to a

design project. Prof. Dr. Li Pang gave the students

guidance on how to achieve a design in Landscape

Architecture based on existing topography.

By understanding the entire process involved from

survey to final data delivery Landscape Architects

can communicate more efficiently with Surveyors,

3D Survey Data for Landscape Architecture

Land Survey Data is the basis for every Landscape

Architecture project. With an increased demand for

3D landscape visualizations and the need for sci-

entific decision-making processes in contemporary

landscape architecture design/planning, precise land-

scape data is becoming ever more essential. Existing

topography, vegetation, buildings and infrastructure

have to be precisely located in digital plan format in

order to develop design concepts for urban green

spaces, plazas, parks and gardens.

14 | Reporter 69

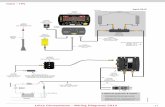

by Thomas Aigner

The annual Bayern Rundfahrt, or Tour of Bavar-

ia, (www.bayern-rundfahrt.com) is Germany's

largest professional stage race. This year the

Regional Surveying and Geoinformation Office

supported the event with maps, aerial photos,

3D animations and live tracking. With live track-

ing, GNSS receivers mounted on escort vehicles

transmit the co-ordinates of the cyclists at the

front and rear of the pack to a centralized ser-

vice. The positions are displayed on a special-

ly adapted Bavarian Surveying Administration

BayernAtlas for cycling fans to track the race

conveniently in real time over the Internet.

In 2012, the Bavarian Broadcasting Company's “BR-

Radltour” was the first public cycling event the

Bavarian Surveying Administration supported with

live tracking. To meet the increased needs of the

second live tracking event – the Tour of Bavaria in

May 2013 over a distance of 783.5 km (487 mi) – the

Bavarian Surveying Administration chose to use more

professional instruments. The previously used simple

GPS tracking transmitters had difficulties with posi-

tion accuracy and mobile reception.

Across Bavaria, powerful Leica Geosystems GNSS

sensors Viva GS15 and GS10 have been used at 51

Cadastral Offices for satellite-supported measur-

ing tasks in the land registry for several years now.

Thus the agency has both experience in using the

devices and sufficient instruments which could be

provided for the Tour of Bavaria. In addition to the

powerful GNSS evaluation hardware, the high-quality

mobile antenna accessory promised a more stable

connection, even in areas of the state with weak

coverage, in comparison to the simple GPS tracking

transmitters. Last, but not least, the many options

for supplying power, including internal batter-

GNSS Live Tracking for Cycling Fans

© S

CH

AA

F /

Baye

rn R

un

dfa

hrt

>>

The Global Magazine of Leica Geosystems | 15

veying Administration escort personnel were only

available part of the time for the Tour of Bavaria,

the instruments had to be operated (set-up, started,

power supply monitored) by whoever else was in the

vehicle, i.e. inexperienced users. Despite this, reliable

functioning had to be ensured.

Orgatour: Successful Equipment Test In addition to materials, training is an important part

of any cyclist's race preparation. Therefore it was

possible to put the instruments through their paces

in advance of the race. The selected equipment (a

Leica AS10 GNSS antenna with a GAT18 GMS/UMTS

antenna on the roof and a Leica Viva GS10 receiver

with power supply in the car) was tested by the event

organizer in May 2013 during a so-called Orgatour, a

preparatory exploration of the route. It became evi-

dent at this point that the right choice of equipment

had been made. The accompanying personnel were

able to reliably operate the test instrument after

ies, external batteries and supply via a 12V vehicle

electrical system, guaranteed a flexible and secure

solution.

By nature, complex, high-performance systems also

place greater demands on the user. The critical ques-

tion then arose as to whether the selected Leica

Viva GS10 receiver would be easy enough to oper-

ate during an activity as turbulent as a bicycle race.

During the 2012 BR-Radltour, only the very front and

rear positions were tracked, but for the 2013 Tour

of Bavaria, the position of the peloton (main group

of cyclists) also had to be visible as a third position,

should some cycling pros successfully manage an

exciting leap ahead of the pack.

The three escort vehicles: the police's lead vehicle,

the sport physician's vehicle and the event organiz-

er’s “sag wagon” were each equipped with a Leica

Viva GS10 receiver. Since some of the Bavarian Sur-

GSM and GNSS antenna setup

© T

ho

mas

Aig

ne

r /

LVG

16 | Reporter 69

BayernAtlas

Thanks to the free BayernAtlas from the Bavarian

Surveying Administration, free detailed aerial pho-

tos, 3D models of buildings as well as topographical

and historical maps of Bavaria with much additional

information are available to everyone.

www.bayernatlas.de

only ten minutes of instruction. Concerns regard-

ing mobile reception also proved unfounded as the

Orgatour progressed.

Only a few position transmission dropouts remained

unexplained. To localize their source of error, the two

affected stages were travelled again by the Regional

Surveying and Geoinformation Office with two Leica

Viva GS10 receivers and different mobile provider

configurations. This test revealed that, despite the

long stages of just under 200 km (124 mi) in hilly and

forested terrain, the mobile connection was near-

ly always reliably maintained by the instrument. In

rare cases the connection was lost while transition-

ing between cells in a weak mobile network. Setting

“Automatic Connection” in the Leica SmartWorx Viva

field software’s RTK profile quickly solved this prob-

lem. A nice side effect was that this also reduced

operation of the Leica Viva GS10 to a minimum.

Just as with on-site operation, the transmission and

processing of position data proved to be surprising-

ly easy. Since the GNSS rover which calculates the

exact position data using the “virtual reference sta-

tion” RTK concept transfers its current position to

the administration's SAPOS service as an NMEA data

record, the position data then only needed to be

provided to the BayernAtlas server. Elaborate and

error-prone configuration of the network connec-

tions on the rover was completely unnecessary. The

vehicle positions were collected as a by-product of

the SAPOS correction data server and then only had

to be filtered out.

© T

ho

mas

Re

ine

l /

LVG

Good preparation leads to a successful race Every imaginable preparatory measure for smooth

technical support of the race had thus been taken.

The day before the first stage, the escort vehicles

were outfitted and the occupants where instructed

in the operation of the instruments. Although each

installation arrangement wasn't yet known and many

of the power sources had already been taken up by

the tour's mobile needs, the optimum solution was

quickly found for each vehicle using either batteries

or the vehicle's electrical system. Time-consuming

recharging of batteries could even be fully dispensed

with, thanks to good advance planning and compre-

hensive accessories.

Good preparation enabled trouble-free live tracking

of the Tour of Bavaria. The only thing worth com-

plaining about was the cold, wet weather during

the tour, but even this didn't negatively affect the

instruments in any way. Despite constant rain, the

equipment served flawlessly and reliably transmitted

the position data of the racing cyclists. Subsequent

evaluation of the transmitted NMEA data showed

that an impressive 75 % of all points achieved an RTK

accuracy of about 2 cm (0.8 in) and another 24 % a

DGPS accuracy of about 1.5 m (4.9 ft) – thus by far

exceeding the requirements.

Apart from the technical details, both the tour orga-

nizers and many other people interested in the

2013 Tour of Bavaria profited from the Surveying

Administration's “live-tracking project”. The feed-

back received was also correspondingly positive.

Both visitors to the Bavarian Surveying Administra-

tion's information stand at the stage destinations

and fans at home were able to track the race's prog-

ress live at all times and estimate the cyclists' arrival

at the finish line. At the end, the Tour of Bavaria

organizers expressed their sincere thanks for the

successful project. As far as the Bavarian Surveying

Administration is concerned, there is nothing stand-

ing in the way of a repeat performance at the 2014

Tour of Bavaria.

About the author:

Thomas Aigner is a Surveying Engineer (UAS) at the

Bavarian Agency for Surveying and Geographic Infor-

mation (Landesamt für Vermessung und Geoinforma-

tion / LVG) and is responsible for all Cadastral Offices

in Bavaria. [email protected]

The Global Magazine of Leica Geosystems | 17

© A

ngu

s Fo

rbe

s

18 | Reporter 69

Preserving an African Legacyby Michelle Dye

There’s a spectacular mountain range linking

South Africa and Lesotho that is known in some

quarters as the Drakensberg, ‘dragon moun-

tain’, and by Bantu-speakers as uKhahlamba,

‘the row of upward-pointing spears’. But it is the

San people who left the greatest legacy in these

mountains: a treasure trove of priceless art. The

San people lived in the uKhahlamba Drakens-

berg range for about 4000 years, during which

time they adorned more than 600 known sites

with 40,000 individual paintings, the largest and

most concentrated collection of rock art in sub-

Saharan Africa. The paintings are outstanding

in their quality. Their diversity of subject and

their exquisite depiction of animals and human

beings and their world-wide significance con-

tributed to the uKhahlamba Drakensberg Park

being listed as a UNESCO World Heritage Site

in 2000. Leica Geosystems’ cutting-edge HDS

technology is helping to preserve this legacy.

© V

ick

y N

ard

ell

permanent, millimeter-accurate record of the paint-

ings so that future generations will still be able to

appreciate them.

Multiple scans were taken all around the rock shel-

ters so the scanner could “see” the art from all

angles. Millions of 3D points are initially displayed

on a computer as a point cloud so dense it looks

like a solid surface. The scans from each station are

then stitched together to form a single point cloud of

the whole site. Digital photographs taken from each

scanner position are used to color the point cloud,

transforming the yellow and orange raw scan data

into a real-color computer model.

A virtual tour, a 360-degree digital 3D video, 3D ter-

rain modeling and GPS plotting complete the tech-

nology package for each site. And GIS web-based

mapping systems was then produced for the proj-

ect as a whole. The extensive collection of data is

housed at the KwaZulu-Natal Museum and shared

with the province’s heritage agency, Amafa aKwaZu-

luNatali, and Ezemvelo KZN Wildlife, which manages

the World Heritage Site.

This article is adapted from the original issue pub-

lished in Africa Geographic in March 2013.

www.africageographic.com

About the author:

Michelle Dye is a Geographical Information Systems

Specialist based in KwaZulu-Natal/South Africa.

The Global Magazine of Leica Geosystems | 19

Without doubt the finest and most accomplished

rock artists in the land, the San painters worked in

exceptional detail and with an extensive color pal-

ette. For paint they used a mixture of red and yellow

ochre, charcoal, manganese oxide and clay, which

was bound together with blood, fat, plant extract

or egg; their brushes were feathers, animal hairs or

grass stems. It is rare to see poor art in the Drakens-

berg, which suggests that not just anyone had the

right to paint on the rock walls. These were sacred

places, reserved for the masters to record deeply

meaningful statements. The paintings depict hunt-

ing, dancing, fighting, food gathering and ritual or

trance scenes of hunting or rainmaking. The ani-

mal that appears most often is the eland – the San

not only relied on the large antelope for meat, but

believed its blood and fat had a mystical potency.

Unfortunately much of the rock art has been dam-

aged by vandalism, fire, encroaching vegetation and

natural weathering. Exposed to the elements, the

fragile paintings are gradually deteriorating as time

passes. As it is not possible to restore them, it is of

the utmost importance to digitally preserve the art

so that the San legacy will not be lost. The Univer-

sity of KwaZulu-Natal and the African Conservation

Trust have just completed a three-year project to

create the first digitized archive of the San rock art

in uKhahlamba Drakensberg. It was a great success:

more than 500 rock shelters and caves were docu-

mented and their condition assessed, and focused

exploration led to the discovery of no fewer than 80

new sites. 3D laser scanning was used to create a

At one of the rock art sites scanned by the project,

a red-and-white eland is painted below a mythical

figure with human, antelope and praying mantid fea-

tures. Archaeologist Vicky Nardell says, “The feath-

ered white lines emerging from the top of the fig-

ure may be seen as lines of energy or supernatural

power. The simple lines connecting the figure and

the eland probably signify the complex relationships

between San shamans and ‘potent’ animals, like the

eland. Below the antelope, several human figures are

dancing.”

20 | Reporter 69

Superstorm Sandy Recoveryby Angus W. Stocking, LS

When Superstorm Sandy hit the East Coast in

October 2012, it left a wide swath of damage and

destruction in its wake. Gayron de Bruin (GdB),

a 14-person land surveying and engineering firm

based in Bethpage, N.Y., a Long Island hamlet,

was among the businesses severely affected.

The firm, which has been standardized on Lei-

ca Geosystems instruments for several years,

specializes in applying progressive technology

to traditional survey tasks. They were an ear-

ly adopter of GNSS, robotic total stations and

other progressive instrumentation, and one of

the first providers of GIS expertise and consult-

ing in the Long Island area. The combination of

modern technology, high standards and excel-

lent service allowed the firm to thrive despite

challenges.

“I was actually at work during the day as the storm

got going,” says GdB President Christine Gayron,

LS. “I went home at 4:00 pm as it got more intense.

We lost power of course – everyone did – and had

The Global Magazine of Leica Geosystems | 21

ways, and major state parks, such as Jones Beach

and Robert Moses. “Sandy washed water over the

entire island and parkway in some spots, completely

wiping out the dunes that normally protect the road,”

Gayron says. “So we didn’t know what to expect; we

weren’t even sure we’d be able to get to the site.”

Fortunately, NYSDOT had already made progress

clearing the road, using snowplows and other meth-

ods to push away sand. When GdB trucks arrived,

state troopers were onsite to restrict access but,

in the cooperative spirit that prevailed after Sandy,

waved the surveyors through to do their work.

GdB had been asked to complete an emergency con-

trol survey to support photogrammetric and aerial

LiDAR mapping being performed to assess parkway

damage. NYSDOT was concerned about the parkway

being buckled or undermined by storm surges. “NYS-

DOT set targets before the storm and didn’t know if

they would still be there,” says Gayron, “And if they

were in place, would they still be visible or would

some IT issues. A bigger problem was gas; In the days

after the storm just getting to work was hard for our

employees. Filling up trucks meant waiting in line at

the filling station for hours.”

GdB felt more pressure than most businesses to get

up and running quickly. The firm has a Term Agree-

ment for Survey Services (TASS) with the New York

State Department of Transportation (NYSDOT) and

knew that preliminary survey work would be needed

prior to important storm recovery projects. “Sandy

hit on Monday, and we didn’t have power at the

office until Thursday,” says Gayron. “I called our NYS-

DOT contact that very day, to let them know we

were available.” NYSDOT wasted no time. GdB had an

assignment the next day and early Saturday morning

two crews were on their way to Ocean Parkway, a

state road that runs along one of the barrier beach

islands on the south side of Long Island.

In fact, Ocean Parkway is the only connection

between several islands, communities, other park- >>

A GdB field crew uses a Leica Viva GS15 to survey post-Sandy beach erosion for the town of Oyster Bay.

22 | Reporter 69

they be covered with sand? We found that most

were there; many had to be swept off, and a handful

had to be reset.” The job involved “only” a hundred

points or so but, like the rest of Long Island, crews

would be dealing with Sandy’s aftermath. And GdB’s

practice of collecting GNSS data twice for each point,

at different times of day, compounded the challeng-

es. “Really,” says Gayron, “We were collecting about

200 points, in difficult conditions.”

Because of uncertainty about cell phone use and the

state of NYSNET, the NYSDOT continuously operated

reference station (CORS) system, GdB brought every

receiver in its shop out to Ocean Parkway. “We were

prepared to set up a base station, if needed,” Gay-

ron explains. “But during the project, we were able

to use a combination of cell phones and radios to

get NYSNET data, and we were able to do this work

as accurately as we could have pre-Sandy. Getting

around was hard sometimes, but getting the preci-

sion we needed wasn’t.” An added complication was

that midway through the project, the NYSNET sta-

tion coordinates were updated. But even that went

smoothly; GdB is an all Leica Geosystems office and

used Leica Geo Office to update the GNSS data from

the Leica GS15 and System 500 receivers with the

changed coordinates. Surveyors were able to make

the mid-project conversion without a hitch.

Crews worked east and west from Gilgo Beach,

near the center of the most damaged area. Work-

ing 10-hour days, the crews made good progress.

“We were able to survey 92 out of the 100 control

points we were assigned,” says Gayron. “The eight

we didn’t get to were on marsh islands that were

inaccessible due to Sandy. We also helped out NYS-

DOT by uncovering or resetting a lot of the targets

they’d been setting.”

In two long weekend shifts and some office time

on Monday, data was collected, post-processed,

checked for quality and delivered to NYSDOT less

than 72 hours after the initial call. In addition to

assessing damage and planning repairs, the data is

also being used to calculate the volume of sediment

moved by Sandy.

Several smaller, but still urgent, projects kept GdB

busy in the weeks following. For example, the village

of Saltaire’s surveyor John Mayer, LS, wanted GdB to

A Leica Viva TS15 is used to survey Udalls Pond in Nassau County to determine the sedimentation effects of Sandy.

The Global Magazine of Leica Geosystems | 23

the bridge. In some areas, GdB was forced to use

a “custom pond-crossing gadget,” which is essen-

tially a sled with a Leica Geosystems prism attached;

crews towed the sled across areas of thick mud to

capture profiles of surfaces that defied walking and

boating. Using these methods, GdB was able to show

that sediment hadn’t returned to dredged areas, and

around the bridge (desirable) sediment buildup had

actually increased. “It was nice to deliver some good

news for a change,” says Gayron.

This article is adapted from the original issue pub-

lished in POB Magazine March 2013.

About the author:

Angus W. Stocking, L.S., is a licensed land surveyor

who now writes full time on infrastructure topics.

find the village’s missing sand. Saltaire is a village on

Fire Island, another of Long Island’s barrier islands,

and it’s one of the few Long Island communities that

can only be reached by boat or on foot. Sandy wiped

out dunes that the village depends on to protect

residential areas from tides and erosion, so a beach

section survey was needed to find areas where sand

could be removed for dune reconstruction. By law,

sand can only be repositioned if it’s above a defined

elevation. Sand is so important to Saltaire that the

mayor got involved and even made a site visit. But

the mayor didn’t like what the survey said. “We had

to tell him, ‘No sand’,” says Gayron. “Sandy washed

it all away.”

Nassau County also called, worried about their mud.

“We’ve been doing pre-dredge and post-dredge sur-

veying for the county since 2008,” Gayron explains,

“monitoring sediment buildup in the pond and near

a bridge. Basically, they were wondering if four years

of work had been undone.”

The “pond” is Udall’s Pond, a 230-acre, tidally influ-

enced wetland area. It’s muddy, but most of the

hydrographic work can be done with a boat or from

24 | Reporter 69

Manual Work Means Top QualityEvery detail counts. With this in mind, Leica

Geosystems develop instruments and fastidi-

ously design complementary accessories, such

as prisms, for these instruments. Gerhard Söns-

er, product manager for original accessories,

explains the steps required to manufacture a

360° prism, such as the Leica GRZ4 and GRZ122,

and how an original Leica Geosystems accessory

differs from a third-party prism.

Who manufactures the prism?

Gerhard Sönser: The Leica GRZ4 and GRZ122 are

produced by our strategic partner, SwissOptic AG, in

Heerbrugg, Switzerland. SwissOptic is a former Leica

optics producer located on our premises in Heer-

brugg and has been part of the Berliner Glas Group

since 2004.

How can a piece of glass, even one which is

admittedly precision-ground, be comparatively

cost-intensive?

It's hard to believe it when you see the finished

product, but there are about 90 steps involved in

manufacturing this product, and most of them are

done manually. At the beginning is a block of glass.

It is optical glass and must be absolutely stress-free,

which is why the molten product has to cool over a

period of weeks or even months.

The Global Magazine of Leica Geosystems | 25

>>

About 90 processes are required to make a 360°

prism ready for sale. What are the most critical

aspects? What is the relationship between

production and inspection/testing of the quality

of the intermediate steps and the end product?

The most critical aspects are definitely the manu-

facturing of the glass, the coating and the bond-

ing process. The entire process to make a finished

prism takes 5 to 6 months if the block of glass used

for processing is already available. Naturally, CNC

technology is also used in modern optics produc-

tion. However, highly precise manual work is often

required before the parts can be made with such

machines. All quality testing is done by hand as well.

Thus the great majority of work is still manual.

If a single element is damaged, can it

be repaired? If so, is the cost justified?

The prism is a bonded block. You would have to dis-

assemble the entire prism, and then it wouldn't be

possible to reuse it. Each 360° prism is unique, which

is why it isn't possible to swap out individual prisms.

How do you test final quality and

environmental specifications?

All original accessory parts are subject to stringent

quality requirements, from reflector poles, tribrachs

and batteries to the carriers and even the tripods.

For example, the 360° prism is tested by knocking

over the pole from a height of 2 m (6.6 ft). A variety

of endurance tests under climatic conditions from

– 40 °C to + 70 °C and high humidity must also be

passed before it can be put on the market. In addi-

tion to precision, environmental compatibility must

also be tested. All accessories are subject to quality

testing on a regular basis.

Speaking of original accessories: In many sec-

tors they're considered too expensive and third

party products are thought to be just as good.

How would you convince people otherwise?

Our accessories are optimally matched to our instru-

ments. Naturally, we also test accessories from oth-

er manufacturers. So-called Leica-like, Leica-type or

Leica-lookalike products look deceptively similar to

the original accessory, but fall far short of meeting

our quality requirements. Customers often purchase

such products thinking they are original accessories.

If they end up being defective or if the results aren't

right, they bring them in to our service centers. Ini-

tially this puts our products in a bad light. Then they

A 360° prism starts life as a glass cube with an

edge length of 45 mm (1.8 in). How is this cube

made, and how exactly is it ground?

Cubes are ground from a block of glass. All six

sides are then ground with an angular accuracy of

less than 8", lapped (smoothed by machining) and

then polished. The precision of the evenness is in

the two-digit nanometer range after polishing. To

achieve this, each of the prisms must undergo opti-

cal contact blocking. Four triangular pyramids of the

same size are then ground from the cube. To be able

to polish the entry and exit faces, the prisms must

undergo optical contact bonding again. This achieves

an angular accuracy of 2"!

After every step, the various specifications are

checked using a host of different measuring instru-

ments, e.g. an interferometer, which is essential. This

high degree of precision is especially important so

that the signal returns to the Total Station receiver

even over long distances. Operational range in track-

ing mode is up to 800 m (2,600 ft). An angular error

in the prism of 1’ corresponds to a 1 cm (0.4 in) signal

offset at 1,000 m (3,300 ft).

What does optical contact blocking mean?

It's a procedure whereby the prisms are set firm-

ly in place on a device by hand, where the attach-

ment occurs purely through natural adhesive force. It

cannot be done by machines, as it requires a highly

developed sense of touch, competency and experi-

ence. To retain this special knowledge, SwissOptic

invest greatly in training junior employees.

How are the six individual prisms united to

form a complete prism?

The six individual prisms are bonded to one anoth-

er very precisely using special bonding devices. The

entire process takes 2 weeks, whereby the harden-

ing process takes the most time.

The finished prism is a golden-brown color.

Is there a technical reason for this?

The color is a result of the copper coating. We use

copper because it is optimally attuned to the wave

length of our instruments. The coating itself is com-

prised of an adhesive layer, the copper layer and

then a top layer. This arrangement makes the prism

highly resistant to environmental influences. The

coating must be applied in a clean room in a vacuum

and under specific climatic conditions.

26 | Reporter 69

realize they have nothing but a cheap copy of the

real thing. Incidentally, we hold the patent for the

360° prism.

What do you do to protect yourselves from oth-

er companies making copies of your products?

We take this issue very seriously, both for our sake

and that of our customers, and are currently working

on measures to make all our accessories unique and

easier to identify.

Where can customers find out which

accessories are right for their needs?

We have a dedicated website for accessories:

accessories.leica-geosystems.com. You will find all

relevant information there, including white papers on

the comprehensive testing we've done and recom-

mendations derived from them. Naturally, customers

also receive expert advice at our sales and distribu-

tion offices around the globe.

Thank you for the detailed information, Mr. Sönser!

The original version of this interview between Gerhard

Sönser and the VDV editor-in-chief Rolf Bull appeared

in the June issue of the German VDVmagazin, 3/13.

Who is SwissOptic AG?

SwissOptic AG is recognized worldwide as a provid-

er of quality and highest precision in the world of

optics. Former Leica optics producers, they became

independent in 1997 and have been part of the Ber-

liner Glas Group since 2004. The company develops

and produces a wide range of precise optical and

optoelectronic components, modules and systems.

SwissOptic is a competent partner along the entire

process chain, from design to series production.

SwissOptic is located on the Leica Geosystems AG

premises in Heerbrugg, Switzerland.

www.swissoptic.com

>>

The Global Magazine of Leica Geosystems | 27

by Nicolette Tapper and Dr. Brendon Lilly

Global Navigation Satellite Systems (GNSS) rev-

olutionized the world of measurement by pro-

viding accurate positioning signals, available

for commercial and public use. Mining sites are

reliant on these GNSS signals, particularly when

maintaining a consistent level of operational

output. Obstruction of these signals results in

drop out areas, or “black spots” which cause

mining machinery to park up and stop work.

In 2005, Leica Geosystems Mining and Locata

Corporation began a partnership. The goal was

to achieve zero-mark up on all high precision

equipment by resolving the loss of GNSS sig-

nals in deep pit mines. The same level of accu-

racy as GNSS was required, but with greater

reliability.

Drop outs commonly occur in the bottom of pits

due to the height of high walls. This is due to GNSS

signals not reaching machinery receivers which high

precision guidance systems rely on for reliable posi-

tioning. This directly affects productivity, and in

A New Constellation for Gold

Leica Jps installed at the edge of NBG's North Pit.

28 | Reporter 69

worse cases, intermittently stops mining production.

Additionally, safety is a concern when surveyors are

required on site to provide back up when GNSS fails

to deliver.

Therefore, Locata Corporation created a radio loca-

tion technology that replicated GNSS satellites on

the ground. Leveraging a history of innovative mea-

surement solutions, Leica Geosystems combined

Locata’s ground breaking radio-location technology

with GNSS to develop the Leica Jigsaw Positioning

System Jps.

”We have been working closely with Leica Geosys-

tems to develop the Jigsaw Positioning System, which

is powered by Locata technology and is a part of

the Leica Jigsaw product suite. Locata, across the

open pit mine area, is ensuring that Jps customers

have solid, operational cm-level positioning which is

independent of GNSS,” says Nunzio Gambale, Chief

Executive Officer and founder, Locata Corporation.

Leica Jps includes self-surveying Jps LocataLites™

that each act like a GNSS satellite, but on the ground.

These Jps LocataLites™ are portable and can be

placed around the edge of a pit. They work with high-

ly integrated RTK GNSS+Locata Jps Receivers which

are placed onto the mine machinery. The Jps receiv-

ers use the LocataLites™ as another constellation in

addition to the GNSS satellites. This network – Leica

Jps – provides consistent RTK accurate positioning to

the high precision guidance systems. Leica Jps seam-

lessly augments the GNSS and Locata signals with no

interruption to machine operation.

“Through this partnership the Jigsaw Positioning

System will continue to meet and exceed industry

expectations. We are truly providing a new capabil-

ity for mining applications, enabling them to oper-

ate with unprecedented signal up time and bene-

fit from the huge associated financial return. And

we know it works – we have the data,“ says Haydn

Roberts, Chief Executive Officer, Leica Geosystems

Mining. Initial beta testing of the fledgling system

was conducted at DeBeers Venetia mine in South

Africa. The results gathered from DeBeers provid-

ed substantial data for Newmont Boddington Gold

(NBG), Western Australia to initiate a working part-

nership with Leica Geosystems and Locata Corpo-

ration. All parties recognized the need to achieve

a reliable positioning system across NBG’s high-

precision fleet, in their ever deepening pits, and Jps

was the solution. NBG are no strangers to highly

integrated mining solutions: in 2006 NBG incorpo-

rated Leica Geosystems High Precision systems into

their drilling operations. “Newmont’s association

with Locata and Leica Jps evolved from a need to

achieve reliable and consistent GNSS coverage across

its high-precision fleet, something that we now

know from experience to be an idealistic but near-

impossible dream,” said John Carr, Senior Technical

Specialist, NBG.

In March 2012, field tests concluded that Leica Jps

provided not only immediate improvement in posi-

tioning signals but additionally, increased overall

mining production and performance. “Under the

specter of the current global economic environment,

it is paramount for miners to maximize the efficien-

cy of their operations,” explained John Carr, Senior

Technical Specialist, NBG.

Today, NBG have deployed Leica Jps over two pits,

north and south, and fitted most of their high preci-

sion fleet with Jps receivers.

Mining operations at NBG North Pit utilzing Leica Jps.

The Global Magazine of Leica Geosystems | 29

remaining high-precision fleet of shovels and excava-

tors with Jps,” said Brendon Lilly. “Leica Geosystems

Mining and Locata Corporation with the assistance

of Newmont Boddington Gold have made the impos-

sible, possible. Leica Jps is a proven true alternative

to GNSS. Boddington have achieved their zero-mark-

up goal for their blast hole drills and are now looking

to implement this for their digging equipment, all

because of Leica Jps,“ he concludes.

About the authors:

Nicolette Tapper is Marketing & Communications

Coordinator and Dr. Brendon Lilly is Product Manager

for the Mining division at Leica Geosystems Pty Ltd

located in Brisbane, Australia.

The results are clear. Examined over a two month

period, the availability of GNSS was reasonably

good at 92.3 %. However, Jps reported an impres-

sive 98.8 % signal availability that equated to a 6.5 %

increase in operational productivity. Specifically in

the North Pit, where the GNSS coverage is inherently

poor, results showed GNSS at 75.3 % in comparison

to Jps at 98.7 %, a significant 23.4 % improvement.

The cost savings are significant. Two drills over a

two month period reporting an increase of 6.5 % in

coverage equates to 112.7 hours of additional guid-

ance. The cost downtime for a high precision drill

(due to no signal availability) is about AUD$ 1,000 per

hour, applying the additional coverage of 112.7 hours

results in AUD$ 112,700 of savings for two drills over

two months. These operational cost savings for a

mine dramatically boost the bottom line.

“Newmont Boddington Gold is so happy with the

results that they have turned off their GNSS-only

solutions altogether, and now rely solely and success-

fully on Leica Jps alone. They have already installed

Jps on all their drills and have started to equip the

30 | Reporter 69

– when it has to be right For the third consecutive “– when it has to be

right” contest, Leica Geosystems again asked

customers to post exciting application images

with Leica Geosystems instruments on the Face-

book page and to vote for their favorite. Here

is a random selection of numerous submitted

photographs. We would like to thank all par-

ticipants who made this contest such a great

success again!

www.facebook.com/LeicaGeosystems

Leica Nova MS50 Make the right decision

Leica Nova MS50 – World`s First MultiStation

You only get a moment to make the right decision. So ultimate performance

and absolute reliability are critical. Our new Leica Nova MS50 MultiStation

combines total station, imaging and scanning technologies together to

create a unique solution that covers the complete workflow process from

capturing and visualising to deciding, acting on and delivering.

Leica Nova: a whole new dimension in measuring technology

www.leica-geosystems.com/nova

Illustrations, descriptions, and technical data are not binding. All rights reserved. Printed in Switzerland. Copyright Leica Geosystems AG, Heerbrugg, Switzerland, 2013. 741802en – 09.13 – RVA

Leica Geosystems AGHeinrich-Wild-StrasseCH-9435 HeerbruggPhone +41 71 727 31 31Fax +41 71 727 46 74www.leica-geosystems.com