The Elastic Limit of Metals Exposed to Tri-Axial Stress

-

Upload

gilbert-cook -

Category

Documents

-

view

213 -

download

1

Transcript of The Elastic Limit of Metals Exposed to Tri-Axial Stress

The Elastic Limit of Metals Exposed to Tri-Axial StressAuthor(s): Gilbert CookSource: Proceedings of the Royal Society of London. Series A, Containing Papers of aMathematical and Physical Character, Vol. 137, No. 833 (Sep. 1, 1932), pp. 559-574Published by: The Royal SocietyStable URL: http://www.jstor.org/stable/96029 .

Accessed: 03/05/2014 20:00

Your use of the JSTOR archive indicates your acceptance of the Terms & Conditions of Use, available at .http://www.jstor.org/page/info/about/policies/terms.jsp

.JSTOR is a not-for-profit service that helps scholars, researchers, and students discover, use, and build upon a wide range ofcontent in a trusted digital archive. We use information technology and tools to increase productivity and facilitate new formsof scholarship. For more information about JSTOR, please contact [email protected].

.

The Royal Society is collaborating with JSTOR to digitize, preserve and extend access to Proceedings of theRoyal Society of London. Series A, Containing Papers of a Mathematical and Physical Character.

http://www.jstor.org

This content downloaded from 130.132.123.28 on Sat, 3 May 2014 20:00:23 PMAll use subject to JSTOR Terms and Conditions

559

The Elastic Limit of Metals Exposed to Tri-Axial Stress.

By GILBERT COOK, D.Sc.

(Communicated by E. V. Appleton, F.R.S.-Received April 22, 1932.)

? 1. Introduction. The numerous investigations which have been carried out since the opening

of the present century into the elastic breakdown of metals have resulted in the formulation of several hypotheses concerning the conditions of stress and strain necessary for its occurrence. The methods generally employed in the investigations have consisted in the application of combinations of tension and compression with torsion, and of bending with torsion, to solid bars and thin tubes, and of tension and compression combined with internal and external pressure to thin tubes; so that the stress system produced in the metal was essentially bi-axial in character, the third principal stress being either very small or zero. The results of these experiments have given general support to the shear stress hypothesis of Guest,* although with deviations which in some cases are not insignificant.

Experiments employing a tri-axial stress system, in which the relation to each other of the component stresses could be varied, have been comparatively few in number. Tests by Turnert on thick walled cylinders of mild steel exposed simultaneously to internal pressure and axial tension, were inconclusive, possibly owing to the irregularity of the tubes. Those by Cook and Robert- son4 also on thick-walled tubes of varying dimensions, showed a reasonably constant value of the maximum shear stress at the instant of elastic breakdown at the internal surface; this stress was, however, considerably higher than the shear stress observed in the uni-axial state of stress in a simple tensile test of the same material, a result confirmed in more recent tests of a similar kind by the author.? The newer hypotheses of Haighll and of von Mises? requite an effect of this kind; but it has been suggested by the aulthor that the observed effect may nevertheless be associated more directly with the non-uniform character of the stress distribution, rather than as an indication of the

* 'Phil. Mag.,' vol. 50, p. 69 (1900). t 'Engineeg,' vol. 92, p. 115 (1911). 1 ' Engineering,' vol. 92, p. 786 (1911). ? I Phil. Trans.,' A, vol. 230, p. 103 (1931). l} Haigh, 4 Rept. Brit. Assn.,' p. 486 (1919), and p. 324 (1921). ? von Mises, 'Nachr. Ges. Wise. G6ttingen,' p. 582 (1913).

This content downloaded from 130.132.123.28 on Sat, 3 May 2014 20:00:23 PMAll use subject to JSTOR Terms and Conditions

560 G. Cook.

inapplicability of the hypothesis which regards failure as due to the existence of a critical value of the shear stress.

The investigation described in the present paper is a further attempt to ascertain more definitely which of these three hypotheses most closely repre- sents the conditions at the elastic limit in certain metals when exposed to a tri-axial stress system. If pO, p,, p, are the principal stresses, then according to the Guest hypothesis of constant shear stress at least one of the equations

P -PY 4fs Pv- Pz A= f Po-p fx = (1) must hold, f being a constant equal to the stress at the elastic limit in a uni- axial system. The Haigh hypothesis of constant strain energy is represented by the equation

p 2 + pv 2 + p2 - 2a (pypz + pp. + pxpy) =f2, (2)

where a is Poisson's ratio, while the relation proposed by von Mises is

(P?C- 8)I + (pt - pz)2 + (pz - px)2 -- 2f2, (3) which, as shown by Hencky,* is also the condition of constant energy of shear strain.

Regarding the principal stresses as co-ordinates, the surfaces represented by the above equations have been discussed in detail by iaigh (loc. cit.), Westergaard,t and Schleicher.t Equations (1) and (3) represent the surface of a hexagonal prism and its circumscribing cylinder respectively, both extend- ing indefinitely in the axial direction, which is equally inclined to the positive directions of the co-ordinate axes. Equation (2) is that of a prolate spheroid whose major axis also lies in this direction.

It will thus be seen that the hypotheses of Guest and of von Mises, as distinct from that of Haigh, require that the liability of a material to elastic breakdown under a given stress system should not be affected by the addition of a fluid stress. On the other hand, variations in the value of the intermediate principal stress will be without effect on the conditions of failure only if the Guest hypothesis is valid. The two lines of attack thus suggested are described in ? 2 and ? 3 below.

? 2. The Effect of Fluid Stress on the Elastic Limit.

There is little definite knowledge available as to the behaviour of materials under fluid tensile stress. No method of imposing this kind of stress in any

* ' Z. angew. Math. Mech.,' vol. 4, p. 323 (1924). t ' Franklin Inst.,' vol. 189, p. 627 (1920). i 'Z. angew. Math. Mech.,' vol. 6, p. 199 (1926).

This content downloaded from 130.132.123.28 on Sat, 3 May 2014 20:00:23 PMAll use subject to JSTOR Terms and Conditions

Elastic Limit of Metals. 561

considerable intensity and in such a manner that it can be measured even approximately has been discovered; and although there is reason to believe that such states of stress exist under particular circumstances, and give rise to brittle fractures in otherwise ductile materials, little is known as to the intensity of stress which produces such fractures. It is probably very high compared with the elastic limit in uni-axial tension.

The available knowledge regarding the effect of high fluid compressive stress on metals is chiefly due to the researches of Bridgman. The general conclusion to be drawn from them is that the application of a pure hydrostatic pressuxe, even of extreme intensity, produces no permanent change in the metal It is, of course, inconceivable that plastic flow would occur in an isotropic material under simple fluid stress, either tensile or compressive. It does not, however, necessarily follow from the absence of an observed permanent effect that a critical state is not reached during the application of the fluid stress which might make possible a permanent change of shape under the action of a dis- torting stress which, applied alone, would be within the elastic limit. In this connection an observation made by Bridgman* in an investigation of the effect of pressure on the rigidity of metals is of interest. A number of metals in the form of helical springs were exposed to torsional stress simultaneously with hydrostatic pressure up to 12,000 atmospheres. With one exception, all the metals tested had high elastic limits, and no permanent change in the dimensions of the springs made from these metals could be detected. The exception was that of the metal palladium, whose elastic limit was rather low. As no numerical data are given by Bridgman for this case, his own remarks upon it may be quoted:-" The original spring" . . . [as extended] "was not far from its elastic limit, and under pressure there was an effect which amounted to an increase of set or lowering of the elastic limit. .

After the termination of the experiment " [involving applications of pressure up to 12,000 atmospheres] " the palladium spring was found to have received considerable permanent elongation. The effect of pressure on the elastic limit has apparently never been determined; what we have here is virtually a qualitative observation that the limit is lowered by pressure, an unexpected result."

It seemed important, therefore, to the author that a critical test on this point should be performed, a metal of sufficiently low elastic limit being used so that a fluid pressure many times greater than the shear stress at the elastic

* ' Proc. Amer. Acad. Arts Sci.,' vol. 64, p. 39 (1929).

VOL. CXXXVII.-A.

This content downloaded from 130.132.123.28 on Sat, 3 May 2014 20:00:23 PMAll use subject to JSTOR Terms and Conditions

562 G. Cook.

limit could be imposed. The method adopted was similar to that employed by Bridgman. The material chosen was soft iron wire 0 * 0275 inch in diameter. It was coiled into the form of a helical tension spring of about 25 coils having a mean diameter of 0*560 inch, and was then annealed in a vacuum furnace. Reference marks were made on the spring in two pairs separated by 17 coils, each mark of a pair being at opposite ends of a diameter. By this means the axial extension while under load in the atmosphere, and any permanent set which occurred, could be measured by observation through the telescope of a cathetometer.

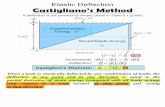

The spring was first extended by successive loads at atmospheric pressure in order to determine the position of the elastic limit. The observations are given in Table I, and the load-extension curve in fig. 1.

Table I.

Mean distance Total load. between reference Extension.

marks.

lb. mM. mm. Zero 48-38

0 054 56-21 7-83 0*104 63v37 14*99 0114 64*84 16*46 0124 66-43 18'05 0 134 68-31 19-93

It will be seen that there is a fairly well defined elastic limit at a load of 0 * 114 lb., corresponding to a maximum shear stress in the wire of 3*5 tons per square inch. The spring was now re-annealed, and a load of 0 104 lb., slightly below that corresponding to the elastic limit as determined above, was applied and removed as described in part (i), Table II. The small permanent set produced by the first two applications of this load is seen to remain unaltered after a further 48 hours' continuous application of the same load; thus, although the material is exposed to a stress little less than that wbich would cause considerable plastic flow, it appears to be quite stable.

The spring was now suspended vertically in a pressure vessel, fig. 2, consisting of a thick-walled tube of high tensile steel, filled with glycerine. A load equivalent to that previously imposed, 0 104 lb., was suspended from the spring, due allowance being made for the density of the glycerine. The pressure was raised to 21 5 tons per square inch by means of an intensifier, and was allowed to remain at this figure for a period of 48 hours. The spring

This content downloaded from 130.132.123.28 on Sat, 3 May 2014 20:00:23 PMAll use subject to JSTOR Terms and Conditions

Elastic Limit of Metals. 563

was then removed from the apparatus, particular care being taken to avoid imposing any strain upon it in doing so. A measurement on the unloaded

01i4

0'12

0.10

9N 006/

0-02

1 2CM. J Extension

FIG. 1.

Table lI

Load applied and removed. Mean distance Permanent extension. Duration between

of reference marks Axial Fluid app:lication. after removal Total Per- load. pressure. of load. cenrtage.

(i) lb. tons/sq. in. hours mm. mM. - - - 50'81 -

0104 2 051*08 *27 0.54 0-104 - 16 51*13 0*32 0.64 0-104 _ 48 51-13 0'32 0'64

0)104 21-5 48 51.03 0-22 J 0.44 2 p 2

This content downloaded from 130.132.123.28 on Sat, 3 May 2014 20:00:23 PMAll use subject to JSTOR Terms and Conditions

564 G. Cook.

spring now gave the figures shown in part (ii), Table II. The small per- manent extension previously observed has apparently been diminished slightly,

but it is considered that the difference is prob- ably due to the unavoidable handling of the spring in placing it in, and withdrawing it from, the pressure apparatus. It is, in any case, in the opposite direction to that which would be found if the elastic limit were lowered by the application of the fluid pressure. It will be noted that the fluid pressure imposed in this test was more than six times as great as the shear stress at the elastic limit observed under atmospheric conditions; and the absence of any appreciable effect due to its application justifies the conclusion that the addition of such pressure does not increase the liability of this material to elastic breakdown. Although it cannot with certainty be inferred that other ductile materials would behave in a similar manner, it seems highly probable that the effect observed by Bridgman in -the case of palladium is due to some other cause.

? 3. Effect of Variations in the Magnitude of the Intermediate Principal Stress.

If the conclusion is accepted that the position of the elastic limit is independent of the intensity

__j + of the fluid stress, it follows that stress differ- ences alone will be found in the expression of any theory which can be applicable. The shear stress theory of Guest, and the shear strain energy theory of von Mises-Hencky comply with this condition. The question as to which of these two hypotheses is preferable may be ex- amined by observing whether the maximum shear stress, or, what is equivalent, the differ-

FIG#. 2. ence between the extreme principal stresses, prevailing in the material at the elastic limit, is affected by the value of

This content downloaded from 130.132.123.28 on Sat, 3 May 2014 20:00:23 PMAll use subject to JSTOR Terms and Conditions

Elastic Limit of Metals. 565

the intermediate principal stress. This has been the method used in recent investigations where, however, the enquiry has been confined to the conditions necessary to set up and maintain a condition of plasticity in material which. has already received a considerable amount of plastic deformation. The work of Lode* on thin tubes of iron, nickel, and copper exposed to combinations of internal pressure and longitudinal tension; of Hohenemsert on thin steel tubes subjected to combined tension and torsion, and particularly the recent work of Taylor and Quinneyl on tubes of copper, aluminium and iron, have shown that the onset of plastic flow under such conditions is undoubtedly affected by the value of the intermediate principal stress, and to an extent, moreover, which is in good agreement with the hypothesis of constant energy of shear strain. The experiments to be described in this section were undertaken in order to discover whether a similar effect was observable in regard to the elastic limit in previously unstrained materials.

The case of compound stress chosen for this study was that which exists at the inner surface of a thick-walled cylinder exposed simultaneously to internal pressure and longitudinal tension. In a cylinder in which the longitudinal stress is due solely to the internal pressure, the principal stresses at a point in the inner surface are, from the well-known theory

_ 1 )

=z k2+1 + I Pv =Pk2+ (4)

Pz=P J

where p is the numerical value of the internal fluid pressure, and k the ratio of external to internal diameter. In this the axis of x is taken parallel to the axis of the cylinder, and those of y and z in the tangential and radial directions respectively, tensile stresses being positive. The relative values of p, and pz may be varied over a considerable range by varying k, but px, although depen- dent also on k, is comparatively small except in very thin tubes. It may, however, be varied independently of p, and Pz, by applying an additional axial load, and it is the intermediate principal stress so long as the additional axial stress is less thanp . k2/(k2 -1). By choosing a suitable value for k we may

* ' Ver. deuts. Ing. Forschrft.,' vol. 303 (1928). t ' Z. angew. Math. Mech.,' vol. 11, p. 15 (1931). : 'Phil. Trans.,' A, vol. 230, p. 323 (1931).

This content downloaded from 130.132.123.28 on Sat, 3 May 2014 20:00:23 PMAll use subject to JSTOR Terms and Conditions

566 G. Cook.

-examine by this method the effect of the intermediate stress extending, from a comparatively low value, over a range greater than the internal pressure applied, without altering the disposition of any of the principal stresses.

Two varieties of mild steel, containing 0 * 21 per cent. C and 0 * 35 per cent. C respectively were used in the investigation. These were specially prepared and supplied by Messrs. Thos. Firth & Sons. The analyses are given in Table III.

Table III.-Analysis of Steels.

Reference. C. Si. Mn. S. P. Ni. Cr.

C 021 0109 0165 0018 i o18 0.11 - J 0.35 0-22 0066 00020 0020 046 0.05

A considerable amount of information was available from a previous investigation in regard to the behaviour of the 021 per cent. C steel under other non-uniform stress systems.

Stress-strain diagrams obtained from tests in simple tension on specimens of the same shape and with the same heat treatment as the cylinders, are shown in fig. 5, and it will be seen that no deviation from a linear relation between stress and strain is pereeptible- up to the yield point, which thus coincides with the elastic limit.

The cylinders used in the tests under tri-axial stress were machined to the form shown in fig. 3. It was decided to keep the dimensions the same in all

;~~~~~~~~~~ 4 se

I pctrua/el I cYrad

FIG. 3.

cases, so that no variation in the ratio of the transverse principal stresses would occur. The external diameter of the central parallel portion was made twice the internal diameter, and this portion was connected to the screwed ends by fillets of large radius to avoid concentrations of stress due to the axial load. The specimens were carefully machined internally and externally and were then heat treated in vacuo to remove initial stresses. The temperatures employed were 900? C. for the 0 21 per cent. C steel, and 8700 C. for the 0 35

This content downloaded from 130.132.123.28 on Sat, 3 May 2014 20:00:23 PMAll use subject to JSTOR Terms and Conditions

Elastic Limit of Metals. 567

per cent. C steel, the specimens being allowed to remain for 20 minutes at this temperature. The specimens of 0 21 per cent. C steel were allowed to cool in the furnace, as it was desired + to compare the results of the tests applied to this material with others in which the same heat treat- ment had been given, while those of 0 35 per cent. steel were removed from the furnace to cool by radia- tion in vacuo.

The method used for applying the combination of fluid pressure and axial stress is shown in fig. 4. The longitudinal telnsion, applied through axial loading grips of the ball type from a special straining gear, is I measured by the elastic extension, as recorded by a mirror extensometer, of a weigh bar A of high tensile steel cou.pled in series with the specimen B. Fluid pressure was transmitted to the interior of the test piece through a fine bore steel tube C from an intensi- fier and was measured by means of a steel tube Bourdon ga.uge with jewelled bearings reading to 20 tons per square inch, and graduated in divisions of B 041 ton per square inch. The gauge was calibrated against a dead weight tester at the makers' works in the presence of the author.

In order to observe the strains produced in the specimen two extensometers were used. The radial - extension of the external surface was measured by means of a Lamb diametral extensometer,* and for the axial extension a mirror extensometer embodying the Martens principle was employed. The purpose of both extensometers was to indicate when any de- I

parture occurred from a linear relation between the strains and applied stresses, and it was unnecessary therefore to convert scale readings into actual strains. I | |

The method generally employed in carrying out a test was first to strain the cylinder axially to a stress

F such as, with the addition of the stress due to the FIG. 4. estimated internal pressure, would give approximately a predetermined

* For a description of this extensometer, see 'Engineering,' vol. 119, p. 207 (1925).

This content downloaded from 130.132.123.28 on Sat, 3 May 2014 20:00:23 PMAll use subject to JSTOR Terms and Conditions

568 G. Cook.

value of the total axial stress. The fluid pressure was now raised, and readings on both extensometers attached to the specimen, and also on that on the weigh bar, were taken, the intervals being reduced to 0 - or O 05 ton per square inch as the point of breakdown was approached. As the pressure was raised the extensions, both radial and axial, were almost exactly proportional to the increase in pressure. A period of at least 1 minute was allowed to elapse

28 _ _ _ _

24

o J5C. Stee1l 209

t I2 -- -

__ _

.

12 ~ ~ _

4 _ 1 __e

FIG. 5. Strain

at each value of the pressure during which the extensometers were carefully observed for any sign of creep, or departure from the proportional increment in extension. The elastic limit was marked by a much larger increment in the radial strain than had previously occurred, or in a contraction, both being accompanied by a slow creep.*

* The contraction in diameter frequently observed is not due, as might be supposed, to an increase in the axial strain, but to the initial localisation. of the breakdown causing the external surface to become slightly elliptical. The effect has been discussed in detail elsewhere by the author (loc. cit.).

This content downloaded from 130.132.123.28 on Sat, 3 May 2014 20:00:23 PMAll use subject to JSTOR Terms and Conditions

Elastic Limit of Metals. 569

In an investigation of this nature it is desirable to obtain as large a number of test results as possible, and for this purpose one or other of the following courses may be adopted

(1) A considerable number of specimens may be used, and a single test only carried out on each specimen. Where a large amount of machining is required, as in the present case, this method is expensive, and there is also the possibility of variations in properties from specimen to specimen due to variations in composition. It is, however, probably the best method, and was employed for the tests of the 0 35 per cent. C steel, but it was not possible, owing to the cost, to use a large number of specimens.

(2) By immediately relieving the pressure on the first sign of elastic break- down the amount of overstrained material would be small and probably localised in a small area. A second test would produce breakdown at another point, and in this way the same specimen could be used for a number of tests with different amounts of axial stress. This method was employed for the 0 21 per cent. C steel. It is not altogether free from objection, but repeat tests under the same conditions show that the eflects of previous tests are inappreciable.

(3) The specimens may be renormalised or re-annealed after each test. This method was, however, not used owing to the possibility of structural changes following the process when repeated many times.

Fig. 6 shows the character of the stress strain diagrams. The ordinates represent the internal pressure, while the abscissse represent, to an arbitrary scale, the radial extension. The whole of the diagrams for the tests with 0 35 per cent. C steel are shown, but for reasons of space the series for one specimen only (No. 4) of the 0 * 21 per cent. C steel is given.

The numerical results are contained in Tables IV and V. The radial and tangential principal stresses are obtained from the second and third of equations (4), while the axial principal stress is given by the equation

where p,0 is the externally applied axial stress as measured by the weigh bar. In order more readily to see the effect of variations in the intermediate principal stress, the tests are tabulated in order of increasing axial stress. The

This content downloaded from 130.132.123.28 on Sat, 3 May 2014 20:00:23 PMAll use subject to JSTOR Terms and Conditions

570 G. Cook.

O35%C Steel 12 - -_

0~~~~~~~~~~~~~~~~~ t2v Cstee-'r-l

10 _ . /I - --t - l l -- k7~~ ~ I I_ I! _22C38

$ ~~~~~~~~ ~ ~~ ~~9 t._

7X 3 5 ___No6

specimen T 2 est

s4 t '-AI IX __ I_ KI I/X7-~/It;-l z I

21 it--/ I__ / 4//S Radial Extension

FIG. 6.

Table TV.-Tests on 0 35 per cent. C Steel Cylinders. Elastic Limit and Yield-point in Simple Tension,f = 27 9 tons per square inch.

Ratio, external to internal diameter, 2: 1. Principal stresses at Equivalent uni-axial

Spedi-I elastic limit. stress for same value of men No. Maximum Maximum fs/f. fe/f.

Axial Tangential Radial shear shear i (p ). (Pr). (pz)- stress energy

l l l l fs). | -(fe).

tons/sq. in.1 tons/sq. in. tons/sq. in. tons/sq. in. tons/sq. in. 1 4*00 19'90 -11*95 31-85 27 60 11140 0990 8 4 40 19-30 -11-60 30 90 26.75 1'105 0-960 2 8*90 19-50 -11-70 31*20 27 45 1-115 0-982 9 14.05 1 19-40 -11-65 31-05 28.75 1-110 1-030 4 17 80 1 19-30 -11*60 30 90 30 10 11105 1-075 7 19-00 19*00 -11-40 109 090 3 20-20 18 33 -11 00 31-20 30 30 11115 1-085 5 24-05 12-00 - 7*20 31*25 27-30 1 120 0-975 6 27-95 0 0 27 95 27 95 - -

Mean .... ......... .....1........ .......... 1 112 1-023 Maximum variation (per cent.) .......................................... 4.5 13-0 M ean variation from mean (per cent.) ............................... ..................|. 1 0 4.6

This content downloaded from 130.132.123.28 on Sat, 3 May 2014 20:00:23 PMAll use subject to JSTOR Terms and Conditions

Elastic Limit of Metals. 571

Table V.-Tests on 0 21 per cent. C Steel Cylinders. Elastic Limit and Yield-point in Simple Tension,f = 21 6 tons per square inch.

Ratio, external to internal diameter, 2: 1.

Principal stresses at Equivalent uni-axial elastic limit. stress for same value of

men Tt aximum Maximum fsef. fe If Axial Tangential Radial shear shr (p$). (Pu). (). ' Stress sn

(fs).~~(e)

tons/sq.in. tons/sq. in. tons/sq. in. tons/sq. in. tons/sq. in. (1) 3-25 14-60 -8.75 23-35 20-20 1.080 0 935 (4) 3 70 14-60 -8.75 23-35 20-20 1l080 0 935

1 (5) 7 70 14-50 -8 70 23-20 20-65 1075 0 955 (3) 13-40 14-50 -8 70 23-20 22 70 1-075 1-052 (2) 15-05 14-00 -8 40 23-45 22 95 1087 1-063 (6) 16-05 14-00 -8-40 24-45 23 50 1'132 1 089

(1) 3 50 14.65 -8-80 23-45 20 30 1-087 0 940 (5) 3 70 14-60 -8.75 23-35 . 20-20 1P080 0 935

2 (3) 10-35 14-50 8*70 23-20 21-40 1-075 0 990 (4) 13-85 14*15 -8-50 22-65 22 50 1 050 1-042 (2) 14-60 13-65 -8*20 22 80 22.40 1-057 1-037

(1) 3*40 14-65 -8-80 23v45 20v35 1 087 0*942 (4) 12 00 14-65 -8-80 23 45 22 25 1 087 1 030

3 (2) 14-40 14-00 -8 40 22-80 22*60 1-057 1-047 (3) 14*65 14*30 -8-60 23-25 23*00 1 078 1-065 (5) 16*60 13 40 -8-05 24-65 23 25 1 140 1 077

(6) 3.55 14-65 -8-80 23-45 20-35 1.087 0 942 (7) 3.95 14-75 -8-85 23-60 20-45 1 092 0-948 (2) 4-55 14-60 -8-75 23-35 20 30 1-080 0 940 (3) 7 05 14 40 -8-65 23-05 20 40 1-069 0'945 (4) 10'10 14-15 -8 50 22-65 20 90 1.050 0 968 (5) 13-05 14 15 -8-50 22-65 22-10 1*050 1 023 (8) 14-25 14-15 -8 50 22-75 22-70 1-054 1.051 (1) 14 55 13'85 -8 30 22 85 22 50 1 060 1 041

(1) 3-60 14-50 -8 70 23-20 20-10 1-075 0.930 5 (2) 9 05 14*40 -8.65 23-05 20*90 1-069 0 968

(3) 14-80 14-00 -8-40 23 20 22*80 1-075 1-057 (4) 18-65 10-20 -6-10 24-75 21-80 1-146 1P010

6 (1) 5 .45 14-50 -8 70 23-20 20.20 1-075 0 935 (2) 21-80 4'85 -2-90 24-70 21-90 1 143 1'014,

Mean ............... ......................................... .. ...................... | 1082 0O997 Maximum variation (per cent.) .......................... .......................................................... 8 9 159 Mean variation from mean (per cent.) .......................... ............5.0...:....... 1 6 5 0

equivalent uni-axial stress, that is, the value of f calculated from the tabu- lated values of the principal stresses by means of equations (1) and (3), and the ratios of this to the stress at the elastic limit observed in the simple tensile test, are given in the last four columns.

This content downloaded from 130.132.123.28 on Sat, 3 May 2014 20:00:23 PMAll use subject to JSTOR Terms and Conditions

572 G. Cook.

The results are also shown graphically in fig. 7. The ratio k being constant throughout the present series makes it possible to represent them on a two- dimensional diagram in which the internal pressure is plotted against the total axial stress. On the same dia-gram are plotted, by means of broken lines,

01_ 5C.Steel

Zo < i L. -V4- _s _

$E~~~~~~ -I X ' 46 C t t '_ l--T-~~~~EktiLmi Elastfi,nli

? 4 8 X2 X~~~~~6 20 24 2 6 3 AxialPncipal Stressp,, (Tons sc,ln)

FIG. 7.w

-- - Constant shear strain energy 1_equal to value observed a,t tensile yield -.-.- Constant shear stress f point.

___- Constant shear stress, equal to mean of observed values.

the theoretical relations according to the two hypotheses, based upon the observed value of the tensile elastic limit; that is to say, the lines are made to pass through the point on the axis of pZ representing that stress. These linles are part of the intersection of the surfaces corresponding to equations (1) and (3) with the planle

r2+rp. (k2+ l)/(k2- 1) =0.

The full line in each case is drawn for a constant value of the shear stress equal to the mean value olbserved in the tests.

This content downloaded from 130.132.123.28 on Sat, 3 May 2014 20:00:23 PMAll use subject to JSTOR Terms and Conditions

Elastic Limtt of Metals. 573

The mean value of the ratio given in the last column in Tables IV and (7 is much closer to unity than that obtained from the figures in the previous column, which might suggest that failure under tri-axial stress is better correlated with that in simple tension on the basis of the hypothesis of con- stant shear strain energy rather than on that of constant shear stress. But it may be observed that the individual variations in value of the ratio from test to test is much less for the shear stress hypothesis than for the shear strain energy hypothesis, and it will be noticed that in the value of the latter ratio there is a progressive variation which is absent from the former. If we exclude those cases in which the axial stress is appreciably greater than the tangential principal stress, the shear stress figures will be seen to be in still closer agreement; and since, under these conditions, the axial stress is the intermediate principal stress, the conclusion appears to be unavoidable that it is without appreciable effect upon the conditions under which the elastic limit is first reached in these materials.

It is interesting to note that the average value of the maximum shear stress observed in the present tests on the 0 21 per cent. (C steel, namely 11 7 tons per square inch, is in close agreemeut with the values 119 tons per square inch and 12-I tons per square inch previously obtained with the same material in torsion and flexure respectively.

The evidence therefore favours the view that as regards the initial elastic breakdown in mild steel, the maximum shear stress is the critical factor; that the Guest hypothesis is true to the extent that, for the same kind of stress distribution, the values of the principal stresses at the elastic limit; are such as to give a constant value of the maximum shear stress. But, further, in this material the critical value of the shear stress depends on the character of the stress distribution, so that the results obtained from the ordinary tensile test, in which the stress distribution is uniform, are not strictly comparable with systems of combined stress where, as is generally the case, the distribution is not uniform.

Summary.

The paper describes an investigation carried out to determine the relation holding between the principal stresses at the elastic limit in certain ductile materials when eiposed to stresses in three dimensions, and to examine the applicability of the hypotheses of constant maximum shear stress (Guest), constant total strain energy (Haigh), and constant energy of shear strain (von Mises-Hencky).

This content downloaded from 130.132.123.28 on Sat, 3 May 2014 20:00:23 PMAll use subject to JSTOR Terms and Conditions

574 Elastic Limit of Metals.

An observation by Bridgman, suspecting an effect upon the elastic limit under distorting,stresses by the superposition of high hydrostatic pressure, was examined by exposing an annealed iron wire to torsional stress (a) at atmospheric pressure, and (b) under hydrostatic pressure of 21-5 tons per square inch. No lowering of the elastic limit was observed, a result which suggests that the Haigh hypothesis does not hold.

To discriminate between the two remaining hypotheses, tests were carried out on thick-walled cylinders of mild steel, exposed to combinations of internal pressure and axial tensile stress. It is shown that variations in the axial stress, provided that it remains the intermediate principal stress, have a negligible effect on the internal pressure required to cause initial failure at the internal surface ; and therefore for the same kind of stress distribution the values of the principal stresses at the elastic limit are such as to give a constant value of the maximuim shear stress.

The author desires to express his indebtedness to Dr. W. H. Hatfield and Messrs. Thos. Firth & Sons, who very kindly prepared and supplied the mild steel used in the tests, and to the Government Grant Committee of the Royal Society for a grant to defray the cost of machining the specimens. The experimental work was carried out in the Engineering Laboratories of King's College, London.

This content downloaded from 130.132.123.28 on Sat, 3 May 2014 20:00:23 PMAll use subject to JSTOR Terms and Conditions