The Digital Michelangelo Project - Computer Graphics · 1999-05-07 · M. Levoy / The Digital...

Transcript of The Digital Michelangelo Project - Computer Graphics · 1999-05-07 · M. Levoy / The Digital...

EUROGRAPHICS ’99 / P. Brunet and R. Scopigno(Guest Editors)

Volume 19, (1999), Number 3

The Digital Michelangelo Project

Marc Levoy

Computer Science Department, Stanford University, USA

EXTENDED ABSTRACT

Introduction

Recent improvements in laser rangefinder technology, to-gether with algorithms developed at Stanford for combiningmultiple range and color images, allow us to reliably and ac-curately digitize the external shape and reflectance of manyphysical objects.

As an application of this technology, I and a team of30 faculty, staff, and students from Stanford University andthe University of Washington spent the 1998-99 academicyear digitizing the sculptures and architecture of Michelan-gelo. During this time, we scanned the David, the Unfin-ished Slaves, and the St. Matthew, all located in the Galleriadell’Accademia in Florence, the four allegorical statues inthe Medici Chapel, also in Florence, and the architecturalsettings of both museums. In the months ahead we will pro-cess the data we have collected to create 3D digital modelsof these works.

The goals of this project are scholarly and educational.Our sponsors are Stanford University, Interval Research Cor-poration, and the Paul G. Allen Foundation for the Arts. Inthis extended abstract and invited talk, I will outline the tech-nological underpinings, logistical challenges, and possibleoutcomes of this project.

Technological underpinings

From a technological standpoint, the Digital MichelangeloProject contains two components: a collection of 3D scan-ners and a suite of software for processing range and colordata.

Our principal scanner is a laser triangulation rangefinderand motorized gantry, built to our specifications by Cy-berware and customized for scanning large statues. Therangefinder has a standoff distance of 1.2 meters, a Z-resolution of 0.1mm, and an X-Y sample spacing of 0.25mm- sufficient to capture Michelangelo’s chisel marks. The

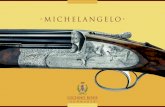

scanner head also contains a calibrated white light sourceand high-resolution color camera with a pixel size of0.125mm on the statue surface. The scanner head is mountedon a 4-axis motorized gantry (Figure 1) with a working vol-ume 3 meters wide by 7.5 meters high - tall enough to scanMichelangelo’s David on its pedestal. For those hard-to-reach places, we have also used a commercial jointed digitiz-ing arm and small triangulation laser scanner manufacturedby Faro Technologies and 3D Scanners.

Our range processing pipeline consists of aligning thescans taken from different gantry positions, combining thesescans together using a volumetric algorithm, and filling holesusing silhouette carving and similar techniques. Since gantrymovements are not tracked in hardware, alignment is boot-strapped by aligning each scan to its neighbor interactively.This is followed by automatic pairwise alignment of scansusing a modified iterated-closest-points (ICP) algorithm andfinally by a global relaxation procedure designed to mini-mize alignment errors across the entire statue.

Our color processing pipeline consists of compensatingfor ambient lighting, discarding pixels affected by shadowsor specular reflections, and factoring out the dependence ofobserved color on surface orientation. This requires knowingthe bidirectional reflectance distribution function (BRDF) ofthe surface being scanned. For marble statues, we have suc-cessfully employed a simple dichromatic model consistingof a colored diffuse term and a white specular term. Theresult of our range and color processing pipeline is a sin-gle, closed, irregular triangle mesh with a diffuse RGB re-flectance at each vertex.

Non-photorealistic renderings of our datasets are also pos-sible. For example, by coloring each vertex of a mesh ac-cording to its accessibility to a virtual probe sphere rolledaround on the mesh, a visualization is produced that seemsto show the structure of Michelangelo’s chisel marks moreclearly than a realistic rendering (see Figures 3 and 4). Webelieve that the application of geometric algorithms and non-

c The Eurographics Association and Blackwell Publishers 1999. Published by BlackwellPublishers, 108 Cowley Road, Oxford OX4 1JF, UK and 350 Main Street, Malden, MA02148, USA.

M. Levoy / The Digital Michelangelo Project

Figure 1: Our laser scanner gantry positioned in front ofMichelangelo’s David. From the ground to the top of thescanner head is 7.5 meters.

photorealistic rendering techniques to scanned 3D artworksis a fruitful area for future research.

Logistical challenges

The Digital Michelangelo Project has been as much a pro-duction project as a research project, and we therefore havefaced logistical challenges throughout the project.

One significant challenge we have faced is the size of ourdatasets. Our largest dataset is of the David (Figure 2). Itwas acquired over a period of 4 weeks by a crew of 22 peo-ple scanning 16 hours per day 7 days a week. The datasetcontains 400 individually aimed scans, comprising 2 billionpolygons and 7,000 color images. Losslessly compressed,it occupies 60 gigabytes. Although most of the techniquesused in this project are taken from the existing literature, thescale of our datasets has precluded the use of many publishedtechniques, and it has forced us to modify or re-implementother techniques.

A second logistical challenge we have faced is insuringsafety for the statues during scanning. Laser triangulation isfundamentally a non-contact digitization method; only light

touches the artwork. Nevertheless, the digitization processinvolves positioning a scanner close to a precious artwork,so accidental collisions between the scanner and the statueis a constant threat. To prevent collisions, we have used acombination of scanner design features - in particular a longstandoff distance, as well as safe operating procedures andextensive training of our scanning crew.

A third logistical challenge we have faced is the de-velopment of meaningful, equitable, and enforceable intel-lectual property agreements with the cultural institutionswhose artistic patrimony we are digitizing. Since the goalsof our project are scientific, our arrangement with the muse-ums is simple and flexible: we are allowed to use and dis-tribute our models and computer renderings for scientificuse only. The corollary issues of distribution, verification,and enforcement, although difficult in principle, are simpli-fied in the near term by the size of our datasets. In partic-ular, they are too large to download over the Internet. Simi-larly, distinguishing our computer models from other modelsof Michelangelo’s statues is not currently a problem, sincenone exist. In the long term, we are investigating methodsof 3D digital watermarking as they apply to large geometricdatabases.

Uses for our models

The first question people ask us about these models iswhether we plan to use them to make copies of the statues forsale. We have no such plans. However, our technology cancertainly be used to scan and replicate statues. Among theother clients we envision for these models are art historians,museum curators, educators, and the public.

For art historians, our methods provide a tool for answer-ing specific geometric questions about statues. Questionswe have been asked about Michelangelo’s statues includecomputing the number of teeth in the chisels employed incarving the Unfinished Slaves, determining the smallest sizeblock from which each of the allegories in the Medici Chapelcould have been carved, and determining whether the gi-ant statue of David is well balanced over his ankles, whichhave developed hairline cracks. Aside from answering spe-cific questions like these, art historians envision computermodels becoming a repository of information about specificworks of art. Our model of the David, when it is completed,is expected to become the official record of diagnostics andrestorations performed on this statue.

For educators, computer models provide a new tool forstudying works of art. In a museum, we see most statuesfrom a limited set of viewpoints. Computer models allowus to look at statues from any viewpoint, change the light-ing, and so on. In the case of Michelangelo’s statues, mostof which are large, the available views are always from theground looking up. Michelangelo knew this, and he designedhis statues accordingly. Nevertheless, it is interesting and in-

c The Eurographics Association and Blackwell Publishers 1999.

M. Levoy / The Digital Michelangelo Project

Figure 2: A 1-million polygon, 2-millimeter model of David’s head, constructed from our 20-billion polygon, 0.25-millimeterdataset of the statue. The color and shading are artificial.

structive to look at his statues from other viewpoints. Look-ing at the David from unusual directions has taught us manythings about the statue’s ingenious design.

For museum curators, while models displayed on a com-puter screen are not likely to replace the experience of walk-ing around a statue, they can nevertheless enhance the ex-perience. As an experiment, we allowed selected visitors inthe museums of Florence to manipulate our models interac-tively. We found that the computer focuses their attention onthe statue and allows them to view it in a new way. By ex-ploring the statue themselves, they turn the viewing of artinto an active rather than a passive experience. The art mu-seum becomes a hands-on museum.

Finally, for the public, we think that interactive viewingof computer models may eventually have the same impacton the plastic arts that high-quality art books have had onthe graphic arts; they give the educated public a level of fa-miliarity with great works of art that was previously possibleonly by traveling.

Side projects

Although the primary goal of this project was to scan statues,our team and equipment have been involved in several other3D scanning projects in Italy.

One such sideproject is the scanning of the architecturalsettings of Michelangelo’s statues. For this purpose we haveused a time-of-flight laser scanner manufactured by CyraTechnologies. This scanner has a Z-resolution of 5mm anda typical X-Y sample spacing of 4mm at a distance of 10meters. Using this scanner and an attached color camera, wehave built a colored 15-million polygon model of the Tri-bune del David in the Galleria dell’Accademia and a 50-million polygon model of the Medici Chapel. Unfortunately,these models are irregular triangle meshes, like those pro-duced by our other scanners, and are therefore not useful formost practical architectural applications. Converting such adataset into a conventional graphical representation such asa plan or elevation drawing is not easy. Converting it into a

c The Eurographics Association and Blackwell Publishers 1999.

M. Levoy / The Digital Michelangelo Project

segmented, structured, and annotated architectural databaseis even harder.

A second sideproject in which we are involved is the fu-sion of 3D scanning and other imaging modalities. Specifi-cally, during our scan of Michelangelo’s David, we also ac-quired a photographic dataset of the statue under ultravio-let illumination, thereby producing a per-vertex UV fluores-cence map of the statue. This map, which shows the loca-tion of waxes and other organic materials, will be used whenplanning future cleanings and restorations of the statue.

A final sideproject is the scanning of the Forma Urbis Ro-mae, a giant map of ancient Rome carved onto marble slabsin circa 200 A.D. The map now lies in fragments - over 1,000of them. Piecing this map together is one of the key unsolvedproblems in classical archeology. Fortunately, the fragmentsare several centimeters thick, and the broken surfaces giveus strong three-dimensional cues for fitting the pieces backtogether. Our primary tool in this project will be automaticsearch algorithms that operate on geometric signatures com-puted from our models of these broken surfaces.

Conclusion

Although we had run many back-of-the-envelope calcula-tions in preparation for scanning the statues of Michelan-gelo, the actual difficulty of the task surprised us. In par-ticular, the statues contained more recesses and partiallyoccluded surfaces than we anticipated, and positioning ourgantry to reach them required more time and effort than weimagined. We typically spent 50% of our time scanning thefirst 90% of the statue, 50% on next 9%, and the last 1%was unscannable. To improve on these numbers, a scannersystem would need a more compact scanner head, more po-sitional and angular flexibility, a variable standoff distance,automatic tracking of the gantry position, and a suite of au-tomatic view planning software.

Another hard lesson we learned was about scattering oflaser light from the crystal structure of marble. The effectof this scattering is to introduce noise into the range data.In joint experiments with researchers from the NationalResearch Council of Canada, we found that this scatteringis dependent on surface polish, highly dependent on inci-dent beam angle, and can be reduced but not eliminatedby narrowing the laser beam. Furthermore, although thescattering is related to laser speckle, it would occur evenwith incoherent illumination. In short, there appears to be afundamental resolution limit for structured light scanning ofmarble surfaces.

Web pages

More information about the Digital Michelangelo Project,including images of our scanners in use and renderings of

our computer models, can be found at:http://graphics.stanford.edu/projects/mich/

Figure 3: A single raw scan of the unfinished statue ofSt. Matthew. The X-Y resolution is 0.29 mm. At this scale,Michelangelo’s chisel marks can be seen. The color andshading are artificial.

Figure 4: A non-photorealistic, accessibility-shaded color-ing of the same mesh. To us, it seems to show the structureof Michelangelo’s chisel marks more clearly than figure 3.

c The Eurographics Association and Blackwell Publishers 1999.