UNIVERSITY OF SYDNEY - The Australian National Construction Review

The Australian National Construction Review

Click here to load reader

-

Upload

trade-media-group-ptd-ltd -

Category

Documents

-

view

263 -

download

12

description

Transcript of The Australian National Construction Review

AUSTRALIAN NATIONAL

MAJOR PROJECT REVIEWCONSTRUCTION

PP255003/07071A

USTRALIA

N N

ATIO

NA

L CO

NSTRUC

TION

- MA

JOR PRO

JECT REV

IEW

1 BLIGHSTREET

GROCON’S

ENLIGHTENS NSW

ALSO INSIDE:1 BLIGH STREET Grocon MOORE PARK SUPA CENTRE Lipman Properties ATLAS NORWEST Taylor Construction Group OXLEY HIGHWAY UPGRADE BMD Constructions STAR CITY REDEVELOPMENT Brookfield Multiplex ELIZABETH MACARTHUR AGRICULTURAL INSTITUTE OF BIOSECURITY Cockram Construction THE WESTERN HIGHWAY Western Highway Anthongs Cutting Alliance DOCKLANDS NEW QUAY CLARA PALERMO TOWNHOUSES PDS Group DANDENONG HOSPITAL MENTAL HEALTH FACILITY Kane Constructions PROJECT AURORA Project Aurora STATE EQUESTRIAN CENTRE Walton Construction BALLINA BYPASS Ballina Bypass Alliance & RTA NOTTINGHAM SQUARE AVJennings TOWNSVILLE PORT ACCESS ROAD Abigroup & Seymour Whyte AIRPORT LINK Thiess John Holland BLUNDER ROAD Golding Contractors HARDENED AND NETWORK ARMY Baulderstone KARARA RAIL WORKS Macmahon Contractors SOUTHERN SEAWATER DESALINATION PLANT Water Corporation HARRISON SECONDARY SCHOOL St Hilliers DILSTON BYPASS Shaw Contracting PACIFIC MOTORWAY UPGRADE

IT’S NO-WELD IT’S MODULAR IT’S ROBUST …SAVING TIME & MONEYEASILY INSTALLED, GALVANISED HANDRAIL & BALUSTRADE SYSTEMS

COMBINING STRENGTH, SAFETY & STYLE > No onsite fabrication or welding, eliminates corrosion > Modular design, reduced lead times & rapidly installed > Easily configured & colour matched to suit any application > Australian Standards, BCA, DDA & OHS compliant

™

CALL 1800 663 339 WEB moddex.com.au

SPECIFIED & SOLD AUSTRALIA WIDE

AUS $14.95 (INC GST)PRINT POST APPROVEDPP: 255003/07071 OCTX24P119

771449734009

04ISSN

1449-7344

AUSTRALIAN NATIONAL CONSTRUCTION REVIEW2 ANCR SPECIAL FOCUS

3ANCR SPECIAL FOCUSWWW.ANCR.COM.AU

AUSTRALIAN NATIONAL CONSTRUCTION REVIEW4 ANCR SPECIAL FOCUS

PUBLISHERK.M. Hanson

GENERAL MANAGERPhil Reynolds

GRAPHIC ARTISTSPeta Brunell, Nick Barth, Charlotte McLaren

SALES MANAGERSHolly Mills, Chris Randles

SALESBen Newell, Sam French, Michael Matthews, Ashley Deal, Hannnah Kelland

BUSINESS DEVELOPMENTSarah Giles

ADMINISTRATIONJenny Bow, Michelle Tyson

DISTRIBUTIONGordon & Gotch

PUBLISHED BYTrade Media Group Pty LtdACN 118312404t. 02 4322 1200f. 02 4322 1400www.ancr.com.auwww.trademediagroup.com.au

WRITERSWillow Aliento, Kylie Bishop, Keeli Cambourne, Prue Clark, Lyndall Lee Arnold, John Davies, Christine Paul, Marie-Laure Bouchet, Rowena Robertson

PHOTOGRAPHERSMike Chorley, Michael Embelton, Lewis Krebs, Alan Roberts, Rod Vella, Robin Gauld, Jose Figlioli, Julie Emonson-Clyde, Miro Ertel, Darren Daly, Chris Coumbe, Simon Hughes, Adam Sutton, Elisha McDonald, Molly Pacitti, Pene Stevens, David Bailey

COPYRIGHTAll material in this publication is copyrighted to the publisher and/or its advertisers and contributors. No material or portion of this publication may be reproduced in whole or part without the express written permission of the publisher.

DISCLAIMERThe Australian National Construction Major Project Review and the publisher reserve the right to alter or omit any advertisement, editorial, or advertorial. Advertisers and/or their representatives indemnify the Australian National Construction Major Project Review and the publisher in relation to defamation, slander, breach of copyright, infringements of trademarks of name of publication titles, unfair competitor or trade practices, royalties or violation of rights and privacy and warrant that their material complies with all the relevant laws and regulations and that its publication will not give rise to any rights against or liabilities against the Australian National Construction Major Project Review, its publisher, its servants or agents. The Australian National Construction Major Project Review and the publisher are not liable for inaccuracy in any advertisement or editorial and do not accept responsibility for any claims made by advertisers. Any material supplied to the Australian National Construction Major Project Review or the publisher are at the contributors risk. No responsibility will be taken by the Australian National Construction Major Project Review, its publisher, its servants or agents. Opinions published in The Australian National Construction Major Project Review are not necessarily those of the publisher or staff of The Australian National Construction Major Project Review.

The Australian National Construction Major Project Review is not related to any other publication.

CONSTRUCTIONAUSTRALIAN NATIONAL

MAJOR PROJECT REVIEW

CONTENTSGrocon's,1 Bligh Street.Image by Mike Chorley

AUSTRALIAN NATIONAL CONSTRUCTION REVIEW

5ANCR SPECIAL FOCUSWWW.ANCR.COM.AU

PROJECTS

• VIC CLARA PALERMO TOWNHOUSES - PDS Group .34 THE WESTERN HIGHWAY - Western Highway Anthongs Cutting Alliance .40 DOCKLANDS NEW QUAY .48 DANDENONG HOSPITAL MENTAL HEALTH FACILITY - Kane Constructions .54

• NSW OXLEY HIGHWAY UPGRADE - BMD Constructions .62 MOORE PARK SUPA CENTRE - Lipman Pty Ltd .70 STAR CITY REDEVELOPMENT - Brookfield Multiplex .72 ATLAS NORWEST - Taylor Construction Group .86 ELIZABETH MACARTHUR AGRICULTURAL INSTITUTE OF BIOSECURITY - Cockram Construction .90 1 BLIGH STREET - Grocon .102 BALLINA BYPASS - Ballina Bypass Alliance & RTA .126

• QLD PROJECT AURORA - Project Aurora .134 STATE EQUESTRIAN CENTRE - Walton Construction .152 NOTTINGHAM SQUARE - AVJennings .156 PACIFIC MOTORWAY UPGRADE - Bielby Hull Albem Joint Venture .162 TOWNSVILLE PORT ACCESS ROAD - Abigroup & Seymour Whyte .170 AIRPORT LINK - Theiss John Holland .174 BLUNDER ROAD UPGRADE - Golding Contractors .188 • SA HARDENED AND NETWORKED ARMY - Baulderstone .192 • WA KARARA RAIL WORKS - Macmahon Contractors .206 SOUTHERN SEAWATER DESALINATION PLANT - Water Corporation .214

• ACT HARRISON SECONDARY SCHOOL - St Hilliers .222

• TAS DILSTON BYPASS - Shaw Contracting .226

NEWS .06 ARCHITECTURE NEWS .12 ENGINEERING NEWS .14

FEATURES COMPANY FOCUS - Coffey .16 SPECIAL FOCUS .18 SPECIAL FEATURE - Built Environment Meets Parliament (BEMP) 2011 .132

CONTENTS

5WWW.ANCR.COM.AU

6 ANCR CONSTRUCTION NEWS

CONSTRUCTION

The secrets behind 10 of Melbourne’s most recognisable buildings have been unlocked in a free iPhone application that takes users on a guided walking tour of one of the world’s most liveable cities.

Developed for the Victorian State of Design festival, the Sound of Buildings application was jointly funded by a $20,000 grant from the Coalition Government through Major Projects Victoria and was officially launched today by Major Projects Minister Denis Napthine.

“Victoria has a tradition of great architecture dating back to the gold rush and this application is a wonderful and innovative way to showcase our culture of good design,” Dr Napthine said. “Sound of Buildings gives a behind-the-walls view of the inspiration and history behind our most prominent buildings to locals, architecture enthusiasts and visitors to Melbourne. “This is not only a celebration of Melbourne’s unique buildings, it is also a fantastic tourism asset.”

Already download figures indicate there has been significant overseas interest in this application which features ten of Melbourne’s most iconic constructions, including AAMI Park, St Paul’s Cathedral, Federation Square and the National Gallery of Victoria.

“This application uses GPS to give directions to the 10 local icons, and then allows users to view images and listen to interviews with designers, users and developers while walking between the landmarks,” Dr Napthine said.

“Sound of Buildings will be a fantastic addition to the State of Design Festival and will complement the Melbourne Open House which takes place at the end of the month.”

Associate Victorian Government Architect Jill Garner said the tour would enrich the architectural experience of Melbourne’s landmark buildings, through its collection of personal stories about these icons.

“The tools of architecture include the drawing, but not everyone has the skill to understand the three dimensional implications of a drawing. Behind every drawing there is a process of invisible deliberation and a perception of an architectural experience – of space, of openness and closure, of light and shadow,” Ms Garner said.

“Buildings do talk – both to those who understand their architectural language, and to those who are

moved or intrigued by space, materiality, detail, or by a shaft of sunlight through a strategically placed hole in a wall at a certain hour on a certain day.”

Cox Architecture Director Patrick Ness said the tour would allow people to engage with Melbourne in a new and exciting way and give people an interesting insight into the evolution of Melbourne architecture.

“These stories from the architects, engineers and builders of our city will offer a new understanding of the city and reinforce Melbourne as a thriving centre for cultural exchange.” State of Design Festival Creative Director Kate Rhodes said the tour’s title was reference to how buildings interact with each other.

“Not only do the creators and end users of the buildings speak about their experience in the Sound of Buildings tour, but in some ways, so too do the buildings themselves,” Ms Rhodes said.

“As many of the architects note, there is carefully considered dialogue between a building, where it is located and the buildings that surround it. In addition to the individual stories behind each design and its development, there exists a 'conversation' between each of the buildings in this tour, across time and space.”

Out of the 10 locations featured in the Sound of Buildings, five are Major Projects Victoria

iPHONE APPLICATION GIVES A VOICE TO MELBOURNE’S BUILDINGSdevelopments. The full list includes:• AAMI Park;• Westpac Centre;• Melbourne Recital Centre and MTC Theatre;• National Gallery of Victoria;• Federation Square;• St Paul’s Cathedral;• Council House 2 (CH2);• Monaco House;• Royal Exhibition Building; and• Melbourne Museum.

The design of the application allows for more buildings to be added at a later date. Dr Napthine said Sound of Buildings was a joint effort between Major Projects Victoria, the Victorian Government Architect, Cox Architecture and the State of Design Festival. “I wish to congratulate all of these organisations for coming together to develop the Sound of Buildings,” Dr Napthine said.

The Sound of Buildings can be downloaded free from the Apple app store or via the State of Design Festival website.

Grand Designs Australia host Peter Maddison at Federation Square

Charlie, age 3 and his mother Kate Nelson at Federation Square

(from left) Peter Maddison, Patrick Ness, John Wiles (Executive Director, Major Projects Victoria), Kate Brennan (CEO, Fed Square), KateRhodes, Minister Denis Napthine

Right: The Sound of Buildings iPhone screen shot

See top left image caption

comment

7ANCR CONSTRUCTION NEWS

By Angie Zigomanis Senior Manager of Building and

Construction Forecasting BIS Shrapnel

continues page 11

New dwelling starts are estimated to have declined by 6% to 155,000 in 2010/11 after experiencing a post GFC peak of 165,500 in 2009/10. BIS Shrapnel is forecasting new dwelling starts to decline further to 150,000 in 2011/12. This is below BIS Shrapnel’s forecast of underlying demand for new dwellings averaging 182,000 per annum over the next five years, driven in part by a return to growth in migration levels.

Unless construction rises to levels commensurate with underlying demand, dwelling shortages will intensify, placing pressure on rents and ultimately prices.

Although net overseas migration has fallen from its peak of 300,000 in 2008/09, the 2010/11 estimate of 165,000 remains high in a long-term sense, above the previous record level of 160,000 in 1988/89. Net inflows are forecast to recover to a peak of 240,000 by 2013/14 as resource investment peaks drive a higher Federal Government intake, as well as rises in long term overseas visitors on various forms of work visas.

It has been suggested that immigration can be held back to reduce housing demand. However, it’s not that simple. With the first of the baby boomer generation turning 65 years old in 2011, growth in the employment aged population will begin to slow as the rate of population reaching retirement age accelerates over the next ten years.

Unless there are significant rises in productivity, in participation rates, or a greater percentage of the population works past retirement age, growth in the workforce will not be sufficient to accommodate economic growth.

As economic cycles peak, labour shortages will increasingly emerge, translating to wage cost

CONSTRUCTION RATE NEEDS TO RISE TO MEET GROWING POPULATION

Grand Designs Australia host Peter Maddison at Federation Square

Charlie, age 3 and his mother Kate Nelson at Federation Square

(from left) Peter Maddison, Patrick Ness, John Wiles (Executive Director, Major Projects Victoria), Kate Brennan (CEO, Fed Square), KateRhodes, Minister Denis Napthine

Right: The Sound of Buildings iPhone screen shot

See top left image caption

Murrumbidgee Irrigation Ltd has established the MIA Renewal Alliance to carry out modernisation infrastructure works that will improve productivity and create water savings for the future. The Alliance is made up of Murrumbidgee Irrigation, GHD, John Holland Group and UGL Infrastructure.

Infrastructure works are expected to commence from early 2012, subject to project planning and funding approvals. The MIA Renewal Alliance is therefore calling for expressions of interest from suppliers and subcontractors who may wish to provide their services to the Alliance in the future.

This will provide the Alliance with the opportunity to assess the capability of interested organisations and further develop

supplier and subcontractor capability to ensure compliance with the relevant requirements.

Those organisations and individuals who respond will be asked to complete a confidential questionnaire relating to their current capacity, experience and capabilities.

Expressions of interest should be forwarded by 30 September 2011 to:Mr Ian ButlerDelivery ManagerMurrumbidgee Irrigation Area Renewal AlliancePO BOX 716Griffith NSW 2680To know more please email: [email protected]

The National Code of Practice for the Construction Industry (the Code) and the Australian Government Implementation Guidelines for the National Code of Practice for the Construction Industry, reissued August 2009 (the Guidelines), apply to this project. By agreeing to undertake the works, you will be taken to have read and to agree to comply with the Code and Guidelines.

SUPPLIERS AND SUBCONTRACTORS – EXPRESSIONS OF INTEREST

Broad Construction Services (WA) recently transformed South Hedland’s existing recreation facility, known as the JD Hardie Centre, into one of the State’s best recreation venues.

The centre is located approximately 1660 km’s north of Perth, Western Australia and reached formal Practical Completion in May. The JD Hardie Centre was officially opened on Tuesday, 28 June 2011 by Regional Development Minister Brendon Grylls, BHP Billiton Iron Ore Vice-President Health, Safety, Environment and Community Carl Binning and Town of Port Hedland Mayor Kelly Howlett.

In celebration of the town’s new and modern multi-purpose facility and to thank the community for their warm welcome during the redevelopment, Broad has donated an inflatable jumping castle as a fundraising opportunity for the community and is set to arrive in the coming weeks.

“The site team thoroughly enjoyed working on this project and their time spent within the community. They wanted to give something back as a small token of their appreciation,” said Broad WA Director and General Manager Nick Cater. The jumping castle will be presented to the Town of Port Hedland Mayor Kelly Howlett.

BROAD CONSTRUCTION SERVICES (WA) JUMPS IN TO THANK THE COMMUNITY

“The upgrade and redevelopment of the JD Hardie Centre is one of Council’s three major projects and also the first to be completed. It is great to see Broad Construction come on board in celebrating this milestone and provide something which will have a positive ongoing effect for the youth and community of Hedland. It is partnerships such as this that will help the Town of Port Hedland transform into Pilbara’s Port City,” said Town of Port Hedland Mayor Kelly Howlett.

The JD Hardie Centre will operate as the largest youth precinct in Western Australia once the Multi- Purpose Recreation Centre is completed in May 2012. It will offer facilities such as health and recreation and support services and will provide a base for local government, not for profit organisations and allied community groups.

“Thank you BHP Billiton Iron Ore, Royalties for Regions, Pilbara Cities, the Country Local Government Fund, the Department of Housing’s South Hedland New Living project and the Town of Port Hedland for providing such fantastic facilities” said Nick. Broad delivered the JD Hardie Centre project on schedule and within budget.

8 ANCR CONSTRUCTION NEWS

comment

8 ANCR CONSTRUCTION NEWS

Sustainability and social responsibility remain key issues within the property industry and have filtered through from the development sector to office fitouts. Facility Managers are becoming increasingly savvy about fitouts and are looking at ways to provide increasingly functionality, rather than pure aesthetics.

Facility Managers now play a critical role in managing the look and feel of modern work environments as human resources and occupational health and safety become increasingly important factors in workplace design.

As a result, Facility Managers have become more educated about commercial office fit-outs and are playing an even larger role within work space design and in the selection of furniture.

Many Facility Managers feel it necessary to extend the lifecycle of furniture without forgoing comfort and aesthetic style. This has seen a significant shift in acquiring office furniture that blends design style with functionality, affordability and durability.

A growing trend has seen an increase in recycling existing workstations and furniture pieces and also the acquisition of high quality second-hand pieces to meet the strict criteria of Facility Managers. The use of recycled furniture has risen by 30 per cent since 2007.

Budget-conscious managers are now leading the trend in sustainable fit outs and often choose to reuse and recycle furniture and create a cheaper and greener office fit-out.

The pressure is on Facility Managers to use furniture that is sustainable, economically viable and socially responsible to employees – whilst also performing all essential functions and being in line with the overall “look” of the office.

FACILITATING GREENER FITOUTS

By Andrew HolderManaging Director TDA Interiors and Furniture For Business

continues page 11

It seems highly appropriate that the new Gold Coast Stadium, home to the AFL’s Gold Coast Suns, draws a substantial amount of its energy requirements from the sun itself. Completed just in time for the newest team to enter the Australian Football League, the impressive $144 million redevelopment now known as Metricon Stadium, features more than 450 metres of solar panels lining the inner edge of the stadium roof.

The panels form a unique solar halo and generate an expected 20% of the stadium’s energy requirements over the course of the year. The stadium also boasts a Polytetrafluoroethylene (PTFE) glass fibre membrane horseshoe roof that spans more than

16,000sq.m providing cover for the east, west and southern perimeter of the structure. Work began on the project in August 2009 under the control of managing contractor Watpac with the upgrade taking capacity at the stadium to 25,000. The construction involved 1400 tonnes of structural steel, 7000 cubic metres of concrete, 5600 metres of precast concrete seating plats and 92,000 square metres of plaza works.

The project, which employed up to 1100 workers during the construction phase, was funded by the Queensland government ($71.9 million), Commonwealth government ($36 million), Gold Coast City Council ($23 million and the AFL ($13.3 million).

SOLAR STADIUM FOR GOLD COAST SUNS

Dreamworld celebrates its 30th birthday in 2011, and there has never been a better time to visit as Australia’s favourite theme park goes all out with a host of additions including a bone chilling new thrill ride, BuzzSaw.

The biggest year ever for the iconic entertainment destination, Dreamworld has added a new exotic animal exhibit, ‘The Lair’, a new adventure ride, ‘ShockWave’ and now a major thrill ride so extreme it will boost the park’s Big 6 Thrill Rides to the Big 7.

Opening in time for the September school holiday period, BuzzSaw is an Australian first and will be the ride to conquer for high-action adrenaline seekers.

Seated in an open carriage, riders will be held in by a single waist harness leaving the upper body fully exposed to the elements, and with little to cling onto. This white-knuckle ride starts with a suspenseful 46m vertical ascent that will have riders instantly wishing they were back on the ground.

At its peak, the rider’s centre of gravity is flipped and they are dangled upside-down 15 storeys in the air before the ride car free-falls through a 360 degree heart roll, and plummets down a final vertical drop at speeds of up to 105km/hour. BuzzSaw will be the highest inversion ride experience in the Southern Hemisphere.

Situated in the park’s Gold Rush precinct, the construction of the new ride has unearthed some unusual stories about the make-believe mining township, which has been part of Dreamworld since the mid 1980’s.

DREAMWORLD REVEALS ITS NEW BONE CHILLING THRILL RIDE

Unexplainable occurrences recounted by staff working in the area and historic research dating back to the late 1800’s have inspired the ride’s theme and will have guests wondering where fact ends and fiction begins.

With construction now well underway, BuzzSaw will be one of the first menacing thrill rides guests can spot as they arrive in the main car park adding to the already impressive landscape including the Tower of Terror II and The Giant Drop.

Dreamworld’s line-up of new rides and attractions in 2011 makes now the best time ever to visit our worlds of fun. Visit www.dreamworld.com.au to grab a $99.99 World Pass for unlimited entry until June, 2012.

Stay tuned for more details on this year’s biggest, fastest thrill ride, BuzzSaw.

comment

9ANCR CONSTRUCTION NEWS

By Mark BeattieManaging Director

Davis Langdonand AECOM Company Australia New Zealand

continues page 11

After almost a decade of using Building Information Modelling (BIM) for property design and construction, property owners are now applying it in new and innovative ways.

Many are realising that BIM can add significant value to the lifecycle of their property, extending its traditional use in design to the property’s operation and ultimate demolition. It can also make the construction process more efficient for designers and builders.

The BIM process revolves around the collection and reuse of many types of data. Traditionally, the emphasis has been on using BIM to create a design model of the project that may or may not be handed over to the construction team. Today, we are using the BIM data to go beyond design to deliver an ‘as built model’ of the project. This can plug into a Computer Aided Facilities Management (CAFM) system and Building Automation System to improve informed decision-making.

To leverage the full value of BIM and its data, the client needs to define at the start of the building process what information is required and in what format. This requires dedicated information management, vertical integration and engagement from architects through to facility operators.

Cost and time can be wasted onsite during the construction stage because of uncoordinated documentation. BIM can mitigate this by ensuring minimal loss of knowledge at the traditional project information exchange points of design to construction and construction to operation. However, the information that is entered is just as important as the results generated by the model. Allowing input by trades, specialists and end users leads to designs that work better, are more sustainable and more fun to work on.

BIM: WHAT’S IN IT FOR PROPERTY OWNERS?

The latest Enerpac ZU4 hydraulic pumps engineered specifically for pre and post-stressing contain fewer moving parts and generate less friction than conventional pumps to give more power and reliability .

The ZU4 A300 series stressing pump with its1.25kw motor increases speed of operation which reduces cycle times. Ergonomic design enhances ease of transportation and reduces operator fatigue.

Outstanding flow dynamics also mean the energy saving ZU4 class 1.25kw 700 bar electric pumps will stay on the job longer, run cooler and be easier to service when the need eventually arises, says Enerpac.

Rugged workhorses such as the ZU448REA300 double-acting pump can be coupled with compact and powerful Enerpac post-tensioning tools for mono strand construction applications common on building, mining and infrastructure development sites.

These single-acting PT and double-acting DPT post-tensioning tools deliver 20 or 30 tons tensioning capacity when coupled with the ZU4408REA300, which features remote pump control and advance/hold/retract valving.

Compact and highly portable ZU4T Series electric pumps - weighing between 30-32kg –employ a powerful 1.25kW universal motor that provides a high power-to-weight ratio and excellent low voltage operating characteristics. The motor is coupled with a totally new pump element design that reduces oil flow turbulence, producing an industrial workhorse with fewer moving parts, less friction and which requires 18 per cent less current draw than comparable pumps.

Enerpac says the universal motor offers important jobsite benefits. One is a low starting current draw, much reducing the likelihood of tripping breakers at startup. Another is outstanding tolerance for low supply voltage – in contrast with bulkier, heavier induction motors, which tolerate under-voltage poorly and quickly overheat. The universal motor can operate satisfactorily from a long extension cord or portable generator.

The ZU4’s high efficiency, cooler running design, combined with its heavy duty FRP composite shroud, help it to resist the ravages of sun as well as rain. An optional heat exchanger stabilises oil temperature in applications where this is required. Enerpac features a versatile line of concrete pre-stressing and post-tensioning products, along with an extensive range of associated hydraulic pumps and accessories, all from a single source

* Durable field proven mono strand designs in capacities from 20-30 tons with soft-grip ergonomic handles to reduce operator fatigue

* Single acting PTJ models incorporating new Enerpac post-tensioning cylinders with 254mm stroke ideal for slab-on-grade applications

* Double-acting DA models with 216mm stroke, machined from a single billet with gun drilled internal hydraulic passages

* A complete range of both re useable and one time use barrels and wedges from 5mm to 15.2mm

Enerpac has been established in Australia and New Zealand as a major supplier of high-pressure (700 bar) hydraulic equipment for 50 years, having nationwide service backup and a strong distribution network. Its ranges of 700 Bar (10,000 psi) precision hydraulic cylinders, tools and pre and post-stressing tensioning equipment (contained in its E326A catalogue) is complemented by professional bolting technology being introduced by Enerpac to address the needs of major areas of industry, including mining and energy, infrastructure construction, manufacturing, pipelines, mobile machinery, tracked and heavy vehicles, cranage and fixed plant.

For more information about Enerpac equipment in Australia, please contact Enerpac, Block V. Unit 3, Regents Park Estate, 391 Park Road, Regents Park, Sydney 2143, ph Australia (61) Sydney (02) 9743 8988, fax (61) (02) 9743 8648, e-mail [email protected]. For more information about En-erpac equipment in New Zealand please contact Neville Stuart on 0800 ENERPAC (363-772) [email protected]

PURPOSE-BUILT ENERPAC ZU4 PUMPS DELIVER BETTER ERGONOMICS AND PRE AND POST-STRESSING PERFORMANCE

10 ANCR CONSTRUCTION NEWS

comment

10 ANCR CONSTRUCTION NEWS

Ongoing research, particularly in the areas of environmental, social and economic sustainability, is essential for continued productivity and industry development in the Australian built environment industry over the next ten years. Researchers at the Sustainable Built Environment National Research Centre (SBEnrc) are seeking to maximise the benefits of R&D to Australia’s infrastructure and building industry through better matching funding strategies to industry needs.

The research project outcomes will provide benefit to public and private organisations in increasing uptake of R&D outcomes for business impact. This is being achieved through the active involvement of public sector infrastructure and building agencies, along with private-sector industry leaders.

Early research findings by Dr Thomas Barlow (2011) clearly show there was a substantial increase in private sector investment between 1992-2008, while public sector investment over this same period decreased as a percent of total spending (in particular, this has occurred since 2001). In the early 1990s, Australian public institutions were spending 3 times more on construction related R&D than Australian businesses did. Yet by 2008, Australian businesses were spending 8 times as much on construction-related R&D as public research institutions.

The next stage of this research will look at specific investments in R&D - construction safety, green buildings, and CADD and integrated project delivery - with the aim of determining the impact of R&D to industry practice. The research team is now considering investigating the role played by the CRC for Construction Innovation (2001 – 2009) and R&D tax concession arrangements in the dramatic post-2001 growth in construction R&D. It is expected that a greater understanding of the significant increase in construction R&D in the Australian construction industry

THE FUTURE OF CONSTRUCTION RESEARCH

By Keith HampsonCEO, Sustainable Built Environment National Research Centre

continues opposite page

Spanning a distance of some 3.2 kilometres construction has recently commenced on what will become Australia’s longest bridge as part of the $618 million Kempsey Bypass Pacific Highway upgrade. Nearly 400 piles will be driven into the ground over the coming months during the initial stage of construction.

When completed the bridge will stretch from the Macleay River in the north to the floodplain to the south and will take the title of Australia’s longest away from Brisbane’s Ted Smout Memorial Bridge, which opened last year and is about half a kilometre shorter.

The design incorporates 93 support Opiers, including eight in the river, spaced 34m apart, with the deck of the bridge to be formed using 941 super-T concrete beams each weighing 65 tonnes. The Roads and Traffic Authority undertook the Environmental Assessment for the Kempsey project. The Kempsey Bypass Alliance carried out the preliminary design with Abigroup responsible for the detailed design and construction of the bridge. The remainder of the works are being delivered by the Kempsey Bypass Alliance – comprising Leighton Contractors, AECOM and Coffey Geotechnics.

With a completion date due by mid 2013 the bypass is expected to be completed one year ahead of schedule and will take 2000 trucks a day off the local streets of Kempsey – located

CONSTRUCTION STARTED ON AUSTRALIA’S LONGEST BRIDGE

halfway between Sydney and the Gold Coast. The duplication of the Pacific Highway is currently the country’s largest road project, with $4.84 billion committed to further upgrade the highway to mid 2014. The Kempsey Bypass, which is funded by the Federal government, will be a 14.5km, four-lane divided road to the east of the existing Pacific Highway. In addition to the new bridge, work also continues on the construction of the Crescent Head Road overpass bridge that forms part of the South Kempsey interchange and the erection of twin bridges over the north coast rail line as well as Pola Creek.

Sydney Ports Corporation has awarded Leighton Contractors a $115 million contract to deliver the main construction phase of the Intermodal Logistics Centre in southwest Sydney. The Centre is located on a 60 hectare industrial site and connected by a dedicated freight line to Port Botany, forming part of a network of planned and existing intermodal facilities in Sydney.

When in full operation it will service approximately a quarter of Sydney’s total intermodal demand. Major features of the ILC will include warehouse and container storage areas, an intermodal terminal and internal rail siding, northern and southern rail connections and an environmental project to encourage the recovery of the Green and Golden Bell Frog population in the area.

Leighton Contractors was responsible for completion of $17 million of early works at the site, including the construction of a vehicular

bridge over the adjacent railway marshalling yards and drainage and earthworks for the construction of a frog habitat area. Leighton Contractors executive general manager of the construction division Mike Metcalfe said securing the main construction contract with Sydney Ports Corporation was an opportunity to contribute to a critical piece of Sydney’s freight chain.

“The ILC at Enfield will help achieve a key objective of the New South Wales government to move 40% of port-related contained freight by rail,” Metcalfe said. “Once complete, container trucks will spend less time on the roads and freight logistics will become more reliable, cost efficient and economically sustainable. “We look forward to continuing to work with Sydney Ports and bringing our integrated capabilities in rail, heavy pavements, structures, complex utility relocation and environmental management of the project.”. The contract is scheduled for completion in early 2013.

LEIGHTON WIN SYDNEY PORTS CONTRACT

Construction of the Kempsey Bypass

comment

11ANCR CONSTRUCTION NEWS

commentcontinued

David Foleycontinued from page 14

Drenka Andjeliccontinued from this page

By Drenka Andjelic Managing Director

Construction Assignments

continues this page

Of course the softening of global markets may still affect the hotel sectors with companies keeping a close eye on financial markets before making any large decisions. With investor sentiment buoyant in the sector, new construction in the sector will now largely be swayed by Government measures.

The hotel sector is seeing a resurgence with record occupancy rates in capital cities across Australia delivering solid returns on hotel investments despite financial markets suffering from a tumultuous year and this is forecast to drive construction of new hotels.

For the first time in 10 years the hotel sector is being seen as a favourable investment, lack of stock and investment in the sector is seeing room rates driven up resulting in higher profits for the sector.

Long term concerns that hotels are risky investments are slowly falling away. Hotels are now seeing unprecedented sales, with $445 million of assets changing hands so far this year as Asian investors keenly invest in the Australian market.

While many hotels have been upgraded or refurbished recently to keep up with technological requirements of core business clientele, there have been very few new builds.

The trend towards hotel investment will see a two pronged approach to hotel construction. While some hotel groups will see it as an opportunity to either reinvest in larger upgrades or undertake complete overhauls of older stock, others may see it as a welcome opportunity to expand their portfolios.

There is a call for the Government to step in and grant zoning concessions to make building hotels more viable for developers and ensure that new hotel stock is brought onto the market.

The hope is that the renewed interest in the sector will result in more projects being “green lit”, faster. Currently banks are holding off on financing new hotels with the commercial viability questioned in a weak economic market and this may be off putting to some hoteliers who will take their investment returns and stash them away for when the economic market stabilises.

HOTEL CONSTRUCTION RESURGENCE

orientated Bowden Urban Village, and addressing the sustainable integration of the extension with the Adelaide Park Lands.

HASSELL developed an integrated design response with the State Government (DTEI) and the project’s contractors (Thiess/Downer EDI) and engineers (Aurecon and Parsons Brinckerhoff) to create a desirable, functional and timeless design aimed at increasing public transport patronage in South Australia to 15 per cent of all trips by 2015.

A commitment to re-invigorating Australia’s public transport provides design professionals with a unique opportunity to take a completely re-energised, reinvigorated and integrated approach to design to create accessible, vibrant and sustainable cities.

Daniel Bennettcontinued from page 13

Angie Zigomaniscontinued from page 7

Peter Galvincontinued from page 15

Mark Beattiecontinued from page 9

Keith Hampsoncontinued from oppsosite page

Andrew Holdercontinued from page 8

element is the ability to create teams, particularly high performance teams with blended skillsets. There is no point in having the smartest people if you aren’t able to harness their thinking.

At Meinhardt we are launching an internal training programme in Entrepreneurship & Innovation to support this approach. But more than this we are looking to share this knowledge and show clients how innovation activities can help them develop new and improve existing revenue streams; how it can enable them to look at key areas, such as new service lines or new geographies.

There are opportunities throughout the industry - information, process and technology gaps - and we welcome hearing from like-minded partners interested in innovation collaboration.

The movement to use BIM is not currently universal. However, some large players in the industry are capitalising on its value and structuring submissions to include ongoing running costs, sometimes for 25 years ahead. In the nearer future, we will hopefully bear witness to a revamp in the way projects are developed, designed and delivered, resulting in more cost-effective outcomes for clients.

BIM works best in collaborative environments, which to achieve often requires a fundamental shift in work practices. Also, to apply BIM effectively beyond design, contractual models need be re-examined, IP issues need to be negated and incentives tied to project outcomes.

Whilst BIM is taking advantage of modern powerful technology, we can now harness this power in a way that makes it simple and accessible to all, from sub-contractors on site to facilities managers, from property design to demolition.

from 2001 will provide very useful insights for policy makers interested in stimulating R&D investment in other areas of industry.

inflationary pressures, causing the Reserve Bank to maintain a higher interest rate environment to slow growth.

Consequently, higher levels of migration will be required, which in turn will require new dwelling construction to reach a higher plane to accommodate the resultant increase in underlying housing demand.

With Human Resources and Facility Managers working closely together the future of office fitouts will see increased demands on furniture requiring it to be more than just aesthetically pleasing design as FM’s place more value on other criteria such as sustainability and occupational health and safety.

12 ANCR ARCHITECTURE NEWS

ARCHITECTURE

A new paradigm for planned community design is being explored by Woodhead Architects’ South Australian Office, as the lead Master Planners and Architects on Minda’s $200m development of its 28Ha site in Brighton, South Australia. Working with Minda management, Woodhead is creating an integrated, vibrant, liveable and sustainable urban village that will support Minda’s ability to deliver their services to the residents. The project is the physical expression of ‘person-centered’ thinking in planning and design and will be a new coastal community offering a diversity of choices for residents. A variety of commercial opportunities to support the organisation in the long term and a mix of facilities, including accommodation and service facilities will allow persons with intellectual disabilities to explore their full potential in life.

“We usually design for commercial imperatives, creating places and buildings for the archetypal voting, employed, able-bodied person. With this project we have got to design for diversity,” said Woodhead Principal, Karl Traeger. “Designing for the most vulnerable people in society is designing for all. The development seeks to provide all the choices of a normal community with an overlay of tuning - Universal Design – as a way of being responsive to

MASTER PLANNING GUIDED BY HUMAN RIGHTS

providing choices, access and freedoms for all residents. “We are Master Planning an integrated village, with high quality urban links between a hierarchy of public and semi-private spaces. The main public spaces are to be of a civic scale and function that speak of great destinations for visitors from the Adelaide area and interstate.

“Our design keywords are about choice and diversity, journey and destination; opportunities for private activities and experiences and opportunities for engaging one another at different levels.”

With both institutional accommodation models and the group home models of disability accommodation, the core issue remains that a person with a disability is like any other person, and needs to like their cohabitants in order to enjoy their home. For this reason, the accommodation being designed for the Stage 1 of Minda’s Brighton project will offer a variety of floor plans from one, two and three bedroom apartments to detached dwellings, suitable for varying personal preferences.

“We have an urgent requirement to provide new accommodation for people, and we are also with this project addressing the overall financial sustainability of the organisation,”

explained Minda Executive Project Manager, Roddy Clark.

“Minda’s vision and mission is underpinned by respect, inclusion, and choice. We are guided by the United Nations Convention for Human Rights in all we do. In this plan, we will be having overall integration across the site, and areas and zones that lead to interaction, plus secluded areas for quiet time.

“There will be activated space, and public art which involves the residents to add to their sense of place. We will be developing a lifestyle program which meets the wants and desires of Minda’s residents for social inclusion. This will be a fully integrated community, rather than an institutional setting.” In ESD terms, Minda’s management are taking a truly long-term view. “We are looking at what the lifecycle opportunities are over 100 years – what is beneficial, and what the payback period is,” said Roddy.

Priorities include reducing bore water use, reducing energy use and reducing the CO2 footprint. Options under consideration include precinct energy generation. Water sensitive urban design is part of the overall master planning framework. There is also an exciting possibility for reducing the CO2 footprint of new buildings. Woodhead are involved in the University of South Australia research project with a number of other partners in the construction industry to develop a plant in South Australia for the digital construction of prefabricated multistorey timber frame buildings. This will

Woodhead – Lead Consultant - Planning, Urban Design, ArchitectureJensen Planning + Design - Planning & Community EngagementTaylor Cullity Lethlean - LandscapeArtscape - Public ArtSystem Solutions - Precinct & Building Engineering Briefing and ConceptAurecon - Precinct & Building EngineeringCundall - SustainabilityDavis Langdon - BCA & DDA

The Brighton site

13

ENGINEERING

ANCR ENGINEERING NEWS

comment

13ANCR ARCHITECTURE NEWS

If you have ever caught a train, tram or bus in one of our major cities you can probably relate to the daily frustrations faced by commuters. Across Australia, public transport is on the agenda at all levels of government, each considering ways they can revitalise and improve the system for the future.

In the next 40 years, 70 per cent of Australia’s population will reside in cities, putting increased pressure on public transport and infrastructure. Public transport will become increasingly central to high intensity living as well as reducing Australia’s carbon emissions and congestion. Intelligent and integrated investment is required around existing and future transit based corridors, with equitable access to quality open space.

In order to meet this challenge a more integrated design approach needs to be embraced. We need to put ‘people’ back at the centre of the design process and ask what we can do to make public transport easier, safer and more enjoyable for all to use, more often. If we don’t, people will continue to drive, congest and consider private options for transport.

An integrated design approach will address the character of the region and allow foe the integration of planned transport routes, as well as fitting in with the surrounding environment. It will also influence how people will choose to engage with future public transport options.

In South Australia, HASSELL employed an integrated design approach through our work on the Coast to Coast Light Rail Extension, extending the existing service from City West to the Entertainment Centre, with plans to link to Port Adelaide and Semaphore.

The new extension features four new energetic and bold stations, capturing emergent development opportunities including the award winning transit-

By Daniel Bennett PrincipalHASSELL

AN INTEGRATED APPROACH TO INFRASTRUCTURE?

continues this 11

be put forward as an option for some of the project’s built assets, potentially delivering buildings with reduced on-site construction time and vastly reduced CO2 footprints compared to traditional steel and concrete.

Green spaces planned for the village include a coastal park which preserves one of the only primary and secondary sand dune ecosystems still intact in the region. At the heart of Minda are existing Heritage buildings, which will be retained amid parklike settings.

In the northwest portion of the site, a mixed use commercial precinct is proposed, including a retirement development, apartments, restaurants, and the potential for future commercial leasing opportunities allowing Minda to generate another income stream. Possible health facilities, child care services and hospitality businesses are not only planned for the benefit of Minda’s staff and residents but also to provide services for the surrounding

Two projects meeting important social needs won top awards at the Australian Institute of Architects’ 2011 NSW Architecture Awards. BVN Architecture’s Brain and Mind Research Institute (BMRI) – Youth Mental Health Building in Camperdown won the Sulman Award for Public Architecture. The distinctly non-institutional design for BMRI creates a space which unifies patients, carers, clinicians and scientists working in the fields of neuroscience and mental health.

VISIONARY DESIGNS REWARDEDThe National Centre of Indigenous Excellence at inner city Redfern by Tonkin Zulaikha Greer was awarded the Lloyd Rees Award for Urban Design, as well as a commendation for public architecture. The community hub embodies the ideals of Reconciliation in a built form, with a naturally-ventilated sports hall, gymnasium, weights room, kiosk and adjacent 25-metre swimming pool, all of which are accessible by both Aboriginal and non-Aboriginal members of the public at all times.

community. The commercial developments may also provide further supported employment options in addition to the businesses including landscaping and nursery operations which Minda already manages.

“There are multiple educational opportunities on this site – social, environmental, and financial modelling. The concept of creating an ‘Integrated biosphere’ is part of our inspiration. We are assessing various precinct and building rating tools to determine which ones are most suitable for the project and will inform best practice,” said Karl.

Ideally, Minda’s management and their project team hope to be turning soil on this innovative, fully integrated community early next year. Construction will be staged at a pace which is comfortable for the current Minda residents, guided by an overall ethos of progress which is person-centered, rather than developer-driven.

National Centre of Indigenous Excellence, Redfern.

Photo by Brett Boardman.

comment

14 ANCR ENGINEERING NEWS

ENGINEERING

With the recent advancement of 3D model packages and design tools, the innovative and cutting edge Building Information Modelling (BIM) is a hot topic in the construction industry. BIM is much more than a software package. In fact, it is redefining workflows and the way in which we collaborate with others. With the world economy on edge, clients in the construction industry are seeking increased value for money, and as engineering consultants we have a responsibility to deliver the best possible solution, cost-effectively. BIM helps us achieve this with greater success.

BIM is revolutionising internal and external engineering workflows and processes. Internally it is changing the way we produce, store and publish our designs and it is altering how we execute a project. Externally it is shifting our roles and relationships with architects, project managers, main contractors, facilities mangers and end-users. In general, we are looking at projects from a different viewpoint and programme timelines are redefined to assist with the production of a BIM, take advantage of offsite prefabrication efficiencies and onsite installation time savings. Dealing with data and virtual objects is no less complex than constructing an actual building. In fact the management of the data before, during and after construction can have significant impact on the overall construction and operational costs of the building, and thus must be managed correctly. BIM provides a solution to realising this result.

In response to the current economic landscape, some contractors are utilising BIM as a 3D coordination tool that helps to reduce capital costs, construction time, and rework and defects. Beyond this construction outcome, imagine the future savings to building owners and occupiers when BIM is utilised for refurbishment, expansion or upgrades of mechanical plant to be more green and efficient, as well as the ongoing maintenance and management of these facilities.

By David FoleyAssociate/Manager-BIMNorman Disney & Young

BUILDING MODELLING INFORMATION (BIM) – THE ECONOMIC EFFECT

continues page 11

Strategic Value of adapting technology with environmental sustainability The overriding philosophy of technology application to solve business issues has been spread throughout global organisations. Technology providers need to work closely with all industries’ clients and stakeholders. This will help industries defining and modelling their business processes, leading eventually to a successful modelling of technology to work with their business, rather than modelling their business around their software.

Organisations are always seeking a new kind of business intelligence to manage and measure their energy, carbon and environmental performance. Implementing the latest technologies in system developments and database management along with the right decision support tools, they can increase efficiency, reduce costs and deliver sustainable outcomes across the organisation. The R&D Department at ICAD Consultants Pty Ltd Led by A. Professor Michel Chaaya and Dr Milad Saad has developed an Integrated Greenhouse gas and Environmental Sustainability System (IGESS) to assist organisations in measuring the strategic value of environmental sustainability and to assist in implementing their social responsibilities to conserve resources and reduce waste generation.

IGESS is a web-based platform that can be used on the spot without complex IT integration. The intuitive user-friendly system will assist the organisations in reporting, tracking and managing their key energy and sustainability metrics without the need of a third party. The innovative approach of IGESS is its full integration (and configuration capability) with the most advanced Total Infrastructure and Facilities Management (TIFM) system which provides solutions and considerable savings in many applications including:

• Real Property & Lease Management• Project Management, Risk Management • Space Management, Room Booking & Hoteling• Move Management• Building Operations Management - CMMS• Asset Management• Furniture & Equipment Management• Condition Assessment • Environmental Sustainability Assessment

• Emergency Preparedness• Telecommunications & Cable Management• Capital Budgeting & Project Management• Fleet Management• Web Portal Solutions - Dashboard & Scoreboard

IGESS exclusivity is the adaptability to other technological and innovative modules which extends specifically to the construction industry with advanced solutions in the following arising fields:

• Intelligent Expert Systems for Risk Allocations;• Contractor Selection Systems; and • Defects Management Systems

The introduction of IGESS could not been better with the announcement of the carbon tax in Australia on the 10th July 2011. IGESS tracks and generates real-time business reports on power, fuel, and water use and carbon emissions across all branches of business entities. Figure 1 presents IGESS capabilities environment within TIFM for the provision of facility replacements, upgrades, and renovations, based on environmental sustainability criteria.

Figure 1. IGESS Capabilities Environment

The web based application of IGESS along with the integrated TIFM platform constitutes a comprehensive solution that streamlines the capture and reporting of all quantitative and qualitative source data across your

STRATEGIC VALUE OF ADAPTING TECHNOLOGY WITH ENVIRONMENTAL SUSTAINABILITY

15

ENGINEERING

ANCR ENGINEERING NEWS

comment

15ANCR ENGINEERING NEWS

Why does it take so long to commercialise anything in the construction industry? There are certainly issues preventing new technologies coming to market, while a lack of funding available for ventures in their early stages means that cutting edge, intellectual property is often leaving these shores. So how can we in the construction industry do better when it comes to connecting between ourselves, Universities, the CSIRO, clients, other consultants to innovate? And do we really need to?

I would strongly argue ‘yes, we do!’ Robert Cantrell, former Director at the Intellectual Property Library, says: “Any business that is not continually developing, accessing, buying or adapting technology has made a strategic decision to be out of business”.

But problem solving is not enough, we need to create solutions. Either through product innovation - what we do – or process innovation - the way we do it.

There is a tendency, over time, for us all to get comfortable in what we do and the way we do it and thereby develop “blinkers”. Such thought processes can lead to a perception that innovation is high-risk and high cost. It’s not about this; it’s about developing technical skills and internal teams and demonstrating vision, adding value and improving external perception. The ability to learn to distinguish between a good idea and a viable business opportunity is a vital first step in any innovative endeavour. No one gives money to a good idea but a viable, commercial opportunity will attract collaborators, investors and clients.

This process fundamentally begins with a mindset shift encouraging people to see areas of change, whether market or legislative conditions, not as a threat but as an opportunity and to actively embrace them in a proactive way for the creation of new products and services. The next important

By Peter GalvinDirector of Strategy

and OperationsMeinhardt

INNOVATION IN CONSTRUCTION: ARE YOU UP FOR THE CHALLENGE?

continues page 11

energy, carbon, environmental and social responsibility portfolios. Users may be looking to successfully achieve carbon footprint goals or manage environmental sustainability certifications across the portfolio. Organizations using IGESS may be looking to operate within a “green” environment for ethics, marketing, or global purposes and they can identify areas suitable for improvement when it comes to bottom line costs as well as carbon footprint contributions.

Figure 2. IGESS regulatory environment and application fields

Organisations in Australia are facing social, political, economic and technological threats and opportunities (Figure 3). With the dynamic business models and processes, organisations’ drivers to implement IGESS may vary. Internal or External regulatory compliance, Tax or other financial incentives may be the main incentives. However, improving environmental stewardship along with consumer or market driven response may form another vital issue for adaptation.

IGESS provides a good starting point to meet minimum National Greenhouse and Energy Reporting System (NGER) requirements. With no infrastructure cost, low investment cost and small management costs, IGESS forms an ideal solution to assist many stakeholders in the organisation and to improve business performance as can be seen in Figure 4.

Figure 4. IGESS integration with organisa-tions’ business model

Dr Milad Saad is the Chairman and CEO of ICAD Consultants Pty Ltd. Dr Michel Chaaya is the Director of business development. ICAD Consultants offers a full range of Facilities Management solutions for many organisations and industries including construction, education, transport, real estate, mining , banking and many government institutions.

Dr Milad Saad Dr Michel Chaaya

AUSTRALIAN NATIONAL CONSTRUCTION REVIEW16 ANCR SPECIAL FOCUS

COFFEY Company Focus

Richmond Football Club’s Punt Road Oval is now home to a striking redevelopment, project managed by Coffey Projects. The bold yellow and black metal sheet clad building houses the clubs new administration and training centre.

The $20 million project will bring enormous benefits to Richmond Football Club, which now has training and administrative facilities commensurate with an elite sporting club.

The new facilities also place the club in a very good position to attract new players from 2012, when player free agency is introduced by the AFL.

The development will provide public access to function areas, a community gym, indoor sports centre, meeting rooms, lecture theatre and a new museum situated within the renovated Jack Dyer Grandstand.

The facility also aims to help close the gap between indigenous and non-indigenous Australians with the inclusion of the Australian Institute for Indigenous Learning and Skills Development, the Korin Gamadji Centre, which means ‘grow and emerge’. The Institute will offer education and employment opportunities to young people.

Coffey Projects were able to draw upon experience from working with Collingwood, St Kilda and Geelong AFL Football Clubs to add value to this project for Richmond Football Club. Some of these projects were occurring concurrently, lessons learned were able to be transferred in “real time” between projects.

Coffey Projects successfully managed the design and construction of the new iconic building in one of the busiest parts of Melbourne, working adjacent to a public park, while Richmond Football Club continued

to operate. Under these circumstances, the project was still completed under budget, with the new building finished in time for a major fund raising event held earlier this year.

Coffey Projects Project Director Rob McFee said, “The building is outstanding, not only because of its striking architecture, but also the high quality football facilities it provides Richmond Football Club. It was a challenging project, but has delivered extremely gratifying outcomes.”

The project was jointly funded by the Richmond Football Club, Australian Football League, Federal and State Government and the City of Melbourne. The final stage will be the reconfiguring of the oval, which will commence following the 2011 AFL season.Other companies involved in the project include the building contractor, Buxton Construction and the architects, Suters.

COFFEY PROJECTS KICK WINNING GOAL WITH PUNT OVAL REDEVELOPMENT

17ANCR SPECIAL FOCUSWWW.ANCR.COM.AU

Global professional services consultancy Coffey Projects has announced the appointment of Alan Milligan as Health Project Director in NSW.

Alan, who has over 30 years experience in construction and project management, is a highly experienced senior executive with international expertise gained in Australia, North Africa, Turkey, Middle East and South East Asia.

He will be responsible for growing the health business profile in New South Wales, as well as servicing our existing and future clients.

Commenting on his appointment, Alan acknowledged Coffey’s strategic focus to expand the health project management business and to add value and strength to existing client relationships within this specialised market sector.

COFFEY PROJECTS APPOINTS NEW HEALTH PROJECT DIRECTOR

Rosanna Petteno, employee of global professional services consultancy Coffey International Limited (“Coffey”) has been announced as the NSW winner of the Award for Achievement in Construction, Refurbishment and Fitout as part of the 2011 National Association of Women in Construction Awards for Excellence.

Rosanna, a Project Manager for Coffey Projects, is being recognised for her work on Burberry’s new Sydney flagship retail store and new office accommodation at 343 George Street. The visually stunning $6 million development represents a makeover of huge proportions, and successfully maintained heritage elements of the former bank site – the project included restoration and re-instatement of the heritage fabric - with a modern, high-end fitout.

COFFEY EMPLOYEE ROSANNA PETTENO WINS NAWIC AWARD FOR BURBERRY FLAGSHIP

The award acknowledges exceptional processes, with criteria including: contribution to the project, quality of the construction outcomes, application of innovation and active cost management.

Tony Carroll, Coffey Projects Manager NSW/ACT, commented: “Rosanna is to be commended on winning this award for her successful management of the Burberry project. It was a high profile project which required the management of multiple stakeholders, including an overseas client, heritage considerations and met a very tight timeframe.

“Rosanna demonstrated a commitment and passion to deliver positive outcomes within the project, providing valuable recommendations, communicating effectively

with all stakeholders and providing design and construction guidance through the process. The success of the project was testament to this commitment and dedication.”

Opened to rapturous acclaim, the project was delivered within budget and was highly praised by Angela Ahrendts, CEO of Burberry’s UK head office, “We are so proud of the store, which combines the full Burberry product offering with the very latest in digital technology and great customer service, giving our shoppers in the city an unrivalled brand and luxury experience.”

Rosanna has worked at Coffey Projects for four and a half years and has completed a Bachelor of Design (Interior Design) and a Diploma of Urban Estate Management, both at the University of Technology, Sydney.

“I look forward to becoming part of Coffey Projects and to working with the existing team of experienced and highly motivated professionals already in place in NSW. I do see great opportunities for the group and relish the challenge associated with broadening the client base and the extent of support services we can offer to the industry within a competitive market.”

Prior to returning to Australia in 2009, Alan was Managing Director and Principal of Ellerbe Becket Inc, Dubai, United Arab Emirates where he delivered a number of major healthcare facilities within the Middle East region. He is a Chartered Builder and is a Member of both the Australian Institute of Building and the Australian Institute of Project Management.

In more recent times, Alan was engaged as Principal Project Manager with Aurecon

QLD with responsibilities for healthcare and education projects under the Federal BER initiatives. Tony Carroll, Coffey Projects Manager NSW/ACT said, “We are delighted to have Alan joining the Coffey Projects team. Alan has a wealth of healthcare experience and will provide leadership and focus to our existing strong health sector.”

Coffey Projects provides a wide range of specialist consulting services and products.

Equipped with the right experience, a strong culture of customer service and strong organisation and leadership skills, the team is focused on achieving total quality outcomes for clients.

AUSTRALIAN NATIONAL CONSTRUCTION REVIEW18 ANCR SPECIAL FOCUS

HUNTER DOUGLAS COMMERCIAL WINDOW COVERINGS PROVIDE A SUSTAINABLE SOLUTION

M acquarie University Library in Sydney is an architecturally designed building, intended to optimise the use of

natural light while controlling glare and heat in order to create a comfortable study area within the large 16,900m2 space.

Hunter Douglas Commercial supplied facade panels which were used to make the building look like an open book with individual pages and the spine of the book on show. Following the successful working relationship in designing the facade, Turner Bros in association with Hunter Douglas Commercial then provided a sustainable solution for the window coverings.

The project demanded window coverings that could perfectly control light and glare, without blocking out natural light altogether. Hunter Douglas Commercial GREENSCREEN® Generation Sunscreen was chosen for the project due to its environmentally sound properties.

The eco-friendly GREENSCREEN® Generation Sunscreen is a lineal twill weave knitted polyester solar shading fabric which meets the maximum VOC (Volatile Organic Compound) content criteria specified by the Green Building Council of Australia (IEQ-11). The GREENSCREEN® Generation Sunscreen fabric is also very dimensionally stable, designed to eliminate telescoping on the roll which makes the blinds easier to operate and assists them to last longer. The fabric is also capable of being recycled at the end of its lifecycle making it not only a great choice for commercial fit outs, but the environment too1. Almost 200 Hunter Douglas Commercial GREENSCREEN® Generation Sunscreen Smart Glide Roller Blinds in Bronze colour were installed.

“GREENSCREEN® Generation Sunscreen effectively reflects the light coming into the building, reducing glare without reducing the view-through to the outside,” comments Genevieve Marshall from Hunter Douglas Commercial.

“We were thrilled that we were able to offer Australian-made GREENSCREEN® Generation Sunscreen as an environmentally sound choice for this project. We continue to see a demand for such products grow in the current Australian marketplace,” continued Genevieve.

Turner Bros then recommended an 80mm External Venetian Blind to fit into a very small double skin facade.

The silver aluminium slats were fitted and completely motorised, creating an energy efficient solution where the amount of heat and light entering the building can be controlled throughout the day.

“Managing glare in this library was clearly their number one concern. Hunter Douglas Commercial GREENSCREEN® Generation Sunscreens, couple with the External Aluminium Venetian Blinds provided the best solution.” concluded Genevieve.

For further information visit www.hunterdouglascommercial.com.au or call 1300 733 078.

[1] Greenscreen can be recycled for specified and limited applications. The fabric is shredded into “shoddy” fibres and blended with other selected fibres, depending on the intended end use of the recycled yarn.

HUNTER DOUGLAS338 Victoria RoadRydalmere NSW 2116t. 1300 733 078www.hunterdouglascommercial.com.au

19ANCR SPECIAL FOCUSWWW.ANCR.COM.AU

HUNTER DOUGLAS COMMERCIAL WINDOW COVERINGS PROVIDE A SUSTAINABLE SOLUTION

M acquarie University Library in Sydney is an architecturally designed building, intended to optimise the use of

natural light while controlling glare and heat in order to create a comfortable study area within the large 16,900m2 space.

Hunter Douglas Commercial supplied facade panels which were used to make the building look like an open book with individual pages and the spine of the book on show. Following the successful working relationship in designing the facade, Turner Bros in association with Hunter Douglas Commercial then provided a sustainable solution for the window coverings.

The project demanded window coverings that could perfectly control light and glare, without blocking out natural light altogether. Hunter Douglas Commercial GREENSCREEN® Generation Sunscreen was chosen for the project due to its environmentally sound properties.

The eco-friendly GREENSCREEN® Generation Sunscreen is a lineal twill weave knitted polyester solar shading fabric which meets the maximum VOC (Volatile Organic Compound) content criteria specified by the Green Building Council of Australia (IEQ-11). The GREENSCREEN® Generation Sunscreen fabric is also very dimensionally stable, designed to eliminate telescoping on the roll which makes the blinds easier to operate and assists them to last longer. The fabric is also capable of being recycled at the end of its lifecycle making it not only a great choice for commercial fit outs, but the environment too1. Almost 200 Hunter Douglas Commercial GREENSCREEN® Generation Sunscreen Smart Glide Roller Blinds in Bronze colour were installed.

“GREENSCREEN® Generation Sunscreen effectively reflects the light coming into the building, reducing glare without reducing the view-through to the outside,” comments Genevieve Marshall from Hunter Douglas Commercial.

“We were thrilled that we were able to offer Australian-made GREENSCREEN® Generation Sunscreen as an environmentally sound choice for this project. We continue to see a demand for such products grow in the current Australian marketplace,” continued Genevieve.

Turner Bros then recommended an 80mm External Venetian Blind to fit into a very small double skin facade.

The silver aluminium slats were fitted and completely motorised, creating an energy efficient solution where the amount of heat and light entering the building can be controlled throughout the day.

“Managing glare in this library was clearly their number one concern. Hunter Douglas Commercial GREENSCREEN® Generation Sunscreens, couple with the External Aluminium Venetian Blinds provided the best solution.” concluded Genevieve.

For further information visit www.hunterdouglascommercial.com.au or call 1300 733 078.

[1] Greenscreen can be recycled for specified and limited applications. The fabric is shredded into “shoddy” fibres and blended with other selected fibres, depending on the intended end use of the recycled yarn.

HUNTER DOUGLAS338 Victoria RoadRydalmere NSW 2116t. 1300 733 078www.hunterdouglascommercial.com.au

AUSTRALIAN NATIONAL CONSTRUCTION REVIEW20 ANCR SPECIAL FOCUS

W hen the economic going gets tough, information about opportunities is the key to keeping a construction trade

or service business thriving. Cordell Information have the data on 90 per cent of all the construction activity occurring across the nation, from earliest tendering and design stages through to completion, commissioning and handover.

This means Cordell’s clients can tap into all the possibilities available in the marketplace, whether they are a contractor looking for an ECI project, or a finishing trade looking for work on the final stages of interior fitout, or a business which sells services or products to projects or subcontractors at any stage of works, such as site hygiene services, catering and pre-handover cleaners.

“We give our clients the information on what the projects are, where they are and the name of who they need to speak to, and their phone and email contact details, so our client can get in touch and sell their services or products,” said Cordell Information National Sales Manager, Martin Stevens.

“Our information has to provide reliability, it has to be timely, and it has to be comprehensive. Part of our integrity as a company is, if we say a project is happening, or say a particular architect is designing a project, then that is reliable information. It all starts with reliable information.

“The information has to be timely. For example, if a project is at tender stage, our information has to say who is tendering, and the moment the main contractor is known, we upload that information the moment we find out. It is in our interests – and our clients’ interests - to ensure we get information into our system at the earliest possible opportunity, and then get that reliable information out to our subscribing clients in a timely manner.

“Our information is comprehensive. We look at every type of construction from private house extensions up to the $100 billion Gorgon Gas project and everything in between.”

NO-ONE KNOWS THE INDUSTRY LIKE CORDELL

Cordell Information has a dedicated corps of highly skilled, experienced researchers located at offices in Sydney (Head Office), Melbourne, Brisbane, Perth and Adelaide. These researchers scrutinise all the nation’s daily newspapers, internet sources

CORDELL INFORMATIONTHE INSIDE TRACK TO BUSINESS SUCCESS

and local council websites for details of construction activity, and canvass the company’s extensive network of long term relationships with Government departments, councils, builders, interior designers and other industry sources for details of projects and construction activity.

The results of the constant research into construction activity are uploaded into the Cordell database, and then made available to subscribing clients in the form that best meets their needs: as printed publications; emails; or through internet access to the Cordell Connect database. Subscribers also set the parameters, in terms of the stages, locations, sector types and sizes of projects that form the basis of their target market.

Perhaps the best endorsement of the comprehensive and reliable qualities of Cordell data is the fact the Australian Bureau of Statistics rely on Cordell for information, as does the Housing Industry Association, who generate their reports on the state of the industry based on Cordell insight.

By generating such a detailed picture of construction industry activity in all sectors across the nation, Cordell are the trend spotters companies including Woolworths, Bunnings and TradeLink rely on to inform critical decisions. Cordell produces quarterly reports which identify not only which sectors are blowing hot or cold, but where in the country the high levels of activity are occurring. For companies looking to open new hardware and DIY retail outlets, knowing where the new residential corridors are can guide decisions about where to most profitably locate new stores. For trades and specialist suppliers, this provides the knowledge of where to target new marketing efforts.

TURNING KNOWLEDGE INTO OPPORTUNITY

Cordell Information has been researching the construction industry since 1969, giving their team a vast experience in understanding how the industry works.

As the decades have passed, and new digital technologies have created new opportunities, Cordell Information has developed three specific divisions which maximise the possibilities their comprehensive information offers for savvy construction operators. And all of this

21ANCR SPECIAL FOCUSAUSTRALIAN NATIONAL CONSTRUCTION REVIEW20 ANCR SPECIAL FOCUS WWW.ANCR.COM.AU

21ANCR SPECIAL FOCUSWWW.ANCR.COM.AU

W hen the economic going gets tough, information about opportunities is the key to keeping a construction trade

or service business thriving. Cordell Information have the data on 90 per cent of all the construction activity occurring across the nation, from earliest tendering and design stages through to completion, commissioning and handover.

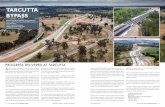

This means Cordell’s clients can tap into all the possibilities available in the marketplace, whether they are a contractor looking for an ECI project, or a finishing trade looking for work on the final stages of interior fitout, or a business which sells services or products to projects or subcontractors at any stage of works, such as site hygiene services, catering and pre-handover cleaners.