Texture Yarn

description

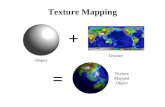

Transcript of Texture Yarn

46

air content and therefore greater insulating capacity,gloss reduction, improved texture, avoid pilling.Chemical fibre filaments are usually used as fibre ma-terial (in addition to acetate, tri-acetate, cupro, viscose,mainly polyamide 6/6.6, polyester, polyacrylonitrile,modacryl). Special yarns made of natural fibre(e.g. → Slack mercerization of cotton) are less signifi-cant.

The extensive range of textured yarns makes it nec-essary to divide them simply into the following tex-tured yarn types in accordance with their main proper-ties of appearance and manufacture:

I. Stretch-yarns: highly elastic, stretchable to ap-prox. 5-fold length, usually made of thermoplastthreads with relatively low bulk (→ Helenca principle),preferable not doubled but in Z or S form. Producedmainly by means of real or false twist process, Klingenprocess. (→: Core spun yarns; Elastomeric fibres).

II. Crimped yarns: in addition to strong mechanicalor chemically-created crimp, these are characterised bymoderate elasticity and moderate to strong volume.Production particularly according to stuffer-box proc-ess, gear-wheel crimping process. (Bi-component yarn;in the case of bi-component thread material bulking isalso by means of subsequent hot-air treatment in tum-bler or in specialised dry-cleaning machine).

III. Bulked yarns: are characterised by high volumeand therefore good covering power, combined with rel-atively low additional elasticity. Produced mainly byair jet technique.

IV. Types on the borderline of basic types I.-III, forexample highly-elastic volume-yarns, elasticity-regu-lated (so-called modified) stretch yarns, high-volumecrimped yarns and the like (e.g. →: Torque; Non-torqueyarns).

BISFA definition of textured yarns:– Dual-component yarn: textured yarn containing fil-

aments which consist of two components (dual-component fibres).

– False twist bulked yarn: texture yarns treated withfalse twist process producing high crimp elasticityor crimp contraction.

– False twist yarn (set yarn): yarn treated with falsetwist process where a heat fixing process is carriedout in a state of intermediate tension between com-plete relaxation and complete uncrimping.

– Yarns with variously shrinking filaments: texturedyarn made of two groups of filaments with differingshrinking properties.

– Knit/de-knit yarn which is de-knitted after knitting.– Torque-yarn: yarn with a strong looping tendency.

Texturing This term isused to include all processstages downstream of the actual texturing process. Inthe filament yarn sector these include:– Intermingling: normally accomplished by air-jet

techniques,

– Assembling: combination of multiple yarns withzero twist,

– Coning (winding): transferring the yarn onto a suit-able carrier.Texturizing The treatment of smooth filament

yarns by permanently modifying the orientation of themolecular structure giving it more textile character.The changes to texturized yarns are: improved softness,volume and covering power, increased thermal insula-tion effects and an end-use required increase in elastic-ity. Thermoplastic filament yarns are particularly suita-ble for texturizing, i.e. yarns which are deformable un-der the influence of heat. These are mainly polyamideand polyester yarns. The most important texturizingprocesses are (Fig. 1):– Twist-texturizing (including false twist): A filament

yarn which has been twisted under the influence ofheat is straightened again.

– Air jet texturizing: Yarn is crimped in a turbulentcurrent of air (gas or steam).

– Knit/de-knit texturizing: Yarn is knitted, subjectedto heat treatment and then de-knitted.

– Stuffer box-texturizing: Yarn is crimped by meansof compression.

– Asymmetrical heat-texturizing: Contraction of thefilaments on one side only is induced by asymmetri-cal heat treatment.

– Edge-texturizing: Yarn is pulled over an edge at anacute angle.

– Gear wheel-texturizing: Yarn is crimped betweentwo sprockets.

Processes have been developed for the most commonlyused twist-texturizing with which the texturizing pro-cedure is combined with stretching.

Thermoplastic filament yarns are usually smoothwhen they have been spun and less well adapted to re-quirements than natural fibre yarns. The textile quali-ties of such yarns are improved significantly by textur-izing procedures. Texturizing often increases the vol-ume of the filament yarn by modifying the geometricalform of the filaments resulting in a certain elasticity insome cases which represents an advantage for the yarn.In the lower decitex range up to 300 dtex (frequentlyclothing fabrics, underwear and curtains) the false twisttexturizing process is the predominant texturizing tech-nique. This is mainly due to the economical nature ofthe technique but also to the elastic properties of theresulting yarn.

The false twist texturizing process (Fig. 2) is basedon twisting the filament to a high-twist density and fix-ing this twist into the molecular structure of the fila-ments by heating and subsequent cooling in this twistedform. The yarn is then completely straightened. As thefilaments and therefore their molecules have had a mi-grated spiral-form configuration, back-winding the fil-aments does not re-align the molecules. The filaments

Texturing

47

Fig. 1: Comparison of the most current texturizing processes.

GEOMETRICCONFIGURATION

MOLECULARSTRUCTURE

FIRSTHEATER

SPINDLE(S)

SECONDHEATER

corkscrewed HE yarn

SET corkscrewed yarn

Fig. 2: Schematic illustration of thefalse twist texturizing process with thegeometric and molecular structure ofan individually texturized filament in

different processing stages (accordingto Akzo).

Texturizing

Zig-zag to Inelastic yarn,wavy increasedcrimp, low loftiness dueelasticity, to capillaryincreased thread loop

formation,fancy yarns

Workingplan

Falsetwist

Edge crimpingprocess

Knit/Deknitprocess

Stuffer boxprocess

Air jetprocess

Properties

Crimpstructure

Highly elastic (HE)yarn, goodextensibility andlarge bulk volume,as stabilised (set)yarn, lofty withless elongation

Helical crimp,elastic yarn lowwith increasedbulk volume

Wavy crimp,elongation, yarnproduces aloftiness crepeeffect