Test report of the room heaters SIGMA & DELTA of … · done by SGS, see report nr. EZKA/11/054-15....

Transcript of Test report of the room heaters SIGMA & DELTA of … · done by SGS, see report nr. EZKA/11/054-15....

SGS Nederland B.V.. Malledijk 18 P.O. Box 200 3200 AE Spijkenisse The Netherlands t+31 (0)181 69 33 33 f+31 (0)181 62 35 66 www.sgs.nl

R.C. Rotterdam No. 24226722 Member of the SGS Group

All orders are executed only in accordance with the latest version of our conditions filed at the Rotterdam District Court or the General Cargo Survey and

Inspection Conditions, last version, filed at the Rotterdam District Court and at the Chamber of Commerce in Rotterdam. Upon request the conditions will be sent to you.

Test report of the room heaters

SIGMA & DELTA

of PANADERO DENIA S.L.

SGS registration

Our reference EZKA/13/104-2

Revision 0

Date report June 27, 2013

Author report J. Dekker

SGS Environmental Services P.O. Box 5252 NL-6802 EG Arnhem Tel : +31 (0) 26-38 44 500 Fax : +31 (0) 26-44 29 410 BTW : NL 00 44 0 77 26 B01 R.C. Rotterdam: 24226722 www.sgs.com

© SGS Environmental Services Page 2 of 15 Reportnr.: EZKA/13/104-2

Status : final

Revision history

Rev. Date Changes

0 June 27, 2013

1

2

3 At revision the prior editions of this report are to be discarded.

Project managment data

General

Company name Panadero Denia S.L.

Address P.I. Campollano - Avda. 5ª 13-15, 02007 ALBACETE, Spain

Internet address www.panadero.com

Reference number customer -

Reference number SGS EZKA/13/104-2

Appliance

Name Sigma & Delta

Category Space heating appliance fired by solid fuel.

Material Steel body. Combustion chamber and baffle plate made of vermiculite.

Measurement information

Test category Initial type test based on historical data

Method In accordance with NEN EN 13240:2001 and NEN EN 13240-A2:2004

Period April 2013

Measurement technician J. Dekker

Authentication

Consultant Manager Environmental Services

J. Dekker

J. Boot

Quality

For our scope of accreditation (RvA L092) of the Environmental department of SGS Nederland BV we refer to the site of the Dutch Council for Accreditation (RvA)

(http://www.rva.nl/?p=cins0200), last three pages

Disclaimer Unless otherwise agreed, orders are executed in accordance with the latest version of the SGS Nederland BV General Conditions. Upon simple request the

conditions will again be sent to you. Attention is drawn to the limitation of liability, indemnification and jurisdiction issues defined therein.

Any holder of this document is advised that information contained hereon reflects the company’s findings at the time of its intervention only and within the limits

of Client’s instructions, if any. The Company’s sole responsibility is to its Client and this document does not exonerate parties to a transaction from exercising all

their rights and obligations under the transaction documents. Any unauthorized alteration, forgery or falsification of the content or appearance of this document is

unlawful and offenders may be prosecuted to the fullest extent of the law.

© SGS Environmental Services Page 3 of 15 Reportnr.: EZKA/13/104-2

Status : final

Table of contents

1 INTRODUCTION ................................................................................................................. 4

1.1 SPECIFICATION OF THE TYPE TEST ............................................................................................. 4

1.2 DESCRIPTION OF THE ROOM HEATER ......................................................................................... 4

1.3 ABSTRACT OF THE TEST RESULTS .............................................................................................. 5

2 RESULTS OF ASSESSMENTS .......................................................................................... 6

2.1 USED MATERIALS, DESIGN AND CONSTRUCTION ......................................................................... 6

2.2 SAFETY REQUIREMENTS............................................................................................................. 8

2.3 APPLIANCE INSTRUCTIONS ......................................................................................................... 9

2.4 MARKING ................................................................................................................................... 9

3 MEASUREMENTS ............................................................................................................ 10

3.1 TEST FUEL SPECIFICATION ....................................................................................................... 10

3.2 PERFORMANCE TEST AT NOMINAL HEAT OUTPUT ...................................................................... 11

3.3 TEMPERATURE SAFETY ............................................................................................................ 12

ANNEX A ................................................................................................................................. 13

ANNEX B ................................................................................................................................. 14

© SGS Environmental Services Page 4 of 15 Reportnr.: EZKA/13/104-2

Status : final

1 Introduction

1.1 Specification of the type test

Test report of a room heater fired by solid fuels in accordance with NEN EN 13240:2001 and

NEN EN 13240-A2:2004.

Laboratory

Name, address SGS Nederland BV Leemansweg 51 6827 BX Arnhem The Netherlands

Notified under EC number 0608

Manufacturer Panadero Denia S.L.

P.I. Campollano - Avda. 5ª 13-15 02007 ALBACETE Spain

Principal Panadero Denia S.L.

Appliance Sigma & Delta

Nominal heat output 10 kW

Recommended fuels Wood logs

Test category Type test based on historical data of a test on room heater

Kiev of Panadero Denia, S.L. in accordance with EN 13240

done by SGS, see report nr. EZKA/11/054-15.

1.2 Description of the room heater

Sheet metal stove with a front window door. The combustion chamber is insulated with vermicu-lite and equipped with a vermiculite baffle plate. The amount of combustion can be regulated by two controllers at the bottom of the appliance. The flue gas connection is situated at the top of the stove. Room heaters Sigma and Delta are technically the same as model Kiev. The new models have a different door and body cover. These changes have no influence on the technical performance of the appliances. Therefore no objections exist from the side of the test laboratory in using the data obtained with the room heater Kiev for room heaters Sigma and Delta.

© SGS Environmental Services Page 5 of 15 Reportnr.: EZKA/13/104-2

Status : final

1.3 Abstract of the test results

The following essential characteristics as defined in Annex ZA of NEN-EN 13240:2001 and NEN-EN 13240-A2:2004 have been tested with beech and fir timber (5*5 cm) as fuel and the results are as shown in the table below. Test results Kiev (SGS report: EZKA/11/054-15)

Essential characteristic Performance

Test fuel Beech

Fire safety Pass

Emission of combustion

products, related to 13% O2

CO:

NOx:

CxHy:

Dust:

0.09

104

18

35

vol%

mg/m03 y

mg/m03 y

mg/m03

Surface temperature Pass

Thermal output 10.1 kW

Energy efficiency 78.7 %

Release of dangerous

substances

Pass

Sigma and Delta are intermittent burning appliances. The appliances are not suitable for installation on a shared flue gas system. This test report with pages 1 until 12 and the annexes A and B contain the results of the type test in compliance with NEN-EN 13240:2001 and NEN-EN 13240-A2:2004.

© SGS Environmental Services Page 6 of 15 Reportnr.: EZKA/13/104-2

Status : final

2 Results of assessments

2.1 Used materials, design and construction

Clause Approved

Production documentation

Documentation and/or drawings contain:

- Specification of used materials

- Nominal heat output using recommended fuels

When fitted with a boiler, specification of the:

- used welding process

- permissible max. operating temperature, °C

- permissible max. operating pressure, bar

- type test pressure, bar

- water heating output, kW

4.1

yes

yes

n/a

General construction requirements

No asbestos

No hard solder, containing cadmium

Thermal insulation materials: non-combustible, no health risk

Design of spare parts ensures correct fitting

Seals made of fire cement supported by adjacent metal surfaces

4.2.1

yes

yes

yes

yes

n/a

Integral boiler

4.2.2 n/a

Cleaning of heating surfaces

- all heating surfaces accessible

- easy cleaning with commercially available tools or brushes

- cleaning tools provided by the manufacturer

4.2.3

yes

yes

n/a

Flue spigot or socket

Fitting overlap is:

≥ 25 mm for vertical connection

≥ 40 mm for horizontal connection

≥ 6 mm for inset appliances with insulating mortar infill

4.2.4

yes

n/a

n/a

Flue ways and cleaning tools

Minimum size:

- bituminous coal > 30 mm

- no bituminous coals > 15 mm

- easy cleaning with commercially available tools or brushes

- cleaning tools provided by the manufacturer

4.2.5

n/a

yes

yes

n/a

Ash pan and ash removal

Volume of ash pan enough for two full charges of fuel

No obstruction of combustion air

4.2.6

yes

yes

© SGS Environmental Services Page 7 of 15 Reportnr.: EZKA/13/104-2

Status : final

Clause Approved

Bottom grate

When removable – correct assembly is ensured

Capable of de-ashing without undue effort

4.2.7

yes

yes

Combustion air supply

Primary air inlet control:

- manual or thermostatic control

- adjusting control clearly visible and permanently marked

- correct setting for each fuel type is identifiable

- no obstruction of the air inlet control by ash or unburnt fuel

Secondary air (air wash) and tertiary air inlet control:

- Passage of air is not restricted by fuel

4.2.8

yes

yes

n/a

yes

n/a

Control of flue gas

If flue damper is fitted:

- easily operable

- aperture ≥ 20 cm2 or 3% of the cross-sectional area

- position of damper can be identified

If draught regulator is fitted:

- easily accessible for cleaning

4.2.9 n/a

Fire doors and charging doors

Large enough to fill appliance with commercially available fuels

Accidental opening is prevented

Positive closure

4.2.10

yes

yes

yes

Flue bypass device

Easy operable

Position easily identifiable

4.2.11

n/a

n/a

Front fire bars – deepening plate

Correct assembly is ensured

No accidental dislodging

4.2.12

n/a

yes

Solid mineral fuel and peat briquettes burning appliances

Bottom grate and ash pan present

4.2.13 n/a

© SGS Environmental Services Page 8 of 15 Reportnr.: EZKA/13/104-2

Status : final

2.2 Safety requirements

Clause Approved

Natural draught safety test

Flue draught ≥ 3 Pa

If Flue draught is < 3 Pa:

- CO-volume ≤ 250 dm3/10 h

5.1 n/a

Spillage of gas, discharge of embers

No escape of harmful gases

Embers do not fall out

5.2

yes

yes

Strength and leak tightness of boiler shells

No leakage or permanent deformation after completion of the tests

5.3 n/a

Temperature in fuel storage container (above ambient)

Temperature < 65 K

5.4 n/a

Operating tools

Operating tools provided

Touched areas without tools

Temperature: metal < 35 K (above ambient)

porcelain < 45 K

plastics, rubber, wood < 60 K

5.5

yes

n/a

Temperature of adjacent combustible materials

Temperature ≤ 65 K (above ambient)

(see installation and operating manual for information about

clearing distances and insulation)

5.6

yes

Thermal discharge control

If discharge control is part of appliance:

opens at water temperature > 105 °C

or

opens at water temperature > declared value

5.7 n/a

© SGS Environmental Services Page 9 of 15 Reportnr.: EZKA/13/104-2

Status : final

2.3 Appliance instructions

Instructions Clause Approved

In the language of the country of intended

destination

7.1 -

Not in contradiction to the requirements and test

results

7.1 -

Contains the required information 7.2 -

Contains the required information 7.3 -

- Not reviewed.

2.4 Marking

Clause Approved

Permanently and legibly marked

Readable

8

8

-

-

Durable and abrasion proof

No discoloration or detachment

8

8

-

-

Contains the required information 8 -

- Not received.

© SGS Environmental Services Page 10 of 15 Reportnr.: EZKA/13/104-2

Status : final

3 Measurements

3.1 Test fuel specification

Test fuel

Moisture

%

Ash

%

Volatile matter

% dry, ash free

H

%

C

%

S

%

Hu

kJ/kg

Size, length

Beech 13.8 1.16 84.2 4.7 43.4 0.03 16,013 20

Fir timber 12 0.98 84.5 4.92 43.9 0.04 16,247 20

© SGS Environmental Services Page 11 of 15 Reportnr.: EZKA/13/104-2

Status : final

3.2 Performance test at nominal heat output

Test results Kiev (SGS report: EZKA/11/054-15)

Clause Test 1 Test 2 Test 3

Mean of

3 tests Approved

Date (dd-mm-yy) 03-11-11 03-11-11 03-11-11

Test fuel Tab. B1 Beech Beech Beech Beech

Total mass kg A.4.2 2.00 2.10 1.93 2.01 yes

Setting of air slide

- Combustion air 10% 10% 10% 10%

Mean flue draught Pa 6.1 11.8 11.8 11.9 11.8 yes

Mean flue gas temperature

(above ambient#) K 284 303 303 296

Mean CO2 concentration % 9.86 12.32 11.76 11.32

Mean CO concentration % 0.18 0.10 0.11 0.13

Mean CO concentration at 13% O2 vol% 6.3 0.14 0.06 0.08 0.09 yes

Mean CO concentration at 13% O2 mg/m03 1797 763 938 1164

Mean CO2 concentration during dust

measurement vol% 11.02 13.11 12.47 12.21

Dust concentration mg/m03 76 35 50 53

Dust concentration at 13% O2 mg/m03 53 21 32 35

NOx concentration mg/m03 161 141 141 148

NOx concentration at 13% O2 mg/m03 127 90 94 104

CxHy concentration mg/m03 37 16 23 25

CxHy concentration at 13% O2 mg/m03 29 10 15 18

Combustion time Dev.

from required combustion time h % 6.5

0.70 0.73 0.67 0.70 yes

-7 -3 -11 -7

Theoretical combustion time h A.4.7.3 0.68 0.75 0.68 0.70

Thermal heat losses % 21.41 19.05 19.78 20.07

Chemical heat losses % 1.2 0.5 0.6 0.8

Heat losses due to combustible

constituents in the residue

% 0.5 0.5 0.5 0.5

Efficiency % 6.4.3 76.9 80.0 79.1 78.7 yes

Mean nominal heat to space kW 6.6 9.7 10.3 10.2 10.1 yes

Theoretical heating output kW A.5 9.1 10.0 9.1 9.4

Flue gas mass flow g/s 8.4 7.0 7.3 7.6

# Room temperature during tests: 21.1 OC

© SGS Environmental Services Page 12 of 15 Reportnr.: EZKA/13/104-2

Status : final

3.3 Temperature safety

Test results Kiev (SGS report: EZKA/11/054-15)

§ Test Approved

Date (mm-dd-yy) 09-11-11

Test fuel A.4.9.2.2.1 Fir timber 5*5 yes

Total load kg A.4.9.2.2.1 8.1 yes

Number of loads - 6

Settings of controls for:

- primary air

30%

Mean flue draught Pa 6.1 15 yes

Ambient temperature °C - 22.0

Max. surface temperature (above ambient)

Trihedron floor*

K 5.6 n/a n/a

Trihedron back wall

(distance 30 cm)

K 5.6 45 n/a

Trihedron side wall

(distance 30 cm)

K 5.6 64 yes

Fuel storage container K 5.4 46 n/a

Loss of fire bed 4.2 no yes

Escape of harmful combustion gases 4.2 no yes

Damage on the appliance caused by the test 4.2 none yes

* Appliance must be placed on a non-combustible floor.

© SGS Environmental Services Page 13 of 15 Reportnr.: EZKA/13/104-2

Status : final

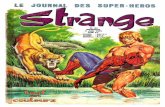

Annex A

Pictures of the appliances

- Sigma - - Delta -

© SGS Environmental Services Page 14 of 15 Reportnr.: EZKA/13/104-2

Status : final

Annex B

Drawings of the appliances