Tensile Test

Transcript of Tensile Test

Title: The Tensile test

Objective:

To become familiar with tensile testing system

To learn how to develop stress-strain curve from load-displacement curve

for materials

To learn how to extract important material properties from these curve

such as engineering stress, strain, yield stress, percentage of

elongation…etc

Introduction:

In order to compare and select materials for various applications, one must

have access to the important properties of that material i.e. material constant.

One of the most often used tests performed to determine a number of

important mechanical properties of material is tensile test. This test is

conducted to specimens that have uniform horizontal cross section in the

Universal Testing Machine that can show the load applied for any elongation

that is obtained from the gauge length

Based on the load and displacement obtained from the experiment, we can

get:

(a) Engineering tensile stress,

ε = F/Ao (N/mm²)

(b) Strain,

ε = L1 – Lo / Lo

(c) Yield stress,

σy = Yield load / initial cross-sectional area (N / mm²)

(d) Ultimate tensile stress,

σm = Maximum load / initial cross-sectional area (N / mm²)

(e) Elongation percentage,

%EL = (L1 – Lo / Lo) × 100 (%)

(f) Reduction percentage in area

(%) = (Ao– A1 / Ao) × 100

Where:

F = Load (N)

Ao = Initial horizontal cross- sectional area, (mm²)

A1 = Final horizontal cross- sectional area, (mm²)

Lo = Initial gauge length, (mm)

L1 = Final gauge length, (mm)

Yield load and maximum load can be obtained from the load-displacement

curve produced from each experiment is

(1) Mild Steel

Fy = Yield load, (N)

Fm = Maximum load, (N)

Fp = Load at break, (N)

Displacement (mm)

Fy

Fp

Fm

Load (N)

(2) For aluminium alloys or specimen that does not have certain yield load, it

can be obtained with “offset strain 0.2 % method” and known as ‘pruf

stress’.

Fm = Maximum load (N)

Fp = Load at break (N)

F0.2% = pruf stress

Specimen:

Mild Steel

Aluminiun Alloy

Apparatus:

Universal testing Machine

Procedure:

(a) The diameter and gauge length for all the specimen provided is taken

(b) The specimen is installed inside the testing machine and load is added

little by little until the specimen break, Value of the load applied and

elongation is recorded

(c) The diameter and the gauge length of the specimen at the fractured part is

once again measured and recorded

(d) The it fracture for both specimen is observed

F0.2%

Fp

Fm

Displacement (mm)

Load (N)

Result:

Diameter of the specimen

Specimen Reading / mm (i) (ii) (iii) Average

Aluminium alloy

Initial diameter 9.70 9.80 9.80 9.77

Final diameter 6.80 6.80 6.80 6.80

Diameter difference 9.77 – 6.80 = 2.97

Mild SteelInitial diameter 9.80 9.90 9.90 9.87

Final diameter 6.50 6.40 6.60 6.50

Diameter difference 9.87 - 6.50 = 3.37

Specimen gauge length:

Specimen

Reading/ mm

Initial lengthFinal length Difference

1 2 3 Average

Aluminium alloy 50.00 61.10 61.50 61.10 61.23 11.23

Mild steel 50.00 71.70 68.00 73.70 71.00 21.00

Calculation:

Aluminium alloy

Initial cross-sectional area, Ao = π(d²/4)

= π (9.77²/4)

= 74.97mm²

Final cross-sectional area, A = π(d²/4)

= π (6.80²/4)

= 36.32mm²

Based on the computer calculated data;

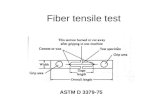

Title: Mechanical properties of plastic

Objective: To obtain yield tensile stress (σy), breaking stress (σb) and

elongation (ε) for plastic.

(i) PE (Polyethelene), (ii) ABS (Acrylonitrile Butadiene Styrene)

Introduction: Refer to the figure to obtain:

Figure

(1) Tensile stress

σ = F/A

σ = stress- tensile (N/m²)

F = force (N)

A = area (m²)

(2) Elongation

ε = (L-Lo/Lo) × 100%

ε = elongation

Lo = initial length

L = final length

(3) Stress- elongation curve

i.e. polyethelene ( PE)

F

F

A

F

F

Lo L

σy = yield stress

σb = breaking stress

Procedure:

(a)The dimension of the plastic specimen given is measured

(b) Change the shape until the specimen breaks

(c) Elongation and the load is obtained to calculate tensile stress

Result and Discussion:

(1) PE (polyethelyne)

Lo= 50 mm

Reading/mmFinal

length(L1)Initial

width(wo)Final

width (w1)Initial

thickness(to)Final

thickness(t1)1 211.0 12.85 5.25 3.30 1.102 210.0 12.85 6.40 3.30 1.103 210.0 12.85 5.25 3.30 1.10

Average 210.3 12.85 5.63 3.30 1.10

(2) ABS (Acrylonitrile butadiene styrene) Lo = 50 mm

Elongation %

Stress (MN/m)

σy σb

Reading/mmFinal

length(L1)Initial

width(wo)Final

width (w1)Initial

thickness(to)Final

thickness(t1)1 50.0 13.15 13.15 3.30 3.302 50.0 13.10 13.10 3.25 3.253 50.0 13.15 13.15 3.25 3.25

Average 50.0 13.13 13.13 3.27 3.27

Calculation:

PE: Ao = wo× to

= 12.85×3.30

= 42.405mm²

ABS: Ao = wo× to

= 13.13×3.27

= 42.935mm²

For PE plastic:

Maximum load (based on computer data), F = 807 N

Yield stress, σy= F/Ao

= 807/ 42.405

= 19.03 N/mm²

Breaking load (based on computer data), F = 51 N

Breaking stress, σb = F/Ao

= 51/ 42.405

= 1.12 N/mm²

Elongation, ε = x 100%

= [(210.3 – 50.0)/50.0] × 100%

= 320.6%

For ABS plastic:

Maximum load (based on computer data), F = 1689 N

Yield stress, σy= F/Ao

0

01

L

LL

= 1689/ 42.935

= 39.34 N/mm²

Breaking load ( based on computer data), F = 1630

Breaking stress, σb = F/Ao

= 1630/ 42.935

= 37.96 N/mm²

Elongation, ε = x 100%

= [(50.0 – 50.0)/50.0] × 100%

= 0.00%

Conclusion:

PE plastic is more ductile compared to ABS plastic. The difference in property of

PE plastic is because it can absorb more energy compare to ABS plastic. PE

plastic has larger area under the curve thus it shows that it can absorb more

energy. Furthermore, the higher value of elongation percentage,ε for PE plastic

compare to ABS plastic suggests that PE plastic is more elastic than ABS plastic.

0

01

L

LL