Tender No. : 12000111-HB-12001 Basic Information Of...

Transcript of Tender No. : 12000111-HB-12001 Basic Information Of...

Delivery Terms - Free to Destination location unless specified otherwise. Validity of offer - 90 days from the initial or extended Due Date for submission

of Tender whichever is later unless specified otherwise. Liquidated Damages accepted unless specified otherwise.

In case bidder does not deviate from the standard offer validity in on line deviation form, bid’s offer validity shall be considered as mentioned above.

In case a Revised priced bid is initiated for this tender, at a later date (eg Technical evaluation stage etc), it shall be incumbent upon the bidder to submit

revised bids for the specified items/entire tender. In the absence of revised bids rom the bidder within specified time period, the original bid submitted by

the bidder shall not be considered for evaluation.

Tender No. : 12000111-HB-12001 Tender Published On : 23-Nov-2012 15:36

Basic Information Of TenderTitle SEAMLESS PIPES J12 - MLIF

Description SUPPLY OF SEAMLESS PIPES AT JETTY-12, MLIF

Tender Type Limited

Tender Scope Domestic

Bid Type Two Bid

Evaluation Criteria Schedule Wise

Tender Due Date & Time 18-Dec-2012 15:00

Pre Bid Conference Start Date & Time

Pre Bid Conference End Date & Time

Queries Start Date & Time 24-Nov-2012 09:00

Quries End Date & Time 06-Dec-2012 15:00

Un Priced Bid Open Date & Time 18-Dec-2012 15:01

Tender Description This Limited Tender is floated for procurement of seamless pipes for J12 facilities.Delivery period : 2monthsApplicable Evaluation criteria : Schedule-wiseNOTICE INVITING e TENDER (NIT) : This e Tender is invitedunder TWO BID system as per details enclosed in the tender. Bidders are requested to note that this tender is alimited tender on e-procurement platform and hence the interested bidders can participate in the tender only throughthe internet through the website https://etender.hpcl.co.in. The minimum requirement is of possession of DigitalCertificate Class II/ Class III ( for tender purpose having the facility of signing, data encryption and decryption) by thevendor .The system requirement details are also available at the website https://etender.hpcl.co.in. NSIC registeredparties will be given price preference as per applicable govt. guidelines subject to their uploading of NSIC registrationcertificate. It will be entire responsibility of the vendor to get registered in HPCL e procurement module & to submitthe bid in e procurement module within due date & time. HPCL will not be responsible for delay of submission of biddocument by vendor due to any reason whatsoever. Contact Prabhakar Sant ( 022-22637013)- Manager--EP&P-LPG regarding any query about this tender. You may also contact the Help Desk at 022-42100111. HPCL has agrievance handling system details of which is available at HPCL Web site.

Currency Type Tender Fee EMD

INR 0.0 0.0

Tender No. : 12000111-HB-12001 Tender Published On : 23-Nov-2012 15:36

Line Details Of TenderSrl.No.

Line Description UOM Quantity Mandatory

SUPPLY OF SEAMLESS PIPES AT JETTY-12, MLIF Manadatory: Yes

1 3/4" PIPE,ASTM A 333 Gr. 6, SM Meters 60 Yes

DESCRIPTION => 3/4" PIPE,ASTM A 333 Gr. 6, SMLS, SCH 80, PE, ASME B 36.10

2 3/4" PIPE,ASTM A 333 Gr. 6, SM Meters 30 Yes

DESCRIPTION => 3/4" PIPE,ASTM A 333 Gr. 6, SMLS,SCH 160, PE, ASME B 36.10

3 1" PIPE,ASTM A 333 Gr. 6, SMLS Meters 30 Yes

DESCRIPTION => 1" PIPE,ASTM A 333 Gr. 6, SMLS SCH 80, PE, ASME B 36.10

4 1" PIPE,ASTM A 333 Gr. 6, SMLS Meters 30 Yes

DESCRIPTION => 1" PIPE,ASTM A 333 Gr. 6, SMLS, SCH 160, PE, ASME B 36.10

5 2" PIPE,ASTM A 333 Gr. 6, SMLS Meters 30 Yes

DESCRIPTION => 2" PIPE,ASTM A 333 Gr. 6, SMLS, SCH 40, BE, ASME B 36.10

6 6" PIPE,ASTM A 333 Gr. 6, SMLS Meters 90 Yes

DESCRIPTION => 6" PIPE,ASTM A 333 Gr. 6, SMLS,SCH 40, BE, ASME B 36.10

7 8" PIPE,ASTM A 333 Gr. 6, SMLS Meters 30 Yes

DESCRIPTION => 8" PIPE,ASTM A 333 Gr. 6, SMLS, SCH STD, BE, ASME B 36.10

8 10" PIPE,ASTM A 333 Gr. 6, SML Meters 30 Yes

DESCRIPTION => 10" PIPE,ASTM A 333 Gr. 6, SMLS, SCH STD, BE, ASME B 36.10

9 12" PIPE,ASTM A 333 Gr. 6, SML Meters 30 Yes

DESCRIPTION => 12" PIPE,ASTM A 333 Gr. 6, SMLS, SCH STD, BE, ASME B 36.10

10 14" PIPE,ASTM A333 Gr.6, SMLS, Meters 2400 Yes

DESCRIPTION => 14" PIPE,ASTM A333 Gr.6, SMLS, SCH STD, BE, ASME B 36.10

11 1" PIPE,ASTM A106 Gr. B, SMLS, Meters 60 Yes

DESCRIPTION => 1" PIPE,ASTM A106 Gr. B, SMLS, SCH 80, PE, ASME B 36.10

12 1" PIPE,ASTM A106 Gr. B, SMLS, Meters 30 Yes

DESCRIPTION => 1" PIPE,ASTM A106 Gr. B, SMLS, SCH 160, PE, ASME B 36.10

13 2" PIPE,ASTM A106 Gr. B, SMLS, Meters 60 Yes

DESCRIPTION => 2" PIPE,ASTM A106 Gr. B, SMLS, SCH 40, BE, ASME B 36.10

14 3" PIPE,ASTM A106 Gr. B, SMLS, Meters 60 Yes

DESCRIPTION => 3" PIPE,ASTM A106 Gr. B, SMLS, SCH 40, BE, ASME B 36.10

15 10" PIPE,ASTM A106 Gr. B, SMLS Meters 60 Yes

DESCRIPTION => 10" PIPE,ASTM A106 Gr. B, SMLS, SCH STD, BE, ASME B 36.10

16 12" PIPE,ASTM A106 Gr. B, SMLS Meters 60 Yes

DESCRIPTION => 12" PIPE,ASTM A106 Gr. B, SMLS, SCH STD, BE, ASME B 36.10

Tender No. : 12000111-HB-12001 Tender Published On : 23-Nov-2012 15:36

INTEGRTY PACTSl.No. Description HPCL File HPCL Value Supporting

Doc. Req'd

1 PL SIGN AND UPLOAD INTEGRITY PACT - Allowed

2 PL SIGN AND UPLOAD IP IP 12000111.pdf - No

Tender No. : 12000111-HB-12001 Tender Published On : 23-Nov-2012 15:36

TENDER DOCUMENTSSl.No. Description HPCL File HPCL Value Supporting

Doc. Req'd

1 1) Please confirm that you have studied and understood all the technicalspecifications, general terms and conditions of the tender and your offer is inconformity with the same.

2) Please also confirm that you shall be able to complete the subject job strictlyconfirming to the specifications and terms of the tender, if a purchase order isplaced on you.

- Allowed

2 PSU/SSI/NSIC: Are you Registered with PSU/SSI/NSIC (copy of registration tobe attached if applicable)

- Allowed

3 Name of the authorise Person of the Company: - Allowed

4 Phone, Fax No of your company: - Allowed

5 e mail ID: - Allowed

6 Latest address: - Allowed

7 VALIDITY: Confirm your offer is valid for 90 Days from due date/extended duedates for placement of order.

- Allowed

8 TECHNICAL SPECS AND SPECIAL TERMS 285731-MLIF-SP-PIP- 3003.pdf - No

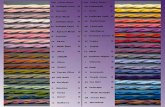

9 COLOUR CODE Colour Coding Pipes.pdf - No

10 ITP PIPES ITP Pipes.pdf - No

11 MR FRO PIPES MR for Pipes.pdf - No

12 TECHNICAL SUPPLY Technical Supply ConditionsPipes.pdf

- No

13 TENDER SUPPLY PIPES Tender Supply of pipes.pdf - No

14 GENERAL TERMS CONDITIONS GTC supply items e-proc.pdf - No

Page 1 of 26

Hindustan Petroleum Corporation Ltd Mott MacDonald Pvt. Ltd.

8, Shoorji Vallabhdas Marg Kothari House, CTS No. 185

P.O.Box No. 155 Off Andheri - Kurla Road

Mumbai 400 001 Andheri (East)

Mumbai 400 059

LPG RECEIPT AND ASSOCIATED FACILITIES AT HPCL’S MANGALORE LPG

IMPORT FACILITIES JETTY NO 12

Rev: ADoc No: 285731-MLIF-SP-PIP-3003

PIPING MATERIAL SPECIFICATION

Tile : PIPING MATERIAL SPECIFICATION

C:\Documents and Settings\shi50029\Desktop\mlif\Copy of LINE WISE MTO-GFL.xls

Page 2 of 26

Issue and Revision Record:

Description

HPCL – MLIF LTD.

285731

RMS JSP

Group Disclaimer

C

Doc No: 285731-MLIF-SP-PIP-3003 Rev: A

Originator Checked Approved

B

SNAISSUED FOR

COMMENTS/APPROVALA 28/09/2011

Rev Date

Client

MMCI Project No.

Tile : PIPING MATERIAL SPECIFICATION

PIPING MATERIAL SPECIFICATION

LPG RECEIPT AND ASSOCIATED FACILITIES AT HPCL’S MANGALORE LPG

IMPORT FACILITIES JETTY NO 12

“This document is issued for the party which commissioned it and for specific purposes connected with the above-captioned project only. It

should not be relied upon by any other party or used for any other purpose.

We accept no responsibility for the consequences of this document being relied upon by any other party, or being used for any other

purpose, or containing any error or omission which is due to an error or omission in data supplied to us by other parties.”

C:\Documents and Settings\shi50029\Desktop\mlif\Copy of LINE WISE MTO-GFL.xls

List of Contents

1 Scope

2 Reference Codes and Standards

3 Class designation philosophy

4 Pipes

5 Flanges, Spectacle Blinds, Spade/Spacer

6 Fittings

7

8 Gaskets

9 Bolting

Tile : PIPING MATERIAL SPECIFICATION

Doc No:-285731-MLIF-SP-PIP-3003 Rev: A Page 3 of 26

LPG RECEIPT AND ASSOCIATED FACILITIES AT HPCL’S MANGALORE

LPG IMPORT FACILITIES JETTY NO 12

Bends, Miters And Reducers Fabricated From Pipe

General Notes on Piping Specifications

1 Scope

1.1 This Specification (PMS) covers the various piping classes for Process and utility piping.

2 Referred Codes & Standards

2.1 All Piping shall be design in accordance with the Process Piping Code, ASME B31.3- 2010 selected shall be followed

throughout the job. Edition and addenda (if any) of referred codes and Standards shall be as per the Design Basis

(Piping) Doc No:

2.2 All materials shall conform to ASTM or API or BS or IS standards as applicable. Design and fabrication shall conform

to American Society of Mechanical Engineers (ASME) code for Pressure Piping , ”Process Piping” ASME B31.3. &

IS 1239 & IS 3589 as applicable Only latest editions of standards mentioned in Piping Design Basis shall be referred.

2.3 Individual Piping class has been generally design to cover a set of services operating within pressure-temp. combination

as per ASME B16.5 / B16.34 or part of it.

2.4 The PMS shall be strictly adhered to in the design, requisition, purchasing, fabrication and testing of piping system.

However, deviation may occure due to design conditions and/or availability.All substituition must be duly approved.

3 Class Designation Philosophy

3.1 For Piping Class designation refer Document No. 288310-500-PH-PIP-001

4 Pipes

4.1 Pipe dimensions shall be in accordance with ASME B36.10 for Carbon Steel & Alloy Steel pipe and to ASME B36.19

for Stainless Steel pipe and IS 1239 , & IS 3589 for CS Pipes.

4.2 Pipe made by acid-bessemer process shall not be acceptable, steel pipe shall be made by open hearth, electric furnace

or basic Oxygen process.

4.3 Non-Standard pipe sizes 1 ¼”, 2 ½”, 3 ½”, 5” & 22” shall not be used except where they are required for connections

to mechanical equipment for standard design or where specific velocities must be maintained. When these sizes are

used on equipments, the connecting piping shall be increased or decreased to standard sizes as close to equipment as

practical

4.4 All distribution/collection headers shall have their dead ends blind flanged.

4.5 Screwed Full Coupling shall be restricted for Instrument connections only (upto 1 ½”).

4.7 The minimum nominal pipe size shall be DN20 (¾”) except for air, instrument air,water and manufacturer’s standard

equipment piping.

4.8 Galvanized pipe shall not be bent or welded. Piping requiring bending, welding or threading shall be galvanized after

fabrication.

5 Flanges, Spectacle Blinds, Spade/Spacer

5.1 Flanges shall be in accordance with the following codes:

Steel Flanges

Class 150 to 1500 As per ASME B16.5

5.2 Class 400 flanges shall not be used unless required to match nozzles of standard design equipment’s supplied by

equipment manufacturers.

5.3 Flanges in the piping shall be kept to a minimum. Flanges shall be installed only to facilitate construction, maintenance

and inspection and in cases where process conditions dictate.

5.4 Flange boltholes shall straddle the piping vertical and horizontal centerlines.

5.5 Flange bolting shall be a fully threaded alloy steel stud bolt with two heavy hex nuts as per the relevant material standard.

All CS/AS stud bolts and nuts shall be hot dip galvanized as per ASTM A153 or Electro galvanised.Stud bolts shall have

full continuous threads & have lengths in accordance with B 16.5 with the provision that a minimum of one thread &

LPG RECEIPT AND ASSOCIATED FACILITIES AT HPCL’S MANGALORE

LPG IMPORT FACILITIES JETTY NO 12

Tile : PIPING MATERIAL SPECIFICATION

Doc No:-285731-MLIF-SP-PIP-3003 Rev: A Page 4 of 26

a maximum of three threads outside each nut & complete with 2 nuts to facilitate bolt tensioning.Stud bolts shall be

threaded full length with two heavy hexagonal nuts. Length tolerance shall be in accordance with the requirement of

table F2 of Annexure F of ASME B 16.5.

5.6 Two jack screws, 180 degrees apart shall be provided in one of the flanges for all Orifice flange assemblies,

all RTJ flange assemblies and spectacle blind assemblies.

5.7 Permanent hook eye shall be provided on blinds of weight greater than 60 lbs to facilitate changing of rings

5.8 The process of manufacture, heat treatment, chemical and mechanical requirements and marking for all stud bolts

,m/c bolts, jack screws and nuts shall be in accordance with the codes/standards and specifications given in the

requisition.

5.9 All bolting shall be as per ASME B 18.2.1 for studs and jackscrews and ASME B 18.2.2 for nuts.

5.10 Threads shall be unified (UNC for 1” dia and 8UN for >1” dia ) as per ASME B.1.1 with class 2A fit for studs and

jack screws and class 2B fit for nuts.

5.11 The nuts shall be double chamfered, semi-finished, heavy hexagonal type and shall be made by the hot forged process

and stamped as per respective material specification.

5.12 Heads of jack screws shall be heavy hexagonal type. Jack screw end shall be rounded.

5.13 The bolthole pitch circle diameter for orifice flanges DN50, DN80 and DN100 shall be 1.6 mm smaller than specified

in ASME B16.5.

5.14 When specified as Galvanised Studs, m/c bolts and nuts shall be hot dip zinc coated in accordance with requirements

of class 'C' of ASTM A 153 or Electro galvanised.

5.15 Unless otherwise specified, ID of weld neck (W.N.) flanges shall match the connecting pipe I.D and its thickness

while bore of socket weld (S.W.) flanges shall match the connecting pipe O.D and its thickness.

5.16 Colloidal molybdenum disulphide or other approved lubricant shall be applied to all Flange bolts faces before the

joints are assembled.

5.17 Flange bolts shall be tightened evenly and sequentially to impose equal pressure on the gasket and to avoid distortion

or over stressing of equipment.

5.18 When rating changes occur at flanged joints both the flange shall be of higher rating if they are of same material.

5.19 Spectacle blinds rather than spade blinds shall be provided where required.Thickness of blinds shall be calculated

in accordance with ASME B31.3. Pairs of spacers and blinds shall be used instead of spectacle blinds of

size DN 350 and larger.

5.20 The dimensions of spectacle blinds, spacer and blinds shall be as per ASME B 16.48. Spectacle blinds/spacers and

blind for sizes and ratings not available in ASME B 16.48, shall be supplied as per manufacturer standard and the

design shall be submitted to the HPCL/MMCI for review and approval.The corrosion allowance etc. shall be as per

the respective piping class.

5.21 The hydraulic bolt tensioning shall be applied for bolt diameters of 50mm & above in 150 lbs & 300 lbs rating and

38mm & above in 1500 lbs.

6 Fittings

6.1 All fittings shall be seamless in construction unless otherwise specified.

6.2 All pipe fittings specified as galvanized shall be hot dip galvanized with a minimum of 763 grams of galvanizing material

per square meter of surface area, in accordance with ASTM A153.

6.3 Fittings shall have at least the same nominal wall thickness as the pipe to which they attach. Welded fittings materials

shall be compatible with the piping material.

6.4 Usage of unions shall be restricted to utilities only.

6.5 The thickness of reducing fittings shall match the wall thickness of the higher schedule pipe wall. The fitting wall

thickness shall be tapered on a 1:4 gradient to ensure that the pipefitting wall thickness matches the lower schedule

pipe wall

LPG RECEIPT AND ASSOCIATED FACILITIES AT HPCL’S MANGALORE

LPG IMPORT FACILITIES JETTY NO 12

Tile : PIPING MATERIAL SPECIFICATION

Doc No:-285731-MLIF-SP-PIP-3003 Rev: A Page 5 of 26

6.6 Welded fittings materials shall be compatible with the piping material.

6.7 Fittings DN40 (1-½”) and smaller shall be socket weld except as dictated.

6.8 Fittings DN50 (2”) and larger shall be butt welded except as dictated.

6.9 Miter joints shall not be used.

Branch Connections

Branch connections shall be in accordance with 31.3. Branch connections for nonferrous materials shall be as per

manufactures standard with prior approval from HPCL. Contractor to prepare and list the branch tables in piping

class data sheets. The lists shall show requirements for branches at 90º angles to the header & branching component

with sufficient details. Stub in connection shall not be used.For welding run pipe directly to branch pipe

with/ without reinforcement contractor to take prior approval from the HPCL.

7 Miters And Reducers Fabricated From Pipe

Miters And Reducers Fabricated From Pipe shall not be used.

8 Gaskets

8.1 Gasket materials must be such that the internal fluids shall have no harmful or corrosive effects on them.

8.2 Gaskets or seals, when provided for end closure shall be self sealing and suitable for service conditions.

8.3 The process of manufacture dimensions and tolerances not specified in requisition shall be in accordance with the

requirements of the manufacturer’s standards.

8.4 All gaskets shall conform to the codes/standards and specifications given in the requisition. Deviation(s) if any

shall be clearly highlighted in the quotation.

8.5 All gaskets shall be supplied as per the following codes:

8.6 Metallic gaskets for piping, double jacket corrugated & spiral wound : ASME B 16.20

8.7 Non metallic flat gaskets for pipe flanges : ASME B 16.21

8.8 Asbestos or asbestos containing gaskets shall not be used.

8.9 Spiral wound gasket shall be provided with outer CS centering ring for all sizes.

8.10 Spiral wound gasket shall be provided with inner SS ring for 150# class above 24" and for 300# class above 18"

9 Bolting

9.1 All Bolts shall conform to B18.2.1 , nuts to be B18.2.2. Reference shall also be made to ASME B16.5 for Studs.

9.2 Threads shall be to coarse thread series, B1.1, having class 2A allowance for Bolts and Studs, and class 2B

tolerance for nuts.

9.3 Nuts for Bolts and Studs shall be the American Standard Hexagon heavy series.

9.4 Stud bolts shall be used for all piping closures except where tapped wafer valves dictate the use of machine bolts.

LPG RECEIPT AND ASSOCIATED FACILITIES AT HPCL’S MANGALORE

LPG IMPORT FACILITIES JETTY NO 12

Tile : PIPING MATERIAL SPECIFICATION

Doc No:-285731-MLIF-SP-PIP-3003 Rev: A Page 6 of 26

REVISION NUMBER

No of Shts A B C D E

1 TO 3 √

2 TO 3 √

3 TO 4 √

4 TO 4 √

5 TO 3 √

REVISION NUMBER

No of Shts A B CREFERENCE DOCUMENTS

10

13

21

24Pipe Class :

A09A0 8

11

18

Pipe Class :

Pipe Class :

Pipe Class :

B09A0

Q94A0

B19A0

22

PAGE NOS.SR. NO. DESCRIPTION

PIPING CLASS INDEX

DOCUMENT NUMBER

LPG RECEIPT AND ASSOCIATED FACILITIES AT HPCL’S MANGALORE LPG

IMPORT FACILITIES JETTY NO 12

Tile : PIPING MATERIAL SPECIFICATION

REV: A PAGE: 7 OF 26Doc No: 285731-MLIF-SP-PIP-3003

Pipe Class : A19A0 14 17

PIPE

FITTINGS

PIPING CLASS : A09A0

Page No. 8 OF 26

SCH 40

8" - 14"

2" - 6"

STD

SCH 40 x SCH 40

ASTM A234 Gr.WPB, SMLS

ASTM A234 Gr.WPB, SMLS BW

ASTM A234 Gr.WPB, SMLS

ASTM A105

ASME B16.9BW

BW ASME B16.9

ASTM A105

BW

BW

SW

BW

BE ASME B36.10

ASME B16.9

ASTM A106 Gr. B, SMLS POE-TOE

BW

BW

SW

BW

SW

ASME B16.11

ASME B16.9

BW ASME B16.9

ASME B16.9

ASTM A234 Gr.WPB, SMLS

ASTM A234 Gr.WPB, SMLS

ASTM A234 Gr.WPB, WELDED

ASTM A234 Gr.WPB, WELDED

PIPE 16" - 20"

CORROSION ALLOWANCEDRAIN,VENT 1.5mm

PR - 19.99 kg/cm²g,

TEMP - 38 °C

DESIGN TEMPERATURE (°C)

SERVICE

SERVICE CODE

RATING

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

ASME B36.10

ASME B36.10

BW

ASTM A234 Gr.WPB, SMLS

ASTM A234 Gr.WPB, SMLS

BW

BWASTM A234 Gr.WPB, SMLS

ASTM A234 Gr.WPB, SMLS

ASTM A234 Gr.WPB, SMLS

BW

ASME B16.9

ASME B16.9

ASME B16.9

LPG RECEIPT AND ASSOCIATED FACILITIES AT HPCL’S MANGALORE LPG IMPORT FACILITIES JETTY NO 12

Tile : PIPING MATERIAL SPECIFICATION

PREP. BY / DATE

REDUCING TEE

RMS/ 17-09-2011

CHKD. BY / DATE

APPR. BY / DATE

JSP/17-09-2011

6" x (3" to 4")

SNA/17-09-2011

8" x (4" to 6")

STD x SCH 40REDUCING TEE 10" x (4" to 6")

REDUCING TEE

REDUCING TEE

REDUCING TEE

REDUCING TEE

ASME B16.11

R = 1.5D

ASME B36.10

R = 1.5D

ASME B16.9

R = 1.5D

R = 1.5D

R = 1.5D

R = 1.5D

R = 1.5D

BW

ASTM A234 Gr.WPB, SMLS BWSTD x SCH 40

REVISION A

1/2" - 1 1/2"

STD x SCH 40

REDUCING TEE 10" x 8"

DESIGN PRESSURE (kg/cm²g)

NOTESITEM CODE TYPE SIZE RANGE(NB) REMARKS

SCH 80 ASTM A106 Gr. B, SMLS PE ASME B36.10

DIMENSIONAL

STANDARD MATERIAL ENDS

Doc No: 285731-MLIF-SP-PIP-3003 Rev: A

STD

ASTM A234 Gr.WPB, SMLSSCH 40

BW

ELBOW 90 DEG 16" - 20" STD ASME B16.9 R = 1.5D

ASME B16.11

ASME B16.9

SCH 40 x SCH 40

SWASTM A105 ASME B16.11

ASTM A234 Gr.WPB, SMLS

8" - 14"

1/2" - 1 1/2"

2" - 6"

2" - 6"ELBOW 90 DEG

ELBOW 90 DEG

NIPPLE

1/2" - 1 1/2"

ELBOW 90 DEG

ELBOW 45 DEG

ELBOW 45 DEG

EQUAL TEE

ELBOW 45 DEG 16" - 20"

EQUAL TEE 16" - 20"

1/2" - 1 1/2"

PIPE

PIPE

BE

2" - 6"

PIPE ASTM A106 Gr. B, SMLS

ASTM A106 Gr. B, SMLS BE

STD

SCH 40

1/2" - 1 1/2"

REDUCING TEE

8" - 14"

ELBOW 45 DEG

EQUAL TEE

ISSUED FOR

12" x (8" to 10")

REDUCING TEE STD x SCH 40

STD x STD

12" x 6"

STD

COMMENTS

14" x 6"

EQUAL TEE

BW

STD x STD

3000#

ASTM A105

STD

ASTM A234 Gr.WPB, SMLS

ASTM A234 Gr.WPB, SMLS

STD

3" x 2"

4" x (2" to 3")

38

3000#

ASTM A234 Gr.WPB, WELDED

STD

3000#

SCH 80

3000#

SCH 40

SCH. / THK. RATING

ASTM A672 GR B60 CL12, EFW 100% RAD.

1/2" - 1 1/2"

8" - 14"

-29

REDUCING TEE

SCH 40 x SCH 40

GOVERNING RATED CONDITION

150#

DR,VT

19.99 19.2

50

19.99

C:\Documents and Settings\shi50029\Desktop\mlif\Copy of LINE WISE MTO-GFL.xlsA09A0

Page No. 9 OF

ASTM A1052" X (1/2" to 1 1/2") SCH 40 x SCH 80

ASTM A105SCH 40 x SCH 80

MSS-SP-95

MSS-SP-95

MSS-SP-95

ASTM A105

ASTM A105

SCH 40 x SCH 80

3000#

3000#

BW

ASME B16.9

SCH 40 x SCH 40 ASTM A234 Gr.WPB, SMLS BW ASME B16.9

ASME B16.9

ASTM A234 Gr.WPB,WELDED

ASTM A234 Gr.WPB, SMLS

ASTM A234 Gr.WPB,WELDED

SCH 40 x SCH 80

SCH 40 ASTM A234 Gr.WPB, SMLS

12" x 6"

STD x STD

ASTM A234 Gr.WPB, SMLS

12" x (8" to 10") ASTM A234 Gr.WPB, SMLS

REDUCER ECC.

6" x (3" to 4")

STD x STD

20" x (12" to 16")

STD x STD

STD x SCH 40

STD x STD

STD x SCH 40

18" x (10" to 16")

STD x STD

18" x (10" to 16") STD x STD

12" x (8" to 10")

ASTM A234 Gr.WPB, SMLS

ASTM A234 Gr.WPB,WELDED

14" x (8" to 12")

STD x STD

ASTM A234 Gr.WPB, SMLS14" x 6"

8" x (4" to 6")

10" x 8"

STD x SCH 40

STD x STD

12" x 6"

STD x SCH 40

REDUCING TEE 20" x (8" to 18") STD x STD

18" x (8" to 16")REDUCING TEE

BW

ASTM A234 Gr.WPB, SMLS BW

BW

BW

BW

BW

BW

6" x (3" to 4")

BW

ASTM A234 Gr.WPB, SMLS

ASTM A234 Gr.WPB, SMLS

STD x STD

BW

BW

STD x SCH 40

20" x 18" STD x STD

3" x 2"

8" x (4" to 6")

20" x (12" to 16")

SCH 40 x SCH 40

SCH 40 x SCH 40

ASTM A234 Gr.WPB,WELDED

STD x STD14" x (8" to 12")

STD x STD

ITEM CODE TYPE SIZE RANGE(NB)

Tile : PIPING MATERIAL SPECIFICATION

Doc No: 285731-MLIF-SP-PIP-3003 Rev: A 26

LPG RECEIPT AND ASSOCIATED FACILITIES AT HPCL’S MANGALORE LPG IMPORT FACILITIES JETTY NO 12

BW

ASTM A234 Gr.WPB, SMLS

ENDSDIMENSIONAL

STANDARD

ASME B16.9BW

MATERIAL

ASME B16.9BW

BW

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

NOTES

ASTM A234 Gr.WPB, SMLS

ASME B16.9

ASME B16.9

BW

ASME B16.9

BW

ASTM A234 Gr.WPB, SMLS ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

BW

SCRD

LEB-SEP

SW

REDUCER ECC.

REDUCER CONC.

REDUCER CONC.

REDUCER ECC.

REDUCER CONC.

REDUCER CONC.

REDUCER CONC.

REDUCER CONC.

REDUCER CONC.

REDUCER CONC.

REDUCER CONC.

REDUCER CONC.

REDUCER CONC.

16" x (8" to 14")

REDUCING TEE

REDUCING TEE

16" x (8" to 14")

REDUCER CONC.

REDUCER CONC.

16" x 6"

ASTM A234 Gr.WPB, SMLS

ASTM A234 Gr.WPB, SMLS

ASTM A234 Gr.WPB, SMLS

ASTM A234 Gr.WPB, SMLS

BW

BW

ASTM A234 Gr.WPB,WELDED

ASTM A234 Gr.WPB,WELDED

PIPING CLASS : B09A0

ASTM A234 Gr.WPB, SMLS

SCH. / THK. RATING

BW

3" X (1/2" to 1 1/2")

REDUCER ECC.

REDUCER ECC.

REDUCER ECC.

SWAGE CONC.

SWAGE CONC.

REDUCER ECC.

16" x (8" to 14")

20" x 18"

SCH 40 x SCH 80

2" - 6"

1/2" - 1 1/2"

1/2" - 1 1/2"

4" x (1/2" to 1 1/2")

4" x (1/2" to 1 1/2")

STD

REDUCER ECC.

BW

ASME B16.9

STD x SCH 40

STD x STD

STD x STD

ASTM A234 Gr.WPB, SMLS

ASTM A234 Gr.WPB,WELDED

BW

ASTM A234 Gr.WPB,WELDED

BW

SWAGE CONC.

CAP

CAP

REDUCER ECC.

REDUCER ECC.

REDUCER ECC.

REDUCER ECC.

REMARKS

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

REDUCER CONC.

10" x (4" to 6")

4" x (2" to 3")

STD x STDREDUCING TEE

ASTM A234 Gr.WPB, SMLS

ASTM A105

STD x STD

STD x SCH 40

STD x SCH 40

ASTM A234 Gr.WPB, SMLS

STD x STD

ASTM A234 Gr.WPB,WELDED

ASTM A234 Gr.WPB,WELDED

BW

BW

BW

ASTM A234 Gr.WPB,WELDED

ASTM A234 Gr.WPB,WELDED

BW

ASME B16.9

ASTM A105

SCH 40 x SCH 80

14" x 6"

STD x SCH 40

SCH 40 x SCH 40

SCH 40 x SCH 40

3" x 2"

SCH 40 x SCH 40

BW

ASTM A234 Gr.WPB, SMLS

LEB-SEP

ASTM A234 Gr.WPB, SMLS

ASME B16.11

2" X (1/2" to 1 1/2")

BW

LEB-SEP

LEB-SEP

LEB-SEP

ASTM A105

ASTM A105

BW

BW

BW

BW

LEB-SEP

ASME B16.9

ASME B16.9

MSS-SP-95

MSS-SP-95

ASME B16.11

MSS-SP-95

SWAGE ECC.

CAP

SWAGE ECC.

COUPLING FULL

SWAGE ECC.

8" - 14"

14" x (8" to 12")

4" x (2" to 3")

10" x (4" to 6")

3" X (1/2" to 1 1/2")

10" x 8"

REDUCER ECC.

REDUCER ECC.

C:\Documents and Settings\shi50029\Desktop\mlif\Copy of LINE WISE MTO-GFL.xlsA09A0

FLANGES

GASKETS

FASTENERS

VALVES

SPACER : FINISH 63-125

µIn AARH

CAP 16" - 20" STD

SWRF : FINISH 63-125

µIn AARH

STUD BOLTS / NUTS

REDUCED COUPLING

REDUCED COUPLING

3000#

SPECTACLE BLIND : RF,

FINISH 63-125 µIn AARH

STD

2" - 6"

1" x (3/4" to 1/2")

1 1/2" x (1" to 1/2")

150# / SCH 40

10 OF 26

LPG RECEIPT AND ASSOCIATED FACILITIES AT HPCL’S MANGALORE LPG IMPORT FACILITIES JETTY NO 12

Page No.

TYPE

PIPING CLASS : B09A0

BALL VALVE

BALL VALVE

SOCKOLET

WELDOLET

ITEM CODE

8" - 20"

2" - 20"

1/2" - 20"

1/2" - 20"

8"

ASTM A105

ASTM A105

ASTM A105

ASTM A105

1/2" - 6"

150# / STD

6"

8" - 20"

8" - 20"

150# / SCH 40

150# / STD

150#

150#

150#

800#

150#

DIMENSIONAL

STANDARD NOTES REMARKSSCH. / THK. RATING

3000#

SCH 80

ASTM A105

150#

SCH 40

Flanged to ASME B16.5

RF, 63-125 µIn AARH

BS EN ISO 17292

ASME B16.9

MSS-SP-97

BW

SWASTM A105

Tile : PIPING MATERIAL SPECIFICATION

Doc No: 285731-MLIF-SP-PIP-3003 Rev: A

SW to ASME B16.11 with

Welded-on Nipples

ASME B 18.2.1/

ASME B 18.2.2

BODY: ASTM A216 GR.WCB

BALL : ASTM A 182 GR.F316

BODY SEAT-RPTFE

BODY: ASTM A105,

BALL : ASTM A 182 GR.F316

BODY SEAT-RPTFE

ASME B16.48

ASME B16.48

ASME B16.20

RF

RF

RF

RF

ASME B16.5

RF

RF

ASME B16.5

RF

RF

ASME B16.5

ASME B16.5

ASME B16.11

ASME B16.11

MATERIAL ENDS

BW

ASTM A234 Gr.WPB, WELDED

ASTM A105

SW

SW

ASTM A105

ASTM A105

BW

ASTM A105

SW3/4" x 1/2" 3000#

ASTM A105

ASTM A105

ASTM A105 MSS-SP-97

ASME B16.11

MSS-SP-97

GASKET

SPADE : FINISH 63-125

µIn AARH

ASME B16.5

ASME B16.5

150#

150#

ASTM A105

ASTM A105

ASME B16.48

BS EN ISO 17292

RF

4

150#

1/2" - 1 1/2"

SS316 Spiral With Graphite Filler, with

CS Outer Ring, 4.5 mm.

ASTM A193 Gr.B7 ASTM A194 Gr.2H RF

BLIND FLANGE : RF,

FINISH 63-125 µIn AARH

COMPANION FLANGE

WITH TWO NOS. TAPPED

HOLES

REDUCED COUPLING

WNRF : FINISH 63-125

µIn AARH

WELDOLET

COMPANION FLANGE

WITH TWO NOS. TAPPED

HOLES

1/2" - 20"

SIZE RANGE(NB)

1/2" - 1 1/2"

2" - 6"

8" - 20"WNRF : FINISH 63-125

µIn AARH

1/2" - 1 1/2"

C:\Documents and Settings\shi50029\Desktop\mlif\Copy of LINE WISE MTO-GFL.xlsA09A0

BRANCHING TABLE

LEGEND

SW TEES

BW TEES

BW TEE & REDUCING SWAGE

WELDOLET

SOCKOLET

REMARKSDIMENSIONAL

STANDARD

PIPING CLASS : B09A0

E

E

E

E

E

E

E

E E20" S S S S W W W W

W E E

E E

E

18" S S S ES W W W

E E E ES W W W16" S S S

PLUG VALVE

CHECK VALVE

GATE VALVE

1/2" - 1 1/2"

LPG RECEIPT AND ASSOCIATED FACILITIES AT HPCL’S MANGALORE LPG IMPORT FACILITIES JETTY NO 12

Tile : PIPING MATERIAL SPECIFICATION

Rev: A

T T

1 1/2" T TT

S

ES

SS

S S

S S E

S S

S

E

S S

12"

8"

S

S

S S

10" SSS

6" S S W E

S

S

S S

E E

S

E

E

W

E

E

E

E E

E

W

W

W W

W

W

HE

AD

ER

SIZ

E

NOTES :

3"

BRANCH SIZE

1/2"

Doc No: 285731-MLIF-SP-PIP-3003

GLOBE VALVE

1/2" - 1 1/2"

TYPE

150#

ES

800#

SCH. / THK. RATING

NOTE 1 : REFER "PIPING SPECIFICATION INDEX" DOC NO.285731MLIFSPPIP3002_REV.A.XLS , FOR SPECIAL REQUIRMENT & RADIOGRAPHY ETC.

6"1 1/2"

NOTE 2 : REFER "GENERAL NOTES"ON PIPING MATERIAL SPECIFICATION FOR FURTHER DESCRIPTION .

16"

800#

150#BODY: ASTM A105/ASTM A 216 GR.B

TRIM: 13% Cr Trim

PLUG-HARDENED.

BODY: ASTM A105,

TRIM: 13% Cr Trim

Flanged to ASME B16.5

RF, 63-125 µIn AARH

SW

Flanged to ASME B16.5

RF, 63-125 µIn AARHAPI 600

Page No. 11 OF 26

NOTES

API 602

BODY: ASTM A216 Gr.WCB

TRIM: 13% Cr Trim

BODY: ASTM A216 GR.WCB

TRIM:- 13% CR + STELIITED

STEM:- 13%CR (NO CASTING)

BODY: ASTM A216 GR.WCB

TRIM:- 13% CR

STEM:- 13%CR (NO CASTING)

MATERIAL

14" S

T

T

S

4"

3/4"

2"

3"

T

E

T

3/4" 20"4"

NOTE 3 : PIPE WALL THICKNESS CALCULATIONS ARE BASED ON THE RATED TEMP. & PRESSURE CONDITION ( CLASS CONDITION ) .

T

SIZE

1/2"

1"

S S S W E

T

W

EE

E E E

E E

E

12"

BODY: ASTM A105 ;

TRIM:- 13% CR

STEM:- 13%CR (NO CASTING)SW

1"

E E

E

W

S

API 609

W

2" 14"10" 18"8"

Flanged to ASME B16.5

RF, 63-125 µIn AARHBS 1873

Flanged to ASME B16.5

RF, 63-125 µIn AARHBS 5353

6

BS EN ISO 15761BODY: ASTM A105 ;

TRIM:- 13% CR

STEM:- 13%CR (NO CASTING)SW

GATE VALVE

GLOBE VALVE

ITEM CODE

2" - 20"

SIZE RANGE(NB)

2" - 20" 150#

1/2" - 20"

1/2" - 1 1/2"

CHECK VALVE 2" - 20" 150#

800#

150#Double Flanged Tripple

Eccentric TypeBUTTERFLY VALVE

BODY: ASTM A216 Gr.WCB ,

TRIM: SS316

STEM : Graphite8" - 20"

ENDS

BS 5352

BS 1868

C:\Documents and Settings\shi50029\Desktop\mlif\Copy of LINE WISE MTO-GFL.xlsA09A0

PIPE

FITTINGS

BE

GOVERNING RATED CONDITION

300#

DR

50.06 50.06

1/2" - 1 1/2"

8" - 14"

-29

REDUCING TEE

SCH 40 x SCH 40

50

SCH. / THK. RATING

ASTM A672 GR B60 CL12, EFW 100% RAD.

XS ASTM A672 GR B60 CL12, EFW 100% RAD.

50.06

38

6000#

ASTM A234 Gr.WPB, WELDED

STD

6000#

XS

SCH 160

6000#

SCH 40

STD

STD x STD

6000#

ASTM A105

STD

BW

STD

COMMENTS

14" x 6"

EQUAL TEE

ISSUED FOR

12" x (8" to 10")

REDUCING TEE STD x SCH 40

STD x STD

12" x 6"

1/2" - 1 1/2"

PIPE

REDUCING TEE

18" - 20"

8" - 14"

ELBOW 45 DEG

EQUAL TEE

PIPE

PIPE

BE

2" - 6"

PIPE ASTM A106 Gr. B, SMLS

ASTM A106 Gr. B, SMLS BE

STD

SCH 40

EQUAL TEE

EQUAL TEE

ELBOW 45 DEG 16"

EQUAL TEE 16"

18" - 20"ELBOW 45 DEG

1/2" - 1 1/2"

ELBOW 90 DEG

ELBOW 45 DEG

ELBOW 45 DEG

ELBOW 90 DEG

2" - 6"ELBOW 90 DEG

ELBOW 90 DEG

NIPPLE

1/2" - 1 1/2"

ASME B16.11

XS

ASTM A234 Gr.WPB, SMLS

8" - 14"

1/2" - 1 1/2"

18" - 20"

2" - 6"

SCH 40 x SCH 40

SWASTM A105

ELBOW 90 DEG 16" STD ASME B16.9 R = 1.5D

ASME B16.11

ASME B16.9

Doc No: 285731-MLIF-SP-PIP-3003 Rev: A

STD

ASTM A234 Gr.WPB, SMLSSCH 40

BW

REMARKS

SCH 160 ASTM A106 Gr. B, SMLS PE ASME B36.10

DIMENSIONAL

STANDARD MATERIAL ENDS

DESIGN PRESSURE (kg/cm²g)

NOTESITEM CODE TYPE SIZE RANGE(NB)

REVISION A

1/2" - 1 1/2"

STD x SCH 40

REDUCING TEE 10" x 8"

BWSTD x SCH 40

BW

ASTM A234 Gr.WPB, SMLS

R = 1.5D

R = 1.5D

R = 1.5D

ASME B16.9

ASME B16.11

R = 1.5D

ASME B36.10

R = 1.5D

REDUCING TEE 10" x (4" to 6")

REDUCING TEE

REDUCING TEE

REDUCING TEE

REDUCING TEE

CHKD. BY / DATE

APPR. BY / DATE

JSP/17-09-2011

6" x (3" to 4")

SNA/17-09-2011

8" x (4" to 6")

STD x SCH 40

PREP. BY / DATE

REDUCING TEE

RMS/ 17-09-2011

LPG RECEIPT AND ASSOCIATED FACILITIES AT HPCL’S MANGALORE LPG IMPORT FACILITIES JETTY NO 12

Tile : PIPING MATERIAL SPECIFICATION

ASME B16.9

ASME B16.9

ASME B16.9

ASTM A234 Gr.WPB, SMLS BW

ASTM A234 Gr.WPB, SMLS

ASTM A234 Gr.WPB, SMLS

BW

BWASTM A234 Gr.WPB, SMLS

ASTM A234 Gr.WPB, SMLS

ASTM A234 Gr.WPB, SMLS

ASME B36.10

ASME B36.10

ASME B36.10

R = 1.5D

R = 1.5D

R = 1.5D

R = 1.5D

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

BW

1.5mm

PR - 50.06 kg/cm²g,

TEMP - 38 °C

DESIGN TEMPERATURE (°C)

SERVICE

SERVICE CODE

RATING

CORROSION ALLOWANCE

LPG LIQUID (Between Static Mixer and Booster pumps),LPG LIQUID (Downstream of Booster

pumps),DRAIN (Between Static Mixer and Booster pumps),PROCESS VENT (upstream of booster

pump),PROCESS VENT (on booster pump)

PIPE 16"

ASTM A234 Gr.WPB, SMLS

ASTM A234 Gr.WPB, WELDED

ASTM A234 Gr.WPB, SMLS

ASTM A234 Gr.WPB, SMLS

ASTM A234 Gr.WPB, WELDED

ASTM A234 Gr.WPB, WELDED

ASME B16.11

ASME B16.9

ASME B16.9BW

BW ASME B16.9

POE-TOE

BW

BW

SW

BW

SW

BE ASME B36.10

ASTM A234 Gr.WPB, WELDED

ASME B16.9

ASME B16.9

ASTM A106 Gr. B, SMLS

BW

ASTM A105

BW

BW

SW

BW

ASME B16.9

BW

ASME B16.9BW

BW ASME B16.9

ASTM A234 Gr.WPB, SMLS

ASTM A105

ASME B16.9ASTM A234 Gr.WPB, WELDED

STD

3" x 2"

SCH 40 x SCH 404" x (2" to 3")

ASTM A234 Gr.WPB, SMLS

ASTM A234 Gr.WPB, SMLS BW

SCH 40

18" - 20" XS

8" - 14"

2" - 6"

Page No. 12 OF 26

PIPING CLASS : B09A0

C:\Documents and Settings\shi50029\Desktop\mlif\Copy of LINE WISE MTO-GFL.xlsB09A0

REDUCER ECC.

REDUCER ECC.

4" x (2" to 3")

10" x (4" to 6")

3" X (1/2" to 1 1/2")

8" - 14"

14" x (8" to 12")

10" x 8"

SWAGE ECC.

CAP

SWAGE ECC.

COUPLING FULL

SWAGE ECC.

ASME B16.11

MSS-SP-95

MSS-SP-95

MSS-SP-95

ASME B16.9

ASME B16.9

BW

BW

BW

BW

LEB-SEP

2" X (1/2" to 1 1/2")

BW

LEB-SEP

LEB-SEP

LEB-SEP

ASTM A105

ASTM A105

ASME B16.11

BW

ASTM A234 Gr.WPB, SMLS

14" x 6"

STD x SCH 40

SCH 40 x SCH 40

LEB-SEP

ASTM A234 Gr.WPB, SMLS

ASTM A105

SCH 40 x SCH 160

BW

BW

BW

ASTM A234 Gr.WPB,WELDED

ASTM A234 Gr.WPB,WELDED

SCH 40 x SCH 40

ASTM A234 Gr.WPB, SMLS

ASTM A234 Gr.WPB, SMLS

ASTM A105

3" x 2"

REDUCER CONC.

10" x (4" to 6")

4" x (2" to 3")

STD x STDREDUCING TEE BW

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

REMARKS

REDUCER ECC.

REDUCER ECC.

REDUCER ECC.

REDUCER ECC.

SWAGE CONC.

CAP

CAP

ASME B16.9

BW

ASME B16.9

STD x SCH 40

STD x STD

XS x STD

ASTM A234 Gr.WPB, SMLS

ASTM A234 Gr.WPB,WELDED

BW

ASTM A234 Gr.WPB,WELDED

REDUCER ECC.

XS x XS

SCH 40 x SCH 160

2" - 6"

1/2" - 1 1/2"

1/2" - 1 1/2"

4" x (1/2" to 1 1/2")

4" x (1/2" to 1 1/2")

REDUCER ECC.

16" x (8" to 14")

20" x 18"

3" X (1/2" to 1 1/2")

REDUCER ECC.

REDUCER ECC.

REDUCER ECC.

SWAGE CONC.

SWAGE CONC.

ASTM A234 Gr.WPB, SMLS

ASTM A234 Gr.WPB,WELDED

ASTM A234 Gr.WPB,WELDED

ASTM A234 Gr.WPB, SMLS

ASTM A234 Gr.WPB, SMLS

ASTM A234 Gr.WPB, SMLS

ASTM A234 Gr.WPB, SMLS

BW

BW

16" x (8" to 14")

REDUCER CONC.

REDUCER CONC.

16" x 6"

REDUCER CONC.

16" x (8" to 14")

REDUCING TEE

REDUCING TEE

REDUCER CONC.

REDUCER CONC.

REDUCER CONC.

REDUCER CONC.

REDUCER ECC.

REDUCER CONC.

REDUCER CONC.

REDUCER CONC.

REDUCER CONC.

REDUCER ECC.

REDUCER CONC.

REDUCER CONC.

BW

BW

SCRD

LEB-SEP

SW

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

SCH 40 x SCH 40

STD x SCH 40

ASTM A234 Gr.WPB, SMLS

ASME B16.9

ASME B16.9

BW

ASME B16.9

BW

ASME B16.9

NOTES

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

SCH. / THK. RATING

ASME B16.9

BW

ASTM A234 Gr.WPB, SMLS

ENDSDIMENSIONAL

STANDARD

Tile : PIPING MATERIAL SPECIFICATION

Doc No: 285731-MLIF-SP-PIP-3003 Rev: A 26

ITEM CODE TYPE SIZE RANGE(NB)

ASME B16.9BW

LPG RECEIPT AND ASSOCIATED FACILITIES AT HPCL’S MANGALORE LPG IMPORT FACILITIES JETTY NO 12

MATERIAL

20" x (12" to 16")

SCH 40 x SCH 40

SCH 40 x SCH 40

ASTM A234 Gr.WPB,WELDED

STD x STD14" x (8" to 12")

XS x STD

STD x SCH 40

20" x 18" XS x XS

3" x 2"

8" x (4" to 6")

6" x (3" to 4")

BW

ASTM A234 Gr.WPB, SMLS

ASTM A234 Gr.WPB, SMLS

STD x STD

BW

BW

ASTM A234 Gr.WPB, SMLS BW

BW

BW

BW

BW

REDUCING TEE 20" x (8" to 18") XS x STD

18" x (8" to 16")REDUCING TEE

ASME B16.9BW

BW

BW ASME B16.9

ASME B16.9

BW

14" x 6"

8" x (4" to 6")

10" x 8"

STD x SCH 40

STD x STD

12" x 6"

BW

STD x SCH 40

18" x (10" to 16") XS x STD

12" x (8" to 10")

ASTM A234 Gr.WPB, SMLS

ASTM A234 Gr.WPB,WELDED

14" x (8" to 12")

STD x STD

ASTM A234 Gr.WPB, SMLS

REDUCER ECC.

6" x (3" to 4")

XS x STD

20" x (12" to 16")

STD x STD

STD x SCH 40

XS x STD

STD x SCH 40

18" x (10" to 16")

STD x STD

ASTM A234 Gr.WPB, SMLS

12" x 6"

STD x STD

ASTM A234 Gr.WPB, SMLS

12" x (8" to 10")

STD x SCH 40

STD x STD

ASTM A234 Gr.WPB, SMLS

ASTM A234 Gr.WPB,WELDED

ASTM A234 Gr.WPB,WELDED

ASTM A234 Gr.WPB,WELDED

ASTM A234 Gr.WPB, SMLS

ASTM A234 Gr.WPB,WELDED

SCH 40 x SCH 160

BW

ASME B16.9

SCH 40 x SCH 40 ASTM A234 Gr.WPB, SMLS BW ASME B16.9

ASME B16.9

SCH 40 ASTM A234 Gr.WPB, SMLS

STD

ASTM A105

ASTM A105

SCH 40 x SCH 160

6000#

6000#

MSS-SP-95

MSS-SP-95

MSS-SP-95

ASTM A1052" X (1/2" to 1 1/2") SCH 40 x SCH 160

ASTM A105SCH 40 x SCH 160

Page No. 13 OF

PIPING CLASS : B09A0

C:\Documents and Settings\shi50029\Desktop\mlif\Copy of LINE WISE MTO-GFL.xlsB09A0

FLANGES

GASKETS

FASTENERS

VALVES 5

1/2" - 20"

SIZE RANGE(NB)

1/2" - 1 1/2"

2" - 6"

8" - 16"WNRF : FINISH 63-125

µIn AARH

COMPANION FLANGE

WITH TWO NOS. TAPPED

HOLES

WNRF : FINISH 63-125

µIn AARH

WELDOLET

COMPANION FLANGE

WITH TWO NOS. TAPPED

HOLES

BLIND FLANGE : RF,

FINISH 63-125 µIn AARH

ASTM A193 Gr.B7 ASTM A194 Gr.2H

1/2" - 1 1/2"

SS316 Spiral With Graphite Filler, with

CS Outer Ring, 4.5 mm.

RF

RF

ASME B16.48

BS EN ISO 17292

ASME B16.5

ASME B16.5

ASME B16.5

300#

300#

ASTM A105

ASTM A105

GASKET

SPADE : FINISH 63-125

µIn AARH

MSS-SP-97

ASME B16.11

MSS-SP-97

RF

ASTM A105

ASTM A105

ASTM A105

SW

18" - 20"

3/4" x 1/2" 6000#

ASTM A105

ASTM A105

BW

ASTM A105

ASTM A105

SW

SW

MATERIAL ENDS

ASME B16.5

ASME B16.11

ASME B16.11

RF

RF

ASME B16.5

RF

ASME B16.5

RF

RF

ASME B16.5

ASME B16.5

RF

RF

RF

ASME B16.48

ASME B16.48

ASME B16.20

RF

BODY: ASTM A216 GR.WCB

BALL : ASTM A 182 GR.F316

BODY SEAT-RPTFE

SW to ASME B16.11 with

Welded-on Nipples

ASME B 18.2.1/

ASME B 18.2.2

BW

BW

SWASTM A105

Tile : PIPING MATERIAL SPECIFICATION

Doc No: 285731-MLIF-SP-PIP-3003 Rev: A

ASTM A234 Gr.WPB, WELDED

ASTM A234 Gr.WPB, WELDED ASME B16.9

MSS-SP-97

BS EN ISO 17292

Flanged to ASME B16.5

RF, 63-125 µIn AARH

4

ASTM A105

6000#

SCH 40

SCH. / THK. RATING

6000#

SCH 1601/2" - 1 1/2"

ASME B16.9

DIMENSIONAL

STANDARD NOTES REMARKS

300# / SCH 40

300# / STD

300# / XS

300#

300#

300#

800#

300#

300#

ASTM A105

1/2" - 6"

300# / XS

300# / STD

6"

8" - 20"

8" - 20"

ASTM A105

ASTM A105

ASTM A10518" - 20"

ASTM A105

ASTM A105

BODY: ASTM A105,

BALL : ASTM A 182 GR.F316

BODY SEAT-RPTFE

8"

8" - 16"

18" - 20"

2" - 20"

1/2" - 20"

1/2" - 20"

CAP

SOCKOLET

WELDOLET

ITEM CODE

BALL VALVE

BALL VALVE

BW

TYPE

14 OF 26

LPG RECEIPT AND ASSOCIATED FACILITIES AT HPCL’S MANGALORE LPG IMPORT FACILITIES JETTY NO 12

Page No.

XS

6000#

SPECTACLE BLIND : RF,

FINISH 63-125 µIn AARH

STD

2" - 6"

1" x (3/4" to 1/2")

1 1/2" x (1" to 1/2")

300# / SCH 40

WNRF : FINISH 63-125

µIn AARH

COMPANION FLANGE

WITH TWO NOS. TAPPED

HOLES

REDUCED COUPLING

REDUCED COUPLING

REDUCED COUPLING

STUD BOLTS / NUTS

PIPING CLASS : B09A0

SPACER : FINISH 63-125

µIn AARH

CAP 16" STD

SWRF : FINISH 63-125

µIn AARH

C:\Documents and Settings\shi50029\Desktop\mlif\Copy of LINE WISE MTO-GFL.xlsB09A0

BRANCHING TABLE

LEGEND

SW TEES

BW TEES

BW TEE & REDUCING SWAGE

WELDOLET

SOCKOLET

ENDS

BS 5352

BS 1868

300#Double Flanged Tripple

Eccentric TypeBUTTERFLY VALVE

BODY: ASTM A216 Gr.WCB ,

TRIM: SS316

STEM : Graphite8" - 20"

2" - 20" 300#

1/2" - 20"

1/2" - 1 1/2"

CHECK VALVE 2" - 20"

GATE VALVE

GLOBE VALVE BS EN ISO 15761BODY: ASTM A105 ;

TRIM:- 13% CR + STELIITED

STEM:- 13%CR (NO CASTING)SW

2" - 20"

ITEM CODE SIZE RANGE(NB)

Flanged to ASME B16.5

RF, 63-125 µIn AARHBS 1873

Flanged to ASME B16.5

RF, 63-125 µIn AARHBS 5353

6API 609

W

2" 14"10" 18"8"

S

E E

E

W

12"

BODY: ASTM A105 ;

TRIM:- 13% CR + STELIITED

STEM:- 13%CR (NO CASTING)SW

1"

W

EE

E E E

E E

E

T

S S S

NOTE 3 : PIPE WALL THICKNESS CALCULATIONS ARE BASED ON THE RATED TEMP. & PRESSURE CONDITION ( CLASS CONDITION ) .

T

SIZE

1/2"

1" E

T

3/4"

14" S

T

T

S

4"

3/4"

2"

3"

T

BODY: ASTM A216 Gr.WCB

TRIM: 13% Cr Trim+STELLITED

BODY: ASTM A216 GR.WCB

TRIM:- 13% CR + STELIITED

STEM:- 13%CR (NO CASTING)

BODY: ASTM A216 GR.WCB

TRIM:- 13% CR + STELIITED

STEM:- 13%CR (NO CASTING)

MATERIAL

W

20"4"

E

API 602

Flanged to ASME B16.5

RF, 63-125 µIn AARHAPI 600

Page No. 15 OF 26

NOTES

BODY: ASTM A105/ASTM A 216 GR.B

TRIM: 13% Cr Trim+STELLITED

PLUG-HARDENED.

BODY: ASTM A105,

TRIM: 13% Cr Trim+STELLITED

Flanged to ASME B16.5

RF, 63-125 µIn AARH

SW

800#

NOTE 1 : REFER "PIPING SPECIFICATION INDEX" DOC NO.285731MLIFSPPIP3002_REV.A.XLS , FOR SPECIAL REQUIRMENT & RADIOGRAPHY ETC.

6"1 1/2"

NOTE 2 : REFER "GENERAL NOTES"ON PIPING MATERIAL SPECIFICATION FOR FURTHER DESCRIPTION .

16"

300#

300#

800#

SCH. / THK. RATING

800#

ES

Doc No: 285731-MLIF-SP-PIP-3003

BRANCH SIZE

1/2"

HE

AD

ER

SIZ

E

NOTES :

3"

W

W

W W

W

W

E

W

E

E

E

E E

E

E

S W E

S

S

S S

E E

S

SS

6" S

S S

12"

8"

S

S

S S

10" S

S S

S S E

S S

S

E

T TT

S

ES

SS

T T

1 1/2"

GLOBE VALVE

1/2" - 1 1/2"

LPG RECEIPT AND ASSOCIATED FACILITIES AT HPCL’S MANGALORE LPG IMPORT FACILITIES JETTY NO 12

Tile : PIPING MATERIAL SPECIFICATION

Rev: A

TYPE

300#

GATE VALVE

1/2" - 1 1/2"

PLUG VALVE

CHECK VALVE

16" S S S S W W W E E E E E

18" S S S ES W W W

W

W E E

E E E E20" S S S S W W W

E

E

E

E

E

E E

DIMENSIONAL

STANDARD

PIPING CLASS : B09A0

REMARKS

C:\Documents and Settings\shi50029\Desktop\mlif\Copy of LINE WISE MTO-GFL.xlsB09A0

PIPE

FITTINGS

PIPING CLASS : A19A0

ASTM A420 Gr.WPL6, WELDED BW ASME B16.9

LPG RECEIPT AND ASSOCIATED FACILITIES AT HPCL’S MANGALORE LPG IMPORT FACILITIES JETTY NO 12

Tile : PIPING MATERIAL SPECIFICATION

Doc No: 285731-MLIF-SP-PIP-3003 Rev: A Page No. 16 OF 26

ELBOW 90 DEG 16" - 20" STD ASTM A420 Gr.WPL6, WELDED BW ASME B16.9 R = 1.5D

PIPE 16" - 20" STDASTM A671 Gr.CC60 CL32, EFW

(with 100% Radiography)BE ASME B36.10

12" x 6"

REDUCING TEE

REDUCING TEE

10" x 8" STD x STD

4" x (2" to 3")REDUCING TEE

8" x (4" to 6")

REDUCING TEE

REDUCING TEE

6" x (3" to 4")

STD x SCH 40

STD x SCH 40

COMMENTS

SNA / 17-09-2011

STD

19.99DESIGN PRESSURE (kg/cm²g)

10" x (4" to 6")

2" - 6"

8" - 14"

REDUCING TEE

1/2" - 1 1/2"

SERVICE

SERVICE CODE

DESIGN TEMPERATURE (°C)

DRAIN,VENT

19.2 19.219.99

DIMENSIONAL

STANDARD REMARKSSCH. / THK. RATING

BE

BE

SW

ASTM A 333 Gr. 6, SMLSSCH 80

3000#

ASTM A 333 Gr. 6, SMLS

1.5mm

PR - 52.1 kg/cm²g,

TEMP - 38 °CDR,VT

-45

GOVERNING RATED CONDITION

CORROSION ALLOWANCE

500 38

1/2" - 1 1/2"

16" - 20"

2" - 6"

16" - 20"

ASME B16.9BW

ASTM A420 Gr.WPL6, WELDED

PBE

ITEM CODE TYPE SIZE RANGE(NB)

ASME B36.10

ASTM A350 Gr.LF2, CL 1

ASTM A420 Gr.WPL6, SMLS

ASTM A420 Gr.WPL6, SMLS

ASTM A 333 Gr. 6, SMLS

150#

NOTES

PE

MATERIAL

ASME B36.10

ASME B36.10

STD

STD

SCH 40 x SCH 40

3" x 2"

8" - 14"

1/2" - 1 1/2"

1/2" - 1 1/2" 3000#

SCH 40 x SCH 40

STD x SCH 40

RMS / 17-09-2011

A

REDUCING TEE

REDUCING TEE

BW

BW

BW

ASTM A420 Gr.WPL6, SMLS BW

ASTM A420 Gr.WPL6, SMLS

BW

BW

ASTM A420 Gr.WPL6, SMLS

ASTM A420 Gr.WPL6, SMLS BW

ASTM A420 Gr.WPL6, SMLS ASME B16.9

ASTM A420 Gr.WPL6, SMLS

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

SW

SW

BW ASME B16.9

ASME B16.9

PIPE

PIPE

PIPE

SCH 40

SCH 40

1/2" - 1 1/2"

8" - 14"

2" - 6"

8" - 14"

1/2" - 1 1/2"

2" - 6"

SCH 40

SCH 80

STD

R = 1.5D

R = 1.5D

R = 1.5D

R = 1.5D

R = 1.5D

ASTM A420 Gr.WPL6, SMLSSTD

SCH 40 x SCH 40

SCH 40 x SCH 40

REDUCING TEE

ISSUED FOR

REVISION

APPR. BY / DATE

PREP. BY / DATE

CHKD. BY / DATE JSP / 17-09-2011

EQUAL TEE

EQUAL TEE

ELBOW 45 DEG

EQUAL TEE

EQUAL TEE

NIPPLE

ELBOW 45 DEG

ELBOW 45 DEG

ELBOW 45 DEG

ELBOW 90 DEG

ELBOW 90 DEG

ELBOW 90 DEG

1/2" - 1 1/2"

ASME B16.11

ASME B16.9

BW

BW

ASME B16.11 R = 1.5D

R = 1.5D

ASME B36.10

3000#

ASTM A420 Gr.WPL6, SMLS

ASTM A350 Gr.LF2, CL 1

SCH 40

STD

3000#

ASTM A 333 Gr. 6, SMLS

RATING

ENDS

BW

BW

ASTM A420 Gr.WPL6, SMLS

ASME B16.9

ASME B16.11

BW

SW

ASTM A420 Gr.WPL6, SMLS

ASTM A350 Gr.LF2, CL 1

ASTM A420 Gr.WPL6, SMLS

ASTM A420 Gr.WPL6, SMLS

ASTM A350 Gr.LF2, CL 1

BW

ASME B16.9

ASME B16.11

ASME B16.9

ASME B16.9

ASME B16.9

C:\Documents and Settings\shi50029\Desktop\mlif\Copy of LINE WISE MTO-GFL.xlsA19A0

PIPING CLASS : A19A0

LPG RECEIPT AND ASSOCIATED FACILITIES AT HPCL’S MANGALORE LPG IMPORT FACILITIES JETTY NO 12

Page No.

SWAGE CONC.

SWAGE CONC.

COUPLING FULL

ASTM A350 Gr.LF2, CL 1 LEB-SEP

ASTM A420 Gr.WPL6, WELDED

ASTM A420 Gr.WPL6, WELDED

ASTM A420 Gr.WPL6, WELDED BW ASME B16.9

SIZE RANGE(NB) SCH. / THK. RATING MATERIAL ENDSDIMENSIONAL

STANDARD NOTES

SCH 40 x SCH 80 MSS-SP-95

MSS-SP-95

LEB-SEP

ASME B16.11

ASME B16.11

ASTM A350 Gr.LF2, CL 1 SCRD

2" X (1/2" to 1 1/2")

SCH 40 x SCH 80

4" x (1/2" to 1 1/2")

ASTM A350 Gr.LF2, CL 1

SCH 40 x SCH 80

3000#

ASTM A350 Gr.LF2, CL 1

1/2" -1 1/2"

3" X (1/2" to 1 1/2")

ASTM A350 Gr.LF2, CL 1

SWAGE ECC. 4" X (1/2" to 1 1/2")

SWAGE ECC.

SWAGE CONC.

SWAGE ECC. 2" X (1/2" to 1 1/2")

MSS-SP-953" X(1/2" to 1 1/2")

LEB-SEP MSS-SP-95

LEB-SEP

SWREDUCED COUPLING 3/4" x 1/2" 3000#

MSS-SP-95

MSS-SP-95

LEB-SEP

ASTM A350 Gr.LF2, CL 1

BW

ASME B16.9

ASME B16.9

STD x STD

ASTM A420 Gr.WPL6, WELDED REDUCER ECC. 16" x (8" to 14") STD x STD ASME B16.9BW

BW

SCH 40 x SCH 80

SCH 40 x SCH 80

SCH 40 x SCH 80

STD x STD

REDUCER ECC. 20" x (12" to 14") STD x STD

REDUCER ECC. 18" x 14"

REDUCER ECC. 20" x (16" to 18")

BW

ASTM A420 Gr.WPL6, WELDED

STD x STD

ASTM A420 Gr.WPL6, SMLS

ASTM A420 Gr.WPL6, SMLS

ASTM A420 Gr.WPL6, SMLS

ASME B16.9

ASME B16.9

ASME B16.9

BW

BW

SCH 40 x SCH 40

SCH 40 x SCH 40

ASTM A420 Gr.WPL6, SMLS

SCH 40 x SCH 40

14" x 6" STD x SCH 40

STD x STD12" x (8" to 10")

Tile : PIPING MATERIAL SPECIFICATION

Doc No: 285731-MLIF-SP-PIP-3003 Rev: A 26

REDUCER CONC.

REDUCER ECC. 14" x (8" to 12") STD x STD

3" x 2"

4" x (2" to 3")

REDUCER ECC.

16" x (8" to 14")

18" x (8" to 16")

REDUCER CONC.

STD x STD

REDUCER CONC.

STD x SCH 40

STD x STD

STD x SCH 40

BW

BW

ASTM A420 Gr.WPL6, SMLS

BW

BW

12" x 6" STD x SCH 40

STD x STD

14" x 6"

BW

BW

BW

16" x (8" to 14")

REDUCING TEE 20" x (8" to 18") STD x STD

10" x 8"

18" x (8" to 16")

16" x 6"

STD x STD

BW

STD x SCH 40 ASTM A420 Gr.WPL6, SMLS

ASTM A420 Gr.WPL6, WELDED

ASME B16.9

REDUCING TEE

REDUCING TEE

12" x (8" to 10")

16" x 6"

14" x (8" to 12")

3" x 2"

10" x (4" to 6")

4" x (2" to 3")

REDUCER CONC.

14" x (8" to 12")

20" x (8" to 18")

REDUCER CONC. ASTM A420 Gr.WPL6, WELDEDSTD x STD

STD x STD

ASTM A420 Gr.WPL6, WELDED

ASTM A420 Gr.WPL6, WELDED BW ASME B16.9

BW

ASTM A420 Gr.WPL6, WELDED BW

ASTM A420 Gr.WPL6, SMLS

ASTM A420 Gr.WPL6, SMLS

ASTM A420 Gr.WPL6, SMLS

SCH 40 x SCH 40 ASTM A420 Gr.WPL6, SMLS

ASTM A420 Gr.WPL6, WELDED BW

STD x SCH 40

SCH 40 x SCH 40

8" x (4" to 6") STD x SCH 40

6" x (3" to 4")

STD x STD

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

17 OF

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

REMARKS

ASME B16.9

ASTM A420 Gr.WPL6, SMLS

ASTM A420 Gr.WPL6, SMLS

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

BW

ASTM A420 Gr.WPL6, SMLS

ASTM A420 Gr.WPL6, SMLS

ASTM A420 Gr.WPL6, SMLS

SCH 40 x SCH 40

STD x STD

STD x STD

ASTM A420 Gr.WPL6, SMLS

ASTM A420 Gr.WPL6, SMLS

BW

BW

BW

BW

ASME B16.9

BW

ASME B16.9

BW

BW

BW

ASME B16.9

BW

BW

REDUCING TEE

ITEM CODE TYPE

REDUCING TEE

REDUCER CONC.

REDUCER CONC.

REDUCER CONC.

REDUCER CONC.

REDUCER CONC.

REDUCING TEE

REDUCING TEE

ASTM A420 Gr.WPL6, SMLS

ASTM A420 Gr.WPL6, SMLS

ASTM A350 Gr.LF2, CL 1

ASTM A350 Gr.LF2, CL 1

STD x SCH 40

STD x SCH 40 ASTM A420 Gr.WPL6, SMLS

STD x STD ASTM A420 Gr.WPL6, SMLS

ASTM A420 Gr.WPL6, SMLS

STD x SCH 40 ASTM A420 Gr.WPL6, SMLS

ASTM A420 Gr.WPL6, SMLS

STD x SCH 40

BW

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

REDUCER CONC.

REDUCER CONC.

REDUCER ECC.

8" x (4" to 6")

10" x 8"

14" x 6"

12" x (8" to 12")

REDUCER ECC.

REDUCER ECC.

REDUCER ECC.

REDUCER ECC.

REDUCER ECC.

REDUCER ECC.

REDUCER ECC.

REDUCER CONC.

BW

BW

LEB-SEP

BW

BW

6" x (3" to 4")

12" x 6"

10" x (4" to 6")

REDUCER CONC.

C:\Documents and Settings\shi50029\Desktop\mlif\Copy of LINE WISE MTO-GFL.xlsA19A0

FLANGES

BLINDS

GASKETS

FASTENERS

VALVES

PIPING CLASS : A19A0

REDUCED COUPLING

LPG RECEIPT AND ASSOCIATED FACILITIES AT HPCL’S MANGALORE LPG IMPORT FACILITIES JETTY NO 12

WELDOLET ASTM A350 Gr.LF2, CL 1

8" - 20"

COMPANION FLANGE

WITH TWO NOS. TAPPED

HOLES

REDUCED COUPLING

GASKET

STUD BOLTS / NUTS

Blind Flange : Finish 63-125

µIn AARH

Spectacle Blind : Finish 63-

125 µIn AARH

CAP

ASME B16.11

ASME B16.9

MSS-SP-97

4

ASME B 16.48

ASME B 18.2.1/

ASME B 18.2.2

BS EN ISO 17292

RF

RF

Tile : PIPING MATERIAL SPECIFICATION

ASME B16.5

5

ASME B16.5

ASME B16.5

ASME B16.5

ASME B16.5

TYPE SIZE RANGE(NB) SCH. / THK. RATING MATERIAL

1/2" - 1 1/2"

1/2" - 20"

BODY:- ASTM A352 Gr.LCB,

BALL:-A182 Gr.F316

SEAT:-RPTFE

8" - 20"

Flanged to ASME B16.5

RF, 63-125 µIn AARH

1/2" - 20"

ASME B 16.48

BODY:- ASTM A350 Gr.LF2,

BALL:-A182 Gr.F316

SEAT:-RPTFE

150#

WNRF : FINISH 63-125

µIn AARH

BW

RF

8"

150#

150# / SCH 40

150# / STD

150#/ STD

RF

RF

COMPANION FLANGE

WITH TWO NOS. TAPPED

HOLES

ASTM A350 Gr.LF2, CL 1

150#

150#

COMPANION FLANGE

WITH TWO NOS. TAPPED

HOLES

8" - 20"

ASTM A350 Gr.LF2, CL 1

ASTM A350 Gr.LF2, CL 1

ASTM A350 Gr.LF2, CL 1

2" - 6"

Page No. 18 OF 26

SOCKOLET ASTM A350 Gr.LF2, CL 1

ASME B16.9

16"-20"

SW

BW

BW

STD8" - 14"

SCH 40

NOTES REMARKSENDSDIMENSIONAL

STANDARD

MSS-SP-97

ASME B16.11ASTM A350 Gr.LF2, CL 1

ASTM A420 Gr.WPL6, SMLS

ASTM A350 Gr.LF2, CL 1 ASME B16.11

SW

1/2" - 1 1/2"

ASTM A350 Gr.LF2, CL 1

SS304 Spiral With Graphite Filler, with CS

Outer Ring, 4.5 mm.THK

ASTM A320 Gr.L7 / ASTM A194 Gr.7150#

150#

SWRF : FINISH 63-125

µIn AARH

WNRF : FINISH 63-125

µIn AARH150# / SCH 40

1/2" - 1 1/2"

2" - 6" ASTM A350 Gr.LF2, CL 1 RF

ASTM A350 Gr.LF2, CL 1

ASME B16.5

ASME B16.5

ASTM A350 Gr.LF2, CL 1 BW

STD

MSS-SP-97

ASME B16.5

3000# ASTM A350 Gr.LF2, CL 1

SCH 80

1" x (3/4" to 1/2")

Doc No: 285731-MLIF-SP-PIP-3003 Rev: A

ASME B16.9

SW

SW

2" - 6" SCH 40

3000#

3000#

STD

1/2" - 1 1/2"

1 1/2" x (1" to 1/2")

ITEM CODE

CAP

SPACER : Finish 63-125 µIn

AARH

SPADE : Finish 63-125 µIn

AARH

1/2" - 1 1/2"

CAP

ASTM A420 Gr.WPL6, WELDED

ASTM A420 Gr.WPL6, SMLS

ASTM A350 Gr.LF2, CL 1

150#

RF

CAP

ASTM A350 Gr.LF2, CL 1

ASTM A350 Gr.LF2, CL 1

WELDOLET

150# Reduced Bore5BS EN ISO 17292

8" - 20" 150#

1/2" - 20" ASME B 16.20

RF

Full BoreSW to ASME B16.11

with Welded-on Nipples

BALL VALVE 2" - 20"

800# BALL VALVE

RF

RF

BW

2" - 6"

2" - 6"

C:\Documents and Settings\shi50029\Desktop\mlif\Copy of LINE WISE MTO-GFL.xlsA19A0

BRANCHING TABLE

LEGEND

SW TEES

BW TEES

BW TEE & REDUCING SWAGE

WELDOLET

SOCKOLET

PIPING CLASS : A19A0

800# 1/2" - 11/2"

2" - 20"

GLOBE VALVE 2" - 20"

LPG RECEIPT AND ASSOCIATED FACILITIES AT HPCL’S MANGALORE LPG IMPORT FACILITIES JETTY NO 12

Tile : PIPING MATERIAL SPECIFICATION

5

ENDS

Page No.

BS 5353

BS 5352

BS 1868

API 609

5

NOTES

BODY: ASTM A352 Gr.LCB,

TRIM:-:STELLITED

STEM:- SS304(NO CASTING)150#

150#

19Doc No: 285731-MLIF-SP-PIP-3003

Flanged to ASME B16.5

RF, 63-125 µIn AARH

Body ASTM A350 Gr.LF2 / ASTM A352

Gr. LCB

PLUG: SS304

SEAT : Graphite150#

BODY: ASTM A352 Gr.LCB,

TRIM:-:STELLITEDFlanged to ASME B16.5

RF, 63-125 µIn AARH

BODY: ASTM A350 Gr.LF2 ;

TRIM:-:STELLITED

150#

800# 1/2" - 11/2"

MATERIAL

2" - 20"

E

1/2" - 20"

W

S E

ES

3/4" 1" 10" 20"14"4" 18"SIZE

EE

E E

E EE E20" S S S S W W W W

EW W

E

E18" S S S S W W E

E E16" S S S E E

E

E

W W W

W E14" S S S E E ES W

W

S

OF 26

EHE

AD

ER

SIZ

E

12"

NOTES :

NOTE 3 : PIPE WALL THICKNESS CALCULATIONS ARE BASED ON THE RATED TEMP. & PRESSURE CONDITION ( CLASS CONDITION ) .

ITEM CODE

8" 16"

3/4"

1/2" 1 1/2" 6"2" 3"

T

NOTE 2 : REFER "GENERAL NOTES"ON PIPING MATERIAL SPECIFICATION FOR FURTHER DESCRIPTION .

TYPE SIZE RANGE(NB) SCH. / THK. RATING

T T

T

1/2" T

T

T

SPECIAL PARTS

BRANCH SIZE

1 1/2" T

1"

T

T

3" E ES S S S

6" W E

S S S S4" E

S S S

E

S

8" W W ES S S S

10" SS EW WS S

12" W W WS S S S E

E E

E

E

E

E E

E E

CHECK VALVE

BUTTERFLY VALVE

PLUG VALVE

GLOBE VALVE

NOTE 1 : REFER "PIPING SPECIFICATION INDEX" DOC NO.285731MLIFSPPIP3002_REV.A.XLS , FOR SPECIAL REQUIRMENT & RADIOGRAPHY ETC.

2" EESS S S

1/2" - 11/2" 800#

E

T

E

CHECK VALVE

GLOBE VALVE

GLOBE VALVE

REMARKS

Rev: A

DIMENSIONAL

STANDARD

Flanged to ASME B16.5

RF, 63-125 µIn AARHBS 1873

5 Anti Freeze Type

5

5

BS 5352

BS 5352

BS 1873

SW

SW

Flanged to ASME B16.5

RF, 63-125 µIn AARH

BODY: ASTM A350 Gr.LF2 ;

TRIM:-:STELLITED

STEM:- SS304(NO CASTING)

BODY: ASTM A352 Gr.LCB,

TRIM:-:STELLITED

STEM:- SS304(NO CASTING)

BODY: ASTM A350 Gr.LF2 ;

TRIM:-:STELLITED

STEM:- SS304(NO CASTING)

SW

5

5

8" - 20" 150#Double Flanged Tripple

Eccentric Type

Body: ASTM A352 Gr. LCB

Trim: SS316

Seat : Graphite

Anti Freeze Type

C:\Documents and Settings\shi50029\Desktop\mlif\Copy of LINE WISE MTO-GFL.xlsA19A0

PIPE

FITTINGS

ASME B16.9

ASME B16.9

BW

BW

ASTM A420 Gr.WPL6, SMLS

ASTM A350 Gr.LF2, CL 1

ASTM A420 Gr.WPL6, SMLS

ASTM A420 Gr.WPL6, SMLS

ASTM A350 Gr.LF2, CL 1

BW

SW

BW

ASME B16.9

ASME B16.11

ASME B16.9

ASTM A420 Gr.WPL6, WELDED ASME B16.9

ASTM A 333 Gr. 6, SMLS

RATING

ENDS

R = 1.5D

BW

BW

ASTM A420 Gr.WPL6, SMLS

6000#

ASTM A420 Gr.WPL6, SMLS

ASTM A350 Gr.LF2, CL 1

SCH 40

XS

STD

6000#

ASTM A420 Gr.WPL6, WELDED

ASME B16.11 R = 1.5D

R = 1.5D

ASME B36.10

ASME B16.11

ASME B16.9

BW

BW

BW

PIPE 18" - 20"

ELBOW 90 DEG

ELBOW 90 DEG

1/2" - 1 1/2"NIPPLE

ELBOW 45 DEG

ELBOW 45 DEG

ELBOW 45 DEG

ELBOW 90 DEG

ELBOW 45 DEG

EQUAL TEE

EQUAL TEE

ELBOW 90 DEG

EQUAL TEE

EQUAL TEE

EQUAL TEE

PREP. BY / DATE

CHKD. BY / DATE JSP / 17-09-2011

REDUCING TEE

ISSUED FOR

REVISION

APPR. BY / DATE

ASTM A420 Gr.WPL6, SMLSSTD

XS ASTM A420 Gr.WPL6, WELDED

XS

SCH 40 x SCH 40

SCH 40 x SCH 40

SCH 160

STD

R = 1.5D

R = 1.5D

R = 1.5D

R = 1.5D

R = 1.5D

R = 1.5D

18" - 20"

SCH 40

SCH 40

1/2" - 1 1/2"

8" - 14"

2" - 6"

8" - 14"

1/2" - 1 1/2"

2" - 6"

SCH 40

PIPE

PIPE

PIPE

ASME B16.9

ASME B16.11

ASME B16.9

SW

SW

BW ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

ASTM A420 Gr.WPL6, SMLS

ASME B16.9

ASTM A420 Gr.WPL6, SMLS BW

ASTM A420 Gr.WPL6, SMLS ASME B16.9

ASTM A420 Gr.WPL6, SMLS BW

ASTM A420 Gr.WPL6, SMLS

BW

BW

ASTM A420 Gr.WPL6, SMLS

STD x SCH 40

RMS / 17-09-2011

A

REDUCING TEE

REDUCING TEE

BW

BW

BW

STD

STD

SCH 40 x SCH 40

3" x 2"

8" - 14"

1/2" - 1 1/2"

1/2" - 1 1/2" 6000#

SCH 40 x SCH 40

ASME B36.10

ASME B36.10

ASTM A 333 Gr. 6, SMLS

300#

NOTES

PE

MATERIAL

ASTM A350 Gr.LF2, CL 1

BE

ASTM A420 Gr.WPL6, SMLS

ASTM A420 Gr.WPL6, SMLS

PBE

ASME B36.10

ITEM CODE TYPE SIZE RANGE(NB)

ASTM A671 Gr.CC60 CL32, EFW

(with 100% Radiography)

ASME B16.9BW

ASTM A420 Gr.WPL6, WELDED

1/2" - 1 1/2"

18" - 20"

16"

18" - 20"

2" - 6"

1.5mm

PR - 52.1 kg/cm²g,

TEMP - 38 °CBUTL,PROPL,DR,LPGL

-45

GOVERNING RATED CONDITION

CORROSION ALLOWANCE

500 38

ASME B36.10

SCH 160

6000#

ASTM A 333 Gr. 6, SMLS

BE

BE

SW

XS

ASTM A 333 Gr. 6, SMLS

51.08 49.8252.1

DIMENSIONAL

STANDARD REMARKSSCH. / THK. RATING

SERVICE

SERVICE CODE

DESIGN TEMPERATURE (°C)

BUTANE (LIQUID),PROPYLENE (LIQUID),DRAIN (Manifolds),LPG LIQUID (Upstream of Static

Mixer)

DESIGN PRESSURE (kg/cm²g)

10" x (4" to 6")

2" - 6"

8" - 14"

REDUCING TEE

1/2" - 1 1/2"

52.1

ELBOW 45 DEG 16" STD

SNA / 17-09-2011

COMMENTS

STD x STD

4" x (2" to 3")REDUCING TEE

8" x (4" to 6")

REDUCING TEE

REDUCING TEE

6" x (3" to 4")

STD x SCH 40

STD x SCH 40

12" x 6"

REDUCING TEE

REDUCING TEE

10" x 8"

PIPE 16" STDASTM A671 Gr.CC60 CL32, EFW

(with 100% Radiography)BE ASME B36.10

ELBOW 90 DEG 16" STD ASTM A420 Gr.WPL6, WELDED BW ASME B16.9 R = 1.5D

LPG RECEIPT AND ASSOCIATED FACILITIES AT HPCL’S MANGALORE LPG IMPORT FACILITIES JETTY NO 12

Tile : PIPING MATERIAL SPECIFICATION

Doc No: 285731-MLIF-SP-PIP-3003 Rev: A Page No. 20 OF 26

PIPING CLASS : B19A0

ASTM A420 Gr.WPL6, WELDED BW ASME B16.9

C:\Documents and Settings\shi50029\Desktop\mlif\Copy of LINE WISE MTO-GFL.xlsB19A0

6" x (3" to 4")

12" x 6"

10" x (4" to 6")

REDUCER CONC.

BW

BW

LEB-SEP

BW

BW

REDUCER ECC.

REDUCER ECC.

REDUCER ECC.

REDUCER CONC.

REDUCER ECC.

8" x (4" to 6")

10" x 8"

14" x 6"

12" x (8" to 12")

REDUCER ECC.

REDUCER ECC.

REDUCER ECC.

REDUCER CONC.

REDUCER CONC.

REDUCER ECC.

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

STD x SCH 40

STD x SCH 40 ASTM A420 Gr.WPL6, SMLS

STD x STD ASTM A420 Gr.WPL6, SMLS

ASTM A420 Gr.WPL6, SMLS

STD x SCH 40 ASTM A420 Gr.WPL6, SMLS

ASTM A420 Gr.WPL6, SMLS

STD x SCH 40

ASTM A420 Gr.WPL6, SMLS

ASTM A420 Gr.WPL6, SMLS

ASTM A350 Gr.LF2, CL 1

ASTM A350 Gr.LF2, CL 1

REDUCING TEE

REDUCING TEE

REDUCING TEE

REDUCER CONC.

REDUCER CONC.

REDUCER CONC.

REDUCER CONC.

REDUCER CONC.

REDUCING TEE

ITEM CODE TYPE

BW

BW

BW

BW

BW

BW

BW

ASME B16.9

BW

ASTM A420 Gr.WPL6, SMLS

ASTM A420 Gr.WPL6, SMLS

BW

BW

SCH 40 x SCH 40

STD x STD

XS x STD

ASTM A420 Gr.WPL6, SMLS

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

BW

ASTM A420 Gr.WPL6, SMLS

ASTM A420 Gr.WPL6, SMLS

ASTM A420 Gr.WPL6, SMLS

ASME B16.9

ASTM A420 Gr.WPL6, SMLS

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

ASME B16.9

STD x SCH 40

SCH 40 x SCH 40

8" x (4" to 6") STD x SCH 40

6" x (3" to 4")

XS x STD

ASTM A420 Gr.WPL6, SMLS

ASTM A420 Gr.WPL6, SMLS

ASTM A420 Gr.WPL6, SMLS

SCH 40 x SCH 40 ASTM A420 Gr.WPL6, SMLS

ASTM A420 Gr.WPL6, WELDED BW

ASTM A420 Gr.WPL6, WELDED BW

ASME B16.9ASTM A420 Gr.WPL6, WELDED

ASTM A420 Gr.WPL6, WELDED BW ASME B16.9

BW

20" x (8" to 18")

REDUCER CONC. ASTM A420 Gr.WPL6, WELDEDSTD x STD

REDUCING TEE

REDUCING TEE

12" x (8" to 10")

16" x 6"

14" x (8" to 12")

3" x 2"

10" x (4" to 6")

4" x (2" to 3")

REDUCER CONC.

14" x (8" to 12")

18" x (8" to 16")

16" x 6"

STD x STD

BW

STD x SCH 40 ASTM A420 Gr.WPL6, SMLS

ASTM A420 Gr.WPL6, WELDED

ASME B16.9

BW

BW

16" x (8" to 14")

REDUCING TEE 20" x (8" to 18") XS x STD

10" x 8"

ASTM A420 Gr.WPL6, SMLS

BW

BW

12" x 6" STD x SCH 40

STD x STD

14" x 6"

BW

REDUCER CONC.

STD x STD

REDUCER CONC.

STD x SCH 40

STD x STD

STD x SCH 40

REDUCER CONC.

REDUCER ECC. 14" x (8" to 12") STD x STD

3" x 2"

4" x (2" to 3")

REDUCER ECC.

16" x (8" to 14")

18" x (8" to 16")

14" x 6" STD x SCH 40

STD x STD12" x (8" to 10")

BW

BW

BW

XS x STD

SCH 40 x SCH 40

SCH 40 x SCH 40

ASTM A420 Gr.WPL6, SMLS

SCH 40 x SCH 40

ASME B16.9

BW

BW

ASME B16.9

ASME B16.9

BW

ASTM A420 Gr.WPL6, WELDED

STD x STD

ASTM A420 Gr.WPL6, SMLS

ASTM A420 Gr.WPL6, SMLS

ASME B16.9

ASME B16.9

ASME B16.9

ASTM A420 Gr.WPL6, SMLS

REDUCER ECC. 18" x 14"

REDUCER ECC. 20" x (16" to 18")

XS x STD

REDUCER ECC. 20" x (12" to 14") XS x STD

SCH 40 x SCH 160

SCH 40 x SCH 160

SCH 40 x SCH 160

XS x XS

ASTM A420 Gr.WPL6, WELDED REDUCER ECC. 16" x (8" to 14") STD x STD ASME B16.9BW

BW

BW

ASME B16.9

ASME B16.9

LEB-SEP

ASTM A350 Gr.LF2, CL 1

MSS-SP-95

MSS-SP-95

REDUCED COUPLING 3/4" x 1/2" 6000#

SWAGE ECC. 2" X (1/2" to 1 1/2")

MSS-SP-953" X(1/2" to 1 1/2")

LEB-SEP MSS-SP-95

LEB-SEP

SW

SWAGE CONC.

SWAGE ECC. 4" X (1/2" to 1 1/2")

SWAGE ECC.

2" X (1/2" to 1 1/2")

SCH 40 x SCH 160

4" x (1/2" to 1 1/2")

ASTM A350 Gr.LF2, CL 1

SCH 40 x SCH 160

6000#

ASTM A350 Gr.LF2, CL 1

1/2" -1 1/2"

3" X (1/2" to 1 1/2")

ASTM A350 Gr.LF2, CL 1 SCRD ASME B16.11

ASME B16.11

ASTM A350 Gr.LF2, CL 1

MSS-SP-95

LEB-SEP

REMARKS

SCH 40 x SCH 160 MSS-SP-95

SIZE RANGE(NB) SCH. / THK. RATING MATERIAL ENDSDIMENSIONAL

STANDARD NOTES

ASTM A350 Gr.LF2, CL 1 LEB-SEP

ASTM A420 Gr.WPL6, WELDED

ASTM A420 Gr.WPL6, WELDED

ASTM A420 Gr.WPL6, WELDED BW ASME B16.9

SWAGE CONC.

SWAGE CONC.

COUPLING FULL

21 OF

Tile : PIPING MATERIAL SPECIFICATION

Doc No: 285731-MLIF-SP-PIP-3003 Rev: A 26

PIPING CLASS : B19A0

LPG RECEIPT AND ASSOCIATED FACILITIES AT HPCL’S MANGALORE LPG IMPORT FACILITIES JETTY NO 12

Page No.

C:\Documents and Settings\shi50029\Desktop\mlif\Copy of LINE WISE MTO-GFL.xlsB19A0

FLANGES

BLINDS

GASKETS

FASTENERS

VALVES

2" - 6"

2" - 6"

ASTM A350 Gr.LF2, CL 1

RF

RF

BALL VALVE 2" - 20"

800# Full BoreSW to ASME B16.11

with Welded-on Nipples

8" - 20" 300#

1/2" - 20" ASME B 16.20

RF

300# Reduced Bore5BS EN ISO 17292

BW

WELDOLET

ASTM A350 Gr.LF2, CL 1

300#

RF

CAP

ASTM A350 Gr.LF2, CL 1

ASTM A350 Gr.LF2, CL 1

ASTM A350 Gr.LF2, CL 1

ASTM A420 Gr.WPL6, WELDED

ASTM A420 Gr.WPL6, SMLS

ASTM A420 Gr.WPL6, WELDED

1/2" - 1 1/2"

CAP

SPACER : Finish 63-125 µIn

AARH

SPADE : Finish 63-125 µIn

AARH

BALL VALVE

CAP

ITEM CODE

2" - 6" SCH 40

6000#

6000#

STD

1/2" - 1 1/2"

1 1/2" x (1" to 1/2")

ASME B16.9

SW

SW6000# ASTM A350 Gr.LF2, CL 1

SCH 160

1" x (3/4" to 1/2")

ASME B16.5

ASTM A350 Gr.LF2, CL 1 BW

STD

MSS-SP-97

ASTM A350 Gr.LF2, CL 1 RF

ASTM A350 Gr.LF2, CL 1

ASME B16.5

ASME B16.5

300# / SCH 40

1/2" - 1 1/2"

2" - 6"

SWRF : FINISH 63-125

µIn AARH

WNRF : FINISH 63-125

µIn AARH

300# / XS

ASTM A350 Gr.LF2, CL 1

SS304 Spiral With Graphite Filler, with CS

Outer Ring, 4.5 mm.THK

ASTM A320 Gr.L7 / ASTM A194 Gr.7300#

300#1/2" - 1 1/2"

MSS-SP-97

ASME B16.11ASTM A350 Gr.LF2, CL 1

ASTM A420 Gr.WPL6, SMLS

ASTM A350 Gr.LF2, CL 1 ASME B16.11

SW

ENDSDIMENSIONAL

STANDARD NOTES REMARKS