Tel: Email: Website · Hybrid Reciprocating Grate Boiler Hybrid Revolving Chain Grate Boiler (1)...

Transcript of Tel: Email: Website · Hybrid Reciprocating Grate Boiler Hybrid Revolving Chain Grate Boiler (1)...

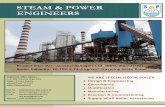

SteamBoilers and

CogenerationPlant

BIOMASS

Address: 22 Third Ave, Malvern, Durban, 4093, South AfricaTel: +2731 464 4661Email: [email protected]: www.somaitech.co.za

Biomass Boiler SystemsEnergy solutions based on biomass and bio-fuels provide clean and renewable energy for large national and international companies. Green-thinking companies are now using biofuels to mitigate the impact their activities have on the environment by reducing emissions of greenhouse gases. This can also generate earnings for your company by saving money on energy costs, and by the sale of carbon credits.

Somai Tech promotes the development of boiler technology and energy management projects through sustainable solutions for renewable energy and energy efficiency by biomass. Somai Tech will strengthen your bottom line by reducing, or even eliminating your energy and disposal costs altogether, through the combustion of renewable fuel sources, also known as Biomass.

CapabilitiesSomai Tech is able to put together the following options to suite clients’ needs:• Installation of a complete CHP (Combined Heating and Power) plant to generate electricity from high

pressure steam and utilise turbine exhaust steam for downstream processes• Installation of a stand-alone boiler plant for the supply of only process steam for operations• Installation of steam process equipment to make steam usage more efficient following outcomes of a

steam balance and plant optimisation study

Product Offerings:• An external capital funded boiler (IDC / DTI / Somai Tech collaborated funded )• A biomass (or dual fired) package boiler• A moving grate system - all types of biomass fuels - efficient ash removal - variable speed drives• Flexibility - large turndown (35-100% of MCR)• Efficient boiler (85-92% on NCV) - wood chips• PLC boiler control system - Improved steam pressure control• Agreed steam quantity and fuel quality - on demand • Efficient steam production and greener technology with low financial risk.

Biomass Boiler TypesThe boiler vessel in each of these systems is a two pass hybrid design incorporating a water tubed boiler-type water membrane and a two-pass fire tube scotch marine vessel. These boilers advantages over standard water tube boilers include a much larger steam disengagement area providing high quality steam, larger steam storage capability for quicker response to sudden steam demand, and much larger thermal storage that provides fast demand response times and safer operation.

They produce high pressure steam in ranges from 1,500 – 27,000 kg/hr output from 700 up to 6,200 kPa. The grate-type stoker system permits biomass fuels with a high proportion of incombustibles to be combusted in an efficient manner with the added advantage of automatic de-ashing. This combination enables these systems to provide a flexible and reliable operation utilizing a consistent "grade" of biomass waste with moisture contents ranging from 30 – 50%

(1) Hybrid" Firetube/Watertube Vessel Design

(2) Watertube Section

(3) Firetube Section

(4) Reciprocating Fire Grates

(5) Under Fire Air Fan

(6) Reciprocating Drive

(7) Over Fire Fan/Dampers

(8) Carry-Over Reinjection Blower

(9) Fire Door

(10) Ash Clean Out Door

(11) Optional Back Up Burner

(12) Fuel Metering Bin

(13) Ash Removal Conveyor

(14) Refractory Arch

Hybrid Reciprocating Grate Boiler

Hybrid Revolving Chain Grate Boiler

(1) Hybrid Firetube/Watertube Vessel Design

(2) Watertube Section

(3) Chain Grate Stoker System

(4) Combustion Chamber

(5) Primary Ash Collection Screw

(6) Secondary Ash Removal Screw

(7) Air Control Dampers

(8) Optional Gas/Oil Back Up Burner

(9) Over Fire Air System

(10) Ash Reinjection Blower

(11) Fire Doors

(12) Water-Side Inspection Ports

(13) Twin Screw Fuel Metering Bin

(14) Fuel Supply Conveyor

ToH

ybri

dD

esig

nH

ybri

dD

esig

n

Co

mp

lete

Bo

iler

Pla

nt

Sch

em

atic

Super

Heate

r

Econom

izer

Co

mp

lete

Co

-ge

ne

rati

on

Pla

nt

Sch

em

atic