TEHNIAL DATASHEET & SPEIFIATIONS - Epsilon Asia · epsilon em-570 gen-4 rtv silicone rubber high...

Transcript of TEHNIAL DATASHEET & SPEIFIATIONS - Epsilon Asia · epsilon em-570 gen-4 rtv silicone rubber high...

EPSILON EM-570

GEN-4 RTV SILICONE RUBBER HIGH VOLTAGE INSULATOR COATING

TECHNICAL DATASHEET & SPECIFICATIONS

Rev. 15; January 2015

TABLE OF CONTENTS

Contents

Introduction ______________________________________________________________________________________________ 1

Technical Specifications __________________________________________________________________________________ 2

Storage, Handling, Application and Maintenance ______________________________________________________ 3

List of Tests Conducted __________________________________________________________________________________ 5

More Information_________________________________________________________________________________________ 6

Contact Us _________________________________________________________________________________________________ 6

EM-570 GEN-4 RTV HIGH VOLTAGE INSULATOR COATING

Page 1

Introduction

ONE-PART ULTRA-HYDROPHOBIC COATING

Epsilon Gen-4 EM-570 is an ultra-hydrophobic UV-resistant coating that enhances an insulator's surface

properties to prevent the formation of a conductive layer even in the most polluted of environments.

The HVIC is designed to protect AC and DC insulators of up to 1200kV class.

INTENDED USAGE

Coastal, Industrial and other forms of pollution are a major cause for leakage current, corona, arcing and

flashovers across insulators (porcelain, glass, ceramic and silicone composite rubber insulators) at

switchyards and substations. The application of EM-570 HVIC on insulators is a proven and 100% effective

method to mitigate the risks of pollution and eliminate flashovers - while reducing or even altogether

eliminating the need for insulator washing.

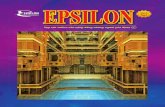

Figure 2: Coated Insulators

Epsilon EM-570 HVIC may also be used on aging composite insulators to avoid degradation and enhance

the life of such insulators. HVIC can also be used on metallic substrates as a ‘paintable electrical

insulation’ due to the high dielectric strength and resistance to UV rays

EM-570 GEN-4 RTV HIGH VOLTAGE INSULATOR COATING

Page 2

Technical Specifications

Epsilon EM-570 Gen-4 RTV HVIC

Type One part, RTV

Appearance Paint

Specific Gravity ≥ 1.26

Primary Filler Type Quartz

Secondary Filler ATH

Color Gray

Usage Temperature Range ºC -4°C to 121°C

Cure Method Oxime

Skin-over time at standard conditions* 15 minutes

Tack free at 25°C and 50% RH 30 minutes

Min Percent Solids (By Weight) ≥ 78%

Min Percent Solids (By Volume) ≥ 64%

Viscosity, cps 1700 to 2500

As cured – at standard conditions* for 7 days

Dielectric Strength, (ASTM D 149) 36.0 kV/mm

Volume resistivity, ohm.cm (ASTM D257) 9.0 × 1014

Dissipation factor at 100Hz (ASTM D150) 0.021

Water Repellency Angle 118° ± 3°

Tracking wheel withstand, hours 1,000 Hours

Min. Salinity Level withstood during Artificial Pollution Test on flashed-over and coated string of disc insulators (400kV)

112 kg/m3

Hydrophobicity Recovery within 48 hours (REC 76/2006) To HC2

Aerosol Can available for purchase (for touch-ups) Yes

Method of Application Airless Spray, brush or roller

EM-570 GEN-4 RTV HIGH VOLTAGE INSULATOR COATING

Page 3

Storage, Handling, Application and Maintenance

STORAGE & HANDLING

• Store in a cool and dry place with adequate ventilation. Keep containers tightly sealed.

• Moisture ingress could lead to unwanted and premature curing of the HVIC.

• Material must be agitated thoroughly prior to use.

• Keep away from heat, sparks, open flame and moisture

• For a detailed safety procedures, please refer to the product Material Safety & Datasheet (MSDS)

• The coating has a shelf life of 12 months from date of delivery to the customer and must be

applied within that period for warranties to hold good

SAFETY

• Please refer to the latest version of the MSDS

HVIC QUANTITY ESTIMATION

Considering HVIC usage is largely dependent upon formulation, application efficiencies, applicator

training, equipment design, weather conditions and other parameters, it is recommended that the

BOQ of equipment to be coated is informed to Epsilon who can provide a detailed calculation of HVIC

usage. A request for an HVIC quantity calculation can be made here.

APPLICATION

Application of HVIC must be conducted by the Epsilon Asia Group or by qualified personnel with suitable

training. Application must be conducted in an off-line state in accordance with:

IEEE Standard_1523 2002_Application maintenance and Evaluation for HVICs And Epsilon RTV HVIC Insulator Coating Application Maintenance and Handling Procedure (V12 or later) In most cases, the Epsilon standard exceeds the IEEE standard and Epsilon HVIC procedure V12 (or later) will be followed. Target thickness of the coating must be after an assessment of site conditions and as per relevant ‘coating thickness table’ stated in the Epsilon RTV HVIC Insulator Coating Application Maintenance and Handling Procedure

EM-570 GEN-4 RTV HIGH VOLTAGE INSULATOR COATING

Page 4

POST-APPLICATION MAINTENANCE

Maintenance not needed after application of Gen-4 HVIC in most cases. However, it is advisable to refer to the Epsilon RTV HVIC Insulator Coating Application Maintenance and Handling Procedure or contact an Epsilon representative. Insulator washing is not required in most cases but if washing is desired, pressure of 400 psi (7.6 bar) should not be exceeded. Care should be taken to not climb on, scratch or physically harm the coating. However, performance of the coating will not be degraded by minor nicks or cuts.

EM-570 GEN-4 RTV HIGH VOLTAGE INSULATOR COATING

Page 5

List of Tests Conducted

1 CPRI - Artificial Pollution Test by Salt Fog Method on coated 'flashed-over' insulators

2 CPRI - Hydrophobicity Recovery Test REC 76/2206

3 ESKOM - Heavy to very Heavy Pollution Test

4 IEC 06587 EM-570 HVIC Tracking and Erosion - Martin Testing Lab (4.5kV)

5 IEC 06587 EM-570 HVIC Tracking and Erosion – Univ. of Waterloo (2.5kV and 4.5kV)

6 ASTM G53 EM-570 HVIC 5000 hour test

7 Water Immersion/Absorption Test – Univ. of Waterloo

8 Hydrophobicity Retention Test – Univ. of Waterloo

9 Hydrophobicity Assessment of – Univ. of Waterloo

10 CEA Purchasing Spec LWIWG -02(96) Water Penetration Test - Power Labs

11 CEA Purchasing Spec LWIWG -01(96) Tracking Wheel & Erosion Test - Powertech Labs

12 ASTM D150 - Relative Permittivity and Dissipation Factor - University of Waterloo

13 Water Repellency Angle Test - University of Waterloo

14 Dielectric Breakdown Strength Test as per ASTM D149 - University of Waterloo

15 Inclined Plane Tracking Test as per ASTM D2303 - University of Waterloo

EM-570 GEN-4 RTV HIGH VOLTAGE INSULATOR COATING

Page 6

More Information

1. Case studies using RTV Coatings across various industries like power generation, transmission,

distribution, metals, cements, refineries, sugar and chemicals

2. Scientific/academic papers authored by Epsilon Asia Group

3. A technical paper authored by TATA POWER/CGPL 4,000 MW Power Plant in Mundra, India

regarding their experiences with Gen-4 RTV Coating

Contact Us

Please visit us at our website, telephone our offices or write to us at [email protected]

Epsilon Asia Group

Worldwide Sales incl. India: Avanza Epsilon Elektro Pvt. Ltd.:

X-29 Hauz Khas, New Delhi – 110016; T: +91.11.4101.4888; F: +91.11.4102.2525

SE Asia and Australia-Pacific: Epsilon Engineering (Thailand) Co. Ltd.:

Level 29, The Offices at CentralWorld, 999/9 Rama-I Road, Bangkok 10330, Thailand;

T: +66.2.207.2487; +66.8148.29021

www.epsilonasia.com