TECHNICAL SPECIFICATION FOR ANNUNCIATORS FOR … · specification, removal of existing old...

Transcript of TECHNICAL SPECIFICATION FOR ANNUNCIATORS FOR … · specification, removal of existing old...

Signature and Seal of Bidder Page 1 of 32

ANNEXURES

TECHNICAL SPECIFICATION

FOR

ANNUNCIATORS

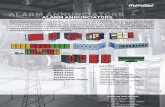

FOR 132/220/400 KV LINE FEEDER PANELS.

Signature and Seal of Bidder Page 2 of 32

INDEX

SL.

NO

CONTENT DESCRIPTION PAGE

NOS.

1 SECTION- I TECHNICAL SPECIFICATION 3

2 SECTION -II ANNEXURES 19

3 SECTION- III TECHNICAL SCHEDULES 22

Signature and Seal of Bidder Page 3 of 32

SECTION-I

TECHNICAL SPECIFICATION

CONTENTS

Sr.

No.

DESCRIPTION PAGE

NO.

1.0 INTENT OF SPECIFICATION. 4

2.0 QUALIFYING REQUIREMENT OF BIDDER. 4

3.0 SCOPE. 5

4.0 PLACE OF INSTALLATION. 6

5.0 CLIMATIC CONDITION. 7

6.0 CODES AND STANDARD. 8

7.0 TECHNICAL REQUIREMENTS. 8

8.0 PRE DESPATCH INSPECTION AND TESTING. 11

9.0 GUARANTEES. 12

10.0 DEVIATIONS. 12

11.0 DOCUMENT SUBMISSION. 13

12.0 DRAWINGS/DATA/DOCUMENTS TO BE SUBMITTED BY

BIDDER ALONGWITH THE BID.

14

13.0 DRAWINGS/DATA/DOCUMENTS TO BE SUBMITTED BY

SUCCESSFUL BIDDER.

14

14.0 DELIVERY SCHEDULE. 15

15.0 PACKING AND TRANSPORTATION. 15

16.0 PAINTING. 17

17.0 DEMONSTRATION. 17

18.0 INSTALLATION, COMMISSIONING AND TRAINING. 17

Signature and Seal of Bidder Page 4 of 32

1.0 INTENT OF SPECIFICATION

1.1. This specification is intended to cover the design, engineering, manufacture,

inspection and testing at manufacturer’s works, packing, supply transportation &

delivery, training, Installation and commissioning of microprocessor based

communicable type annunciators at GSECL power station sites as per

requirement included in this specification.

1.2. It is not the intent to completely specify all details of design and construction

herein. Nevertheless, the equipment shall conform to high standards of

engineering design and workmanship in all respects and shall be capable of

performing continuous operation in a manner acceptable to the Purchaser.

Reliability, availability and maintainability are of the utmost importance to the

Purchaser in the design of the equipment described herein.

2.0 QUALIFYING REQUIREMENT OF BIDDER

2.1. The bidder should be a manufacturer of offered equipment in India who has

designed, manufactured and successfully, tested as per IS/IEC or any equivalent

standard. Equipment of the type and class (voltage and protection types) specified

are in successful operation for not less than 3 years as on the date of bid opening.

2.2. The bidder should have executed such type of supply & work as per tender

specification in past and bidder have to submit documents conforming the same

during last three years in utilities like State Electricity Corporations, NTPC,

PGCIL etc.

2.3. The minimum requirement of manufacturing capacity of offered type, size and

rating of equipment shall be 7 times tender / bid quantity. The bidder should

indicate manufacturing capacity by submitting latest updated certificate of a

Chartered Engineer (CE).

2.4. Equipment offered shall be in service for a minimum period of three (3) years

and satisfactory performance certificate from utilities like State Electricity

Corporations, NTPC, PGCIL etc. in respect of this should be submitted.

2.5. Equipment offered shall have type test certificates from accredited laboratory

(accreditation based on ISO/IEC/Guide 25/17025 or EN 45001 by the national

accreditation body of the country where the lab is located.) as per

IS/IEC/Technical specification, not older than FIVE (5) years from the date of

opening of technical bid.

Signature and Seal of Bidder Page 5 of 32

2.6. The bidder should clearly indicate the quantity and Single Value Contract

executed during last FIVE (5) years, for the offered equipment. Bidder should

have executed one single contract during last five years for the quantity

equivalent to tender / bid.

The details are to be submitted in following format,

Sr.

No

ITEMS

SUPPLIED

TO

ORDER

REFERENCE

No. &

DATE

ITEMS QUANTITY ORDER

FULLY

EXECUTED

YES/NO

STATUS, IF

ORDER

UNDER

EXECUTION

REMARK

2.7. The facility for extending the necessary after sales service, with adequately

trained manpower and establishment, shall be available in India. The documents

indicating the same shall be submitted with the bid.

2.8. Notwithstanding anything stated above, the owner reserves the right to assess

bidder’s capacity to perform the contract, should circumstances warrant such an

assessment in the overall interest of the contract and the owner.

3.0 SCOPE

3.1. The scope includes, but is not limited to design, engineering, manufacture,

inspection and testing at manufacturer’s works, packing, supply, transportation &

delivery at site (FOR site) , microprocessor base annunciators as per

specification, removal of existing old annunciators & associated wiring and

Installation , testing & commissioning of newly supplied annunciators at site in

place of existing old annunciators inclusive of all fittings, accessories and spares

for efficient and trouble-free operation.

3.2. The scope includes supply of 28 / 30 Windows microprocessor base

annunciators , required material for retrofitting like , wires , lugs , ferrules , TBs ,

Blanking plates , nut- bolt , channel etc. hardware , cable for communication up

to existing PC in the switchyard , software for communication with annunciators

etc.

3.3. Cutting, fabrication of panel for fixing new annunciator, Fixing , Installation and

commissioning of new annunciator including removing & refitting of other

Signature and Seal of Bidder Page 6 of 32

equipments like hooter , indicators, meters etc. if required for accommodating

and fitting of new annunciator.

3.4. The scope includes wiring of annunciator up to separate TB in the panel for all

windows.

3.5. The wiring from field to panel is not included in the scope.

3.6. Wiring of annunciator for data communication up to PC (PC is not included in

the scope of bidder).

3.7. Supply, installation and configuration of monitoring software in the given PC for

communication with annunciator .

3.8. The scope includes furnishing all relevant drawings, data, routine & type test

reports, commissioning instructions and operation & maintenance manuals.

3.9. Bidder shall indicate the list of recommended spares as required in appropriate

technical schedule for equipment operation for ten (10) years. Bidder shall quote

for price for recommended spares separately, which shall not be included in the

base bid.

3.10. The purchaser reserves the right of selection of items and quantities of above

spares to be order. The price for spares shall be kept valid till the expiry of

guarantee period.

3.11. Transportation and delivery of all the materials by rail / road to site.

3.12. Bidder shall arrange their representatives / commissioning engineers for

installation, testing, and commissioning of the supplied equipment at each site.

The responsibility of commissioning engineers shall be to install, test,

commission the equipment supplied by the bidder to the satisfaction of owner/

owner’s engineer and hand over the equipment to the Owner.

3.13. Provide training to GSECL engineers for safe operation and maintenance of the

equipment before handing over the equipment.

3.14. The bidder shall visit all sites at his own cost with the prior intimation for

assessing the volume of work prior to quoting bid. No claims for inadequate

description of the scope shall be entertained at a later date.

Signature and Seal of Bidder Page 7 of 32

4.0 PLACE OF INSTALLATION.

4.1. The Annunciators would be supplied at (a) Wanakbori (b) Gandhinagar (C)

Ukai TPS(d) Ukai Hydro PS (e) Sikka (f) Kutch Lignite TPS (g) Kadana

Power Station. The place of installation would be 132/220/400 KV line feeder

panels as indicated below.

Sr. No. Name of Power Station 400 KV 220 KV 132 KV Total

Nos.

1 Wanakbori TPS 3 7 10

2 Gandhinagar TPS 10 10

3 Ukai TPS 1 7 8

4 Kutchh Lignite TPS 6 6

5 Sikka TPS 6 6

6 Ukai Hydro PS 4 4

7 Kadana Hydro PS 4 4

TOTAL 4 38 6 48

5.0 CLIMATIC CONDITIONS

The equipment shall be suitable for satisfactory operation under the following

Climatic Conditions.

1. Altitude : Not exceeding 1000 Meters.

2. Ambient Air Temperature:-

a) Maximum temperature : 45ºC

b) Maximum daily average temperature : 35ºC

c) Minimum temperature : 3.5ºC

3. Rainfall. : 1000/1150 mm. during June to Sept

4. Relative humidity for : 95%

Design of equipment.

5. Climate condition : Hot, humid and conducive to rust

& fungus growth.

6. Isoceraunic level : III

7. Av. Number of thunder : 20

Storm days per Annum (No.)

8. Max. Wind pressure : 150 Kg/Cm2.

9. Earthquake acceleration : 0.08 x 2g (G).

Signature and Seal of Bidder Page 8 of 32

10. Tropicalisation. : 1. All equipment supplied against this

Specification shall be given tropical

And fungicidal treatment in view

Of the severe climatic conditions

Prevailing at site as described above.

2. Tropical protection shall confirm to IS:

3202 entitled “Climatic Protection” of

electrical equipment

or BS: CP-1014-1963 entitled “Protection

of electrical Power equipment against

climatic condition”.

6.0 CODES AND STANDARDS

Design and construction of various components of the equipment shall be in

accordance with the latest editions of the relevant IS/IEC standards and CBIP

recommendations. The supplier shall submit the copy of the relevant standards

applicable to the equipment offered.

In case of any conflict between this document and the codes and standards referred

to herein, the stringent stipulation of these two shall prevail.

Some of the relevant standards, which are to be referred, are listed at Annexure I ,

however the bidder shall check the respective requirement of standard and

equivalent IS / IEC for annunciators and offer accordingly with supporting

documents and this shall be accepted.

7.0 TECHNICAL REQUIREMENTS

7.1. Alarm annunciation system shall be provided on the control board by means

of visual and audible alarm in order to draw the attention of the operator to the

normal operating conditions or the operation of some protective devices and

DC fail condition. The annunciation equipment shall be suitable for operation

on both 220 V DC / 240 V AC (selectively) for normal operating conditions

and for AC / DC fail conditions.

7.2. Alarm annunciation shall be of microprocessor based with replaceable

windows, NO/NC site selectable, sequence/ grouping selectable, choice of

colors, choice of windows sizes and availability of serial part (RS232 to RS

485) output for computer connection. It shall have AC/DC fail facility and

super bright LED facia and through out provisions for trouble shooting and

Signature and Seal of Bidder Page 9 of 32

maintenance. The windows based PC software, cables, converters etc. shall

also be provided. Sequence of operation of the annunciator shall be as

follows;

Sr.

No Alarm condition Fault contact

Visual

annunciation

Audible

Annunciation

1 Normal Open Off Off

2 Abnormal Close Flashing On

3

Acknowledge

push button is

pressed

(a) Close

(b) Open

Steady On

Steady On

Off

Off

4

(a) Reset

Pushbutton

pressed

(b) If abnormal

condition

persists

(a) Close

(b) i-Open

ii- Close

Steady On

Off

Flashing

Off

Off

Off

5 Lamp Push button

pressed Open Steady On Off

Signature and Seal of Bidder Page 10 of 32

7.3. The visual annunciation shall be provided by annunciation fascia, mounted

flush on the top row of the panels. The audible alarm shall be provided on

alarm hooter and bell to differentiate the TRIP AND NON TRIP alarm

respectively.

7.4. Annunciator fascia unit shall have translucent plastic windows for each alarm

point. Annunciation facia shall be engraved in black-in-white lettering for

NON TRIP alarm and black-in-red lettering for TRIP alarm.

7.5. Alarm inscription shall be engraved on each window in not more than three

lines and size of the lettering shall be about 5mm. The inscription shall be

visible only when the respective fascia light is `ON’.

7.6. The cover plate of the fascia windows shall be flush with the panel and shall

be easily removable. The fascia window shall have two white lamps in

parallel to provide safety against lamp failure. The lamps provided in the

fascia windows shall be adequate to ensure clear visibility of the inscriptions

in the control room having high illumination intensity (500 Lux) from the

location of the operator’s desk.

7.7. The annunciator shall be suitable for operation with normally open fault

contacts which close on a fault. For fault contacts which open on a fault, it

shall be possible at site to change annunciator from ` close to fault’ to `Open

to Fault’ and vise versa.

7.8. Each annunciator shall be provided with accept, reset and test push buttons.

7.9. Special precaution shall be taken by the supplier to ensure that alarm

conditions do not appear due to influence of external electromagnetic

/electrostatic interference on the annunciator wiring and switching

disturbances from the neighboring circuits within the panels.

7.10. In case `RESET’ push button is pressed before abnormality is cleared, the

lamps shall continue to flash and shall go out only when `normal’ condition is

restored.

7.11. Any new annunciation appearing after the operation of `accept’ for previous

annunciation, shall provide a fresh `audible alarm’ with accompanied `visual

alarm’ even if the process of `acknowledging’ or `resetting’ of previous alarm

is going on or is yet to be carried out.

7.12. Provision of testing facilities for flasher and audible alarm circuit of

annunciator shall also be made.

Signature and Seal of Bidder Page 11 of 32

7.13. The annunciation shall be of repetitive type and shall be capable of registering

fleeting signal registered by the system shall be of 15ms.

7.14. The schematic drawing of annunciation shall be required to be submitted by

the successful bidders. The one set of spare cards / relays shall be supplied

along with the panels for an individual station.

7.15. The annunciation in facia shall be grouped for tri in one / more row and non

trip be grouped in balance rows.

7.16. The spare facia window provided should have facility to engrave the

inscription on site.

7.17. Auxiliary relay for annunciation system shall have adequate auxiliary

potential free contacts for used in DR and SER.

7.18. The annunciator shall have 28 /30 windows for each scheme.

7.19. The width of panel where annunciator is to be installed varies from 600

mm to 1000 mm at various power stations, therefore the width of

annunciator should be such that it can be feasible to fix in the panel

having 600 mm width.

7.20. The dimension of window should not be less than 65 X 30 mm keeping

over all dimension suitable for fixing it in the panel having 600 mm

width.

7.21. The annunciator shall have facility for interfacing with PC through suitable

network. Separate port for serial interfacing should be available.

7.22. Electronic hooter with selectable tone (minimum three) having suitable

voltage rating to be supplied with each annunciator.

8.0 PRE-DISPATCH INSPECTION AND TESTING

8.1. Bidder shall invariably furnish his standard Quality Assurance Plan along with

the bids. Inspection and testing shall be as per approved QAP.

8.2. Test certificate/ reports for the type tests carried out on similar rating and design

of equipment shall be submitted for Purchaser’s / Owner’s review/ approval.

Test certificate not older than 5 years shall be supplied along with offer by the

bidder

8.3. Purchaser reserves the right to demand repetition of some or all the type test in

the presence of the purchaser’s representative. For this purpose the bidder may

Signature and Seal of Bidder Page 12 of 32

quote unit rates for carrying out each type test. In case, the equipment has not

been type tested earlier, the entire type test as per relevant standards shall be

carried out by the successful bidder in the presence of purchaser’s

representative without any extra cost.

8.4. All acceptance, routine Tests and any other tests, inspection as per relevant

standards must be conducted at the place of manufacture for the offered

equipment in presence of Purchaser’s representative without any extra cost.

8.5. No equipments or systems shall be shipped before all tests and inspections have

been carried out according to the approved quality assurance plan unless

otherwise instructed by the purchaser.

8.6. The acceptance of any material prior to shipment shall in no way relieve the

successful bidder of any of his responsibilities for meeting all the requirements

of the specification and shall not prevent subsequent rejection if such

materials are found to be defective.

8.7. Immediately after finalization of the programme of type / acceptance / routine

testing the supplier shall give two weeks’ advance intimation to the purchaser to

enable him to depute his representative for witnessing the tests.

8.8. The manufacturer shall offer the inspector representing the purchaser all the

reasonable facilities free of charge, for inspection and testing to satisfy him that

the material is being supplied in accordance with this specification.

8.9. The representative / Engineer attending the above testing will carryout

testing on equipments and issue test certificate approval to the manufacturer

and give clearance for dispatch.

8.10. Any test which is not being conducted indigenously, the bidder shall furnish test

report in “English” for the said test being conducted outside India for exactly

identical rated equipment

9.0 GUARANTEE

The supplier shall provide a guarantee in respect of the equipment to be furnished

by him the following:

Signature and Seal of Bidder Page 13 of 32

9.1. All equipment and materials shall be new and in accordance with the

specification, all equipment shall be free from any defect due to faulty design,

materials and/or workmanship.

9.2. Performance Guarantee: Supplier shall guarantee the successful and satisfactory

operation of all the equipment supplied under this specification and shall meet

the ratings and requirements with stipulated accuracy class.

9.3. The above guarantee shall be valid for a period of twelve (12) calendar months

commencing from the date of taking over of the fully commissioned equipment

or eighteen (18) calendar months from date of receipt which ever is later.

9.4. This period of the Guarantee shall be called the “Guarantee period”. During this

period, the successful bidder’s liability shall be replacement of any defective

parts that may develop in the equipment. All such replacements of defective

parts mentioned above shall be made free of cost at site by the supplier. The

service shall be free of cost during Guarantee period.

10.0 DEVIATIONS

No deviations to this specification shall be acceptable unless specifically

indicated in the offer in the relevant schedule. All deviations shall be clearly

spelt out by the Bidder and the price implications thereof.

GSECL at their discretion will decide regarding acceptance of deviation for

fulfilling the requirement of project as per site condition.

Bidder must furnish List of Technical Deviations mentioning the specification

clause nos. against which deviations have been sought for. Compliance with

this specification will be taken for granted in absence of any specific mention

of deviations in the said list of deviations. Any implied deviation or any

deviation mentioned elsewhere in the offer shall not be considered.

Signature and Seal of Bidder Page 14 of 32

11.0 DOCUMENT SUBMISSION

11.1. All drawings/documents submitted by supplier shall be in sufficient detail to

indicate the type, size, arrangement, weight (as applicable), the external

connections, fixing arrangements required, the dimensions required for

installation and interconnections with other equipment and materials, clearances

and spaces required between various portions of equipment and any other

information specifically requested.

11.2. Drawings / Documents submitted shall be signed by responsible representatives

of the Bidder and all drawings shall be of A-3 size. (297mmX420 mm )

11.3. All dimensions on drawings shall be in Metric Units, unless otherwise

specified. The details in the drawings shall be in English language only.

11.4. The Bidder shall prepare and submit to the Purchaser, operation and

maintenance manuals in accordance with the Purchaser’s requirements and in

sufficient detail, for the Purchaser to get familiarized with the equipment and to

enable him to operate, maintain, dismantle, reassemble, adjust and repair the

equipment in a safe and efficient manner. O&M Manual shall contain

i) Vendor Contact Details

ii) Storage Instruction

iii) Erection & Commissioning Instruction

iv) Operating Procedure /Instruction and Maintenance Schedule

v) List of Bought out component & sub vendor’s addresses

vi) Technical Data Sheet

vii) Leaflets of Bought Out component

viii) Drawings etc.

The O&M manual shall be furnished to the Purchaser along with the Bid

submission.

11.5. A separate section of the manuals shall be devoted to each size/ type of

equipment and shall contain a detailed description of construction and

operation, together with all relevant pamphlets, catalogues, drawings and a list

of parts with procedure for ordering spares. Maintenance instructions shall

include charts showing lubrication, checking, testing and replacement

procedures to be carried out daily, weekly, monthly and at longer intervals to

ensure trouble-free operation. Where applicable, fault location charts shall be

included to facilitate finding the cause of mal-operation or breakdown. A

collection of the Manufacturer’s standard leaflets will not be accepted, to mean

Signature and Seal of Bidder Page 15 of 32

compliance of this clause. The manual shall be specifically compiled for the

concerned site.

11.6. DOCUMENT ON ELECTRONIC MEDIA WRITE-PROTECTED:

All documents including drawings, data sheets, erection and commissioning

manuals, O & M manuals shall be provided on electronic media viz. floppies,

CD’s, Each electronic media shall be of high quality and suitable for long-term

storage. The reproduction from media shall be of good quality.

12.0 DRAWINGS / DATA / DOCUMENTS TO BE SUBMITTED BY BIDDER

ALONGWITH THE BID

As a minimum, the bidder shall furnish the following relevant drawings,

documents and catalogues of the major equipment offered in two sets failing

which the bids shall be rejected.

(a) Typical general arrangement drawing of the equipment showing

overall dimensions.

(b) Equipment weight

(c) Shipping weight and dimensions

(d) Quality assurance plan

(e) Type test reports of similar rating equipment

(f) Catalogues for equipment and fittings & accessories (preferably in

electronic form)

(g) Operation & Maintenance Manual.

(h) Experience certificates of supply of identical types of equipment

(i) List of sub-vendors for purchaser’s approval.

(j) Schedules as per Section- III

13.0 DRAWINGS / DATA / DOCUMENTS TO BE SUBMITTED BY

SUCCESSFUL BIDDER

Before dispatch of equipments to consignees, the supplier is required to submit

sets of following drawings / documents in suitable files. There shall be such

three sets per equipment and shall be forwarded to a) Two sets to consignee

before dispatch of equipment b) One set with equipment

a) Equipment Rating and terminal diagram plate drawing.

b) Transportation and shipping dimensions and weights.

Signature and Seal of Bidder Page 16 of 32

c) Control schematics and wiring diagrams.

d) Electronic copy of all the drawings in a floppy disk / CD.

e) Operation and maintenance manual.

f) Commissioning manual.

g) Catalogues for all bought out items.

All Erection, operation & maintenance manuals & drawings shall be furnished

in reproducible form (floppy / CDs) also.

14.0 DELIVERY SCHEDULE.

14.1. Bidder shall supply within 12 weeks from date of LOI or Purchase order which

ever is earlier.

14.2. The consignee details shall be issued to the successful bidder after placement of

orders and after inspection and testing of equipment at manufacturer’s works.

(Annexure II).

15.0 PACKING AND TRANSPORTATION

15.1. All equipment / material shall be suitably packed for transport, carriage at site

and outdoor storage during transit.

15.2. Bidder shall adequately prepare all the equipment for shipment. Where required

by the nature of the equipment, Bidder shall furnish and install necessary covers

to protect the equipment from rain, hail, wind, dust, etc. Equipment shall be

adequately sealed and protected during shipment to prevent corrosion, entrance

of foreign matter, and possible damage from rough handling during transit. Any

articles or materials that might otherwise be lost in shipping shall be boxed or

wired in bundles.

15.3. Suitable weather protection (like PVC sheets) shall be provided to prevent

wetting of components during transportation and outdoor storage at site.

15.4. Protective Coatings and Preservatives

15.4.1. Preservative coatings used on components shall be suitable for the

conditions normally expected during transportation, storage and

throughout the erection period.

15.4.2. Each type of preservative used shall be identified as to quality, life

expectancy and type. Toxic and hazardous – type preservatives will not

be allowed. Complete information shall be submitted to the Purchaser

Signature and Seal of Bidder Page 17 of 32

covering step – by – step procedures, including Indian governing laws

for handling and removal of each type of preservative.

15.5. All loose components shall be identified with company material code,

15.6. Part no, weight and name for easy site identification.

15.7. Each consignment shall be accompanied by a detailed packing list

15.8. Containing the following information. Any material found short inside the

intact packing cases shall be supplied by the supplier without any extra cost. .

a) Purchase order reference.

b) Name of consignee

c) Details of consignment

d) Destination

e) Total weight of consignment

f) Handling and unpacking instructions.

g) Bill of materials indicating contents of each package

e) All instructions for proper care and handling after delivery, including

outdoor storage procedures, shall be furnished by the Bidder before the

equipment is dispatch .A comprehensive list of all items shipped shall

also be submitted before dispatch to purchaser.

f) All equipment shall be adequately prepared for transportation and for a

maximum period of outdoor storage of six months. At time of shipment,

equipment shall be clean and properly protected against transit damages.

The supplier shall be responsible for any damage to the equipment during

transit due to improper and inadequate packing

g) The equipment shall be prepared for transportation after testing has been

completed.

h) The cases containing easily damageable material shall be very carefully

packed and marked with appropriate caution symbols i.e. `FRAGILE’

`HANDLE WITH CARE’, `USE NO HOOK’ etc

Wherever necessary proper arrangement for attaching slings for lifting

shall be provided, and all packages clearly marked with signs showing

`UP’ and `DOWN’ sides of boxes and lifting points.

Signature and Seal of Bidder Page 18 of 32

i) Before the equipment is shipped, the original shipping stops, bolts, ties,

etc., shall be reinstalled in all devices.

j) Electrical and control panels shall be protected against corrosion, weather,

and mechanical damage during transit. Temporary structural bracing shall

be installed as required to allow for normal field handling, skidding, and

hoisting.

k) In addition to the foregoing, the Supplier shall provide internal and

external protection from the effects of corrosion for all parts not otherwise

coated or painted. Where closure is incomplete, plastic material

adequately supported, protected, and sealed shall be used to provide an

effective barrier.

16.0 PAINTING

The painting scheme shall be suitable for an equipment to be operated in a

highly polluted and corrosive atmosphere. Climate is saline, tropical, and

conducive to fungus growth. Painting shall be in accordance with Painting

Specification.

17.0 DEMONSTRATION

During technical scrutiny of the bid, the purchaser may ask to offer

demonstration of the Annunciator with accessories which has been offered in the

bid. The bidder shall demonstrate the same within two weeks of intimation from

purchaser. The acceptance of equipment is subject to successful demonstration to

the satisfaction of GSECL at prescribed site of GSECL

Signature and Seal of Bidder Page 19 of 32

18.0 INSTALLATION, COMMISSIONING AND TRAINING:

18.1. The bidder shall depute their Engineer to the various sites for carrying out

testing and commissioning of testing equipments at no extra cost.

18.2. In addition to providing commissioning assistance, the vendor’s representative

shall also train the purchaser and its designee’s personnel (up to a maximum of

5 people per power plant site) in the operation and maintenance, trouble

shooting etc of the equipment under vendor’s scope of supply, including

classroom, on-the-job and safety training. The training shall be of such quality

so as to provide the purchaser’s or its esignee’s personnel with a

comprehensive working understanding of all operational and maintenance

aspects of the equipment.

18.3. The program of the training shall be mutually discussed and finalized by the

purchaser with suppliers.

Signature and Seal of Bidder Page 20 of 32

SECTION-II

ANNEXURES

CONTENT

SL.

NO CONTENT DESCRIPTION

PAGE

NOS.

1 ANNEXURE-I Codes And Standards 20

2 ANNEXURE-II Consignee Details 21

Signature and Seal of Bidder Page 21 of 32

ANNEXURE- I

CODES AND STANDARDS

Sr.

No.

Standard No. Title

1 IEC 60364-4-41 Protection against electric shock.

2 IEC 61721 Classification of Environmental conditions.

3 IEC 61010-1 & 2 Safety requirements for electrical Equipment for

measurement, control and laboratory use.

4 IS – 2147

IP-54

Degree of protection, Ingress protection, dust & moisture.

5 IEC-60255-22-1 MHz burst disturbance

6 IEC-60255-22-2

IEC-61000-4-2

Electrostatic discharge Direct application

Indirect application

7 IEC-60255-22-4 Fast transient disturbance

8 IEC-, 60255-22-5 Surge immunity test

9 IEC-60255-22-7 Power frequency immunity test

10 IEC-61000-4-8 Power frequency magnetic field test

11 IEC- 60255-22-3 /

EN-61000-4-3 /

IEEE/ANSI/C37.90.2

Radiated electromagnetic field disturbance

12 IEC- 60255-22-3 Conducted electromagnetic field disturbance

13 IEC- 60255-25 Radiated emission

14 IEC- 60255-5 Dielectric test ,Impulse voltage test ,Insulation resistance

15 IEC-60068-2-1 Cold test ,Storage test

16 IEC-60068-2-2 Dry heat test

17 IEC-60068-2-3 Damp heat test, steady state

18 IEC-60068-2-30 Damp heat test, cyclic

19 IEC- 60255-26 Immunity / Emissivity

20 EN-50178 Low voltage directive

21 IEC- 60255-21-1

IEC –60088-2-6

Vibration

Vibration during operation and transport

22 IEC- 60255-21-2

IEC-60088-2-29

Shock and bump

Bumping during transport

23 IEC- 60255-21-3 Seismic

24 IEC-60088-2-1 Low temperature test

25 IEC-60088-2-2 High temperature test

26 IEC-60088-2-3 Humidity test

Signature and Seal of Bidder Page 22 of 32

ANNEXURE –II

CONSIGNEE DETAILS

Sr.No.

For Power Station Consignee Mode of Dispatch

1 Wanakbori TPS Chief Engineer Road / rail

2 Gandhinagar TPS Chief Engineer Road / rail

3 Ukai TPS Chief Engineer Road / rail

4 Kutchh Lignite TPS Chief Engineer Road / rail

5 Sikka TPS Chief Engineer Road / rail

6 Ukai Hydro PS Chief Engineer Road / rail

7 Kadana Hydro PS Superintending

Engineer

Road

Signature and Seal of Bidder Page 23 of 32

SECTION-III

TECHNICAL SCHEDULES

The bidder shall fill in the following schedules which form part of the bid specification

and offer. If the schedules are not submitted duly filled in with the offer, the offer is

likely to be rejected.

CONTENTS

SCHEDULE

NO. DESCRIPTION

PAGE

NO.

SCHEDULE -1 GENERAL PARTICULARS OF BIDDER 24

SCHEDULE -2 SCHEDULE OF GUARANTEED

TECHNICAL PARTICULARS 25

SCHEDULE -3 SCHEDULE OF DEVIATIONS FROM

TECHNICAL SPECIFICATION 28

SCHEDULE -4 LIST OF SPARES RECOMMENDED 29

SCHEDULE -5 EXPERIENCE LIST 30

SCHEDULE -6 LIST OF DOCUMENTS SUBMITTED WITH

THE BIDS 31

SCHEDULE -7 TRANSPORTATION SCHEDULE,

INDICATING WEIGHT, DIMENSION OF

EACH TRANSPORTING UNITS

32

Signature and Seal of Bidder Page 24 of 32

SCHEDULE – 1

GENERAL PARTICULARS OF BIDDER

1 Name of Bidder with registered office

address

2 Bidder’s proposal number and date

3 Telegraphic / Telex Address

4 Telephone No.

5 Fax No.

6 E – Mail

7 Name and Designation of the Official

of the Bidder to whom all reference

shall be made

8 Project Organization chart showing

staffing, furnished?

Yes / No

9 List of important personnel with brief

curriculum vitae, furnished?

Yes / No

Signature and Seal of Bidder Page 25 of 32

SCHEDULE – 2

SCHEDULE OF GUARANTEED TECHNICAL PARTICULARS

The GTP is to be filled up in this format and, to be submitted in duplicate along with the

offer. This is intended for speedy comparison of various bidders GTP. The Bidder shall fill

in the particulars against appropriate items in respect of each rating and type of equipment

offered in the broad categories listed below. Please fill all the detail invariably , instead of

stating like ‘refer catalogue or other document’ etc.

Sr.

No. Specification

Vender’s Data /

Confirmation

1. Name of Manufacturer

2. Type designation, Complete model No. Offered

3. Is the offered Annunciators based on Microprocessor

technology? Furnish detail

4. Input Mains supply. , Voltage , Frequency with range

5. Number of Windows offered

6.

Dimension size of Annunciator

Overall

Cutout

7. Window Size.

Are the windows replaceable?

8. Power Consumption

9. Response Time

10.

Flashing Rate

Fast

Slow

11.

Pushbutton

Inbuilt or External

Type of pushbutton

12. Audible output contact available? No & Type

13. Relay Contact rating

14. Available standard and optional operating sequence.

Furnish detail

Signature and Seal of Bidder Page 26 of 32

15. Construction detail

16. Is Annubnciator having communication & interface

facility with PC through network? Furnish detail

17. No. and type of ports available for communication

Is any converter required? Specify detail.

18. Type of protocol for communication.

19. Name of software for communicating , data downloading ,

analysis etc. with features and facilities

20. Whether hardware & Software for above to be supplied as

a part of supply.

21. Selectable NO/NC input contact configuration available?

22. Window LED color

23. Type of LED used

24. AC / DC fail annunciation facility available?

Specify with Supply Input range

25. Watchdog facility available? Furnish detail

26.

Protection available for ,

Input supply (Under / Over voltage)

Wrong energizing of Field sensing contact

27. List of Accessories supplied with equipment like

Testing Cable, Case, Connectors, TBs , etc.

28. List of IEC / IS Standard to which equipment confirms

Environment

Operating Temperature

Storage & Transport temperature

Humidity

29. The equipment shall be Compatible for EMI/EMC

Environment as per relevant IEC and certificate

submitted.

Please assure and specify the confirmation with relevant

test carried out.

Please furnish all type test certificates.

30. Make , Type & Model of Electronic Hooter offered with

above annunciator

31. Dimension of Hooter

32. Input voltage & range for hooter

33. Audible out put in db. Of hooter.

34. No. of selectable Tones available

Signature and Seal of Bidder Page 27 of 32

Documents submitted.

(a) Type test reports (list of reports with date, rating of

equipments, Testing authority etc.)

(b) List of Schedules

(c) List of Drawing

(d) List of Manuals

36.

(e) Other furnished details

37. Guarantee / Warranty offered.

38. Any other related information to furnish.

NAME OF THE FIRM

SIGNATURE OF THE BIDDER

DESIGNATION

DATE

SEAL OF THE COMPANY

Signature and Seal of Bidder Page 28 of 32

SCHEDULE - 3

SCHEDULE OF DEVIATIONS FROM TECHNICAL SPECIFICATION

Reference

Section and

page

Description of Exceptions /

Deviations

Reason for Exception /

Deviation

NAME OF THE FIRM

SIGNATURE OF THE BIDDER

DESIGNATION

DATE

SEAL OF THE COMPANY

Signature and Seal of Bidder Page 29 of 32

SCHEDULE - 4

LIST OF SPARES RECOMMENDED

Item Quantity Unit Price

(Rs.)

Total Price

(Rs.)

NAME OF THE FIRM

SIGNATURE OF THE BIDDER

DESIGNATION

DATE

SEAL OF THE COMPANY

Signature and Seal of Bidder Page 30 of 32

SCHEDULE - 5

EXPERIENCE LIST

Sl.

No.

Name of the

Purchaser /

Owner with

full address

Location of

the Plant /

Equipment

Date of

Commission

ing

Performan

ce

Certificate

submitted

(Yes/No)

Details of

Equipment

supplied &

installed

Person to

whom

reference be

made

NAME OF THE FIRM

SIGNATURE OF THE BIDDER

DESIGNATION

DATE

SEAL OF THE COMPANY

Signature and Seal of Bidder Page 31 of 32

SCHEDULE - 6

LIST OF DOCUMENTS SUBMITTED WITH THE BIDS

Documents Title and Description

NAME OF THE FIRM

SIGNATURE OF THE BIDDER

DESIGNATION

DATE

SEAL OF THE COMPANY

Signature and Seal of Bidder Page 32 of 32

SCHEDULE - 7

TRANSPORTATION SCHEDULE, INDICATING WEIGHT, DIMENSION OF

EACH TRANSPORTING UNITS

Transporting

unit

Dimension in mm

(LXBXH)

Weight in KG

NAME OF THE FIRM

SIGNATURE OF THE BIDDER

DESIGNATION

DATE

SEAL OF THE COMPANY