TECHNICAL gases - far-mds.com · PDF fileThreads in compliance with ISO228/1 regulation, B...

Transcript of TECHNICAL gases - far-mds.com · PDF fileThreads in compliance with ISO228/1 regulation, B...

094

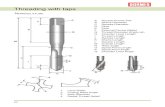

LEGEND

Codes indicated with numbers:

13xxx.1supplied with G 3/8” coupling

13xxx.2supplied with G 1/2” coupling

1. To require chemical nickel plating add NK to the article’s code

EX. 13001.1NK

The taps for technical gases are supplied with re-fined adjustment head valve, with sealing in PTFE.

Fixed nozzle in compliance with the DIN12898 regulation.

Handles in compliance with EN13792:2000 regu-lation and manufactured in acid-resistant PP.

Threads in compliance with ISO228/1 regulation, B tolerance class.

Taps are built following the DIN12918 norm.

The taps for oxygen and hydrogen are equipped with an headwork lubrificated with specific and omologated grease.

Maximum working pressure 10 Bar.

Taps finished with acid-resistant epoxy powder painting.

TECHNICAL INFORMATION

applicationWall mounting - Vertical mounting

DETAILSTest pressure: 9 Bars/air

Max working pressure: 20 Bars

SURFACE PROTECTIONEpoxy powder coating RAL 7035

MATERIALSBrass

Handle in PP

HEADWORK SEALINGPTFE temperature working range: 0 - 100°

CONNECTION TAPMale thread G3/8”

STANDARD AND NORMSEN13792:2000

DIN12898

DIN12918

ISO228/1

OPTIONSFor Purity 4.0 and O2-H2 13000.1MDSDG (o-ring viton)

For Steam 13000.1MDST (o-ring viton)

WARRANTY 2 years

STRAIGHT TAP 13000.1MDS

TECH

NICA

L gas

es

095

STRAIGHT TAP WITH 60° NOZZLE 13001.1MDSapplicationWall mounting - Vertical mounting

DETAILSTest pressure: 9 Bars/air

Max working pressure: 20 Bars

SURFACE PROTECTIONEpoxy powder coating RAL 7035

MATERIALSBrass

Handle in PP

HEADWORK SEALINGPTFE temperature working range: 0 - 100°

CONNECTION TAPMale thread G3/8”

STANDARD AND NORMSEN13792:2000

DIN12898

DIN12918

ISO228/1

OPTIONSFor Purity 4.0 and O2-H2 13001.1MDSDG (o-ring viton)

For Steam 13001.1MDST (o-ring viton)

096

WARRANTY 2 years

TECH

NICA

L gas

es

WALL HANDLE AND NOZZLE 45° TAP

WARRANTY 2 years

097

applicationWall mounting - Vertical mounting

DETAILSTest pressure: 9 Bars/air

Max working pressure: 20 Bars

SURFACE PROTECTIONEpoxy powder coating RAL 7035

MATERIALSBrass

Handle in PP

HEADWORK SEALINGPTFE temperature working range: 0 - 100°

CONNECTION TAPMale thread G3/8”

STANDARD AND NORMSEN13792:2000

DIN12898

DIN12918

ISO228/1

OPTIONSFor Purity 4.0 and O2-H2 13002.1MDSDG (o-ring viton)

For Steam 13002.1MDST (o-ring viton)

13002.1MDS

STRAIGHT TAP WITH 90° NOZZLE

098

WARRANTY 2 years

13003.1MDSapplicationWall mounting - Vertical mounting

DETAILSTest pressure: 9 Bars/air

Max working pressure: 20 Bars

SURFACE PROTECTIONEpoxy powder coating RAL 7035

MATERIALSBrass

Handle in PP

HEADWORK SEALINGPTFE temperature working range: 0 - 100°

CONNECTION TAPMale thread G3/8”

STANDARD AND NORMSEN13792:2000

DIN12898

DIN12918

ISO228/1

OPTIONSFor Purity 4.0 and O2-H2 13003.1MDSDG (o-ring viton)

For Steam 13003.1MDST (o-ring viton)

TECH

NICA

L gas

es

SINGLE STANDOUT

WARRANTY 2 years

099

applicationBench mounting

DETAILSTest pressure: 9 Bars/air

Max working pressure: 20 Bars

SURFACE PROTECTIONEpoxy powder coating RAL 7035

MATERIALSBrass

Handle in PP

HEADWORK SEALINGPTFE temperature working range: 0 - 100°

CONNECTION TAPMale thread G1/2”

STANDARD AND NORMSEN13792:2000

DIN12898

DIN12918

ISO228/1

OPTIONSFor Purity 4.0 and O2-H2 13010.2MDSDG (o-ring viton)

For Steam 13010.2MDST (o-ring viton)

13010.2MDS

BENCH 180° STANDOUT

100

WARRANTY 2 years

13011.2MDSapplicationBench mounting

DETAILSTest pressure: 9 Bars/air

Max working pressure: 20 Bars

SURFACE PROTECTIONEpoxy powder coating RAL 7035

MATERIALSBrass

Handle in PP

HEADWORK SEALINGPTFE temperature working range: 0 - 100°

CONNECTION TAPMale thread G1/2”

STANDARD AND NORMSEN13792:2000

DIN12898

DIN12918

ISO228/1

OPTIONSFor Purity 4.0 and O2-H2 13011.2MDSDG (o-ring viton)

For Steam 13011.2MDST (o-ring viton)

TECH

NICA

L gas

es

BENCH 90° STANDOUT

WARRANTY 2 years

101

applicationBench mounting

DETAILSTest pressure: 9 Bars/air

Max working pressure: 20 Bars

SURFACE PROTECTIONEpoxy powder coating RAL 7035

MATERIALSBrass

Handle in PP

HEADWORK SEALINGPTFE temperature working range: 0 - 100°

CONNECTION TAPMale thread G1/2”

STANDARD AND NORMSEN13792:2000

DIN12898

DIN12918

ISO228/1

OPTIONSFor Purity 4.0 and O2-H2 13012.2MDSDG (o-ring viton)

For Steam 13012.2MDST (o-ring viton)

13012.2MDS

BENCH 4 WAY STANDOUT

102

WARRANTY 2 years

13013.2MDS applicationBench mounting

DETAILSTest pressure: 9 Bars/air

Max working pressure: 20 Bars

SURFACE PROTECTIONEpoxy powder coating RAL 7035

MATERIALSBrass

Handle in PP

HEADWORK SEALINGPTFE temperature working range: 0 - 100°

CONNECTION TAPMale thread G1/2”

STANDARD AND NORMSEN13792:2000

DIN12898

DIN12918

ISO228/1

OPTIONSFor Purity 4.0 and O2-H2 13013.2MDSDG (o-ring viton)

For Steam 13013.2MDST (o-ring viton)

TECH

NICA

L gas

es

STRAIGHT TAP

WARRANTY 2 years

103

applicationWall mounting - Vertical mounting

DETAILSTest pressure: 9 Bars/air

Max working pressure: 20 Bars

SURFACE PROTECTIONEpoxy powder coating RAL 7035

MATERIALSBrass

Handle in PP

HEADWORK SEALINGPTFE temperature working range: 0 - 100°

CONNECTION TAPMale thread G1/2”

STANDARD AND NORMSEN13792:2000

DIN12898

DIN12918

ISO228/1

OPTIONSFor Purity 4.0 and O2-H2 13050.2MDSDG (o-ring viton)

For Steam 13050.2MDST (o-ring viton)

13050.2MDS

WALL MOUNTED TAP WITH 60° NOZZLE

104

WARRANTY 2 years

13051.2MDSapplicationWall mounting - Vertical mounting

DETAILSTest pressure: 9 Bars/air

Max working pressure: 20 Bars

SURFACE PROTECTIONEpoxy powder coating RAL 7035

MATERIALSBrass

Handle in PP

HEADWORK SEALINGPTFE temperature working range: 0 - 100°

CONNECTION TAPMale thread G1/2”

STANDARD AND NORMSEN13792:2000

DIN12898

DIN12918

ISO228/1

OPTIONSFor Purity 4.0 and O2-H2 13051.2MDSDG (o-ring viton)

For Steam 13051.2MDST (o-ring viton)

TECH

NICA

L gas

es

WALL MOUNTED TAP WITH 45° HANDLE AND NOZZLE

WARRANTY 2 years

105

applicationWall mounting - Vertical mounting

DETAILSTest pressure: 9 Bars/air

Max working pressure: 20 Bars

SURFACE PROTECTIONEpoxy powder coating RAL 7035

MATERIALSBrass

Handle in PP

HEADWORK SEALINGPTFE temperature working range: 0 - 100°

CONNECTION TAPMale thread G1/2”

STANDARD AND NORMSEN13792:2000

DIN12898

DIN12918

ISO228/1

OPTIONSFor Purity 4.0 and O2-H2 13052.2MDSDG (o-ring viton)

For Steam 13052.2MDST (o-ring viton)

13052.2MDS

90° TECHNICAL GASES TAP

106

WARRANTY 2 years

13053.2MDSapplicationWall mounting - Vertical mounting

DETAILSTest pressure: 9 Bars/air

Max working pressure: 20 Bars

SURFACE PROTECTIONEpoxy powder coating RAL 7035

MATERIALSBrass

Handle in PP

HEADWORK SEALINGPTFE temperature working range: 0 - 100°

CONNECTION TAPMale thread G1/2”

STANDARD AND NORMSEN13792:2000

DIN12898

DIN12918

ISO228/1

OPTIONSFor Purity 4.0 and O2-H2 13053.2MDSDG (o-ring viton)

For Steam 13053.2MDST (o-ring viton)

TECH

NICA

L gas

es

STRAIGHT “Y” TECHNICAL GASES TAP

WARRANTY 2 years

107

applicationWall mounting - Vertical mounting

DETAILSTest pressure: 9 Bars/air

Max working pressure: 20 Bars

SURFACE PROTECTIONEpoxy powder coating RAL 7035

MATERIALSBrass

Handle in PP

HEADWORK SEALINGPTFE temperature working range: 0 - 100°

CONNECTION TAPMale thread G1/2”

STANDARD AND NORMSEN13792:2000

DIN12898

DIN12918

ISO228/1

OPTIONSFor Purity 4.0 and O2-H2 13060.2MDSDG (o-ring viton)

For Steam 13060.2MDST (o-ring viton)

13060.2MDS

90° “Y” TECHNICAL GASES TAP

108

WARRANTY 2 years

13062.2MDSapplicationWall mounting - Vertical mounting

DETAILSTest pressure: 9 Bars/air

Max working pressure: 20 Bars

SURFACE PROTECTIONEpoxy powder coating RAL 7035

MATERIALSBrass

Handle in PP

HEADWORK SEALINGPTFE temperature working range: 0 - 100°

CONNECTION TAPMale thread G1/2”

STANDARD AND NORMSEN13792:2000

DIN12898

DIN12918

ISO228/1

OPTIONSFor Purity 4.0 and O2-H2 13062.2MDSDG (o-ring viton)

For Steam 13062.2MDST (o-ring viton)

TECH

NICA

L gas

es

VERTICAL TAP

WARRANTY 2 years

109

13064.2MDSapplicationWall mounting - Vertical mounting

DETAILSTest pressure: 9 Bars/air

Max working pressure: 20 Bars

SURFACE PROTECTIONEpoxy powder coating RAL 7035

MATERIALSBrass

Handle in PP

HEADWORK SEALINGPTFE temperature working range: 0 - 100°

CONNECTION TAPMale thread G1/2”

STANDARD AND NORMSEN13792:2000

DIN12898

DIN12918

ISO228/1

OPTIONSFor Purity 4.0 and O2-H2 13064.2MDSDG (o-ring viton)

For Steam 13064.2MDST (o-ring viton)

TECHical GASES REMOTE CONTROL BACK AND FRONTAL ASSEMBLY 13300.MDSFapplicationFume cupboard

DETAILSTest pressure: 9 Bars/air

Max working pressure: 20 Bars

SURFACE PROTECTIONEpoxy powder coating RAL 7035

MATERIALSBrass

Handle in PP

HEADWORK SEALINGPTFE temperature working range: 0 - 100°

CONNECTION TAPFlexibles with swivelling nut F3/8”

STANDARD AND NORMSEN13792:2000

DIN12898

DIN12918

ISO228/1

OPTIONSFor Purity 4.0 and O2-H2 13300.MDSFDG (o-ring viton)

For Steam 13300.MDSFT (o-ring viton)

110

WARRANTY 2 years

TECH

NICA

L gas

es

TECHnical GASES REMOTE CONTROL BACK AND FRONTAL ASSEMBLY

applicationFume cupboard

DETAILSTest pressure: 9 Bars/air

Max working pressure: 20 Bars

SURFACE PROTECTIONEpoxy powder coating RAL 7035

MATERIALSBrass

Handle in PP

HEADWORK SEALINGPTFE temperature working range: 0 - 100°

CONNECTION TAPCopper Tubes Ø10

STANDARD AND NORMSEN13792:2000

DIN12898

DIN12918

ISO228/1

OPTIONSFor Purity 4.0 and O2-H2 13300.MDSTDG (o-ring viton)

For Steam 13300.MDSTT (o-ring viton)

WARRANTY 2 years

111

13300.MDST

45° CONNECTION NOZZLE 13321.1MDS

112

WARRANTY 2 years

applicationWall mounting

Fume cupboard

SURFACE PROTECTIONEpoxy powder coating RAL 7035

MATERIALSBrass

CONNECTION TAPMale thread G3/8”

STANDARD AND NORMSEN13792:2000

DIN12898

DIN12918

ISO228/1

OPTIONSWith chemical nickel plating 17 microns inside

TECH

NICA

L gas

es

45° CONNECTION NOZZLE

applicationWall mounting

Fume cupboard

SURFACE PROTECTIONEpoxy powder coating RAL 7035

MATERIALSBrass

CONNECTION TAPMale thread G3/8”

STANDARD AND NORMSEN13792:2000

DIN12898

DIN12918

ISO228/1

OPTIONSWith chemical nickel plating 17 microns inside

WARRANTY 2 years

113

13321.1MDSE

45° CONNECTION NOZZLE 13324.2MDS

114

WARRANTY 2 years

applicationWall mounting

Fume cupboard

SURFACE PROTECTIONEpoxy powder coating RAL 7035

MATERIALSBrass

CONNECTION TAPMale thread G1/2”

STANDARD AND NORMSEN13792:2000

DIN12898

DIN12918

ISO228/1

OPTIONSWith chemical nickel plating 17 microns inside

TECH

NICA

L gas

es

45° CONNECTION NOZZLE

applicationWall mounting

SURFACE PROTECTIONEpoxy powder coating RAL 7035

MATERIALSBrass

CONNECTION TAPMale thread G3/8”

STANDARD AND NORMSEN13792:2000

DIN12898

DIN12918

ISO228/1

OPTIONSWith chemical nickel plating 17 microns inside

WARRANTY 2 years

115

13324.1MDSE

90° CONNECTION NOZZLE 13325.2MDSapplicationBench - Wall mounting

Fume cupboard

SURFACE PROTECTIONEpoxy powder coating RAL 7035

MATERIALSBrass

CONNECTION TAPMale thread G1/2”

STANDARD AND NORMSEN13792:2000

DIN12898

DIN12918

ISO228/1

OPTIONSWith chemical nickel plating 17 microns inside

116

WARRANTY 2 years

![FARM TAPS 2019.pptx [Read-Only]Farm Taps • Exercise of Enforcement Discretion Regarding Farm Taps – Issued March 28, 2019 • Choice of managing risk to farm taps by either §192.740](https://static.fdocuments.us/doc/165x107/600e7275e0429a22ec32de4b/farm-taps-2019pptx-read-only-farm-taps-a-exercise-of-enforcement-discretion.jpg)