Technical Assistance Consultant’s Report · 3.1 Refurbishment and expansion of 35kV substation...

Transcript of Technical Assistance Consultant’s Report · 3.1 Refurbishment and expansion of 35kV substation...

Technical Assistance Consultant’s Report

This consultant’s report does not necessarily reflect the views of ADB or the Government concerned, and ADB and the Government cannot be held liable for its contents. (For project preparatory technical assistance: All the views expressed herein may not be incorporated into the proposed project’s design.

Project Number: 46343-002 December 2018

Mongolia: Energy Efficiency and Urban Environment Improvement Project (Financed by the Japan Fund for Poverty Reduction)

Prepared by

HJI Group Corporation, United States in association with Richwell Engineering LLC, Mongolia

Ulaanbaatar, Mongolia

For the Ministry of Energy

TA-8649 MON

ENERGY EFFICIENCY AND URBAN ENVIRONMENT

IMPROVEMENT PROJECT (PART 2)

Technical Due Diligence

Final Report

Prepared for

Asian Development Bank

By

HJI Group Corporation

In association with

Richwell Engineering LLC

January 2018

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

i

ABBREVIATIONS

ADB – Asian Development Bank BoT – Build, Operate, Transfer CES – Central Energy System CHP – Combined Heat & Power CO2 – Carbon Dioxide EA – Executing Agency EIA – Environmental Impact assessment EIRR – Economic Internal Rate of Return ESP – Electrostatic Precipitator FGD – Flue Gas Desulphurization FIRR – Financial Internal Rate of Return GDP – Gross Domestic Product HOB – Heat Only Boiler OHL – Overhead Line MDB – Multi-lateral Development Bank MoE – Ministry of Energy MoF – Ministry of Finance NPTG – National Power Transmission Grid Company NOx – Nitrogen Oxides ROW – Right-Of-Way TA – Technical Assistance TOR – Terms of Reference UB – Ulaanbaatar UG – Underground UBHDN – UB Heating District Network Company UBEDN – UB Electricity Distribution Network Company WACC – Weighted Average Cost of Capital

NOTE

In this report, “$” refers to US dollars.

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

ii

CONTENTS

I. SUMMARY 1

II. ELECTRICITY TRANSMISSION (NPTG) 2

A. Sub-Project 1a - 220 kV Transmission Line 2

B. Sub-Project 1b – 220 kV GIS Switchyard 4

C. Point of connection with CHP5 and existing circuits 12

III. ELECTRICITY DISTRIBUTION (UBEDN) 16

A. Sub-Projects – UBEDN 16

B. Cost Estimate 29

C. Amorphous Transformers 30

APPENDIX A – COST ESTIMATE FOR 220 KV DOUBLE CIRCUIT OHL TRANSMISSION

LINE (~90 KM) 31

APPENDIX B – COST ESTIMATE FOR 220 KV GIS SWITCHYARD 33

APPENDIX C – COST ESTIMATE FOR UBEDN DISTRIBUTION NETWORK ASSETS 34

APPENDIX D – OBSERVATIONS CONCERNING 220 KV TRANSMISSION LINE DESIGN 36

APPENDIX E – OBSERVATIONS CONCERNING 220KV SWITCHYARD DESIGN 51

APPENDIX G – DNIMS 61

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

1

I. SUMMARY

1. This report provides a detailed technical due diligence of the electrical facilities associated with CHP-5. Base cost estimates have been developed according to the technical requirements to be met in fully utilizing the capacity of CHP-5. The total base cost is estimated at US $133.92 million (refer to Table I-3 below).

2. NPTG sub-projects are as follows:

Table I-1: NPTG sub-Projects

No. Description of SubProject

1 220 kV dbl-cct OHL CHP5 to Songino (90 km)

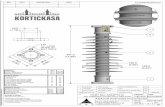

2 220kV switchyard at CHP5 (GIS equipment)

3. UBEDN sub-projects are as follows:

Table I-2: UBEDN sub-Projects

No. Description of sub-Project

1 DNIMS (management information system for distribution network)

2

Training to improve skills of UBEDN engineers and specialists for

selection of state of art technologies and selection of advanced technology equipment

to prepare and compile norms and standards for new equipment

3 Refurbishment Programme

3.1 Refurbishment and expansion of 35kV substation and 35 kV OHL at Gachuurt

3.2 Refurbishment and expansion of capacity 35kV Overhead lines to “Erdene” 35kV OHL

3.3 Refurbishment and new 10kV switching stations

3.4 Refurbishment of 10 kV indoor substations (switchgear replacement only)

4 Amorphous Transformers (Replacement of existing aged indoor distribution transformers)

Table I-3: Summary of Base Costs

Unit: US$ million

220 kV Transmission

Line

220 kV Switchyard

Distribution Network

DNIMS Training AMT Total

1 Material Cost 11.83 13.01 14.12 5.00 0.40 8.88 98.32

2 Construction Cost 3.35 4.35 - - - - 27.03

Sub-Total 15.18 17.36 14.12 5.00 0.40 8.88 125.35

3 Engineering Supervision Cost

0.17 0.07 0.30 - - 0.40 1.24

4 Design cost 0.31 0.14 0.55 - - - 1.42

5 Other Cost 0.58 0.28 0.37 0.11 0.01 - 2.69

6 Safeguards Cost 0.07 0.08 0.03 - - - 0.50

7 Implementation Consultant

0.30 0.35 0.10 0.15 0.10 0.72 2.72

Estimated Base

Cost 16.61 18.28 15.47 5.26 0.51 10.00 133.92

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

2

II. ELECTRICITY TRANSMISSION (NPTG)

A. Sub-Project 1a - 220 kV Transmission Line

1. Description

4. A 220kV double circuit transmission line is required to evacuate power from CHP5. The line will have a route length of approximately 90 km passing to the south of Bogdkhan National Park via Zuunmod to Songino. In addition, a short section of transmission line will interconnect CHP5 to Ulaanbaatar 220 kV substation to form a 220 kV ring around Ulaanbaatar city. The line will utilize AC400/51 ASCR conductor with capacity of 270 MVA1. The line will be constructed with 357 off steel lattice towers selected according to Mongolian transmission tower design standards. Tower footing design will be based on turning angle loads and ground soil conditions. The line will be fitted with earth wires for lightning stroke protection and Optical Ground Wires (OPGW) for communication purpose.

Figure II-1: 220 kV Transmission Line Alignment (blue)

5. The transmission line alignment has been evaluated from the standpoint of civil engineering design. A review was undertaken focusing on preliminary geological and topographical survey data, meteorological data, proposed tower structure designs and tower foundation designs, as well as cost estimates. Site visits were undertaken, discussions and interviews with local engineers, review of relevant technical documents and designs, evaluation of national and international good practices and technical requirements in terms of designs of tower structures and tower foundations, as well as applicable national design codes and standards. 6. The main findings of the review are as follows 1) transmission lines have been constructed in Mongolia since 1981, 2) the applicable standard designs for tower structures and foundations are available for use by local engineers during the engineering designs of the power transmission line, 3) relevant international good practices and technical standards based on Russian Federation and PR China standards are well established and accepted in

1 Long-term current allowed is 835A at temperature of 90oC (air temperature 40oC. wind speed 0.6m/s)

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

3

Mongolia, 4) local engineers have gained good experience both in engineering design and construction of the 220kV transmission line. 7. In recent years, most of the steel towers installed in Mongolia have been imported from PR China. These towers were delivered as pre-fabricated parts and assembled and installed on site. Local engineers were invited to visit the manufacturers in PR China for quality tests before delivery. 8. Tower foundation designs are based on standard designs applicable in Mongolia. A detailed geological survey is undertaken by an external geological survey institute before detailed engineering design is conducted. The preliminary site visits conducted during the TA indicated that there are no unusual geological and topographical conditions along the route of the proposed 220kV transmission line. 9. In summary there are no concerns regarding the design and construction of a 220 kV double-circuit steel tower transmission line in Mongolia. A summary of detailed geological and technical observations is provided by way of reference as Appendix D to this report.

2. Cost Estimate

10. The cost estimates were made based on the feasibility study as follows:

Figure II-2: 220 kV Transmission Line Cost Estimate Breakdown by %

11. A detailed cost estimate (Bill of Quantities) is provided as Appendix A to this report. The BoQ estimate has been prepared in accordance with Mongolian cost estimating standard.

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

4

Table II-1: 220 kV Transmission Tower Type & Quantity

No Description Type of tower

Quantity /pcs/

Average area per

tower, sq.m

Total area, sq.m

1 Steel tower /Suspension/ P220-2t 200 70 14000

2 Steel tower /Suspension/ PS220-6t 25 70 1750

3 Extended steel tower /Suspension/ P220-2t+5 44 80 3520

4 Steel towers /Tension/ U220-2 3 85 255

5 Extended steel tower /Tension/ U220-2+5 25 115 2875

6 Extended steel tower /Tension/ U220-2+9 47 144 6768

7 Extended steel tower /Tension/ U220-2+14 13 180 2340

Grand total /pcs/ 357 31508

B. Sub-Project 1b – 220 kV GIS Switchyard

12. A compact 220 kV GIS switchyard is required to evacuate power from CHP5. GIS switchgear rated at 245kV will be housed in a building of dimension 130m x 66m. The building will occupy a designated switchyard area located directly adjacent to the CHP5 power plant. The GIS switchgear design configuration will comprise a double busbar with 8 feeder bays, two bus sections, two bus couplers and four transformer bays (the CHP5 generator transformers will be located within the CHP5 power plant)2. The switchyard will be equipped with SCADA monitoring equipment. Various accessories will be required to support the operation of GIS switchgear.

Figure II-3: CHP#5 Planned Area View

2 This configuration is the same as that proposed by the CHP5 Consortium

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

5

Figure II-4: CHP#5 Layout

Figure II-5: 220 kV GIS Area (130 m x 66 m)

Area for GIS

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

6

Figure II-6: 220 kV GIS Building Layout

13. Referring to the site layout figures above, the 220kV GIS switchyard requires only small footprint and this compact size of GIS can solve the land restriction or limitation issue. Also, as GIS is enclosed by grounded metal case and all GIS will be sitting in a substation building, the environment resistivity is high. When comparing with 220kV AIS switchyard which requires much higher area and always located outdoor area to provide better ventilation, the 220kV GIS can be operated more efficiently under worst environment condition e.g. minimum -50 °C in Mongolia.

1. Gas Insulation Switchgear (GIS) and Air Insulated Switchgear (AIS)

14. A substation is a part of the power system that built as a link between generation plants and transmission/distribution systems. Switchgear is a major component to provide load switching or fault breaking facility in the substation. For studying the options of the switchgear to be used at 220kV switchyard connected with CHP5, conventional Air Insulated Switchgear (AIS) and Gas Insulated Switchgear (GIS) are considered. An example of GIS and AIS footprints comparison and detail comparison study between the two switchgear types and details GIS and AIS comparison study are as follows:

Figure II-7: Example of GIS and AIS footprints comparison

15. GIS can near the generation and load center due to the electrical safety design and compact size. The connection between the generation plant and the GIS substation can be by underground cable that can be made as short as possible. However, for AIS, due to the requirement electric clearance and larger electrical components e.g. breaker, isolator, the AIS substation shall put a longer distance with the generation plant and normally connected

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

7

by overhead line. Hence, the transmission loss between the generation plant and GIS substation when compared with that and AIS substation is much lower. In turn, the electrical transmission efficiency from the plant to GIS substation will be much higher.

16. Operation of GIS is a safer way when comparing with that of AIS because the GIS panels are grounded at the metal enclosure. Also, the electric arc generated during close or open switching of the mechanism is much smaller due to the insulation strength by the SF6. The GIS is normally housed in the substation building and all operation can be carried out even though in adverse temperature or environment condition. The air insulation level, however, will be affected by humidity, environment issues e.g. rain, storm and pollutants. The operation period will also be restricted in the winter or other adverse condition.

17. GIS has advantage of maintenance free in the operation mechanism while AIS requires periodic mechanism check-up and maintenance. In general, for the operating check-up, GIS is also much shorter than AIS because of the proven reliable gas insulation and grounded metal enclosure. The gas insulation pressure level is continuously being monitored by the associated pressure gauge that the condition status will be sent to the centre SCADA system for record and monitoring. The total enclosed GIS switching mechanism can be resisted insulation deterioration against the environment and result maintenance free and operating check-up as minimum.

18. The substation capital initial cost including equipment procurement and associated civil and electrical system interface components such as cable cost. The equipment cost of GIS is higher than that of AIS, however, GIS has lower civil construction cost because of smaller area occupation of GIS and less footprint concrete loading requirement for GIS equipment. Also, for the interface components such as cable, GIS only require shorter cable for connection to the generation plant and hence, less cost will be involved for this part by using GIS.

19. The overall capital cost of GIS substation will then be approaching that of AIS substation. Meanwhile, the substation operational cost is also a major concern for long term consideration. The GIS maintenance free on switching mechanism and less operating check-up quantity is costing lower operational cost then AIS type. The higher reliability with low fault rate will also minimize the GIS operational cost in long term condition. The fault rate is subject to grid reliability including overall network fault rate and maximum fault level and also environmental factors.

20. After considered the safety, technical, environment, financial and economical factors between the GIS and AIS, GIS is suggested to be adopted to provide a high reliability and efficiency switching and protection way in connection with the new CHP5 and the new/existing power lines. Following table is summarized the comparison between GIS and AIS:

Table II-2: Comparison between GIS and AIS

GIS AIS

Size 10% of AIS 10 times of GIS

Dielectric clearance Superior Normal

Modular assembly Yes No

Maintenance Free Periodic

Fault related outage Lower Higher

Gas monitoring Yes No

Environment resistivity Higher Lower

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

8

21. GIS substation has advantage of compact size which only 1of 10 times when comparing with AIS substation. The major components of GIS are shown in following figure.

Figure II-8: GIS structure and components

22. Each compartment of the GIS is filled with SF6 gas that provides as insulation and results superior dielectric clearance and compact switchgear size. The high reliability of GIS will minimize fault outage time and support maintenance free. However, as the filled SF6 gas pressure to maintain the electrical insulation; the pressure is continuously monitored by gauges and the signal will not only be read on site, but also sent out to SCADA system for record and remote supervision.

2. Busbar configuration and design

23. For designing the switchyard, another critical issue is selection of busbar configuration. Different types of busbar configuration including single busbar, double busbar with or without transfer busbar and one and a half busbar are being discussed as below:

i) Single Busbar

24. It is a most simple design with less capital cost. However, any busbar fault or maintenance will cause total substation switching out. Also, any line or transformer circuit breaker outage will require shut-down of associated line or transformer load. This type of configuration is used for distribution substations up to 35kV but not suitable for transmission substation with higher voltage level and capacity demand such as the new 220kV switchyard applicable.

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

9

Figure II-9:Single Busbar arrangement

ii) Double Busbar

25. This type of busbar configuration is a high flexibility one that half the feeder circuits are being connected to each busbar. Bus-coupler is required for the normal operation and any feeder circuit can be transfer to any busbar. The disadvantage of this type is that outage on the circuit breaker of the feeders will require shut-down of the whole feeder and failure of protection scheme may cause loss of substation supply.

Figure II-10: Double Busbar arrangement

iii) Double busbar with transfer bar configuration

26. This type is combination of double busbar arrangement and transfer busbar. The advantage is that any maintenance or fault at the main busbar, the associated feeder circuits can be switched to the transfer busbar. Also, for circuit breaker maintenance of any circuit,

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

10

the supplying loads can also be switched to the transfer busbar without any power supply interruption. However, this configuration requires additional spacing and cost for the transfer busbar.

Figure II-11: Double Busbar with transfer bar arrangement

iv) One and a half busbar configuration

27. The one and a half configuration has three circuit breakers for two feeder circuits. Normally both feeders are line circuits or one is line circuit and another is transformer or bus reactor. This type of configuration has advantage that when any circuit breaker is under maintenance, the associated feeder circuit load can be transferred to other bus or keeps unchanged without power interruption. Also, during any busbar maintenance or fault, all related feeder circuits can still be in service by switching to adjacent busbar via the tier circuit breaker. The one and a half arrangement provides most flexible operation for breaker maintenance but has highest cost.

Figure II-12: One and a half Busbar arrangement

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

11

v) Conventional and new busbar configuration at new 220kV Switchyard

28. After the studied on the different busbar configuration options, the single busbar with the highest inflexibility and one and a half with highest cost have been excluded. The conventional busbar configuration in Mongolia is an AIS double busbar with transfer bar design. The configuration has an advantage of busbar and loads transfer but more space is required for housing the transfer busbar.

29. To foster the space saving at new 220kV Switchyard to be connected with new CHP5 generation plant, 220kV GIS Double busbar without transfer busbar is considered. The unavailability rate of adoption Double busbar without transfer busbar is 3 days per year when comparing that of Double busbar with transfer busbar is 2 days per year. Details of the study can be referred to page 12 of Interim report and with abstract as follows. However, the unavailability days can be supplemented by line feeder circuits’ arrangement. For example, Songino A and Songino B are double feeder circuits. The Songino A and Songino B feeder circuits are designed to connect at separate adjacent busbars with a bus-section in between (Refer to the schematic diagram for details). The configuration can allow switch-off one of the identical double circuits for busbar or circuit breaker maintenance. Also, this will prevent power interruption during any busbar fault case.

3. Non-Availability

30. The cost of the 220 kV switchyard depends on the busbar and circuit breaker configuration; this in turn depends on consideration of ‘non-availability of the configuration. The non-availability of the double busbar, established by international experience, is 3 days per year.

Figure II-13: Double Bus Bar: Non-Availability (300ppm = 3 days per year)

31. A transfer bus can be added to the double bus bar arrangement; this would reduce switchyard non-availability from 3 days to 2 days per year at a cost penalty of $2.5m. At a Cost of Unserved Energy of $200 per MWh, and production of around 2,000 GWh per year, this additional cost is justified on incremental basis.

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

12

Figure II-14: Double Bus Bar with T/Fer Bus: Non-Availability (200ppm = 2 days per year)

4. Cost Estimate

32. The cost estimates were prepared based on recent international costs for a double bus, single feeder bay arrangement (as proposed by the Consortium).

Figure II-15: 220 kV GIS Switchyard Cost Estimate Breakdown

33. A detailed cost estimate (Bill of Quantities) is provided as Appendix B to this report. The BoQ estimate has been prepared in accordance with Mongolian cost estimating standard.

C. Point of connection with CHP5 and existing circuits

34. Refer to the “Concessionaire and Power Purchaser Interconnection Facilities:

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

13

Interconnection Point”. The facilities responsible by the concessionaire at CHP5 generation plant and power purchaser at 220kV are as below:

35. The concessionaire interconnection facilities consist:

3 x 190MVA step-up generator transformers having an output of 220kV;

1 x auxiliary standby transformer having an output of 220kV;

Protection and control system of the Plant;

Auxiliaries services of the Plant;

Lightning and surge protection system of the Plant;

Earthing grid of the Plant; and

Automation and telecommunication system of the Plant.

36. The power purchaser interconnection facilities consist:

The 220kV overhead lines between the existing substations and the GIS;

The new 220kV substation type Gas Insulated Switchgear (GIS) composed among others of three (3) step-up generator transformer bays and one (1) standby transformer bay;

Cabling and Inter-connection of the 3 step-up generator transformers and 1 auxiliary step-up transformer to the 220kV substation;

Protection and control system of the 220kV substation;

Auxiliary services of the 220kV substation;

Lightning and surge protection system of the 220kV substation;

Earthing grid (indoor and outdoor) of the 220kV substation; and2

Automation and telecommunication system of the 220kV substation.

37. A detail schematic interconnection is shown in the diagram as follow:

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

14

Figure II-16: Interconnection of CHP#5, 220kV Switchyard and existing circuits

38. When the new 220kV switchyard is going to connect with the new CHP 5 generation plant, the interconnection responsibility between the concessionaire and the purchaser and shall be clearly stated. The interconnection parts include primary cable and secondary protection, control and telecommunication equipment and associated facilities such as optical fibers. For the primary part, the purchaser is responsible for the 220kV cable laying and termination at the step-up transformer to be provided by concessionaire. Also, the power purchaser is required to connect the substation earth grid to the generation earthing system for assurance of safe environment during power exportation of generation plant.

39. For the secondary part, it is important to ensure stable and reliable protection, control and telecommunication systems. Hence, the related systems’ equipment including protection cubicles at two sides will be designed and provided by the purchaser. But the telecommunication cable will be provided by the purchaser up to the telecommunication cubicle by the concessionaire. The concessionaire shall provide the power synchronization panel for the power exportation and connection to the existing power system. The synchronization instrument will check the voltage, phase and angle generated by the plant with reference to all parameters of the existing power system for systems integration.

40. Besides, it is vital to verify the power stability after connection of new CHP5 generation plant to the existing power system via the new 220kV switchyard. A power load flow and fault analysis study crucially is required to be carried out by the power purchaser to quantify if the power flowing through all connected equipment will be still fulfilled the design rated level and system requirements and all equipment shall be able to handle the maximum current during different types of system fault. In short-circuit analysis study, the short circuit levels at different buses in the system, there should have already analyzed and indicated the maximum fault current flow via different possible paths. The associated circuit breakers should be referred the maximum fault current flow and designed with proper withstand

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

15

capacity.

41. The concessionaire shall provide all CHP5 generation plant equipment system parameters such as generator and step-up transformer exact rating and impedance to the purchaser team for power system study data input and analysis. For carrying out exact System Integration studies comprising steady-state and dynamic simulations, all CHP5 generators, step-up transformers, all related cables and OHLs and loading ends parameters should be furnished. The cables and OHLs parameters are quite typical; however, the parameters of generations and loading ends are critical for resulting accurate studies.

42. Also, if each of CHP5-Singino lines has rated design capacity 1600A at 220kV, maximum 610MVA or 519MW power (with assumed p.f. 0.85) is allowed to be carried via a single Songino line. The Grid Company must arrange loading assuming that CHP-5 (417.1MW) may need to feed through a single Songino line. Then the n-1 criteria can be fulfilled.

43. When UB and Baganuur lines are also considered, the power flow throughout the system is more optimistic because more lines can be provided for CHP5 (417.1MW) power evacuation. The Grid Company must nevertheless arrange loading for CHP-5 to feed in-service lines. If so, then n-1 criteria can also be satisfied under these cases.

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

16

III. ELECTRICITY DISTRIBUTION (UBEDN)

A. Sub-Projects – UBEDN

Sub-Project 1 – Distribution Network Information Management System (DNIMS)

44. This sub-Project is proposed as a management information system designed for management of distribution network assets. The following figure shows the functionality of a fully-developed DNIMS. Initially the Enterprise Service Bus with DNISM functionality (bottom centre) would be established, along with the AMI system.

Figure III-1: UBEDN DNIMS (full functionality)

45. Initially the system will comprise a Geographic Information System (GIS) and a meter data management system. The majority of distribution utilities around the world use a GIS system to maintain a register of distribution network assets, their location and equipment-related information.

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

17

Figure III-2: GIS Screenshot

46. UBEDN collects data from around 2 000 meters at transmission grid boundary points, at large customer premises and at key points within the distribution network. Again it is common for distribution utilities to operate meter data management software. The large volumes of data captured on monthly basis necessitate the use of a software system with secure database.

47. DNIMS is a comprehensive information system that provides an interface platform for operators to analyze the distribution power system, conduct the load flow and fault analysis, carries out construction, operation and maintenance schedule and assess systems performance based on all information acquired from different systems.

48. Due to the rapid growing of Information technology around the world today, corresponding infrastructure and platform are become an important role to improve sustainable and intelligence in electrical power system. The introduction of the new DNIMS in Ulaanbaatar can directly improve network operation efficiency and benefit short- term interruption of electricity to customers. Meanwhile, the new DNIMS with database structure can provide also more accurate and instant information and promptly assessment and reporting.

49. The DNIMS is important to maintain a reliable and sustainable power distribution system from early stage planning to long term system performance monitoring. Meanwhile, all existing and planned systems information such as circuit and transformer parameters, geographic information shall be ready and sufficient for conducting accurate analysis and monitoring. Once all data information is prepared, the other step is concerning interface among different systems that is required to ensure seamless communication for those data transmission.

50. The systems communication comprises hardware and software parts. The hardware part is preferring use of optical fiber that can furnish sufficient bandwidth for data transmission. Single-mode or multi-mode optical fibers can be used subject to the transmission distance and designed data capacity. Single-mode optical fiber is used for both inter-substation and intra-substation backbone cables. The operating wavelengths are 1310 nm and 1550 nm. The communication infrastructure is proposed to have redundancy network that can provide N-1 contingency structure. When there has failure in one network, the whole system will not be affected due to the redundancy back-up.

51. The software part is crucial for the designers to ensure proper communication of different systems with different source codes and protocols. Follows are the typical network topology and data flow of the systems communication. The network topology is showing the hardware connection between two hosts or substations and Firewall should be included to

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

18

serve as Cyber Security protection. For the data flow, there has process bus and station bus for the data transmission. In the process bus, sensing devices together with instruments will be used for acquiring substation information and then transmitted to the system via the station bus.

Figure III-3: Typical Network Topology and Data Flow

Sub-Project 2 – Training in Engineering Standards Development

52. This training / capacity building component covers two main activities:

To build capacity to select new technology suited to the national power sector and the develop the technical requirements for equipment and materials to be included in the specifications for bidding documents and the national standards for electrical equipment

To obtain technical information and design data of electrical equipment, proven in countries with a similar climate to that of Mongolia, and to investigate international standards and select appropriate standards for Mongolian conditions.

53. It is envisaged that the result of this activity would be an Asset Management Design Standards manual covering all distribution network equipment items, e.g. cables, conductor, transformers, poles, insulators, surge arrestors, insulators, etc.

54. The benefits of the standardization are to elevate the competency of the national power sector for future operation and maintenance handling and upgrade existing systems to in-line with international standards for system optimization.

Sub-Project 3 – Distribution Network Fixed Assets

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

19

Sub-Project 3.1 – Gachuurt 35 kV Substation and OHL

55. This sub-Project involves the replacement of the existing Gachuurt 10 MVA 35 / 10 kV substation with a modern equivalent. The existing substation is aged and unreliable. The age of the substation is 31 years and has reached the end of the typical economic life for a 35 kV substation built with Russian equipment. The existing 10 MVA transformer is only two years old. The new substation will comprise 2 off 10 MVA 35 / 10 kV transformers, 8 off 10 kV feeder bays, and SCADA equipment. The existing transformer will become a spare unit used for emergency in the event of a transformer failure.

Figure III-4: Gachuurt 35 kV OHL Route & Substation

Figure III-5: Existing Gachuurt 35 / 10 kV Substation

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

20

Figure III-6: Existing Gachuurt 35 / 10 kV Substation

56. This sub-Project also involves replacement of the existing aged Gachuurt 35 kV OHL of 24.8 km route length, with a double circuit line utilizing 185 mm2 ACSR conductor and concrete poles. The replacement and strengthening of the OHL will improve the reliability of supply to Gachuurt as the new line will replace the existing line which has an age of 31 years and small conductor size of 50 mm2 ACSR.

Figure III-7: Existing Gachuurt 35 kV OHL

Sub-Project 3.2 – Erdene 35kV OHL

57. This sub-Project involves replacement of the existing aged Erdene 35 kV OHL of 40 km route length, with a double circuit line utilizing 120 mm2 ACSR conductor and concrete poles. The replacement will improve the reliability of supply to Erdene as the new line will replace the existing line which has an age of 44 years and small conductor size of 50 mm2 ACSR.

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

21

Figure III-8: Erdene 35 kV OHL Route

Figure III-9: Elstei 35 / 10 kV Substation

Erdene 35kV OHL, 40km

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

22

Figure III-10: Existing Erdene 35 kV OHL

Figure III-11: Erdene 35 kV OHL (before and proposed)

Erdene 35kV OHL Example Concrete pole for 35kV Double circuit OHL

Sub-Project 3.3a – New 10kV Switching Stations

58. A switching station allows an incoming 10 kV feeder to be split into several feeders. Each outgoing feeder has a circuit breaker or isolating switch allowing the distribution network to be re-configured under emergency conditions to restore supply to as many customers as possible while repair work is undertaken. A total of 5 off new switching stations are required to improve the reliability of the network in growth areas. The switching stations require the installation of incoming 10 kV cables to connect the new stations to the existing network. The following map shows the location of the new switching stations and the route of the feeder cables.

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

23

Figure III-12: New Switching Stations

Sub-Project 3.3b – Refurbishment of 10kV Switching Stations

59. A total of 4 off 10 kV switching stations will be refurbished with modern equivalent equipment. The refurbishment will involve replacement of the circuit breakers and isolating switches reducing the potential for loss of the station due to aged equipment failure. The average age of the switching stations to be refurbished is 27 years, with the oldest being 38 years of age.

Figure III-13: Switching Stations for Refurbishment

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

24

Figure III-14: Existing Aged Switching Station No. 21

Figure III-15: New 10 kV Switching Station

Sub-Project 3.4 – Refurbishment of 10kV Indoor Substations

60. A total of 86 off 10kV substations will be refurbished. The average age of these substations is 35 years with a standard deviation of 12 years. The refurbishment programme will involve replacement of the indoor switchboards with modern vacuum breaker equipment. In addition, the building structures will be renovated.

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

25

Figure III-16: Existing Aged 10 / 0.4 kV Indoor Transformer Substation

Sub-Project 4 – Amorphous Transformer Replacement Programme

61. A total of 760 distribution transformers will be replaced with amorphous ‘low loss’ transformers. All such transformers are housed in indoor substations. The breakdown of transformers to be replaced, by voltage and capacity, is given by the following table:-

Table III-1: AMT Transformer Counts

Types of Transformer No. of Transformers

10kV 6kV

400 kVA Transformers 50 30

630 kVA Transformers 350 120

800 kVA Transformers 100 70

1000 kVA Transformers 20 20

Total 520 240

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

26

Figure III-17: Existing Aged 10 / 0.4 kV Indoor Transformer Substation

Figure III-18: Areas with Distribution Transformers for AMT Replacement

62. An economic life for a distribution transformer in Mongolia is taken to be 40 years. An age profile was developed for UBEDN’s distribution transformers based on statistics provided by UBEDN.

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

27

Figure III-19: UBEDN Distribution Transformer Age Profile

Source: Consultant

63. A replacement cost estimate was developed based on age and condition. Under the replacement scenario, Figure III-20 shows that the weighted average remaining life of UBEDN’s distribution transformers is currently around 30%. According to utility norms for a developing country this index should fall between 50 and 70%. The estimated replacement expenditure under a BaU scenario is of the order of $17m for a total replacement of around 465 transformers. It is apparent that a programme of replacement of 760 existing transformers is justified according to economic life considerations, and will restore the average weighted age to around 60%.

Figure III-20: DT Replacement Cost Profile (Age-Based)

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

28

64. The replacement cost profile has also been forecast for 2020 to ascertain the needed expenditure for distribution transformers in 2020 and beyond. The forecast for the average CAPEX required is $ 530 000 per annum. This expenditure will be required mainly to replace aged pole-mounted distribution transformers.

Figure III-21: DT Replacement Cost Profile (Age-Based)

Source: Consultant

65. OECC has determined by market discovery that AMTs can be obtained at a cost around 30% more than the cost of conventional transformers; however there is a wide variation in costs. Therefore, as a conservative estimate, the incremental cost has been taken to be +35% of the conventional transformer cost. The incremental benefits are the reduction in no-load losses and the improvement in reliability due to avoidance of aging related failure.

1. No-Load Loss Reduction

66. The no-load loss saving of conventional silicon steel-cored transformers that installed in Mongolian distribution when replaced by amorphous core production transformers can be found in Table III-2 below.

67. The proposed replacement by using amorphous core production transformer ranged from 400kVA to 1000kVA power transformers can gain 64 to 74% energy savings.

Table III-2: Steel-cored and Amorphous transformer losses and efficiency comparison

400kVA 630kVA 800kVA 1000kVA Total

Number of Transformer 80 470 170 40 760

Steel-cored Transformer Losses 751 1118 980 800 3649

Amorphous Transformer Loss 180 300 350 288 1118

Savings 571 818 630 512 2531

Total Savings kW 45.7 384.5 107.1 20.5 557.7

Source: Consultant

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

29

68. The reduction in no-load losses relative to conventional distribution transformers was computed, taking into account research into the no-load loss performance of Russian transformers, conducted in 2012 by two Russian universities3 . UBEDN’s program for replacement of transformers will span three years from late 2016 to late 2018. It is assumed that benefits start to flow in 2017 on pro-rata basis, with a terminal value set at 5 years. The reduction in losses for the 760 transformers to undergo replacement is estimated as follows:

Table III-3: Estimated No-Load Loss Reduction (MWh)

Year Annual MWh Saving

2016

2017 3,644

2018 11,566

2019 20,633

2020 24,515

2021 29,126

2. Un-Served Energy Reduction (Aging-Failure)

69. The reduction in energy lost due to transformer failure has been estimated based on aging failure analysis. The age of the transformers has been based on the age profile shown above as Figure III-19. The mean time to replace a failed transformer has been assumed to be 8 hours. Average loading was assumed to be 80% on nameplate rating based on UBEDN statistics (refer Phase 1 report). Average load growth was taken as 11.4% based on UBEDN statistics for electricity sales in the Ulaanbaatar area. A terminal value for total un-served energy loss incurred due to aging failure has been set conservatively at 5 years. The reduction in un-served MW, for the 760 transformers identified to be replaced, is estimated as follows:

Table III-4: Estimated Un-Served Energy Loss Reduction (MW)

Year Annual Incremental MW Saving

2016

2017 1.25

2018 0.73

2019 0.37

2020 0.44

2021 0.53

B. Cost Estimate

70. A detailed cost estimate has been prepared for the UBEDN network asset investments. A pie chart showing the cost breakdown follows:

3 Methods to Determine Loss Effect of Idle Run of Transformers of Different Durability – Ivanovo State Power Engineering

University, Ivanovo, Russia & St. Petersburg State Polytechnic University, St. Petersburg, Russia – 2012

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

30

Figure III-22: Distribution Cost Estimate Breakdown

71. A full cost estimate by sub-Project is provided as Appendix D to this report.

C. Amorphous Transformers

72. Financial and economic valuations for the Amorphous Transformers Replacement sub-Project are based on the incremental costs borne and benefits delivered by the replacement of existing aged distribution transformers with amorphous transformers in comparison to a “Business-as-Usual” (BaU) scenario that would see the transformers replaced with conventional iron-core transformers. The BaU scenario assumes that in order to maintain its operations, UBEDN would have to replace old depleted transformers with new conventional Russian transformers.

73. It is proposed that seven hundred and sixty (760) distribution transformers will be replaced with AMTs replaced under a US 10 M JFJCM grant. It is estimated that purchase cost of the AMTs will form 85% of total CAPEX, while the other 15% will be related to installation costs. It is assumed that the equipment will be financed through foreign sources, and installation costs will be covered by local contribution of UBEDN.

74. When considering the other UBEDN sub-projects and the company’s resource constraints, the implementation of the AMT sub-project is expected to take four years. Therefore, for the purpose of financial and economic evaluation, financing of the project is carried out in equal annual shares during four years starting from 2016.

75. Obligatory taxes and duties, and corporate taxes are handled as incremental costs associated with the adoption of Amorphous Transformers when compared to the BaU scenario. Annual OPEX costs (typically assumed to be 2% of the total CAPEX cost) are not included because such cost will be incurred irrespective of whether the distribution transformers are replaced by AMTs or with conventional transformers.

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

31

APPENDIX A – Cost Estimate for 220 kV Double Circuit OHL Transmission Line (~90 km)

№ Description List of

materials UOM Quantity

Unit Price, USD

Total Price, USD

International Transportati

on, USD

Custom Tax, USD

VAT, USD

Local Transportation,

USD

Installation and erection cost, USD Grand total,

USD Equipment Labour Other cost

VAT

1 Conductor ACSR-400/51

ton 892 3,200 2,854,400 66,500 146,045 292,090 146,200 348,900 284,800 60,500 69,420 4,268,855

2 Grounding wire C70 ton 38 1,600 61,552 1,500 3,153 6,305 3,400 11,200 9,200 1,950 2,235 100,495

3 OPGW OPGW DAB 1x48

km 96 3,600 347,094 8,600 17,785 35,569 19,000 65,400 53,500 11,400 13,030 571,378

4 Steel tower /Suspension/

P220-2t ton 1,314 1,500 1,971,000 50,000 101,050 202,100 108,600 372,000 304,600 64,800 74,140 3,248,290

5 Steel tower /Suspension/

P220-6t ton 222 1,500 333,000 8,300 17,065 34,130 18,200 62,900 51,500 10,950 12,535 548,580

6 Extended Steel tower /Tension/

P220-2t+5 ton 355 1,500 531,960 13,300 27,263 54,526 29,500 100,500 82,200 17,500 20,020 876,769

7 Extended steel tower /Tension/

U220-2+5 ton 454 1,850 839,160 21,000 43,008 86,016 46,000 158,000 130,000 27,500 31,550 1,382,234

8 Extended steel tower /Tension/

U220-2+9 ton 677 1,850 1,251,525 32,000 64,176 128,353 68,000 235,500 192,500 40,880 46,888 2,059,822

9 Extended steel tower /Tension/

U220-2+14 ton 232 1,850 428,904 10,600 21,975 43,950 23,500 80,800 66,000 14,100 16,090 705,920

10 Foundation for suspension steel towers

F3-2 pcs 800 560 448,000 12,000 23,000 46,000 24,500 84,500 68,900 14,800 16,820 738,520

11 Foundation for suspension steel towers

F4-2 pcs 100 550 55,000 1,400 2,820 5,640 3,000 10,400 8,500 1,800 2,070 90,630

12 Foundation for tension steel towers

F5-2 pcs 176 1,650 290,400 7,400 14,890 29,780 16,000 55,100 45,200 9,600 10,990 479,360

13 Foundation for tension F5-Am pcs 96 1,950 187,200 4,600 9,590 19,180 12,000 34,900 28,600 6,200 6,970 309,240

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

32

№ Description List of

materials UOM Quantity

Unit Price, USD

Total Price, USD

International Transportati

on, USD

Custom Tax, USD

VAT, USD

Local Transportation,

USD

Installation and erection cost, USD Grand total,

USD Equipment Labour Other cost

VAT

steel towers

14 Foundation for tension steel towers

F6-Am pcs 132 2,100 277,200 7,000 14,210 28,420 14,800 50,900 41,800 8,900 10,160.00 453,390

15 Foundation for tension steel towers

FS1-A5 pcs 36 3,200 115,200 2,800 5,900 11,800 6,200 22,300 17,500 3,800 4,360.00 189,860

16 Insulators for Suspension Strings

UB70/127 pcs 31,636 10 316,360 7,200 16,178 32,356 15,800 54,800 44,800 9,600 10,920.00 508,014

17 Insulators for Tension Strings

UB160/146 pcs 14,692 15 226,404 5,800 11,610 23,220 12,500 43,100 35,400 7,500 8,600.00 374,134

18 Line fittings for suspension strings

set 1,695 95 161,025 4,000 8,251 16,503 8,600 29,800 24,400 5,200 5,940.00 263,719

19 Line fittings for tension strings

set 832 95 79,040 2,000 4,052 8,104 4,300 14,600 11,900 2,600 2,910.00 129,506

20 Earthing wires for for steel towers

F12 ton 30 810 24,300 800 1,255 2,510 1,400 4,600 3,800 800 920.00 40,385

10,798,724 266,800 553,276 1,106,552 581,500 1,840,200 1,505,100 320,380 366,568 17,339,100

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

33

APPENDIX B – Cost Estimate for 220 kV GIS Switchyard

Material USD

245 kV GIS Equipment 8,640,000

Substation Automation System 720,000

Protection, Control and Communication 883,000

Other 363,785

Mandatory Spares 592,800

Sub-Total 11,199,585

Transport

Transport - International 279,990

Transport - Local 663,497

Sub-Total 943,487

Civils

Building 500,000

Foundation 264,000

Earthing Grid 100,000

Sub-Total 864,000

Erection & Commissioning 5,251,666

Sub-Total 5,251,666

GRAND TOTAL 18,258,738

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

34

APPENDIX C – Cost Estimate for UBEDN Distribution Network Assets

No Scope description UoM Quantity Estimated cost

Unit Total, MNT Total, USD

1 35/10kV "Gachuurt" Substation set 1 2,861,706,653.12 2,861,706,653.12 1,432,285.61

Subtotal for 35kV Substation

2,861,706,653.12 1,432,285.61

2 35kV "Gachuurt" OHL set 1 4,316,670,427.79 4,316,670,427.79 2,160,495.71

3 35kV "Erdene" OHL set 1 6,232,541,344.40 6,232,541,344.40 3,119,390.06

Subtotal for 35kV OHL's

10,549,211,772.19 5,279,885.77

4 New switching Station behind of CTS-673 set 1 1,022,846,009.85 1,022,846,009.85 511,934.94

5 New switching Station behind of CTS-593 set 1 996,203,922.81 996,203,922.81 498,600.56

6 New switching Station behind of CTS-348 set 1 890,847,671.91 890,847,671.91 445,869.71

7 Renovation of Switching Station No.11 set 1 601,875,433.37 601,875,433.37 301,238.96

8 Renovation of Switching Station No.16 set 1 601,875,433.37 601,875,433.37 301,238.96

9 Renovation of Switching Station No.25 set 1 601,875,433.37 601,875,433.37 301,238.96

10 Renovation of Switching Station No.21 set 1 601,875,433.37 601,875,433.37 301,238.96

11 New Switching Station with Transformer, dismantling CTS-319 set 1 1,016,087,062.33 1,016,087,062.33 508,552.08

12 New switching Station for area Chemical liquid feeder set 1 954,636,638.95 954,636,638.95 477,796.12

Subtotal for 10kV Switching Stations

7,288,123,039.34 3,647,709.23

19 Indoor transformer substation rehabilitation (type-1) set 30 79,188,047.54 2,375,641,426.26 1,189,009.72

20 Indoor transformer substation rehabilitation (type-2) set 6 180,271,266.23 1,081,627,597.39 541,355.15

21 Indoor transformer substation rehabilitation (type-3) set 21 96,798,311.49 2,032,764,541.33 1,017,399.67

22 Indoor transformer substation rehabilitation (type-4) set 3 110,294,185.21 330,882,555.63 165,606.88

23 Indoor transformer substation rehabilitation (type-5) set 13 64,898,331.13 843,678,304.69 422,261.41

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

35

No Scope description UoM Quantity Estimated cost

Unit Total, MNT Total, USD

24 Indoor transformer substation rehabilitation (type-6) set 5 165,981,549.82 829,907,749.10 415,369.24

25 Indoor transformer substation rehabilitation (type-7) set 4 99,747,625.39 398,990,501.56 199,694.95

26 Indoor transformer substation rehabilitation (type-8) set 4 99,747,625.39 398,990,501.56 199,694.95

Subtotal for 10/0.4kV Substations

8,292,483,177.52 4,150,391.98

Total for UBEDN

28,991,524,642.16 14,510,272.59

Engineering and design cost 5%

1,449,576,232.11 725,513.63

Government supervision cost 2%

579,830,492.84 290,205.45

Fee for standardization fund 0.18%

52,184,744.36 26,118.49

VAT 10%

3,044,110,087.43 1,523,578.62

Contingency 4%

1,217,644,034.97 609,431.45

GRAND TOTAL

35,334,870,233.86 17,685,120.24

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

36

APPENDIX D – Observations Concerning 220 kV Transmission Line Design

Geological Conditions The 220kV transmission line is to be constructed in areas with the following categories of geological conditions:

Alluvial-proluvial formation (ap Q3-4) has accumulated as field and high prevalence of deep in the Tuul River Valley. Major sediments contain poorly graded shingle, pebble with sand and sandy and mishil layers of various grains sand, sandy and clayey. Alluvial-proluvial sediments vary between 30-50 meters. This formation is unique and contains groundwater;

Deluvium-proluvium formation with different thickness (dp Q3-4) was accumulated in bottom and side of Ukhaa Tolgod mountain. Poorly graded pebble and gravel with clayey and sand mostly overspreads and contains mishil layers of sand, sandy and clayey; and

Sedimentary rock (Pz) is Paleozoic age. Thickness of Sandstone and Schist formed Mountain and hills in the proposed research area. Moreover these rocks have structures with strength to northeast.

Geo-morphological Typological Conditions

The 220kV transmission line is to be constructed in areas with the following geo-morphological typological conditions, including (i) Mountain-side typology; (ii) Lower mountain elevations and hillock typology; and (iii) River valley typology. Specifically:

Mountain-side Typology The mountain-side typology continues from the beginning of the 220kV transmission line to Tuul River Valley II-hilltop along Songinokhairkhan Mountain-side. The altitude ranges from 1330 m to 1190.4 m. Branch Mountains of Songinokhairkhan have many trenches toward the northwest direction. The surface water from the mountains feed the trenches, creating the stream. The middle part of the proposed transmission line begins uplifted 1,485 m mountain’s west slope located in Jargalant valley’s Northwest to 1,355 m mountain located in Yarmag bridge’s northeast. The slope of the middle part of the proposed transmission line is divided relatively low by trench.

Low Elevations of Mountains, Hillock Typology About 50% of the proposed transmission line area is within the region under this typological condition. Moreover, uplifted from 1,300 m to 1,485 m mountains and hills consisting of river sandstones are under these typological conditions. Usually Mountains have arête and steep slopes but hillock creates side with dome and gradual slope.

River Valley Typology About 3.5 km of the total proposed transmission line is within this typological condition. It is crossing over the Tuul River. However, in the northern part of the river valley there have been human activities, the natural view has been lost. The landscape of the river valley is from 1,184 m to 1,200.6 m. This typology is unique and contains groundwater.

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

37

Hydro-geological Conditions Groundwater is connected hydraulically to the Tuul River with feeders. Water source comes from storm water during rainy seasons, as a result that groundwater level raises by 1.0-1.5 m. Groundwater is found at the depth of 1.0 m and is standing at the depth of 0.8 m in borehole/sh-10, sh-11/ of drilled at the proposed transmission line area. Groundwater has hydro-carbonate-sodium-kalium component and belongs to ordinary water type. Groundwater is polluted by natrium and nitrite. The groundwater yield is 5.0-7.0 L/s and permeability ratio is 120-150m/d. Meteorological Data The climatic data is collected at the Buyant-Uhaa and Morin-Uul stations and are shown in Tables 1 to 11.

Table 1 Monthly and annual average ambient air temperatures °С

Station Month

Year I II III IV V VI VII VIII IX X XI XII

Buyant-Ukhaa

-25.7 -21.1 -10.2 0.8 8.7 15.0 17.2 15.0 7.6 -1.5 -14.1 -23.4 -2.6

Morin-Uul -18.3 -15.1 -8.7 0.5 8.2 13.2 15.5 14.0 8.0 0.7 -10.2 -16.0 -1.3

Table 2 Absolute maximum ambient air temperatures, °С

Station Absolute maximum Date Absolute maximum

temperature per month

Buyant-Ukhaa 39.4 2005.VII.15 31.4

Morin-Uul 32.8 1980.VI.24 30.2

Table 3 Absolute minimum ambient air temperatures, °С

Station Absolute minimum Date Absolute maximum

temperature per month

Buyant-Ukhaa -49.0 1954.XII.30 -39.9

Morin-Uul -39.2 1980.I.29 -30.8

Table 4 Design temperatures for constructions and technologies, °С

Station

Design ambient air temperatures °С

The coldest The warmest temperature

per day

Average /climate zone

for construction/

1 day

3 days

5 days

Air ventilation

Buyant-Ukhaa -36.7 -35.3 -34.2 -29.9 25.8 II

Morin-Uul -28.3 -27.3 -26.2 -18.1 22.7 II

Note: This area is located in Region II where snow load in Mongolia and snow surface load is 50 kg/m2.

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

38

Table 5 Parameters of design temperature supply for buildings and technique during winter, °С

Station

Temperature supply of 5 coldest days, % Temperature supply of the coldest day, %

99.2 99.5 94 92 99.9 99.5 94 92

Buyant-Ukhaa

-41.8 -41.7 -39.4 -39.0 -43.3 -43.2 -41.5 -40.7

Table 6 Design parameters of heating period

Station

Firing/heating duration

Start day

Finish day

Duration Average temperature of heating time °С

Degree of heating time, °С (t)

Buyant-Ukhaa

15.IX 12.V 239 -11.4 -2,720.1

Morin-Uul 15.IX 15.V 242 -7.6 -1,838.7

Table 7 Monthly and annual average wind speed , m/s

Station Month

I II III IV V VI VII VIII IX X XI XII Winter Year

Buyant-Ukhaa

0.7 1.3 2.5 3.7 3.8 3.4 2.9 2.6 2.5 2.1 1.3 0.7 0.9 2.3

Morin-Uul 2.5 3.0 4.8 6.2 6.0 5.8 4.9 4.0 4.7 4.3 3.4 2.8 2.8 4.4

Table 8 Atmospheric humidity and precipitation amounts

Station

Average monthly, winter and annual speed м/с

Warmest month

Coldest month

Year Warm period

The most per day

Year Month Day

Buyant - Ukhaa

50 72 248.8 236.5 74.9 1967 VI 27

Morin-Uul 55 75 233.1 220.8 38.2 1991 IX 01

Table 9 Thunder and Lightning Region

Region

Thunder and lightning Per thunder Thunder strike

per km2

Day Average

continuous time The longest

continuous time

Minute

II 22-36 /29/ 43-50 /46/ 56-100 83-121 /94/

5-6

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

39

Table 10 Frequency of precipitation (wet snow, Hoarfrost glaciation) and load region

Region

Wet snow Hoarfrost Glaciation

The Number of days

The Continuous

time

The Number of days

The Continuous

time

The Number of days

The Continuous

time

Thick/Load/mm

Year

10 5

III 1-5 2-3 1-5 6-14 1-2 1-3 10 5

Table 11 Maximum design wind speeds of each region, m/s

Region

Altitude, m

Place /10/ 100 200 500

Wind speed occurs once a year

II 21-25 /22/ 31 34 38

Wind speed occurs once every 5 years

I 19 22 29 33

Wind speed occurs once every 10 years

II 21-25 /23/ 32 35 40

Wind speed occurs once every 20 years

II 26-30 /28/ 39 43 43

Tower Structure Design Principles and Requirements Principles for Selection of Type of Towers International good practice indicates that the following technical requirements are to be referenced to ensure quality of the design:

All design principles, structures and materials shall comply with relevant applicable national standards and codes, as well as requirements;

Tower loads under design conditions, as well as various working conditions shall meet the actual construction requirements. When tower loads exceed design loads under certain conditions, tower strengthen shall be verified against actual loads. In addition, associated tower structures exceeding allowable strength shall be replaced;

Tower dimensions including height, spans, etc shall comply with specific electrical requirements;

The height of support for lightning devices shall meet earthing requirements;

Towers shall be designed to minimize the use of steel structures with least cost solutions, in addition steel materials supply shall be taken into consideration; and

Towers shall be designed to ensure reduced land use

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

40

Major Meteorological Factors in Design of Towers Special attention shall be given to three major meteorological factors in design of towers, involving wind, ice, and temperature. Specifically:

Wind - there are two aspects to consider: i) to design for wind loads affecting conductors and towers; ii) to avoid vibration and resonance

Ice - there are three major aspects to consider: i) to design for ice loads to avoid broken conductors and associated steel structures, or even falling down; ii) to add addition weight as a result of larger radian which lowers the distances to ground causing discharging accidents; iii) to burn wires or lighting devices as a result of discharging between wires due to ice thawing not at the same time

Temperature - causes expansion and contraction due to temperature changes. Under lower temperature, conductor life may be reduced to wires might be shortened as a result of increased tension resulting in broken conductor strands. Under higher temperature, conductor sag increases, reducing the clearance to ground

Type of Tower Foundation

Tower foundations must bear the loads of all super-structures, i.e. press, pull-up, and overturn strengths which transfer to earth together with foundation weight, in order to ensure safe and reliable support of the tower. Tower foundations are normally classified into the following categories:

1) Cast-in-place Concrete Tower Foundation

The reinforced concrete and concrete without reinforced bar are determined according to tower loads, and geological and topographical conditions. In addition, concrete with quality grade is to be considered during the design. Concrete without reinforcement normally requires higher volume and necessary measures are to be taken to reduce the volume thus saving concrete, i.e. larger size rock and stone could be added. A typical concrete tower foundation is shown in Figure A1.

Figure A1: Typical Concrete Tower Foundation

2) Assemble-type Tower Foundation

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

41

An assemble-type tower foundation is normally applied in mountainous areas where soil quality is good without groundwater. It is made of galvanized angle steel which is mounted onto a concrete layer poured on top of foundation bottom and compacted with backfill soil. A typical concrete tower foundation is shown in Figure A2.

Figure A2: Typical Assemble-type Tower Foundation

(3) Pile-type Tower foundation

A pile-type tower foundation is normally applied in areas where subsoil contains soft earth, i.e. river rapids, silt zones, etc. It is made of reinforced bored pile with diameter of between 0.6~1.2 m. It includes two parts: pile body and cap. A typical pile type tower foundation is shown in Figure A3.

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

42

Figure A3: Typical Pile-type Tower Foundation

(4) Anchor-type Tower Foundation An anchor-type tower foundation is normally applied in a rocky mountainous area. The foundation is created to make full use of the physical features of rocks, i.e. integrity and hardness. There are various type of anchor-type foundations: straight, cap, embedded, and digging out. A typical anchor-type tower foundation is shown in Figure A4.

Figure A4: Typical Anchor-type Tower Foundation

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

43

Design Alternatives and Optimization

(1) Principles for Selection of Design Alternatives The following design principles apply in the selection of design alternatives are recommended:

To select the type of foundation in full consideration of transmission line alignments, geological and topographical conditions, and transportation limits, etc.;

To choose the least-cost and environmentally friendly alternatives for a safe and reliable foundation design;

To design various type of foundations reflecting different geological and topographical conditions; and

To propose specific foundation designs and measures for treatment for soil under poor conditions

(2) Major Factors for Selection of Design Alternatives The following major factors are to be fully considered for selection the design alternatives:

To design foundation structures to allow for minimized horizontal strength and bending moment;

To place the choice of priority for use of raw soil due to that fact that it has higher hearing capacity, lower level of distortion, etc.;

To pay attention to environment protection, as to minimize spoil earth and protect side slope

Design Requirements

The following design requirements are to be followed for design of the tower foundation:

Cast-in-place concrete strength shall be guaranteed in line with relevant applicable national codes and standards;

Rock-type foundation shall be checked and verified level by level;

Foundation buried depth shall not be smaller than 0.5 m. In areas where frost soil is to form seasonally, the foundation buried depth shall be greater than the standard frost depth due to its frost-expansion features;

Special care shall be taken for foundations in river-crossing or flooding areas. Hydro-geological data shall be collected and protective measures shall be taken to minimize impacts due to flushing or floating objects;

Seismic data shall be collected and evaluated and the seismic protection measures shall be taken in the design, i.e. foundation liquefaction; and

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

44

The deviation corrective measures shall be taken for all turning towers and dead-end towers to ensure all foundations after correction are on the same elevation

Summary of Applicable National Standards and Codes The applicable national construction standards and codes are summarized as follows:

(1) Construction Codes of Mongolia

(1). CCM 20-01-11 Reliability for structures and bases general principles

(2). CCM 20-03-11 Protection of building structures from corrosion

(3). CCM 2.01.07-90 Loads and Reactions

a. Volume 1 Segment album of reinforced concrete post and beam structure

(4). CCM 21-01-02 Fire safety of buildings and facilities

(5). CCM 21-02-02 Norm on fire safety for developing construction design drawings

(6). CCM 22-01-01*/2006/2013 Construction codes on construction planning at seismic zones of Mongolia

(7). CR 22-101-07 Codes on construction planning in seismic zones. Reference to CCM 22.01.01/2006

(8). CCM 23-01-09 Climatic and geophysical parameters for construction

(9). CR 43-101-14 Designing and planning rules of Industrial power supply

(10). CR 43-101-03 Regulation for electrical installations

(11). CR 43-101-03*12 Regulation for electrical installations

(12). CCM 2.02.01-94 Construction code for developing design drawings for footings and foundation of buildings and facilities

(13). CCM 3.02.01-90 Earthwork, footing and foundation work for construction

(14). CCM 2.03.02-90 Masonry and reinforced masonry structures

(15). CCM 51-02-05 Masonry structures

(16). CR 51-101-05 Instruction on design drawings for masonry structure

(17). CCM 52-01-10 Concrete and reinforced concrete structures. Principal rules

(18). CCM 52-02-05 Concrete curing and reinforced concrete structures

(19). CCM 52-03-05 Prefabricated concrete and reinforced concrete structures

(20). CR 52-105-10 Concrete and reinforced concrete structures without reinforced rebar

(21). CR 52-106-12 Concrete monolithic building structures

(22). CCM 53-02-05 Steel structures

(23). CCM 53-03-07 Steel structure (Codes for developing design drawings)

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

45

The applicable Mongolian national construction standards and codes are summarized as follows:

(2) Mongolian National Standards

(1). MNS 1185:1998 Technical specification for fresh concrete

(2). MNS 2630:2001 Structural metal work. General technical requirements

(3). MNS 3996:1987 Technical specification for classification for concrete

(4). MNS 4237:1997 Building and construction steel. General technical requirements

(5). MNS 1500:1982 Electrical network, normal voltage

(6). MNS 5870:2008 Non-insulating wire for high-voltage transmission lines. Technical requirements

(7). MNS 5871:2008 Centrifugal conic reinforced concrete posts for high-voltage transmission lines. Technical requirements

(8). MNS 1548:1972 Rule and diagram of lightning protection for more than 220kw electric equipment and its buildings.

(9). MNS 2325:1976 Fire resistant products. General requirement

(10). MNS 4244:1994 Health Safety and Environmental standard. Fire safety. General Requirement

(11). MNS ISO 3261:2000 Testing methodology for fine protection-Explanation Dictionary

(12). MNS 0346:2000 Testing specification for course aggregate for building structure

(13). MNS 0346:2000 Testing method for course aggregate for building structure

(14). MNS 0392:1998 Technical specification for fine aggregate for building structure

(15). MNS 3091:2008 Technical specification for cement

Type of Tower Structures A double-circuit 220 kV transmission line comprises steel towers and associated structures, including tower foundations, conductors, cables, earthing system, lightning protection devices, isolators, etc. All structures and materials applied in the design and construction of the towers and associated structures must comply with relevant applicable national design codes, standards, and technical specifications as listed above. In addition, relevant quality certificates must be provided upon delivery and on-site test must be conducted before installation. The standard designs for towers and tower foundations have been widely applied for years in Mongolia, following the design codes, standards, and technical specifications applied in Russian Federation and PR of China. The existing 220kV transmission line towers installed in Mongolia comply with the standard designs as mentioned above. The standard designs for towers in Mongolia are shown in Figure A5. The technical specifications for a double-circuit 220 kV transmission line with feeder wires as well as the standard designs applied in PR China are referenced and shown in Table A1 and Figure A6.

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

46

Table A1: Technical Specifications of Steel Towers for a Double-Circuit 220 kV Transmission Line

Item No.

Type Towers

Clear Height (m) Span Sizes (m) Wind Speed (m/s)

Ice Accretio

n (m) Angle

Frame Primary

Clear Height

Horizontal Vertical

1 220К II- 52С1

Suspension Tower

18-33

27 350 450 35 10 0

2 220К II- 52С2

Suspension Tower

18-39

33 410 550 35 10 0

3 220К II- 52СЗ

Suspension Tower

18-42

36 500 650 35 10 0

4 220К II- ЗЛС1

Turning Tower

18-27

27 450 650 35 10 0-20

5 220К II- 5^Ю2

Turning Tower

18-27

27 450 650 35 10 20-40

6 220К II- 5^ЮЗ

Turning Tower

18-27

27 450 650 35 10 40-60

7 220К II- 5.Ю4

Dead End Tower

18-27

27 450 650 35 10 60-90

8 220К II- 50^

18-27

27 250 450 35 10 0-60

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

47

Figure A5: Standard Designs for 220 kV Transmission Line Steel Towers Applied in Mongolia

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

48

Figure A6: Standard Designs for 220 kV Transmission Line Steel Towers Applied in PR China

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

49

Type of Tower Foundations Tower foundation must be designed in full consideration of tower structures, topographical and geological conditions along route of the proposed 220kV transmission line from CHP5 to Songino Substation. The preliminary investigation based on the historical geological data and the site visits suggested that the proposed route area for construction of the 220kV transmission line is generally under normal geological and topographical conditions, and on a relatively flat and hilly ground. There are a number of foundation footings proposed for the proposed 220 kV transmission line, including i.e. straight footing, cast-in-place footing, socket-type footing, as well as pile-type footing. The standard designs of tower foundation have been widely applied for years in Mongolia, based on historical geological and topographical conditions, tower structures, and good practices applied in Russian Federation and PR China. The tower foundation drawings are shown in the following figure:

Figure A7: Tower Foundation Used in Mongolia

Transmission Line Design Normal capacity of the power transmission line strength and stability conditions and sets the imaginary power or power loss during operation can be determined on the basis of technical data. Transmission system capacity and network structure determines the overall capacity of the transmission line and transmission line conductor is one of major components in the transmission system. Transmission line types AC-240/32 mm2, AC-300/39 mm2, AC-400/51 mm2, AC-500/64 mm2 have been compared as follows.

Table 5: Transmission Line Load Capacities

AC transmission,

cross-sectional area, mm2

Number of phase

conductors

Through the current A (air temperature)

Transmission capacity (MW) (air temperature)

-20°

0 35°

-20°

0 35°

220 kV transmission line

240 1 1045 900 638 318 274 194

300 1 1226 1056 750 374 322 228

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

50

AC transmission,

cross-sectional area, mm2

Number of phase

conductors

Through the current A (air temperature)

Transmission capacity (MW) (air temperature)

-20°

0 35°

-20°

0 35°

300 2 1226 1056 750 598 515 365

400 1 1425 1227 872 434 374 266

400 2 1425 1227 872 694 598 425

500 1 1633 1406 997 98 428 303

500 2 1633 1406 997 796 685 485

CHP-5 450 MW of installed power plant available transmission capacity for internal power usage around 13% and hence maximum of approximately 390 MW output. Assuming that the network load can take all the power output, 390 MW can be evacuated from power plants. It is important for choosing transmission lines with proper cross-sectional size maintain reliable power transmission. Refer to the table above, the 220 kV transmission line with a single-phase circuits when a when AC transmission line is chosen can carry 266 to 434 MW. However, when two phase conductors are chosen, 425 to 694MW capacity can be supported. Hence, two phase conductors circuit for this case is advised.

TA-8649 MON: Energy Efficiency and Urban Environment Improvement - Part 2 Final Report

51

APPENDIX E – Observations concerning 220kV Switchyard Design

A. Standard and Codes

The study of 220kV GIS switchyard proposal is based on relevant standards and codes as listed below. In case of any discrepancy or conflict between the national and international standards or codes, the most stringent requirements with consistency shall be adopted.

Table 6:International Standard

Standard Description

IEC 60517 Gas Insulated Metal Enclosed Switchgear for Rated Voltages of 72.5 kV and above – Specification

IEC 60038 IEC standard voltages

IEC 60050 series International Electrotechnical Vocabulary

IEC 60051 series Direct acting indicating analogue electrical measuring instruments and accessories.

IEC 60061 Lamp caps and holders together with gauges for the control of interchangeability and safety

IEC 60068 Environmental testing

IEC 60071 Insulation coordination

IEC 60085 Electrical insulation - Thermal classification

IEC 60099 Surge arresters

IEC 60129 AC disconnectors and earthing switches

IEC 60137 Insulated bushing for alternating voltages above 1000 V

IEC 60143 Series capacitors for power systems

IEC 60168 Tests on indoor and outdoor post insulators of ceramic material or glass for systems with nominal voltages greater than 1000 V