TEC3000 Series On/Off or Floating Fan Coil Thermostats ......connect them to the appropriate screw...

Transcript of TEC3000 Series On/Off or Floating Fan Coil Thermostats ......connect them to the appropriate screw...

TEC3000 Series On/Off or Floating Fan CoilThermostats Quick Start Guide

North American emissionscomplianceUnited StatesThis equipment has been tested and found to comply withthe limits for a Class B digital device, pursuant to Part 15of the FCC Rules. These limits are designed to providereasonable protection against harmful interference ina residential installation. This equipment generates,uses and can radiate radio frequency energy and, if notinstalled and used in accordance with the instructions,may cause harmful interference to radio communications.However, there is no guarantee that interference will notoccur in a particular installation. If this equipment doescause harmful interference to radio or television reception,which can be determined by turning the equipmentoff and on, the user is encouraged to try to correct theinterference by one or more of the following measures:• Reorient or relocate the receiving antenna.• Increase the separation between the equipment and

receiver.• Connect the equipment into an outlet on a circuit

different from that to which the receiver is connected.• Consult the dealer or an experienced radio/TV

technician for help.

CanadaThis Class (B) digital apparatus meets all the requirementsof the Canadian Interference-Causing EquipmentRegulations.Cet appareil numérique de la Classe (B) respecte toutesles exigences du Règlement sur le matériel brouilleur duCanada.

Parts included• One TEC3000 Series Thermostat Controller with integral

mounting base• One installation instructions sheet

Location considerationsFor networked models, locate the TEC3000 SeriesThermostat Controller:• On a partitioning wall, approximately 5 ft (1.5 m) above

the floor in a location of average temperature, to allowfor vertical air circulation to the TEC

• Away from direct sunlight, radiant heat, outside walls,outside doors, air discharge grills, stairwells, and frombehind doors

• Away from steam or water pipes, warm air stacks,unconditioned areas (not heated or cooled), or sourcesof electrical interference

• In a clear path between the integrated passive infrared(PIR) occupancy sensor, if equipped and the space itmonitors

For wireless models, also locate the thermostat controller:• Outside of a recessed area, metal enclosure, or shelving

unit• On the same building level as the other wireless devices

on the same personal area network (PAN)• At least 2 in. (51 mm) away from any metal obstruction• In the direct line of sight to other wireless devices on

the same PAN. Signal transmission is best if the pathbetween the TEC3000 and other wireless devices isdirect as possible. Line of sight is desirable but notrequired. See Table 1 and Table 2 for the recommendedand maximum distances.

• Away from metal and large solid obstructions, thatincludes equipment rooms and elevator shafts andconcrete or brick walls, between the TEC3000 andthe ZFR182x or ZFR183x Router/Repeater or ZFR ProCoordinator Radio

• Within range of two or more wireless devices on thesame PAN. Redundancy in the layout provides the bestreliability in wireless installations

• At least 20 ft (6 m) from a microwave ovenFor integrated PIR models, make sure that the thermostatcontroller is located centrally, where occupant movementis frequent. Ensure that the unit is not blocked by a plastictamper resistant enclosure (such as the GRD10A-608). Theplastic enclosure blocks the occupancy sensing capability.The use of insulating foam pads is necessary forinstallations where wiring passes through the wall to thethermostat.For wireless models, the effective transmission range anddistance for indoor applications vary because of wirelesssignal absorption and reflection due to metal obstructions,walls or floors, and furniture that is found in buildinginteriors.

Note: Allow for sufficient clearance to insert a USBdrive into the USB portImportant: Only connect memory devices to the USBport. Do not use it for charging external devices.

Table 1: Indoor line-of-sight transmission rangesZFR182x

Range type Transmission distanceWNC CoordinatorRouter, ZFR ProRouter/Repeater

TEC3000 WirelessThermostatController

Recommended 50 ft (15.2 m) 50 ft (15.2 m)Line of sight,maximum

250 ft (76.2 m) 100 ft (30 m)

*241135300001F*

Part No. 24-11353-00001 Rev. F

2020-12-15

(barcode for factory use only)TEC3012-1x-xxx, TEC3013-1x-xxx, TEC3312-1x-xxx,TEC3313-1x-xxx, TEC3612-1x-xxx, TEC3613-1x-xxx,

TEC311x-14-xxx

Note: For more details on using ZFR Pro Seriescommunication devices, refer to the WNC1800/ZFR182x Pro Series Wireless Field Bus System TechnicalBulletin (LIT-12012356).

Table 2: Indoor line-of-sight transmission rangesZFR183x

Range type Transmission distanceWRG CoordinatorRouter, ZFR ProRouter/Repeater

TEC3000 WirelessThermostatController

Recommended 250 ft (76.2 m) 250 ft (76.2 m)Line of sight,maximum

1000 ft (308.4 m) 1000 ft (308.4 m)

Note:• Actual range depends on the site and installation

conditions. See Technical Documentation for moreinformation.

• For more details about using ZFR Pro Seriescommunication devices, refer to the WRG1800/ZFR183x Pro Series Wireless Field Bus SystemTechnical Bulletin (LIT-12013553).

Important: ZFR182x Pro Series Wireless Systemcompatible TEC30xx-1x-000 models and ZFR183x ProSeries Wireless System compatible TEC31xx-1x-000models are not compatible with each other andcannot be used under the same PAN ID (networkaddress).

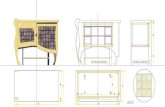

Figure 1: Thermostat controller shown withoutoccupancy sensor, dimensions, in. (mm)

Installing the thermostat controller1. Use a 1/16 in. (1.5 mm) Allen wrench or Johnson

Controls® T-4000-119 Allen-Head Adjustment Tool(order separately) to remove the security screw if itis installed on the top of the thermostat controllercover as illustrated in Figure 2.

2. Pull the top edge of the cover and open thethermostat controller as illustrated in Figure 2.

Important: The cover is not secured on thebottom. Do not drop the cover.Important: If you install more than onethermostat controller, keep track of which coverattaches to which base. The controller versionand the base version must match to ensurecorrect operation.Important: Use correct Electrostatic Discharge(ESD) precautions during installation andservicing to avoid damage to the electroniccircuits of the thermostat controller.

Figure 2: Removing the security screw from the thermostatcontroller cover, shown without occupancy sensor, andremoving the thermostat controller cover

3. Align the thermostat controller mounting base onthe wall with the security screw on the top and usethe base as a template to mark the two mountinghole locations. See Figure 3.

Notes:- If you need to install the thermostat controller

on an electrical junction box, use 2-1/2 x 4 in.(63 x 101 mm) square boxes with mud ringcovers and avoid smaller 1-1/2 x 4 in. (38 x 101mm) square or 3 x 2 in. (76 x 51 mm) boxes.This procedure ensures that you have enoughspace for cabling, if needed.

- For surface-mounted applications, use durablemounting hardware, such as wall anchors, thatcannot be easily pulled out of the mountingsurface.

4. Pull approximately 6 in. (152 mm) of wire from thewall and insert the wire through the center holein the thermostat controller mounting base. SeeFigure 3.

5. Secure the mounting base to the wall surface usingtwo mounting screws (user supplied) as illustratedin Figure 3.

Note: Do not overtighten the mounting screws.

TEC3000 Series On/Off or Floating Fan Coil Thermostats Quick Start Guide2

Figure 3: Mounting hole locations, dimensions, in. (mm)and securing the thermostat controller mounting base tothe wall

Note: When you mount the unit on the wall, youcan hang the front cover on the end of the backcover as illustrated in Figure 4.

Figure 4: Hanging the thermostat controller front cover

WiringAbout this task: When you replace an existingthermostat controller, remove and label the wires toidentify the terminal functions.

WARNING

Risk of Electric ShockDisconnect the power supply before making electricalconnections to avoid electric shock.

AVERTISSEMENT

Risque de décharge électriqueDébrancher l'alimentation avant de réaliser toutraccordement électrique afin d'éviter tout risque dedécharge électrique.

CAUTION

Risk of Property DamageDo not apply power to the system before checkingall wiring connections. Short circuited or improperlyconnected wires may result in permanent damage tothe equipment.

ATTENTION

Risque de dégâts matérielsNe pas mettre le système sous tension avantd'avoir vérifié tous les raccords de câblage. Desfils formant un court-circuit ou connectés de façonincorrecte risquent d'endommager irrémédiablementl'équipement.

Important: Make all wiring connections inaccordance with local, national, and regionalregulations. Do not exceed the electrical ratings ofthe TEC3000 Series Thermostat Controller.Important: Use correct ESD precautions duringinstallation and servicing to avoid damage to theelectronic circuits of the thermostat controller.To wire the thermostat controller, complete thefollowing steps:

1. Strip the ends of each wire 1/4 in. (6 mm) andconnect them to the appropriate screw terminals asindicated in Table 3.

Note: For more details on wiring the MS/TP Communications Bus, refer to the MS/TP Communications Bus Technical Bulletin(LIT-12011034).

2. Attach the communication wires to the terminalblock.

Note: If multiple wires are inserted into theterminals, make sure to correctly twist thewires together before inserting them into theterminal connectors.

3. Carefully push any excess wire back into the wall.

TEC3000 Series On/Off or Floating Fan Coil Thermostats Quick Start Guide 3

Note: Seal the hole in the wall with fireproofmaterial to prevent drafts from affecting theambient temperature readings.

4. For networked models, set the bus end-of-line (EOL)termination switch to the desired location.

You can designate the thermostat controller asthe end of the Field Controller (FC) Bus and N2Bus through the bus EOL termination switch.The default position is OFF. If the thermostatcontroller is at the end of a daisy chain ofdevices on the FC Bus and N2 Bus, set the EOLswitch to the ON position. See Figure 3.

5. Reattach the thermostat controller cover to themounting base, bottom side first.

Important: Make sure you reattach the coverthat corresponds to its correct base. The CPUboard number needs to match the base boardnumber. Otherwise, an operation error occursafter you reattach a cover and base that do notbelong together.

6. Use a 1/16 in. (1.5 mm) Allen wrench or JohnsonControls T-4000-119 Allen-Head Adjustment Tool(order separately) to reinstall the security screwon the top of the thermostat controller cover. SeeFigure 2 for security screw placement.

7. Remove the protective plastic cover sheet from thedisplay.

Important: If the display is dirty, gently wipeit clean with isopropyl alcohol or ethyl alcohol.Do not scrub hard as to avoid damaging thesurface. Do not use other cleaners such aswater, ketones, and aromatic solvents, sincethey may damage the polarizer.Notes:

- For VAV and two-pipe systems, connect thevalve to the heating output.

- Only one transformer is required for each TEC.- Power to the AUX contact comes from the

reheat coil.

Terminal identificationTable 3: Terminal identification (See Wiring diagramsfor details)

FunctionTerminallabel TEC3012,

TEC3013,TEC311xFloating FC/VAV and On/Off FC1

1TEC3312,TEC3313Floating FC/VAV and On/Off FC1

TEC3612,TEC3613Floating FC/VAV and On/Off FC1

24 V 24 VAC hot from transformerFAN H Fan highFAN M Fan mediumFAN L Fan on: single-speed, variable-speed, Fan low:

multi-speedAUX Auxiliary binary outputAUX Auxiliary power input2HC/TRI2 Cool or heat valve output common

COM 24 VAC common from transformerCLG O Cool open (Floating), Cooling NC (On/Off),

TriacCLG C Cool close (Floating), Cooling NO (On/Off),

TriacHTG O Heat open (Floating), Heating NC (On/Off),

TriacHTG C Heat close (Floating), Heating NO (On/Off),

TriacRSEN Configurable analog input 1COS Configurable analog input 2/Changeover

binary switch inputVSF Variable speed fan command, configurable 0

VDC to 10 VDC rangeBI-2 Configurable binary input 2BI-1 Configurable binary input 1NET+ n/a Not connected Field bus+/

N2+NET- n/a Not connected Field bus-/

N2-NET COM n/a Not connected Isolated

common forfield bus

1 There is no support for an On and Off VAV.2 HC/TRI on TB1 must be jumpered to COM on TB2 for low-

side switching or to 24 VAC on TB2 for high-side switching.

TEC3000 Series On/Off or Floating Fan Coil Thermostats Quick Start Guide4

Wiring diagramsSee Table 3 for terminal identification.

Figure 5: Low-side switching on/off wiring diagram

TEC3000 Series On/Off or Floating Fan Coil Thermostats Quick Start Guide 5

Figure 6: High-side switching on/off wiring diagram

TEC3000 Series On/Off or Floating Fan Coil Thermostats Quick Start Guide6

Figure 7: Low-side switched floating wiring diagram

TEC3000 Series On/Off or Floating Fan Coil Thermostats Quick Start Guide 7

Figure 8: High-side switched floating wiring diagram

TEC3000 Series On/Off or Floating Fan Coil Thermostats Quick Start Guide8

Figure 9: Floating control (pressure-dependent VAV)

Figure 10: Floating control (pressure-dependent VAVwith changeover sensor/switch)

Figure 11: Floating control (pressure-dependent VAVwith changeover sensor/switch and reheat)

Figure 12: Floating control two-pipe heating andcooling hydronic valve control fan coil application

Figure 13: Floating control two-pipe heating andcooling hydronic valve control with changeover fancoil application

Figure 14: Floating control (on/off two-pipe and four-pipe fan coil applications)

Figure 15: Floating control (floating two-pipe and four-pipe fan coil applications)

Figure 16: AUX contact wiring

Figure 17: Binary input wiring

Setup and adjustmentsImportant: Table 7 provides a full list of TEC3000menu settings. Refer to TEC3000 Series On/Off orFloating Fan Coil Thermostats Installation Guide(LIT-12013161) for step-by-step instructions on howto access and adjust the more commonly usedmenus.

OverviewAbout this task:Figure 18 shows the thermostat controller home screenin both the light and dark themes in heating mode. Youcan customize it to show or hide various elements fromthe occupant. See Table 4 for a listing of the touchscreenicons. When screen customization is used in conjunctionwith a passcode, the building owner can control whichoptions the occupant can access and adjust.

Important: If lockout levels are used, some iconsare hidden. Table 5 provides details of these levels.

TEC3000 Series On/Off or Floating Fan Coil Thermostats Quick Start Guide 9

Figure 18: Thermostat controller home screen (shownwith light and dark themes)

To switch between the modern, classic, light, anddark themes, complete the following steps:

1. Press the Menu icon.2. Press Settings.3. Press Display Settings.4. Press Change Color Theme.5. Select one of the four options available.

ResultMultiple pages are available on the display. The page thatyou currently view is emphasized with a filled dot. Theother available page display as an empty dot.In the modern theme, the cooling, or blue, and heating, ororange, circles show whether the cooling or heating modeis active.

Figure 19: Thermostat controller home screen incooling mode (left) and heating mode (right)

Customizing the home screenAbout this task:Customizing the Home screen settings include:• Brightness• Enable Backlight• Units• Time• Time Zone• Time Format• Date• Date FormatYou can also show or hide these items on the Homescreen:• Fan Button• Temperature• Humidity• Off Button• Hold Button• Setpoint• Alarms• Occupancy Status• Unit Status• Date/Time

To customize the Home screen, complete the followingsteps:

1. Press the Menu icon.2. Press Display Settings.3. Enable or disable elements of the home screen as

appropriate for the building owner and occupants.4. Set the passcode on the thermostat controller to

prevent the occupants from changing settings thatthey should not have access to change.

Touchscreen iconsTable 4 describes the touchscreen icons on the homescreen. Press and release a touchscreen icon to activatethe TEC. Additional touchscreen icons appear based onthe menu, and those icons are also described in Table 4.Table 4: Touchscreen icons

Icon and icon name DescriptionMenu Displays the configuration

screens where various settingsmay be adjusted.

Alarm Indicates that the thermostatcontroller has triggered analarm.

Unit Power

On

Standby

Powers the thermostat controlleron or off.Notes:• This icon disables all

equipment control but doesnot physically power down theunit.

• On the modern homescreen, if the Unit Powericon is in standby mode, thetemperature and humidityalso display in standby modeto indicate that control off orstandby mode is active.

Humidity

On

Standby

Indicates the humidity reading.

Degree

On

Standby

Indicates that the unit is set todegrees.

TEC3000 Series On/Off or Floating Fan Coil Thermostats Quick Start Guide10

Table 4: Touchscreen icons

Icon and icon name DescriptionNetworkCommunication (forNetworked Models)

NetworkcommunicationNo Signal

Network Communication iconindicates that the thermostatcontroller detected a supervisorycontroller and both are online.No icon indicates that thethermostat controller did notdetect a supervisory controller.

Radio Signal (ForWireless Models)

No signal

Low signal

Medium signal

High signal

Indicates the strength of theradio signal.

Arrow Up

Arrow Down

Increases or decreases thecooling value on the homescreen.

Arrow Up

Arrow Down

Increases or decreases theheating value on the homescreen.

Cooling Hold Indicates that cooling hold modeis enabled. To disable Holdmode, press the button.

Heating Hold Indicates that heating holdmode is enabled. To disable Holdmode, press the button.

Cooling Setpoint Displays the current coolingsetpoint. Indicates that Holdmode is disabled. To enable Holdmode, press the button.

Heating Setpoint Displays the current heatingsetpoint. Indicates that Holdmode is disabled. To enable Holdmode, press the button.

Setpoint Temperature Displays the current setpointtemperature. Indicates that theShow Hold button is set to No.

Heating Mode Indicates that heating mode isselected.

Table 4: Touchscreen icons

Icon and icon name DescriptionCooling Mode Indicates that cooling mode is

selected.

Auto Mode Indicates that Auto mode isselected.

Fan Overrides forSingle-speed Fans

On

Auto

Quiet

Adjusts the fan override betweenOn, Auto, and Quiet for single-speed fans.

Fan Overrides forVariable-speed Fans

On

Auto

Quiet

Adjusts the fan override betweenOn, Auto, and Quiet for variable-speed fans.

Fan Overrides forMulti-speed Fans

Low

Medium

High

Auto

Quiet

Adjusts the fan override betweenLow, Medium, High, Auto, andQuiet for multi-speed fans.

TEC3000 Series On/Off or Floating Fan Coil Thermostats Quick Start Guide 11

Table 4: Touchscreen icons

Icon and icon name DescriptionOccupancy Status

Unoccupied

Occupied

Temporarilyoccupied

Standby

Override-occupied

Override-unnoccupied

Adjusts the occupancy betweenUnoccupied, Occupied,Temporarily occupied,Standby, Occupancy override,Unoccupancy override.

Back Moves the display to theprevious screen.

Forward Moves the display to the nextscreen.

Home Returns the display to the mainhome screen.

Save Saves the current configurationand parameter settings.

Delete Deletes the scheduled event.

Clear Clears the password entry on thekeypad screen.

Exclamation point Indicates that an error hasoccurred.

User lockoutYou can select from three different levels of access atthe local display to manage functionality through thesupervisory controller. This lockout is independent ofany display or passcode settings. The existing temporaryoccupancy capability is unaffected by this feature. Userlockout hides the icons that are not operable. The lockoutlevels are described in Table 5.Table 5: User lockout levels

Lockoutlevel

Capability

State 0 Provides full access to home screendisplay adjustments and icons (default).

State 1 Hides the Menu icon.State 2 Only allows the screen to trigger

temporary occupancy. Menu, Unit Power,the Up and Down arrows, and Run/Holdare hidden.

Using the USB portUse the USB port to quickly and easily load firmwareupgrades, back up the current settings, and restoresettings to the TEC3000 by using a USB drive. The TEC3000can recognize eight configuration files or firmwarepackage files. The USB drive format must be FAT or FAT32.The drive cannot be NTFS format or USB 3.0. If you areupgrading firmware or copying configuration files, youneed the passcode if one has been set up. Do not removethe USB drive until the firmware upgrade is complete.The TEC3000 may restart and go offline to the NAE aftera firmware upgrade. The upgrade takes approximatelythree minutes.

Configuring the thermostat controllerUse the Menu icon on the home screen to access andchange the basic operating parameters of the thermostatcontroller. During normal operation, press the Menu icononce to access the following parameters:• Fault Status• Setpoints• Schedule• Display Settings• Setup• Trend• Status• Update

Installer configuration menuThe thermostat controller comes from the factory withdefault settings for all configuration parameters. Beforeany outputs turn on, the controller must be configuredfor the equipment connected. You need to start from thehome screen to perform any of the following tasks.

TEC3000 Series On/Off or Floating Fan Coil Thermostats Quick Start Guide12

Screen resetThe current screen returns to the home screen and turnsoff if the current screen is not touched for 3 minutes.Touch the screen to turn it on again. To disable thescreensaving option, press Display Settings and setEnable Display Timeout to No.

Selecting the unit typeThere are three unit types. They are:• Four-pipe—This unit type has both heating and cooling

coils plus a supply fan. This configuration can also beused on configurations that are heating or cooling only.

• Two-pipe—This unit type has a single set of pipes thatcan serve hot or chilled water plus a supply fan. TheSupply Temp Type allows for the connection of ananalog sensor or an aquastat to a binary input. Basedon the water temperature or aquastat state, the unitcontrols heating or cooling.

• VAV—This unit type is designed for a pressure-dependent zone damper and the supply fanoutputs are disabled. The TEC senses the supplyair temperature coming from the unit. The SupplyTemp Type setting allows for the connection of ananalog sensor or binary duct thermostat. Based onthe air temperature or duct thermostat state, the zonedamper controls for heating or cooling. The TEC doesnot control the unit delivering the air. The logic needsto be part of another controller.

By default, the thermostat controller is configured forfour-pipe fan coil mode.

Selecting the heating and coolingdevice typeBy default, the thermostat is configured for On-Off(2-position) control. This can be changed to Floating(Incremental) mode when the Unit Type is not set to VAV.For VAV mode, only floating actuators are supported andthis option is unavailable.When in Floating mode, the Actuator Stroke Time mustalso be set to match the equipment.

Configuring the supply fan - fan coilonlyOn two-pipe or four-pipe fan coil units, three differenttypes of supply fans are supported. These are single-speed fans, multi-speed fans up to three discrete speeds,and VSF using a 0 VDC to 10 VDC control signal and anoptional binary on/off command.

Note: Fan control is not available in VAV mode.For multi-speed fan control, you can adjust the pointwhen the medium or high speed turns on. The fan speedis based on the user configurable value of temperaturedifferential from setpoint. By default, the Medium Fan OnDiff Sp is set to 1.5, the Medium Fan Off Diff Sp is set to0.5, the High Fan On Diff Sp is set to 2, and the High FanOff Diff Sp is set to 1.For VSF control, the output is configurable for any rangebetween 0 VDC and 10 VDC. The parameters are StartVoltage, Full Speed Voltage, and Minimum Command.Start Voltage is the voltage output at which the fan begins

running, and Full Speed Voltage is the voltage output atwhich the fan reaches full speed. Minimum Command isthe percentage of the range between the Start Voltageand the Full Speed Voltage. The fan does not go belowthe minimum command when the fan is turned on. Bydefault, the Start Voltage is 2 VDC, the Full Speed Voltageis 10 VDC, and the Minimum Command is 20%.When the variable speed fan is off, the FAN L binaryoutput is off and the voltage at the VSF output is 0 VDC.When the fan turns on, the FAN L binary output turns onand the voltage at the VSF output begins controlling thefan. When the VSF is configured for reverse acting mode,when the Start Voltage is above Full Speed Voltage, theVSF output is set to 10 VDC or the Start Voltage minus 1VDC, whichever value is the lesser, when the fan is turnedoff.

Setting the Control modeThe Control Mode informs the controller to run in Coolingonly, Heating only, or Automatic mode, based on thetemperature in the zone relative to the heating andcooling setpoints. Control Mode does not overrideequipment lockouts or changeover.

Setting the Fan mode - fan coil onlyThe Fan mode informs the controller how to handle thefan. There are two options for fan configuration: a Fanmode available to the installer through the menu system,and a fan override available as an option to the end userfrom the Fan icon on the home screen. See Customizingthe home screen for information about enabling anddisabling end-user controls. The Fan mode available tothe installer is dependent on the fan type. The followingoptions are provided for single- and variable-speed fans:• On—Fan is continuously on• Auto—Fan cycles on demand with the controller

entering cooling, heating, or dehumidification modes• Smart—Fan cycles on demand with the controller

entering cooling or heating modes during unoccupiedperiods but is continuously running during occupiedand standby periods

The following Fan mode options are provided for multi-speed fans:• Low—Fan is continuously on low• Medium—Fan is continuously on medium• High—Fan is continuously on high• Auto—Fan cycles on demand with the controller

entering cooling, heating, or dehumidification modes• Smart—Fan cycles on demand with the controller

entering cooling or heating modes during unoccupiedperiods but is continuously running during occupiedand standby periods

The Fan Override icon on the home screen dependson the fan type. The following options are provided forsingle- and variable-speed fans:• On—Overrides the fan to be continuously on• Auto—Follows the behavior set as Fan Mode• Quiet—Follows the behavior set as Fan Mode, but

prevents the fan from ever going above minimumspeed. The Quiet option has no effect on equipmentwith single-speed fans.

TEC3000 Series On/Off or Floating Fan Coil Thermostats Quick Start Guide 13

The following Fan Override options are provided for multi-speed fans:• Low—Fan is continuously on low• Medium—Fan is continuously on medium• High—Fan is continuously on high• Auto—Follows the behavior set as Fan Mode• Quiet—Follows the behavior set as Fan Mode, but

prevents the fan from ever going above minimumspeed

Configuring the zone space orequipment size - units configured withfloating actuators, multi-speed fans, andvariable-speed fans onlyWith non-binary outputs, the TEC3000 is configured bydefault to have a slower temperature response for largerzones with normal-sized equipment. In installations withsmall zones and oversized equipment, set the EquipmentSize parameter to Oversized.

ChangeoverPressure-Dependent VAV systems and two-pipe fancoils require changeover detection in order to switchseasonal operation between heating and coolingmodes. The TEC supports the following methods forchangeover: automatic changeover using an analogsensor (thermistor), automatic changeover using a binaryswitch, or remote changeover from a BAS and manualchangeover.For automatic changeover, a supply temperature sensoror switch must be connected to the Changeover Sensor(COS) input of the TEC. Changeover Mode must be setto Auto, and Supply Temp Type must be set for AnalogSensor, Cooling N.C. (cooling when switch is closed), orHeating N.C. (heating when switch is closed). When youuse an analog sensor, you can adjust the changeoversetpoint. The changeover logic applies a 10°F differentialto the setpoint. The system switches to cooling modewhen the temperature drops below the changeoversetpoint and remains in cooling mode until the measuredtemperature has risen 10 degrees above the changeoversetpoint.Ensure that the Supply Temp type is set to Analog Sensor.The Changeover Mode is also exposed to the BAS throughthe CGOVR-MODE and can be commanded from the BAS.On two-pipe or VAV systems without an automaticchangeover, or on four-pipe systems, you can use RSENor COS as a monitor-only point for reading an analogsensor. By setting the controller in four-pipe mode, orselecting Heating or Cooling for Changeover Mode, thecontroller defaults to monitor-only mode for RSEN orCOS and exposes the value to the network as the supplytemperature.

Dehumidification controlThe TEC3000 controller support dehumidification controlon fan coil devices under three configurations:• Four-pipe fan coil• Four-pipe fan coil with reheat

• Two-pipe fan coil (with changeover in cooling mode)with reheat

Dehumidification operates when the zone humidityincreases above the humidity setpoint and the controlleris in a satisfied state with no active call for coolingor heating and when the chilled water temperatureis low enough to provide dehumidification. Whendehumidification is active, the cooling device controls tothe humidity setpoint, and the heating device reheats thezone in order to keep the temperature at setpoint. Whenin dehumidification mode, the multi-speed or variable-speed fan operates at the appropriate speed to maintainbalance between maximizing condensation and moistureremoval and keeping the zone from overcooling.

Temperature setpointsThe thermostat controller provides a flexible setpointconfiguration to give power to the building owner whilebeing easy to use by the occupant. In addition to a simpleup/down offset adjustment on the home screen for theoccupant, there are six temperature setpoints on the TEC.The six temperature setpoints are Cooling and Heatingsetpoints for Occupied, Unoccupied, and Standby modes.

Note: The TEC enforces a 2-degree deadbandbetween heating and cooling setpoints. If a setpointviolates this standard (for example, cooling setpointis set to 70 with a heating setpoint already set to 70),the opposing setpoint is modified to comply withthis deadband (in the previous example, the heatingsetpoint would automatically change to 68).

The four modes of setpoint operation are described inTable 6.

TEC3000 Series On/Off or Floating Fan Coil Thermostats Quick Start Guide14

Table 6: Setpoint operation

Mode ofsetpointoperation

Details

Occ SetpointSelect = SetpointOffset andHeatCool SetpointMode = IndividualSetpoints

This is the default mode and theoriginal mode of operation thatthe TEC was released with (thenext three modes are new). In thismode, the TEC has a heating setpointand a cooling setpoint. There is acommon Setpoint Offset (warmer/cooler adjust) that is applied to eachsetpoint simultaneously. The rangeof setpoint adjustment is two-fold:• There are large constant ranges

bounding the individual heatingand cooling setpoints.

• There is also a smallerconfigurable range limit set tothe Setpoint Offset point (ControlSetup > General > Max SetpointOffset).

Occ SetpointSelect = Min andMax SetpointsandHeat CoolSetpoint Mode= IndividualSetpoints

In this mode, the TEC has a heatingsetpoint and a cooling setpoint.Each setpoint has a configurablerange (Setpoints > Min CoolingSetpoint, Max Cooling Setpoint,Min Heating Setpoint, and MaxHeating Setpoint). The configurablerange values are bounded by thelarger constant bounds used inSetpoint Offset mode and areconstrained in the following manner:Min must be below Max and Heatingmust be below Cooling, so in orderfrom least to greatest, the values are:Min Heating Setpoint, Max HeatingSetpoint, Min Cooling Setpoint, andMax Cooling Setpoint.

Occ SetpointSelect = SetpointOffset andHeatCool SetpointMode = CommonSetpoint

In this mode, the TEC has onesetpoint, Common Setpoint, forheating and cooling. There is also acommon Setpoint Offset (warmer/cooler adjust) that is only applied toCommon Setpoint. Otherwise, thissetting works the same as when OccSetpoint Select = Setpoint Offset andHeat Cool Setpoint Mode = IndividualSetpoints.

Occ SetpointSelect = Min andMax SetpointsandHeat CoolSetpoint Mode= CommonSetpoint

In this mode, the TEC has onesetpoint, Common Setpoint, forheating and cooling. There is aconfigurable range for CommonSetpoint, Min Setpoint, and MaxSetpoint.

Scheduling (for all models)The occupancy schedule comes from either the weeklyscheduler built into the TEC or as an input from the

BAS. The Schedule Source must be selected to tell thecontroller where to read the occupancy source from.

Setting the local scheduleA weekly occupancy schedule with up to four occupancyevents for each day can be set locally on the TEC andoperate independently of a supervisor. See Scheduling(for all models) to ensure the schedule source is set toLocal.

Important: Internally, the TEC3000 uses a BACnetschedule where daily schedules are independent ofthe previous and next days. The default occupancyof the TEC3000 from the factory is set to Occupied.As a result, a daily event at 12:00 AM must bescheduled if you do not want the controller totransition to Occupied Mode at midnight.

Overriding the occupancy modeThe TEC supports a manual override of all other schedulesources (for example, Schedule, Occupancy BI, andtemporary occupancy).

Enabling optimal startThe TEC supports an advanced optimal start algorithm.The algorithm works in conjunction with a local scheduleto pre-heat or pre-cool the zone before scheduledoccupancy periods begin, in order to bring the zoneto the required occupied setpoint when the scheduledoccupancy period begins. Occupant comfort is ensuredwhile automatically minimizing energy usage. Thisalgorithm creates a model of the zone being controlledand automatically determines when to start theequipment before the scheduled transition to Occupied.The start time automatically adjusts daily to minimize thetime between reaching setpoint and entering Occupiedstate.

Note: Optimal Start does not work when theschedule source is set to External.

Enabling the motion sensor (TEC3xx3Models)On models with integral motion sensing capability, themotion sensor is enabled with a default timeout of 15minutes from the last detection of motion in the zone.On models without an integrated sensor, the defaulttimeout is still 15 minutes, but it only is applied when oneof the two configurable binary inputs is set to be a motionsensor (see TEC3000 Series On/Off or Floating Fan CoilThermostats Installation Guide LIT-12013161 for informationabout configuring the binary inputs). To disable motionsensing capabilities, set the Motion Sensor Timeout to 0minutes.

Scheduled circulationYou can schedule to run your fan for a minimum durationper hour in order to maintain circulation in a space. Ifthe minimum hourly fan runtime is not exceeded as partof normal HVAC operation, the fan turns on at the endof the hour for the length of time required to fulfill theminimum hourly run time. The fan runtime calculationincludes runtime initiated when the Fan Mode is set toOn and other overrides. The fan does not turn on if the

TEC3000 Series On/Off or Floating Fan Coil Thermostats Quick Start Guide 15

fan runtime is already longer than the minimum hourlyfan runtime. When you enabled the Scheduled CirculationOnly When Occupied setting, the fan does not turn on at

the end of the hour to fulfill the minimum runtime unlessthe occupancy state is set to Occupied.

Menus and submenusIn the following table, the * indicates that the menus depend on your configuration.Table 7: Menus and submenus

Level 1 Level 2 Level 3DehumidificationCooling Valve Minimum Position*Cooling Valve Starting Position*Heating Valve Starting Position*Coil Tempering Time*Dehumidification Overcool Limit*

Dehumidification

Chilled Water Supply Temperature Setpoint*Occupied CoolingOccupied HeatingUnoccupied CoolingUnoccupied HeatingStandby CoolingStandby HeatingOcc Setpoint SelectHeat Cool Setpoint ModeMax Heating Setpoint*Min Heating Setpoint*Max Cooling Setpoint*Min Cooling Setpoint*Max Setpoint*

Setpoints

Temperature

Min Setpoint*Schedule OptionsSet ScheduleOptimal Start EnableTemp Occ DurationMotion Sensor TimeoutManual Occupancy Mode

Scheduling

Schedule Source

TEC3000 Series On/Off or Floating Fan Coil Thermostats Quick Start Guide16

Table 7: Menus and submenus

Level 1 Level 2 Level 3Passcode EnabledPasscode*Brightness SettingEnable Backlight TimeoutUnitsTimeTime ZoneSet Time FormatDateSet Date FormatLanguageShow Fan Button on HomeShow Temp on HomeShow Humidity on HomeShow Off Button on HomeShow Hold ButtonShow Setpoint on HomeShow Alarms on HomeShow Occ StatusShow Unit Status

Display Settings

Show Date/Time

TEC3000 Series On/Off or Floating Fan Coil Thermostats Quick Start Guide 17

Table 7: Menus and submenus

Level 1 Level 2 Level 3Control ModeUnit EnableFan Mode*Max Setpoint OffsetFan On Delay*Fan Off Delay*Frost ProtectionDehum Enable*Unocc Dehum EnableDehumidification Sequence Mode*Aux ModeLoad Shed Rate LimitLoad Shed AdjustFan Alarm DelayFan Alarm Action*Fan Alarm Reset*Fan Runtime LimitFan Runtime Reset*Supply Air Temperature Alarm OffsetSupply Air Temperature Alarm Delay*Unocc Low Speed FanScheduled Circulation EnableScheduled Circulation Only when OccupiedMininum Hourly Fan RuntimeVariable Speed Fan Circulation Setpoint*

General Setup

Multi-speed Fan Circulation Setpoint*BI1 ConfigBI2 ConfigSupply Temp Type*Supply Temp Sensor*Supply Temp Offset*Zone Temp SensorZone Temp OffsetHumidity OffsetReset SensorsFor networked models:Zone Temp Alarm Enabled

For networked models:Zone Temp Low Limit

Setup

Input Setup

For networked models:Zone Temp High Limit

TEC3000 Series On/Off or Floating Fan Coil Thermostats Quick Start Guide18

Table 7: Menus and submenus

Level 1 Level 2 Level 3Temp Control SetupReset PID TuningDeadband*Auto Economizer TuningHeat Prop Band*Heat Integral Time*Heat Process Range*Heat Saturation Time*Heat Time Constant*Heat Process Dead Time*Heat Period*Cool Prop Band*Cool Integral Time*Cool Process Range*Cool Saturation Time*Cool Time Constant*Cool Process Dead Time*Cool Period*

Tuning Setup

Equipment SizeFC Comm ModeBACnet Instance ID*For networked models:N2 Address*

BACnet Address*For networked models:MSTP Baud Rate*

BACnet Encoding TypeBACnet/MSTP Communication Mode

Setup (continued)

Network Setup

For wireless models:Pan ID

TEC3000 Series On/Off or Floating Fan Coil Thermostats Quick Start Guide 19

Table 7: Menus and submenus

Level 1 Level 2 Level 3Unit TypeHtg/Clg Device Type*Actuator Stroke Time*Cooling Min On Time*Cooling Min Off Time*Heating Min On Time*Heating Min Off Time*Unoccupied Off DelayReheat Min On Time*

General

Reheat Min Off Time*Supply Fan Type*Start Voltage*Full Speed Voltage*Minimum Command*Medium Speed On Cmd*High Speed On Cmd*Medium Fan On Diff SP*Medium Fan Off Diff SP*High Fan On Diff SP*

Supply Fan

High Fan Off Diff SP*Reheat InstalledReheat Min Damper Pos*

Reheat

Reheat Fan Required*Changeover Mode*Supply Temp Type*Changeover Setpoint*Supply Temp Sensor*

Equipment Setup

Changeover

Supply Temp Offset*

TEC3000 Series On/Off or Floating Fan Coil Thermostats Quick Start Guide20

Table 7: Menus and submenus

Level 1 Level 2 Level 3EFF-ZNTEFF-SETPOINTEFF-ZNHB1 StatusB2 StatusEFF-OATEFF-SATFANSPD-SCLG1-CCLG2-CHTG1-CHTG2-COAD-OHTG-O

Trend

CLG-OOccupancy SourceUnit StatusSupply Air TemperatureChangeover State

System Status

Zone Temp SourceCooling % CommandHeating % CommandReheat % CommandCool Stage 1Heat Stage 1Reheat Stage 1Fan % Command

Control Status

FanModel NameSoftware VersionUnit NameDevice Name

Controller Info

Device DescriptionSupply Air TemperatureHeat CommandCool CommandSupply Fan

Commissioning

Aux

TEC3000 Series On/Off or Floating Fan Coil Thermostats Quick Start Guide 21

Table 7: Menus and submenus

Level 1 Level 2 Level 3View VersionLoad FirmwareRestore*

Update

Backup*Radio Code VersionRadio PAN IDActive ChannelSignal StrengthConnection StatusNetwork StateIEEE Address

For wireless models:Network Status

Short Address

TroubleshootingTable 8: Fault list

Faults Probable causes SolutionsRemote Zone Temp Fail The External Zone Temperature

sensor has been disconnected or hasfailed.

1. Check the wiring of the sensor.2. If intentionally disconnected, reset sensors

through the menu.3. If the problem persists, order replacement

units and return the affected devices toJohnson Controls under the RMA program.

Supply Temp Fail The External Supply Temperaturesensor has been disconnected or hasfailed.

1. Check the wiring of the sensor.2. If intentionally disconnected, result fault

by entering the menu, enter Control Setup,and select Inputs to reset the sensors.

3. If the problem persists, order replacementunits and return the affected devices toJohnson Controls under the RMA program.

Internal Sensor Fail An internal sensor has failed on theTEC.

Order replacement units and return theaffected devices to Johnson Controls under theRMA program.

Dehum Unavailable Dehumidification is unavailablebecause the zone humidity sensor hasfailed or the humidity reading is notreliable.

1. If the source of zone humidity was a BAS,check the BAS to ensure that it is stillonline and is providing the TEC with thehumidity reading. If removal of the BASmapping was intentional, reset the sensorsthrough the menu.

2. (For all models) If the problem persists,order replacement units and return theaffected devices to Johnson Controls underthe RMA program.

Service Equipment connected to the BIconfigured for a Service alarmtriggers the alarm.

Service the equipment by way of themanufacturer's recommendation.

Dirty Filter Equipment connected to the BIconfigured for a Dirty Filter alarmtriggers the alarm.

Replace the filter in the equipment as explainedin the manufacturer's instructions.

TEC3000 Series On/Off or Floating Fan Coil Thermostats Quick Start Guide22

Table 8: Fault list

Faults Probable causes SolutionsCalibration Corrupt Factory calibration data is lost or is

not installed.Order replacement units and return theaffected devices to Johnson Controls under theRMA program.

Changeover Fail The Supply Temperature Sensor isnot installed, has failed, or has beendisconnected and the TEC can nolonger detect changeover mode tocool or heat.

Follow the same steps as Supply Temp Failalarm.

Zone Temp Unreliable All sources of zone temperature areunreliable, including the onboardsensor.

Order replacement units and return theaffected devices to Johnson Controls under theRMA program.

Open Window The switch connected to the BIconfigured for Open Window sensesthat the window is opened, andcontrol has shut down.

1. Close the window to resume control.2. Check sensor functionality with an

ohmmeter, and verify the wiring to theTEC.

3. Order replacement units and return theaffected devices to Johnson Controls underthe RMA program.

Fan Lock The switch connected to the BIconfigured for Fan Lock did not senseairflow within 10 seconds of startingthe fan, and control has been shutdown.

1. Inspect equipment to ensure fanfunctions.

2. Check sensor functionality with anohmmeter, and verify wiring to the TEC.

3. Reset fault by entering the menu, selectingFault Status, and selecting the Fan Lock.

4. Order replacement units and return theaffected devices to Johnson Controls underthe RMA program.

Humidity Unreliable The zone humidity reading wasreliable and has now failed.

1. If the source of zone humidity was theonboard sensor, contact Johnson Controlsproduct sales and support.

2. If the source of zone humidity was a BAS,check the BAS to ensure that it is stillonline and providing the TEC with thehumidity reading. If removal of the BASmapping was intentional, reset sensorsthrough the menu.

The controller has detected aninternal fault that it cannot recover.

Order replacement units and return theaffected devices to Johnson Controls under theRMA program.

Controller Fault

An unknown error has prevented thecontroller from turning on.

Order replacement units and return theaffected devices to Johnson Controls under theRMA program.

Touchscreen Unavailable The touchscreen components fail toinitialize.

1. Reboot the controller.2. If problems persist, order replacement

units and return the affected devices toJohnson Controls under the RMA program.

Board Mismatch The baseboard and CPU board arepaired incorrectly. An error messageappears on the TEC indicating themodel number of the baseboard andCPU board.

Match the baseboard to its corresponding CPUboard.

TEC3000 Series On/Off or Floating Fan Coil Thermostats Quick Start Guide 23

Table 8: Fault list

Faults Probable causes SolutionsThe previous upgrade did notcomplete.

1. Upgrade the TEC3000 to the latest releasedversion.

2. Upgrade the TEC3000 to the currentversion again.

Firmware Mismatch

The previous downgrade has notcompleted because the previousversion is no longer supported.

Reboot the TEC3000 to clear the fault.

USB Malfunction A USB drive has malfunctioned anddrawn more than the maximumallowed current.

1. Attempt to insert and use the USB driveagain.

2. Try a new USB drive.3. If problems persist, order replacement

units and return the affected devices toJohnson Controls under the RMA program.

Supply Fan Runtime LimitExtended

The Supply Fan Runtime exceeds theconfigured Supply Fan Runtime Limit.

1. Service the Supply Fan.2. Reset the Supply Fan runtime.

Heating Ineffective The Supply Air Temperature hasnot increased above the configuredSupply Air Temperature Alarm Offsetwhile heating has been active forat least the Supply Air TemperatureAlarm Delay.

Verify that the heating elements on the rooftopare functioning correctly.

Cooling Ineffective The Supply Air Temperature has notdecreased below the configuredSupply Air Temperature Alarm Offsetwhile cooling has been active for atleast the Supply Air TemperatureAlarm Delay.

Verify that the cooling elements on the rooftopare functioning correctly.

Supply Fan Fault The Supply Fan Status configuredfor either BI1 or BI2 has not provedwithin the configured Fan AlarmDelay.

1. Verify that the Supply Fan is operatingwhen turned on.

2. Verify that the Supply Fan Status wiring isconnected correctly.

Zone Temperature Too Cold The Zone Temperature decreasedbelow the configured Zone Temp LowLimit.

Verify that the TEC and the RTU heating areenabled and functioning.

Zone Temperature Too Hot The Zone Temperature increasedabove the configured Zone TempHigh Limit.

Verify that the TEC and the RTU cooling areenabled and functioning.

TEC3000 Series On/Off or Floating Fan Coil Thermostats Quick Start Guide24

Table 9: Troubleshooting details

Symptom Probable causes SolutionsThe two-pipe fan coil/VAVsystem does not have achangeover sensor and switchconnected, or the sensor/switchhas failed.

1. Check the wiring of the supply temperaturesensor/switch.

2. Verify that the changeover is set upcorrectly for the type of sensor attached(sensor or switch).

The changeover temperatureis sensing a hot supply, but thecontroller requests cooling.

1. Verify that the supply is not in heatingmode. If it is, nothing can be done from theTEC.

2. Check the wiring of the supply temperaturesensor or switch.

3. Check the placement of the supplytemperature sensor or switch.

4. Verify that the changeover is set upcorrectly for the type of sensor attached(sensor or switch).

The controller displays Idlewith a Unit Status of CoolingUnavailable due toChangeover despite being abovecooling setpoint, or with a statusof Heating Unavailable dueto Changeover despite beingbelow the setpoint.

Changeover temperature issensing a cold supply, but thecontroller requests heating.

1. Verify that the supply is not in coolingmode. If it is, nothing can be done from theTEC.

2. Check the wiring of the supply temperaturesensor or switch.

3. Check the placement of supply temperaturesensor or switch.

4. Verify that the changeover is set upcorrectly for the type of sensor attached(sensor or switch).

The Control Mode is set toCooling Mode, but the controllerrequests heating.

Change the Control Mode to Auto or Heating.The controller displays Idlewith a Unit Status of CoolingUnavailable due to ControlMode despite being above coolingsetpoint, or with a status ofHeating Unavailable due toControl Mode despite beingbelow the setpoint.

The Control Mode is set toHeating Mode, but the controllerrequests cooling.

Change the Control Mode to Auto or Cooling.

The staged equipment shuts offabove the cooling setpoint orbelow the heating setpoint whenthe PID is running on the TEC.If the unit is in On/Off Controlmode, this does not apply.

The PID control algorithmminimizes overshoot andenergy usage for the particularequipment and zone, and maycycle the equipment prior toreaching setpoint.

Expected behavior.

The staged equipment cycles toorapidly or too slowly when the PIDis running on the TEC.

The control band around thesetpoint is determined by theminimum on/off times and is setincorrectly for the equipment,zone, or user preference. Thereis a tradeoff between reducedcontrol band size and increasedenergy usage and equipmentwear from increased cycling.

1. Verify that equipment minimum on/offtimes are set correctly.

2. If the default deadband around thesetpoint does not provide the requiredtemperature control, set Temp ControlSetup to Deadband Override and set theDeadband parameter to the preferredvalue.

The controller provides an errorwhen trying to upgrade firmware.

The firmware on the USB driveis below the minimum requiredversion. Error code 1025.

Please use firmware version 3.0.2.xxxx (fornetworked models) or 2.0.2.xxxx (for wirelessmodels) or higher. A reboot is required to clearthe Firmware Mismatch fault that occurs.

TEC3000 Series On/Off or Floating Fan Coil Thermostats Quick Start Guide 25

Table 9: Troubleshooting details

Symptom Probable causes SolutionsThe TEC3000 zone temperaturedoes not change fast enoughcompared to the measured zonetemperature from a verificationdevice, such as a calibratedsensor.

The TEC3000 is configured bydefault for larger spaces withnormal-sized equipment when aproportional device is active.

Select Control Setup >Tuning > Equipment Size> Oversized.

The zone space temperatureincreases or decreases toomuch when the unit is active inunoccupied mode.

The heating and coolingequipment are too big for theunoccupied space.

Decrease the Unoccupied Off Delay parameterfrom 10 minutes to a more appropriate time forthe equipment configuration.

The controller provides an errorwhen trying to back up settings.

The USB drive is defective. Try a different USB drive.

The USB drive is defective. Try a different USB drive.The Restore file is corrupt. Try restoring a different backup file.

The controller provides an errorwhen trying to restore settingsfrom a backup.

The Restore file is from anincompatible model TEC.

Ensure that the backup file being restored wasfrom the same model TEC.

The drive is formatted as NTFSor another unsupported format.The TEC supports file allocationtable (FAT) (for networkedmodels), FAT16 (for wirelessmodels), and FAT32 (for allmodels) formats only.

Reformat the USB drive, or try a different USBdrive with a supported format.

The controller is unable to accessa USB drive.

The USB drive is defective. Try a different USB drive.The I/O board that the displayboard is currently attached todoes not match the one thatinitially shipped with the displayboard.

Attach the display board to the correct I/Oboard.

The controller displays BoardMismatch.

A hardware failure causesthe two boards to incorrectlyidentify themselves.

Order replacement units and return the affecteddevices to Johnson Controls under the RMAprogram.

The controller displaysController Fault.

An internal fault was detectedand the controller was unable torecover.

Order replacement units and return the affecteddevices to Johnson Controls under the RMAprogram.

The Bell icon is displayed on theTEC home page.

The fault has been detected onthe TEC.

See Table 8 for TEC fault causes and resolution.

Partial Restore Complete isdisplayed when trying to restoresettings from a backup file.

Not all of the items in thebackup file have been restored.This error can occur when avalue is out of the minimum ormaximum range in the backupfile. It may also occur if there areinconsistencies in the reliabilityof a setting in the backup fileand on the TEC device.

1. Create a Backup file on a USB drive for theTEC that is showing the issue.

2. Edit the backup file created in the previousstep on a PC to reflect the preferredsettings.

3. Verify that the modified values are withinminimum and maximum range in thebackup file.

4. Restore the settings from the newly editedbackup file on the TEC.

Cold air drafts enter the back ofthe TEC.

Seal any holes behind the TEC to reduce drafts.The temperature displayed islower than the actual roomtemperature. Air is being forced through the

TEC from a nearby vent.Move the location of the TEC or change theventing to prevent air from being forced throughthe TEC.

TEC3000 Series On/Off or Floating Fan Coil Thermostats Quick Start Guide26

Table 9: Troubleshooting details

Symptom Probable causes SolutionsFor networked models, theOnline icon does not appear for anetworked controller.

There is incorrect field buswiring.

Refer to the MS/TP Communications Bus TechnicalBulletin (LIT-12011034).

For wireless models, SupervisoryStatus = Offline

The supervisory controller isnot communicating with theTEC. The TEC is not mapped toa JCI Supervisory System. TheWNC or WRG Gateway is notcommunicating with the TEC.

1. Map the TEC into a JCI Supervisory system.2. Verify that the PAN’s WNC or WRG Gateway

is online.3. Add ZFR182x or ZFR183x Routers/Repeaters

into the wireless system.

Some icons are hidden. Lockout levels are used or theicons are hidden due to thedisplay settings.

See Table 5 for lockout levels and access details.

The touchscreen is unresponsive.You do not tap the touchscreen,but the display acts as if it istapped, which causes the displayto blink or toggle betweenscreens.You need to tap the display atan offset from a touch point toactivate the display.

You tap the display or touch thecontroller within 5 mm of thedisplay when power is applied tothe controller.

Reboot the controller. Do not interact with thecontroller until the home screen displays.

Note: For common MS/TP troubleshootinginformation, refer to the MS/TP Communications BusTechnical Bulletin (LIT-12011034).

TEC3000 Series On/off or Floating Fan Coil Thermostats technicalspecificationsTable 10: TEC3000 Series Networked and Wireless On/off or Floating Fan Coil and Individual Zone ThermostatControllers with Dehumidification Capability technical specifications

Specification DescriptionPower requirements 19 VAC to 30 VAC, 50/60 Hz, 4 VA at 24 VAC nominal, Class 2 or safety extra-low

voltage (SELV)USB port power rating 120 mA to 250 mA current draw supportedRelay contactrating

On/off or floatingcontrol

19 VAC to 30 VAC, 1.0 A maximum, 15 mA minimum, 3.0 A in-rush, Class 2 or SELV

Fan relay output rating 19 VAC to 30 VAC, 1.0 A maximum, 15 mA minimum, 3.0 A in-rushAuxiliary output rating/triac output 19 VAC to 30 VAC, 1.0 A maximum, 15 mA minimum, 3.0 A in-rushBinary inputs Dry contact across terminal COM to terminals BI1, BI2, or COSAnalog inputs Nickel, platinum, A99B, 2.25k ohm NTC, 10k ohm NTC, 10k ohm NTC Type 3 across

terminal COM to terminals R SEN or COSTemperature sensor type Local digital sensorWire size 18 AWG (1.0 mm diameter) maximum, 22 AWG (0.6 mm diameter) recommended

For wired models: Up to 100 devices maximum for each Metasys SupervisoryEngine; 4,000 ft (1,219 m) maximum cable length. Refer to the MS/TP TechnicalBulletin for the Metasys, FX, or Verasys® system installed.

MS/TP network guidelines

For wireless models: Up to 100 devices maximum for each Metasys SupervisoryEngine

Wireless band (for wireless models) Direct-sequence spread-spectrum 2.4 GHz ISM bands

TEC3000 Series On/Off or Floating Fan Coil Thermostats Quick Start Guide 27

Table 10: TEC3000 Series Networked and Wireless On/off or Floating Fan Coil and Individual Zone ThermostatControllers with Dehumidification Capability technical specifications

Specification DescriptionTEC30xx-1x-000compatible withZFR182x ProSeries

10 mW maximumTransmissionpower (forwirelessmodels)

TEC31xx-1x-000compatible withZFR183x ProSeries

100 mW maximum

TEC30xx-1x-000compatible withZFR182x ProSeries

50 ft (15.2 m) recommended indoor250 ft (76.2 m) line of sight, maximum

Transmissionrange (forwirelessmodels)

TEC31xx-1x-000compatible withZFR183x ProSeries

250 ft (76.2 m) recommended indoor1000 ft (304.8 m) line of sight, maximum

Backlit display -40.0°F/-40.0°C to 122.0°F/50.0°C in 0.5° incrementsHeating control 40.0°F/4.5°C to 90.0°F/32.0°C

Temperaturerange

Cooling control 54.0°F/12.0°C to 100.0°F/38.0°CTemperature ±0.9F°/±0.5C° at 70.0°F/21.0°C typical calibratedAccuracyHumidity ±5% RH from 20% to 80% RH at 50°F to 90°F (10°C to 32°C)

Minimum deadband 2F°/1C° between heating and coolingOccupancy sensor motiondetection (occupancy sensingmodels)

Minimum of 94 angular degrees up to a distance of 15 ft (4.6 m); based on a clearline of sight

Operating 32°F to 122°F (0°C to 50°C); 95% RH maximum, noncondensingAmbientconditions Storage -4°F to 122°F (-20°C to 50°C); 95% RH maximum, noncondensing

BACnetInternational

BACnet Testing Laboratories™ (BTL) 135-2001 Listed BACnet Advanced ApplicationController (B-AAC)UL Listed, File E27734, CCN XAPX, Under UL60730Networked models: FCC Compliant to CFR 47, Part 15, Subpart B, Class B

United States

Wireless models: Transmission complies with FCC Part 15.247 regulations for lowpower unlicensed transmitters; transmitter identification FCC ID: OEJ-WRZRADIO(ZFR182x), OEJ-ZFRRADIO (ZFR183x)UL Listed, File E27734, CCN XAPX7, Under E60730Networked models: Industry Canada, ICES-003

Compliance

Canada

Wireless models: Industry Canada (IC) RSS-210;Transmitter identification ZFR1810-1: IC ID: 279A-WRZRADIO (ZFR182x), 279A-ZFRRADIO (ZFR183x)

Europe (fornetworkedmodels only)

CE Mark – Johnson Controls declares that this product is in compliance with theessential requirements and other relevant provisions of the EMC Directive and theRoHS Directive.

Australia and NewZealand

RCM Mark, Australia/NZ Emissions Compliant

Models withoutoccupancy sensor

0.75 lb (0.34 kg)Shippingweight

Models withoccupancy sensor

0.77 lb (0.35 kg)

TEC3000 Series On/Off or Floating Fan Coil Thermostats Quick Start Guide28

The performance specifications are nominal and conform to acceptable industry standards. For application at conditionsbeyond these specifications, consult the local Johnson Controls office. Johnson Controls shall not be liable for damagesresulting from misapplication or misuse of its products.

Repair informationIf the TEC3000 Series Thermostat Controller fails tooperate within its specifications, replace the unit. For areplacement thermostat controller, contact the nearestJohnson Controls representative.

Product warrantyThis product is covered by a limited warranty, detailsof which can be found at www.johnsoncontrols.com/buildingswarranty.

Software termsUse of the software that is in (or constitutes)this product, or access to the cloud, or hostedservices applicable to this product, if any, issubject to applicable end-user license, open-sourcesoftware information, and other terms set forth atwww.johnsoncontrols.com/techterms. Your use of thisproduct constitutes an agreement to such terms.

PatentsPatents: https://jcipat.com

Single point of contactAPAC Europe NA/SAJOHNSON CONTROLS

C/O CONTROLS PRODUCTMANAGEMENT

NO. 32 CHANGJIJANG RD NEWDISTRICT

WUXI JIANGSU PROVINCE 214028

CHINA

JOHNSON CONTROLS

WESTENDHOF 3

45143 ESSEN

GERMANY

JOHNSON CONTROLS

507 E MICHIGAN ST

MILWAUKEE WI 53202

USA

Contact informationContact your local branch office:www.johnsoncontrols.com/locationsContact Johnson Controls: www.johnsoncontrols.com/contact-us

TEC3000 Series On/Off or Floating Fan Coil Thermostats Quick Start Guide 29

© 2020 Johnson Controls. All rights reserved. All specifications and other information shown were current as of document revision andare subject to change without notice.

www.johnsoncontrols.com