Target Field_case_study 050211

-

Upload

kristy-a-moore-leed-ap-bdc-cppm -

Category

Documents

-

view

11 -

download

0

Transcript of Target Field_case_study 050211

CHAPTER PROJECT PROFILE

30%will use 30 percent less potable (drinking) water than conventional fixtures

27.5%total building materials content has been manufactured using recycled materials

67.6% construction waste generated onsite was diverted from the landfill

TARGET FIELDMINNEAPOLIS, MN

The information provided is based on that stated in the LEED® project certification submittals. USGBC and Chapters do not warrant or represent the accuracy of this information. Each building’s actual performance is based on its unique design, construction, operation, and maintenance. Energy efficiency and sustainable results will vary.

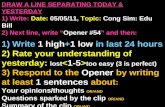

LEED ® FactsTARGET FIELDMinneapolis, Minnesota

LEED for New Construction v2.1Certification awarded April 2010

Silver 36*

Sustainable Sites 11/14

Water Efficiency 3/5

Energy & Atmosphere 3/17

Materials & Resources 6/13

Indoor Environmental Quality 8/15

Innovation & Design 5/5

*Out of a possible 69 points

CHAPTER PROJECT PROFILE

The Minnesota Chapter is an active and thriving organization intent on transforming the State’s built environment. The Chapter has grown to become a leading regional catalyst for the acceptance and adoption of green building practices, technologies, policies and standards.www.usgbcmn.org

TARGET FIELD

LEED-NC Silver Playing (back) in the Great Outdoors

Architects: Populous with HGAStructural Engineer: Walter P. Moore & Assoc.MEP Engineers: ME EngineersLandscape Architect: Oslund and AssociatesCivil Engineer: HGA Bridge Engineer: URS CorporationConstruction Manager: M.A. Mortenson ConstructionProject Size: 990,000 square feetTotal Project Cost: $545 MillionCost per Square foot: $379

Photography Courtesy of:

PROJECT BACKGROUNDNestled in the historic warehouse district of downtown Minneapolis, Target Field is the most urban ballpark in the country. Home to the Minnesota Twins, the Major League Baseball team for the Minneapolis/St. Paul metropolitan area and greater “Twins Territory”, the new ballpark achieved LEED Silver Certification and is the greenest MLB ballpark based on certification points achieved.

GREEN CATALYST Placed on a previously contaminated industrial site on the edge of downtown Minneapolis, the new ballpark connects the historic warehouse neighborhood with downtown Minneapolis by literally bridging over rail lines and highways that separate the two districts. The project’s location provides close proximity to the City Center Shopping area, condominiums and a multitude of local businesses, including the First Avenue Entertainment district, providing yet another draw to the downtown area.

STRATEGIES AND RESULTSTarget Field has created a new transportation hub in downtown Minneapolis, linking Metro Transit’s newly extended Hiawatha light rail line and the Northstar commuter rail service. The nearby Metro Bus station and bike trail also provide alternative transportation access to the ballpark.

The project includes a custom designed rainwater recycling system to capture, conserve and reuse rainwater. Water cisterns buried under the playing field will capture water, which will then be filtered through an intricate mechanical filtration system; this purified water will then be used for field irrigation and seating bowl wash-down. It is estimated this system will save more than 1.26 million gallons of water per year.

Additional water saving fixtures, such as low flow urinals, dual flush toilets and aerated faucets in Target Field will use 30 percent less potable (drinking) water than conventional fixtures. This will save more than 4.2 million gallons of potable water per year, reducing the ballpark’s operating costs and demand on the municipal water supply and treatment facility.

Energy efficient sports lighting fixtures and purchased Green-e accredited Tradable Renewable Certificates (RECs) that equal to 70% of the predicted annual electrical consumption over a 2-year period are a sampling of the ways this ballpark cut energy costs as compared to other sports venues.

The selection of the ballpark’s building material, furniture and components is focused on the use of recycled content, regional availability, and compatibility with LEED indoor air quality standards. By cost value, 27.5% of the total building materials content has been manufactured using recycled materials and 28.7% of the total building materials value is comprised of building materials and/or products that have been extracted, harvested or recovered, as well as manufactured within 500 miles of the project site. Similarly, the construction waste generated onsite, 22,433 tons (67.59%) has diverted from the landfill.

From an operational standpoint, the Minnesota Twins have committed to continuing the goals of sustainability by providing a smoke-free facility as well as the development and implementation of a green housekeeping program.

ABOUT THE MINNESOTA BALLPARK AUTHORITYThe Minnesota Ballpark Authority (MBA) is a public body that was created by the 2006 Minnesota State Legislature to oversee the construction and operation of Target Field. MBA, who owns the site and the facility on behalf of the public, is committed to protecting the public’s investment, while creating a new urban landmark that ties into new rail lines and potential new development.

“Gaining LEED certification has been a longstanding goal…It is our sincere hope that the sustainability aspects of Target Field will provide inspiration to other local, regional and national projects of this magnitude.”

Jim Pohlad, Twins Owner and CEO.