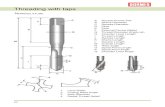

Taps and fluteless taps to JIS standard for universal … d 1 l 1 SW d 2 d k l 2 P l3 d 1 l 1 SW d 2...

Transcript of Taps and fluteless taps to JIS standard for universal … d 1 l 1 SW d 2 d k l 2 P l3 d 1 l 1 SW d 2...

2

New 3

New 3

New 4

New 4

New 5

New 5

JIS taps and fluteless taps

Article no. Ø range Type Form Tool description Tool material

Surface finish Page

1014 M2 - M20 JIS B HSS-E bright

1015 M2 - M20 JIS B HSS-E TiN

Article no. Ø range Type Form Tool description Tool material

Surface finish Page

1012 M2 - M20 JIS C HSS-E bright

1013 M2 - M20 JIS C HSS-E TiN

Article no. Ø range Type Form Tool description Tool material

Surface finish Page

1016 M2 - M20 JIS C HSS-E bright

1017 M2 - M20 JIS C HSS-E TiN

Taps for through holes, M coarse, DIN 13

Taps for blind holes, M coarse, DIN 13

Fluteless taps for through and blind holes, M coarse, DIN 13

Guhring‘s JIS taps and fluteless taps are designed to machine universal materials to ease your tool management and save costs. Choose Guhring and benefit from best quality and cost-perfor-mance-ratio threading a wide range of materials:

• general steels• high tensile steels• stainless and acid-resistant steels• Aluminium and Al-alloys• cast materials• non-ferrous materials• plastics• magnesium alloys• Ti- and Ni-alloys

3

d1

l1

SW

d2

l2dk

l3

d1

l1

SW

d2

l2dk

l3

Taps for through holes, M coarse, DIN 13, HSS-E, bright

Article no. 1014

d1 P mm tolerance d2 mm SW dk mm l1 mm l2 mm l3 mm Availability

M 2 0.40 OH2 3.00 2.5 1.600 40 8 15 •M 2.5 0.45 OH2 3.00 2.5 2.050 44 9 16 •M 3 0.50 OH2 4.00 3.2 2.500 46 10 19 •M 4 0.70 OH2 5.00 4.0 3.300 52 12 21 •M 5 0.80 OH2 5.50 4.5 4.200 60 14 24 •M 6 1.00 OH2 6.00 4.5 5.000 62 16 29 •M 8 1.25 OH2 6.20 5.0 6.800 70 18 37 •M10 1.50 OH2 7.00 5.5 8.500 75 20 41 •M12 1.75 OH3 8.50 6.5 10.200 82 24 48 •M14 2.00 OH3 10.50 8.0 12.000 88 26 48 •M16 2.00 OH3 12.50 10.0 14.000 95 26 52 •M18 2.50 OH4 14.00 11.0 15.500 100 30 55 •M20 2.50 OH4 15.00 12.0 17.500 105 32 58 •

Taps for through holes, M coarse, DIN 13, HSS-E, TiN

Article no. 1015

d1 P mm tolerance d2 mm SW dk mm l1 mm l2 mm l3 mm Availability

M 2 0.40 OH2 3.00 2.5 1.600 40 8 15 •M 2.5 0.45 OH2 3.00 2.5 2.050 44 9 16 •M 3 0.50 OH2 4.00 3.2 2.500 46 10 19 •M 4 0.70 OH2 5.00 4.0 3.300 52 12 21 •M 5 0.80 OH2 5.50 4.5 4.200 60 14 24 •M 6 1.00 OH2 6.00 4.5 5.000 62 16 29 •M 8 1.25 OH2 6.20 5.0 6.800 70 18 37 •M10 1.50 OH2 7.00 5.5 8.500 75 20 41 •M12 1.75 OH3 8.50 6.5 10.200 82 24 48 •M14 2.00 OH3 10.50 8.0 12.000 88 26 48 •M16 2.00 OH3 12.50 10.0 14.000 95 26 52 •M18 2.50 OH4 14.00 11.0 15.500 100 30 55 •M20 2.50 OH4 15.00 12.0 17.500 105 32 58 •

JIS taps and fluteless taps

4

d1

l1

SW

d2

l2dk

l3

d1

l1

SW

d2

l2dk

l3

JIS taps and fluteless taps

Taps for blind holes, M coarse, DIN 13, HSS-E, bright

Article no. 1012

d1 P mm tolerance d2 mm SW dk mm l1 mm l2 mm l3 mm Availability

M 2 0.40 OH2 3.00 2.5 1.600 40.0 4.0 15 •M 2.5 0.45 OH2 3.00 2.5 2.050 44.0 4.5 16 •M 3 0.50 OH2 4.00 3.2 2.500 46.0 5.0 19 •M 4 0.70 OH2 5.00 4.0 3.300 52.0 7.0 21 •M 5 0.80 OH2 5.50 4.5 4.200 60.0 8.0 24 •M 6 1.00 OH2 6.00 4.5 5.000 62.0 10.0 29 •M 8 1.25 OH2 6.20 5.0 6.800 70.0 12.5 37 •M10 1.50 OH2 7.00 5.5 8.500 75.0 15.0 41 •M12 1.75 OH3 8.50 6.5 10.200 82.0 17.5 48 •M14 2.00 OH3 10.50 8.0 12.000 88.0 20.0 48 •M16 2.00 OH3 12.50 10.0 14.000 95.0 20.0 52 •M18 2.50 OH4 14.00 11.0 15.500 100.0 25.0 55 •M20 2.50 OH4 15.00 12.0 17.500 105.0 25.0 58 •

Taps for blind holes, M coarse, DIN 13, HSS-E, TiN

Article no. 1013

d1 P mm tolerance d2 mm SW dk mm l1 mm l2 mm l3 mm Availability

M 2 0.40 OH2 3.00 2.5 1.600 40.0 4.0 15 •M 2.5 0.45 OH2 3.00 2.5 2.050 44.0 4.5 16 •M 3 0.50 OH2 4.00 3.2 2.500 46.0 5.0 19 •M 4 0.70 OH2 5.00 4.0 3.300 52.0 7.0 21 •M 5 0.80 OH2 5.50 4.5 4.200 60.0 8.0 24 •M 6 1.00 OH2 6.00 4.5 5.000 62.0 10.0 29 •M 8 1.25 OH2 6.20 5.0 6.800 70.0 12.5 37 •M10 1.50 OH2 7.00 5.5 8.500 75.0 15.0 41 •M12 1.75 OH3 8.50 6.5 10.200 82.0 17.5 48 •M14 2.00 OH3 10.50 8.0 12.000 88.0 20.0 48 •M16 2.00 OH3 12.50 10.0 14.000 95.0 20.0 52 •M18 2.50 OH4 14.00 11.0 15.500 100.0 25.0 55 •M20 2.50 OH4 15.00 12.0 17.500 105.0 25.0 58 •

5

d1

l1

SW

d2

l2dk

P

l3

d1

l1

SW

d2

l2dk

P

l3

JIS taps and fluteless taps

Fluteless taps for through and blind holes, M coarse, DIN 13, HSS-E, bright

Article no. 1016

d1 P mm tolerance d2 mm SW dk mm l1 mm l2 mm l3 mm Availability

M 2 0.40 RH4 3.00 2.5 1.85 40.0 4.0 15 •M 2.5 0.45 RH4 3.00 2.5 2.30 44.0 4.5 16 •M 3 0.50 RH5 4.00 3.2 2.80 46.0 5.0 19 •M 4 0.70 RH6 5.00 4.0 3.70 52.0 7.0 21 •M 5 0.80 RH6 5.50 4.5 4.65 60.0 8.0 24 •M 6 1.00 RH7 6.00 4.5 5.55 62.0 10.0 29 •M 8 1.25 RH7 6.20 5.0 7.40 70.0 12.5 37 •M10 1.50 RH7 7.00 5.5 9.30 75.0 15.0 41 •M12 1.75 RH8 8.50 6.5 11.20 82.0 17.5 48 •M14 2.00 RH10 10.50 8.0 13.10 88.0 20.0 48 •M16 2.00 RH10 12.50 10.0 15.10 95.0 20.0 52 •M18 2.50 RH11 14.00 11.0 16.90 100.0 25.0 55 •M20 2.50 RH11 15.00 12.0 18.90 105.0 25.0 58 •

Fluteless taps for through and blind holes, M coarse, DIN 13, HSS-E, TiN

Article no. 1017

d1 P mm tolerance d2 mm SW dk mm l1 mm l2 mm l3 mm Availability

M 2 0.40 RH4 3.00 2.5 1.85 40.0 4.0 15 •M 2.5 0.45 RH4 3.00 2.5 2.30 44.0 4.5 16 •M 3 0.50 RH5 4.00 3.2 2.80 46.0 5.0 19 •M 4 0.70 RH6 5.00 4.0 3.70 52.0 7.0 21 •M 5 0.80 RH6 5.50 4.5 4.65 60.0 8.0 24 •M 6 1.00 RH7 6.00 4.5 5.55 62.0 10.0 29 •M 8 1.25 RH7 6.20 5.0 7.40 70.0 12.5 37 •M10 1.50 RH7 7.00 5.5 9.30 75.0 15.0 41 •M12 1.75 RH8 8.50 6.5 11.20 82.0 17.5 48 •M14 2.00 RH10 10.50 8.0 13.10 88.0 20.0 48 •M16 2.00 RH10 12.50 10.0 15.10 95.0 20.0 52 •M18 2.50 RH11 14.00 11.0 16.90 100.0 25.0 55 •M20 2.50 RH11 15.00 12.0 18.90 105.0 25.0 58 •

6

JIS taps and fluteless taps

Materials and application recommendationsMaterial group Tensile strength

MPa (N/mm2)Hardness

HBCutting speed

vc (m/min)

Structural steels ≤ 850 – 15 - 20

Free-cutting steels ≤ 1000 – 15 - 20

Unalloyed case hardened steels ≤ 750 – 15 - 20

Unalloyed heat-treatable steels ≤ 850 – 15 - 20

Alloyed case hardened steels ≥ 850 … 1200 – 10 - 15

Alloyed heat-treatable steels ≥ 850 … 1200 – 10 - 15

Alloyed tool steels ≤ 1000 – 8 - 12

High speed tool steels ≥ 650 … 1000 – 8 - 12

Stainless- and acidresistant steels, sulphured ≤ 850 – 8 - 15

austenitic ≤ 850 – 8 - 15

martensitic ≤ 850 – 8 - 15

Structural steels ≤ 800 – 15 - 20

Free-cutting steels ≤ 1000 – 15 - 20

Case hardened steels ≤ 1000 – 15 - 20

Heat-treatable steels ≤ 1200 – 15 - 20

Nitriding steels ≤ 1200 – 15 - 20

Spheroidal graphite cast iron – ≤ 240 20 - 25

Aluminium und Al-alloys ≤ 400 – 20 - 25

Al wrought alloys ≤ 400 – 20 - 25

Alcast alloys ≤ 10 % Si ≤ 600 – 20 - 25

> 10 % Si ≤ 600 – 20 - 25

Cast iron – ≤ 240 20 - 25

Spheroidal graphite cast iron – ≤ 240 20 - 25

Malleable cast iron – < 300 20 - 25

Brass, short-chipping ≤ 600 – 15 - 20

long-chipping ≤ 600 – 15 - 20

Plastics – – 7 - 12

Magnesium-alloys ≤ 450 – 20 - 25

Titanium and Ti-alloys ≤ 1200 – 2 - 8

Ni-alloys ≤ 1200 – 2 - 8

7

40

80

20

60

100

0

+10

+25

OH1

+40

OH2

+55

OH3

+70

OH4

+85

OH5

+100

OH6

+56

ISO3

+8

+40

ISO2

+24

ISO1

80

160

40

120

0

+20

OH1

+40

OH2

+60

OH3

+80

OH4

+100

OH5

+120

OH6+98

ISO3

+14

+70

ISO2+42

ISO1

60

140

20

100

180

80

160

40

120

0

+13

RH1

+26

RH2

+39

RH3

+51

RH4

+64

RH5

+77

RH6

+56

ISO3

+8

+40

ISO2+24

ISO1

60

140

20

100

180

70

150

30

110

50

130

10

90

170

+89

RH7

+101

RH8

+114

RH9

+127

RH10

+140

RH11

+153

RH12

+98

ISO3

+14

+70

ISO2

+42

ISO1

JIS taps and fluteless taps

RH LIMITS FOR FLUTELESS TAPS

OH LIMITS FOR CUTTING TAPS

P ≤ 0.6 (T.P.I. ≥ 40)upper limit : 0.010+0.015×nlower limit : (upper limit) - 0.015Unit = mm / n = OH number

P ≥ 0.7 (T.P.I. ≥ 36)upper limit : 0.020×nlower limit : (upper limit) - 0.020Unit = mm / n = OH number

JIS LIMITS

OH LIMITS

JIS LIMITS

OH LIMITS

pitc

h di

a. µ

m

pitc

h di

a. µ

m

Pitch ≤ 0.6 Pitch ≥ 0.7

upper limit : 0.0127×nlower limit : 0.0127×n - 0.0127Unit = mm / n = RH number

JIS LIMITS

RH LIMITS

pitc

h di

a. µ

m

class 3

Pitch ≤ 0.6

Pitch ≥ 0.7

class 1

class 2

No liability can be accepted for printing errors or technical changes of any kind.Our Conditions of Sale and Terms of Payment apply. Available on request.The illustrations show optional equipment.

Drilling

Special tooling SolutionS

milling

Modular tooling systeMs

Tool resToraTion service

reaming PCDTapping/Thread milling/fluTeless Tapping

Countersinking/ de-burring

Guhring oHGP.O. Box 100247 • 72423 AlbstadtHerderstraße 50-54 • 72458 Albstadt

Tel. +49 74 31 17-0Fax +49 74 31 [email protected]

147

149/

1242

-III-

09 •

Prin

ted

in G

erm

any

• 20

12

![[PPT]No Slide Title - Wikispacesptec107.wikispaces.com/file/view/Flow_Measurement.ppt · Web viewFlange Taps Corner Taps Radius Taps Vena-Contracta Taps Pipe Taps Multivariable Pressure](https://static.fdocuments.us/doc/165x107/5ad6f9207f8b9a32618bb97e/pptno-slide-title-viewflange-taps-corner-taps-radius-taps-vena-contracta-taps.jpg)