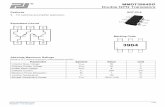

Talha Hassan Ayub 3904

-

Upload

umer-shaikh -

Category

Documents

-

view

217 -

download

0

Transcript of Talha Hassan Ayub 3904

-

8/2/2019 Talha Hassan Ayub 3904

1/6

MM.. TTaallhhaa HHaassssaann AAyyuubb

33990044

SSUUPPPPLLYYCCHHAAIINNMMAANNAAGGEEMMEENNTT

AAssssiiggnneemmnntt##11

-

8/2/2019 Talha Hassan Ayub 3904

2/6

RRoollee ooffBBaarrccooddee iinn WWaarreehhoouussee::

There are two main categories of bar codes, one-dimensional (1D) and two-dimensional (2D).

1D barcodes are the ones most familiar with and consist of many different codes including UPC,Code 128, Code 39, Interleaved 2 of 5, just to name a few (there can be variations within a given

symbology). The symbols used may be dictated by partners in the supply chain through aprogram of compliance with the standard label or, if only used internally, you can choose based

on a specific application (hint: if you are looking for a flexible symbology internal use of thedocuments, labels, plates, etc. Code 128 is a good choice). 2D barcode symbologies such as UPS

MaxiCode (right) are capable of storing more data than its 1D counterparts and require specialscanners to read them. Although one would expect to see continued growth in the use of 2D bar

codes, most applications the warehouse floor and the store will continue to use 1D, simplybecause the technology is less expensive and usually only takes enough data in the barcode to

access the associated records in your database inventory system. 1D codes are very capable of

doing this. If you are interested in more detailed information and barcode specificationsrecommend you get a copy of the book barcode by Roger C. Palmer.

AAddvvaannttaaggeess::

Speed

A bar code label of twelve characters can shovel in about the time it takes a keyboard operator

to make two keystrokes.

Precision

For every 1,000 characters typed by a keyboard operator, an average of ten keying errors. For

an optical character reader (OCR), there is an error in every 10,000 readings. With the wand,

the bar code systems in a focus error every 3,000,000 characters, and laser technology, which is

close to an error in 70 million entries.

Cost-Effectiveness

The bar code systems have demonstrated a recovery period of six to eighteen months, and

provide the highest level of reliability in a wide variety of data collection applications. The barcode systems create value not only saving time but also to avoid costly mistakes.

DDiissaaddvvaannttaaggeess::

Disadvantage of barcode system when it comes to change refers to changes in the workplace.

Many organizations that have been in business for many years really have been adjusted and

-

8/2/2019 Talha Hassan Ayub 3904

3/6

employees generally cover .... The only drawback is that data must be encoded in the barcode.

This may be an additional cost, however, the key to a bar code system is effective to generate the

barcode.

RRFFIIDD::

RFID is the reality for the storage industry. Everybody has been seeing to some degree - this

time directly in the business of the day to day or at industry events and magazines. And it seems

the whole world to vote something. Some vote for him to leave, while others voted for him to get

extended. No matter how you cast your vote, who is here to stay. This article will help you

discover what it means for you, your organization and the electrical industry.

What is RFID? Radio Frequency Identification is the process of wireless communication with

unique identifier tags (labels) to a reader (RF device). This will allow you to track product as it

moves through the supply chain. Ultimately, it could mean that products can reach the port and

not have to be the details received by an employee of the store.

A reader placed in the dock doors that identify each label either placed in a case, the master

package or pallet, and update its warehouse management software (WMS) system automatically

with the correct amounts . This means that each master case pack and pallet must be labeled

with an RFID tag. Before thinking about eliminating your receiving department, we will develop

in the process.

AAddvvaannttaaggeess::

RFID technology has a number of advantages.

RFID tags are very easy to install / inject inside the animal body, which helps youkeep track of them. This is useful in animal husbandry and poultry. Installed RFID

tags provide information about age, vaccines and animal health. RFID technology is better than bar codes because it can not be replicated easily and

therefore increases the safety of the product.

DDiissaaddvvaannttaaggeess ooffRRFFIIDD TTeecchhnnoollooggyy

RFID technology, although very beneficial, it is expensive to install. Small and medium-sized

companies find it expensive to use in their businesses and offices.

It is difficult for an RFID reader to read the information in the case of RFID tagsinstalled in the liquid and metal products. The problem is that the liquid metal

surfaces tend to reflect radio waves, making the labels unreadable. Labels must be

-

8/2/2019 Talha Hassan Ayub 3904

4/6

placed at different angles and alignments for taking appropriate reading. This is atedious task when the job is big business.

Interference was observed when devices such as forklifts and walkie-talkies are in thevicinity of distribution centers. The presence of cell towers has been found to interfere

with RFID radio waves. Wal-Mart, the retail giant, has installed thousands of

millions of RFID tags in its products worldwide and have found this type of problem.

VVooiiccee PPiicckkiinngg::

Voice technology uses voice recognition and voice synthesis to allow workers to communicate

with the Warehouse Management System (WMS). Warehouse operators to use a wireless

computer can be used with a headset and a microphone to receive voice instructions and

verbally confirm their actions back to the system. The laptop or voice terminal, communicates

with the warehouse management software through a radio frequency (RF) local area network

(LAN).

AAddvvaannttaaggeess::

no need topaper work and manual lists and saving paper cost

DDiissaaddvvaannttaaggeess::

Voice takes only few minutes in that we have to understand their commands

IINNTTRROODDUUCCTTIIOONNTTOO RRFFIIDD

Radio frequency identification (RFID) is used to identify the numbers. Objects and personswirelessly it can detect both human body and insulators this small technology is consist of small

antenna and microchip

AApppplliiccaattiioonn

By applying this technology we can access an individual who has the authority to access theoffice building and area

In ware house application we came to know that which shelf requires needed product

BBeenneeffiittss

Inter communication would be easy Wide range accessibility

-

8/2/2019 Talha Hassan Ayub 3904

5/6

DDiissaaddvvaannttaaggeess

Multiple tags can be mixed out It is still expensive as compared to the bare codes

IINNTTRROODDUUCCTTIIOONNOOFFEERRPPSSYYSSTTEEMM

This is a kind of business software program that inter linked all the department like finance,human resources and ware house department. Every department using ERP system in according

to their need and every department can easily share their information to each other this is only aone click approach in that you can connect them

AApppplliiccaattiioonnss

This system can apply in the ware house or many other departments in which we can easily tracethat where our product lies this software is implemented millions

BBeenneeffiittss

They can easily interact with each other Productive changes occurs Check and balance system become easier in that way It developed a customer relationship Very lesser error takes

DDiissaaddvvaannttaaggeess

Without changes if they are working in which they were doing before it will becomeuseless

Every employee should aware of using this software This system is not handled the up front product process

IINNTTRROODDUUCCTTIIOONNOORR MMRRPP

This is kind of planning to raw material till finished goods this is all computerized and its usedto manage manufacture process to control and manage the demand it also manage that what

amount of raw material a company requires by doing this it help us to reduced inventory cost

AApppplliiccaattiioonnss

MRP applies in inventory department to determine the actual need of raw material andpurchasing department and having different purpose for every department

-

8/2/2019 Talha Hassan Ayub 3904

6/6

BBeenneeffiittss

Best order fulfilling Plan for future needs of raw materials

DDiissaaddvvaannttaaggeess

Wrong information can b misleading and pay huge cost Over stock can b takes place

IINNTTRROODDUUCCTTIIOONNOORR MMRRPPIIII

This is all about the new version of MRB andMRP II is linked with human resources, financing,marketing, and engineering. It included the additional data The role of (MRP 2) in the supply

chain management is to identify manufacturing information. How we can make its better for the

production process. This system forecast about the planning that how to make long planning forfurther manufacturing.

AApppplliiccaattiioonn

We apply this soft ware in the production department specially but this is addressing they

financial area as well and in the decision making strategies this will address the queries of the

employee and the suppliers

BBeenneeffiittss

They came to know how can they b the best in production planning This is the competitive component for the company Other than that the efficient labor and perfect time usage

DDiissaaddvvaannttaaggeess

Expensive and high cost consuming If the poor information will b used they have to pay high amount