TAB B - docs2.cer-rec.gc.ca

Transcript of TAB B - docs2.cer-rec.gc.ca

NOVA Gas Transmission Ltd. North Central Corridor Loop (North Star Section 1)

Order XG-028-2019

Application for Leave to Open

TAB B

Hydrotest Summary Report

Schematic of Pressure-Tested Facilities

Summary of Non Pressure-Tested Welds

TC Energy Standards, Specifications and Procedures

NOVA Gas Transmission Ltd. North Central Corridor Loop (North Star Section 1)

Order XG-028-2019 Application for Leave to Open

March 2020

GENERAL SUMMARY

The Project is located entirely on Crown land within the Counties of Northern Lights and Clear Hills County, located approximately 25 km northwest of Manning, Alberta, and consists of approximately 31.1 km NPS 48 pipe. The Project has a MOP of 9,930 kPa.

With this submission, NGTL is providing the LTO application for the Project pursuant to section 213 of the CER Act. The mainline section, security pipe, fabrication assemblies, and final tie-in assemblies have been hydrostatically pressure tested in ten separate hydrostatic tests: • Primary Test Sections (NPS48-NCCL-NS1-SEC1, NPS48-NCCL-NS1-SEC2,

NPS48-NCC-NS1-MEIKLE) • Security Pipe Test Section (2019S-NCCL-NS1-01) • Field Assembly Secondary Test (2019S-NCCL-NS1-03) • Shop Secondary Tests (2019S-01, 2019S-02, 2019S-05, 2019S-14, and 2019S-18)

Table 1: Pipe Manufacturer Information Pipe Description Manufacturer

NPS 56 x 25.4 mm WT, Grade 483, CAT II, -45°C JFE Steel Corporation Japan NPS 48 x 26.2 mm WT, Grade 483, CAT II, -45°C JFE Steel Corporation Japan NPS 48 x 25.4 mm WT, Grade 483, CAT II, -5°C Welspun India NPS 48 x 15.9 mm WT, Grade 483, CAT II, -5°C Evraz Canada NPS 42 x 23.0 mm WT, Grade 483, CAT II, -45°C Sumitomo Metal Japan & JFE Steel

Corporation Japan NPS 36 x 19.7 mm WT, Grade 483, CAT II, -45°C JFE Steel Corporation Japan NPS 16 x 14.3 mm WT, Grade 414, CAT II, -45°C Nippon Steel Japan NPS 12 x 12.7 mm WT, ASTM A333 Grade 6 Seamless Nippon Steel Japan & Tenaris Italy NPS 4 x 6.0 mm WT, ASTM A333 Grade 6, Seamless Tenaris, Italy NPS 2 x 5.5 mm WT, ASTM A106 Grade B Seamless Tenaris Italy NPS 1 ½ x 5.1 mm WT, ASTM A106 Grade B Cap Products Canada, Benteler Steel

Germany, & Vallourec Brazil NPS 1 x 4.5 mm WT, ASTM A106 Grade B Benteler Steel Germany

Page 1 of 17

NOVA Gas Transmission Ltd. North Central Corridor Loop (North Star Section 1)

Order XG-028-2019 Application for Leave to Open

March 2020

Table 2: Hydrostatic Test Data Summaries

Mainline Primary Hydrostatic Test #1 Test Number: NPS48-NCCL-NS1-SEC1 Pipe Data: NPS 48 x 26.2 mm WT, Grade 483, CAT II, -45°C

NPS 48 x 25.4 mm WT, Grade 483, CAT II, -5°C NPS 48 x 15.9 mm WT, Grade 483, CAT II, -5°C

Test Medium: Water Maximum Operating Pressure: 9,930 kPa 100% Specified Minimum Yield Strength (SMYS):

12,600 kPa

110% SMYS: 13,858 kPa Maximum Strength Test Pressure (Critical Low Point):

13,858 kPa (theoretical)

Minimum Strength Test Pressure (High Point)

12,413 kPa (theoretical)

Achieved Pressure at High Point (Qualification Pressure):

12,706 kPa

Achieved Pressure at Test Location (Strength Test):

Min: 12,706 kPa Max: 12,725 kPa

Achieved Pressure at Test Location (Leak Test):

Min: 11,218 kPa Max: 11,232 kPa

Testing Supervisor: Wayne Howarth Mainline Primary Hydrostatic Test #2 Test Number: NPS48-NCCL-NS1-SEC2 Pipe Data: NPS 48 x 26.2 mm WT, Grade 483, CAT II, -45°C

NPS 48 x 25.4 mm WT, Grade 483, CAT II, -5°C NPS 48 x 15.9 mm WT, Grade 483, CAT II, -5°C

Test Medium: Water Maximum Operating Pressure: 9,930 kPa 100% Specified Minimum Yield Strength (SMYS):

12,600 kPa

110% SMYS: 13,858 kPa Maximum Strength Test Pressure (Critical Low Point):

13,858 kPa (theoretical)

Minimum Strength Test Pressure (High Point)

12,413 kPa (theoretical)

Achieved Pressure at High Point (Qualification Pressure):

12,690 kPa

Achieved Pressure at Test Location (Strength Test):

Min: 13,731 kPa Max: 13,753 kPa

Achieved Pressure at Test Location (Leak Test):

Min: 12,264 kPa Max: 12,266 kPa

Testing Supervisor: Wayne Howarth

Page 2 of 17

NOVA Gas Transmission Ltd. North Central Corridor Loop (North Star Section 1)

Order XG-028-2019 Application for Leave to Open

March 2020

Table 2: Hydrostatic Test Data Summaries (cont’d)

Primary Hydrostatic Test – Meikle Compressor Station Test Number: NPS48-NCCL-NS1-MEIKLE Pipe Data: NPS 56 x 25.4 mm WT, Grade 483, CAT II, -45°C

NPS 48 x 26.2 mm WT, Grade 483, CAT II, -45°C NPS 42 x 23.0 mm WT, Grade 483, CAT II, -45°C NPS 16 x 14.3 mm WT, Grade 414, CAT II, -45°C NPS 2 x 5.5 mm WT, ASTM A106 Grade B Seamless NPS 1 ½ x 5.1 mm WT, ASTM A106 Grade B NPS 1 x 4.5 mm WT, ASTM A106 Grade B

Test Medium: Water Maximum Operating Pressure: 9,930 kPa 100% Specified Minimum Yield Strength (SMYS):

17,254 kPa

110% SMYS: 18,980 kPa Maximum Strength Test Pressure (Critical Low Point):

14,895 kPa (theoretical)*

Minimum Strength Test Pressure (High Point)

12,413 kPa (theoretical)

Achieved Pressure at High Point (Qualification Pressure):

12,701 kPa

Achieved Pressure at Test Location (Strength Test):

Min: 12,750 kPa Max: 12,847 kPa

Achieved Pressure at Test Location (Leak Test):

Min: 11,303 kPa Max: 11,313 kPa

Testing Supervisor: Wayne Howarth * Limiting maximum test pressure to 1.5 x PN100 flange rating.

Page 3 of 17

NOVA Gas Transmission Ltd. North Central Corridor Loop (North Star Section 1)

Order XG-028-2019 Application for Leave to Open

March 2020

Table 2: Hydrostatic Test Data Summaries (cont’d)

Security Pipe Secondary Hydrostatic Test Test Number: 2019S-NCCL-NS1-01 Pipe Data: NPS 48 x 25.4 mm WT, Grade 483, CAT II, -5°C*

NPS 48 x 15.9 mm WT, Grade 483, CAT II, -5°C Test Medium: Water Test Location: Midwest Construction Yard (SE 04-094-23 W5M) Maximum Operating Pressure: 9,930 kPa Allowable Test Pressure: Min: 12,413 kPa Max: 12,598 kPa Achieved Pressure: Min: 12,520 kPa Max: 12,525 kPa Testing Supervisor: Wayne Howarth * denotes security pipe utilized for FT-007 to FT-010

Fabrication Secondary Hydrostatic Test Test Number: 2019S-NCCL-NS1-03 Pipe Data: NPS 48 x 26.2 mm WT, Grade 483, CAT II, -45°C

NPS 36 x 19.7 mm WT, Grade 483, CAT II, -45°C NPS 12 x 12.7 mm WT, ASTM A333 Grade 6 Seamless NPS 2 x 5.5 mm WT, ASTM A106 Grade B Seamless NPS 1 ½ x 5.1 mm WT, ASTM A106 Grade B NPS 1 x 4.5 mm WT, ASTM A106 Grade B

Test Medium: Water / Methanol Mixture (70% Water / 30% Methanol) Test Location: NCCA100-0-BV Valve Site (NW 36-093-24 W5M) Maximum Operating Pressure: 9,930 kPa Allowable Test Pressure: Min: 12,413 kPa Max: 18,899 kPa Achieved Pressure: Min: 12,758 kPa Max: 12,860 kPa Testing Supervisor: Wayne Howarth

Page 4 of 17

NOVA Gas Transmission Ltd. North Central Corridor Loop (North Star Section 1)

Order XG-028-2019 Application for Leave to Open

March 2020

Table 2: Hydrostatic Test Data Summaries (cont’d)

Shop Secondary Hydrostatic Tests Test Number: 2019S-01 Spool Control Numbers: CN 12 Pipe Data: NPS 36 x 19.7 mm WT, Grade 483, CAT II, -45°C Test Medium: Water Test Location: Academy Fabricators Inc. Onoway, Alberta MOP: 9,930 kPa Allowable Test Pressure: Min.: 12,413 kPa Max.: 20,821 kPa Achieved Pressure: Min.: 12,540 kPa Max.: 12,556 kPa Testing Supervisor: Brian Hegberg

Shop Secondary Hydrostatic Tests Test Number: 2019S-02 Spool Control Numbers: CN 11 Pipe Data: NPS 36 x 19.7 mm WT, Grade 483, CAT II, -45°C Test Medium: Water Test Location: Academy Fabricators Inc. Onoway, Alberta MOP: 9,930 kPa Allowable Test Pressure: Min.: 12,413 kPa Max.: 20,821 kPa Achieved Pressure: Min.: 12,524 kPa Max.: 12,552 kPa Testing Supervisor: Brian Hegberg

Shop Secondary Hydrostatic Tests Test Number: 2019S-05 Spool Control Numbers: CN 51 Pipe Data: NPS 4 x 6.0 mm WT, ASTM A333 Grade 6, Seamless Test Medium: Water Test Location: Academy Fabricators Inc. Onoway, Alberta MOP: 9,930 kPa Allowable Test Pressure: Min.: 12,413 kPa Max.: 25,197 kPa Achieved Pressure: Min.: 12,614 kPa Max.: 12,638 kPa Testing Supervisor: Brian Hegberg

Page 5 of 17

NOVA Gas Transmission Ltd. North Central Corridor Loop (North Star Section 1)

Order XG-028-2019 Application for Leave to Open

March 2020

Shop Secondary Hydrostatic Tests Test Number: 2019S-14 Spool Control Numbers: CN 13, 16, 17, and 18

Pipe Data: NPS 36 x 19.7 mm WT, Grade 483, CAT II, -45°C NPS 1 ½ x 5.1 mm WT, ASTM A106 Grade B NPS 1 x 4.5 mm WT, ASTM A106 Grade B

Test Medium: Water Test Location: Academy Fabricators Inc. Onoway, Alberta MOP: 9,930 kPa Allowable Test Pressure: Min.: 12,413 kPa Max.: 20, 821 kPa Achieved Pressure: Min.: 12,561 kPa Max.: 12,653 kPa Testing Supervisor: Brian Hegberg

Shop Secondary Hydrostatic Tests Test Number: 2019S-18 Spool Control Numbers: CN 03 Pipe Data: NPS 36, 19.7 mm WT, Grade 483 CAT II, -45°C Test Medium: Water Test Location: Academy Fabricators Inc. Onoway, Alberta MOP: 9,930 kPa Allowable Test Pressure: Min.: 12,413 kPa Max.: 20,821 kPa Achieved Pressure: Min.: 12,561 kPa Max.: 12,574 kPa Testing Supervisor: Brian Hegberg

Page 6 of 17

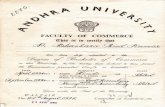

FT-009

FT-008 FT-007

FT-005

FT-006

FT-010

Field Primary Mainline Pressure TestTest Number: NPS48-NCCL-NS1-SEC1

Field Primary Mainline Pressure TestTest Number: NPS48-NCCL-NS1-SEC2

Shop Secondary TestTest Number: 2019S-05

Field Primary TestTest Number: 2019-NCCL-NS1-MEIKLE

Field Secondary TestTest Number: 2019S-NCCL-NS1-03

Shop Secondary TestTest Number: 2019S-14

Security Pipe Secondary Pressure TestTest Number: 2019S-NCCL-NS1-01

Shop Secondary TestTest Number: 2019S-18

FT-001

FT-004

FT-002

Shop Secondary TestTest Number: 2019S-02

Shop Secondary TestTest Number: 2019S-01

FT-003

NOVA Gas Transmission Ltd. North Central Corridor Loop (North Star Section 1)

Order XG-028-2019 Application for Leave to Open

March 2020 Page 7 of 17

Field Secondary TestTest Number: 2019S-NCCL-NS1-03

CN-16Shop Secondary Test

Test Number: 2019S-14

Mainline Pressure TestTest Number: NPS48-NCCL-NS1-SEC1

MAINLINE SECTION 1CONTINUES

CN-03Shop Secondary Test

Test Number: 2019S-18

CN-11Shop Secondary Test

Test Number: 2019S-02

CN-12Shop Secondary Test

Test Number: 2019S-01

FT-003FT-003

FT-001FT-004FT-002

FT-005

FT-006

CN-17Shop Secondary Test

Test Number: 2019S-14

CN-13Shop Secondary Test

Test Number: 2019S-14

CN-18Shop Secondary Test

Test Number: 2019S-14

NOVA Gas Transmission Ltd. North Central Corridor Loop (North Star Section 1)

Order XG-028-2019 Application for Leave to Open

March 2020 Page 8 of 17

Field Primary TestTest Number: 2019-NCCL-NS1-MEIKLE

Field Secondary Test of Meikle Continues

Field Secondary Test of Meikle Continues

NOVA Gas Transmission Ltd. North Central Corridor Loop (North Star Section 1)

Order XG-028-2019 Application for Leave to Open

March 2020 Page 9 of 17

LEFT305

Field Secondary TestTest Number: 2020S-NCCL-NS1-MEIKLE

Mainline Pressure TestTest Number: NPS48-NCCL-NS1-SEC2

MAINLINE SECTION 2 CONTINUES

Security Pipe Secondary Pressure TestTest Number: 2019S-NCCL-NS1-01

FT-010

FT-009

NOVA Gas Transmission Ltd. North Central Corridor Loop (North Star Section 1)

Order XG-028-2019 Application for Leave to Open

March 2020 Page 10 of 17

CN-51Shop Secondary Test

Test Number: 2019S-05

NOVA Gas Transmission Ltd. North Central Corridor Loop (North Star Section 1)

Order XG-028-2019 Application for Leave to Open

March 2020Page 11 of 17

NOVA Gas Transmission Ltd. North Central Corridor Loop (North Star Section 1)

Order XG-028-2019

Application for Leave to Open

March 2020

Table 3 provides justification for all piping and welds which were not subjected to pressure testing following installation.

Table 3: Summary of All Piping and Welds Not Subjected to a Pressure Test Following Installation and Justification for not Pressure Testing

Untested Field Weld

Number Hydrotest Number

Pre-Fabricated

Spool Number Justification

FT-001 2019S-02 CN-11 Alignment of piping to meet the requirements of the design code to produce stress free welds can result in the need for non-pressure tested welds to allow sufficient adjustability to achieve compliant alignment. Where the specified welding alignment cannot be achieved without placing excessive external forces on the pipe, additional non-pressure tested welds are required.

Item has been shop tested and a field hydrotest is considered redundant to the shop test as it will not provide additional information.

See 18496-01-ML-04-001 in Tab B. FT-002 2019S-01 CN-12 Non-pressure tested weld required to tie-in new crossover

pipe to an existing facility (hot tap valve assembly). Items have been shop tested and a field hydrotest is considered redundant to the shop test as it will not provide additional information.

See 18496-01-ML-04-001 in Tab B. FT-003 2019S-01

2019S-14 CN-12 CN-13

Alignment of piping to meet the requirements of the design code to produce stress free welds can result in the need for non-pressure tested welds to allow sufficient adjustability to achieve compliant alignment. Where the specified welding alignment cannot be achieved without placing excessive external forces on the pipe, additional non-pressure tested welds are required.

Item has been shop tested and a field hydrotest is considered redundant to the shop test as it will not provide additional information.

See 18496-01-ML-04-001 in Tab B. FT-004 2019S-01

2019S-02 CN-12 CN-11

Alignment of piping to meet the requirements of the design code to produce stress free welds can result in the need for non-pressure tested welds to allow sufficient adjustability to achieve compliant alignment. Where the specified welding alignment cannot be achieved without placing excessive external forces on the pipe, additional non-pressure tested welds are required.

Item has been shop tested and a field hydrotest is considered redundant to the shop test as it will not provide additional information.

See 18496-01-ML-04-001 in Tab B.

Page 12 of 17

NOVA Gas Transmission Ltd. North Central Corridor Loop (North Star Section 1)

Order XG-028-2019

Application for Leave to Open

March 2020

Table 3: Summary of All Piping, Welds, and Valves Not Subjected to a Pressure Test Following Installation and Justification for not Pressure Testing (cont’d)

Untested Field Weld

Number Hydrotest Number Pre-Fabricated Spool Number Justification

FT-005 2019S-18 CN-03 By necessity, where field pressure testing is performed, space is required to accommodate the required test heads or test caps. Following the test, the head or cap is removed and replaced with a pre-tested pipe piece to make the final connections to other parts of the new facility, resulting in a non-pressure tested field weld.

No modifications were made to the shop-tested final tie-in pipe after testing was completed.

See 18496-01-ML-04-001 in Tab B. FT-006 2019S-18 CN-03 By necessity, where field pressure testing is performed,

space is required to accommodate the required test heads or test caps. Following the test, the head or cap is removed and replaced with a pre-tested pipe piece to make the final connections to other parts of the new facility, resulting in a non-pressure tested field weld.

No modifications were made to the shop-tested final tie-in pipe after testing was completed.

See 18496-01-ML-04-001 in Tab B. FT-007 2019S-NCCL-NS1-01 Security Pipe

(NPS 48, 25.4mm WT, GR 483)

By necessity, where field pressure testing is performed, space is required to accommodate the required test heads or test caps. Following the test, the head or cap is removed and replaced with security pipe/previously tested pipe piece to make the final connections to other parts of the new facility, resulting in a non-pressure tested field weld. The security pipe was tested as part of a secondary field hydrostatic test 2019S-NCCL-NS1-01.

No modifications were made to the field-tested final tie-in pipe after testing was completed.

See 18496-01-ML-04-003 in Tab B. FT-008 2019S-NCCL-NS1-01 Security Pipe

(NPS 48, 25.4mm WT, GR 483)

By necessity, where field pressure testing is performed, space is required to accommodate the required test heads or test caps. Following the test, the head or cap is removed and replaced with security pipe/previously tested pipe piece to make the final connections to other parts of the new facility, resulting in a non-pressure tested field weld. The security pipe was tested as part of a secondary field hydrostatic test 2019S-NCCL-NS1-01.

No modifications were made to the field-tested final tie-in pipe after testing was completed.

See 18496-01-ML-04-003 in Tab B.

Page 13 of 17

NOVA Gas Transmission Ltd. North Central Corridor Loop (North Star Section 1)

Order XG-028-2019

Application for Leave to Open

March 2020

Table 3: Summary of All Piping, Welds, and Valves Not Subjected to a Pressure Test Following Installation and Justification for not Pressure Testing (cont’d)

Untested Field Weld

Number Hydrotest Number Pre-Fabricated Spool Number Justification

FT-009 2019S-NCCL-NS1-01 Security Pipe (NPS 48, 25.4mm WT, GR 483)

By necessity, where field pressure testing is performed, space is required to accommodate the required test heads or test caps. Following the test, the head or cap is removed and replaced with security pipe/previously tested pipe piece to make the final connections to other parts of the new facility, resulting in a non-pressure tested field weld. The security pipe was tested as part of a secondary field hydrostatic test 2019S-NCCL-NS1-01.

No modifications were made to the field-tested final tie-in pipe after testing was completed.

See 18496-01-ML-04-003 in Tab B. FT-010 2019S-NCCL-NS1-01 Security Pipe

(NPS 48, 25.4mm WT, GR 483)

By necessity, where field pressure testing is performed, space is required to accommodate the required test heads or test caps. Following the test, the head or cap is removed and replaced with security pipe/previously tested pipe piece to make the final connections to other parts of the new facility, resulting in a non-pressure tested field weld. The security pipe was tested as part of a secondary field hydrostatic test 2019S-NCCL-NS1-01.

No modifications were made to the field-tested final tie-in pipe after testing was completed. See 18496-01-ML-04-003 in Tab B.

Page 14 of 17

NOVA Gas Transmission Ltd. North Central Corridor Loop (North Star Section 1)

Order XG-028-2019

Application for Leave to Open

March 2020

Table 4: TC Energy Standards, Specifications and Procedures

Name EDMS No. CORROSION PREVENTION TEN-CP-BUILD-GL Corrosion Prevention Construction Standard 1003439376 TEN-CP-DESGN-GL Corrosion Prevention Design Standard 1003455877 TES-CP-COM Cathodic Protection Commissioning Specification 6878838 TEN-CP-DELVR-GL Corrosion Prevention Execution & Deliverables Standard 1003441144 COATING TES-CO-CAD-GL Thermite Weld Coating on Steel Pipeline (CAN-US-MEX) 3672126 TES-CO-EPU-GL Field-Applied External Liquid Coating Systems for Steel Pipe Specification (CAN-US-MEX) 3671710

TES-CO-FBE-GL External Fusion Bond Epoxy for Steel Pipe Specification (CAN-US-MEX) 3670892 TES-CO-PAINT-GL Paint Systems for Above Ground Facilities (Coastal an Non-Coastal) Specification (CAN-US-MEX) 3694704

TES-CO-PET-GL Application of Petrolatum Tape Coating Specification (CAN-US-MEX) 7756 MATERIALS TES-FITG-CIF Contoured Insert Fittings Specification (CDN-US-MEX) 4424021 TES-FITG-EC1 End Closures Specification (CDN-US-MEX) 3779256 TES-FITG-SAD Full Encirclement Reinforcing Saddles Specification (CDN-US-MEX) 3779258 TES-MA-EWPI-GL Electric-Welded Pipe Specification (CAN-US-MEX) 3670788 TES-MA-FITG-GL Carbon Steel Butt-Welding Fittings Specification (CAN-US-MEX) 3671270 TES-MA-FLGEC-GL Carbon Steel Butt-Welding Flanges Specification (CAN) 3671966 TES-MA-SAWPI-GL Double Submerged Arc Welded Pipe Specification (CAN-US-MEX) 3776714 TES-MA-BEND-GL Induction Bends Specification 8194414 TED-MATL-FRAC Materials Fracture Control Plan 7076183 TES-MATL-COMP Materials Requirements of Pressure Containing Equipment Components Specification (CDN-US-MEX)

8071725

TES-MATL-MD1 Piping System Materials for Pipeline, Compression and Metering Facilities 3764909

TES-MA-VALV-G Steel Valves for Gas Service Specification (CAN-US-MEX) 1001891682 MECHANICAL TED-INT-LR Launcher and Receiver Installation and Initial Assessment Technical Directive (CDN-US-MEX)

8098412

TEN-ME-PWT-GL Pipe Wall Thickness Design Standard (CAN-US-MEX) 1009372841 TEN-ME-TH-GL Test Head Assemblies Design Standard (CAN-US-MEX) 1008074465 TEP-ME-VALFB-GL Valve Assembly Fabrication Procedure (CAN-US-MEX) 5741242 TEN-ME-TH-GL Test Head Assemblies Design Standard (CAN-US-MEX) 1008074465 TEN-ME-VENT-G Blowdown Sizing and Venting Times Standard (CAN-US-MEX) 1008095242

Page 15 of 17

NOVA Gas Transmission Ltd. North Central Corridor Loop (North Star Section 1)

Order XG-028-2019

Application for Leave to Open

March 2020

Table 4: TC Energy Standards, Specifications and Procedures (cont’d)

Name EDMS No. MECHANICAL (cont’d) TEP-ME-CLOS-GLE Closure Weld Procedure (CAN) 3670675 TEP-ME-VALFB-GL Valve Assembly Fabrication Procedure (CAN-US-MEX) 5741242 TES-MECH-LIQ-LR Launcher and Receiver Station Design Specification (CDN-US-MEX) 7911970 TES-FITG-T01 Instrument Tube Fitting, Instrument Pipe Fitting and Tubing Material Specification 3697116 TES-ME-FBT-GL Flange Bolt Tightening Specification (CAN-US-MEX) 6489784 TEN-ME-ASSEM-G Assembly Design and Fabrication for Gas Pipelines Standard (CAN-US-MEX) 1008074422

TES-ME-HDD-GL HDD Design and Construction Specification (CAN-US-MEX) 1003103090 TES-ME-STRTN-GL Design and Fabrication of Butt-Welded Transition Joints Specification (CAN-US-MEX)

6256

TES-ME-VOP-G Gas Hydraulic and Gas Pneumatic Operator Specification (CAN) 3671784 STRESS ANALYSIS & BUOYANCY CONTROL TEN-ME-BUOY-GL Buoyancy Control Design and Construction Standard (CAN US MEX) 1011213988 TES-ME-STRHO-GL Pipe Stress Engineering Analysis and Design of Hot Tap Branch Connections

7913244

TES-ME-STRPI-GL Pipeline Stress Analysis Specification 1005882376 TEP-WELD-ECA Engineering Critical Assessment of Girth Welds 7754064 TES-ME-STRPA-GL Pipe Stress Engineering Analysis and Design of Pipeline Assemblies Specification (CAN-US-MEX)

7808806

CIVIL & STRUCTURAL TES-CI-EARTH-GLE Facility Earthwork Specification (CAN-US) 6457 TES-CI-STDES-GLE Structural Design Specification 8040018 TES-CI-CONC-GLE Concrete Specification 6466 TES-CI-SPILE-GLE Driven Steel Pile Specification (CAN-US) 6459 TES-CI-STEEL-GLE Structural Steel and Miscellaneous Metals Specification (CAN) 6488 TES-DV32-3115 Portable Chain Link Fence 3744430 CONSTRUCTION TES-CT-BLAST-GL Pipeline and Construction Blasting Specification (CAN-US-MEX) 3672450 TES-CT-TAS-GL Temporary Access Roads Specification (CAN-US-MEX) 8960813 TES-CT-COMPC-GL Compaction Control Measures for Pipeline Excavations Specification (CAN-US-MEX)

5974567

TES-CT-GEN-GL Pipeline Construction Specification (CAN) 3745282 TES-CT-SLOPE-GL Slope Work Specification 9199892 TES-CT-OHP-GL Overhead Powerline Specification (CAN-US-MEX) 6179816 TES-CT-THSSP-GL Transportation, Handling and Stockpiling of Steel Pipe and Pipe Assemblies Specification (CAN-US-MEX) 5415573

Page 16 of 17

NOVA Gas Transmission Ltd. North Central Corridor Loop (North Star Section 1)

Order XG-028-2019

Application for Leave to Open

March 2020

Table 4: TC Energy Standards, Specifications and Procedures (cont’d)

Name EDMS No. CONSTRUCTION (cont’d) TES-ILI-DEF Specification for Deformation In-Line Inspection Technologies (CDN-US-MEX) 6980231

TES-CT-EXC-GLE Excavation Specification (CDN-US-MEX) 5890120 TES-PROJ-ROW Right of Way Specification (CDN) 6363243 WELDING TES-WELD-PL Welding of Pipelines and Tie-ins Specification (CDN) 3670960 TEP-WELD-ABR Removal of Arc Burns (New and Existing Piping Facilities) (CDN) 3670959 TEP-WELD-DEMAG Demagnetization of Pipe Ends in Preparation for a Tie-in Weld (CDN-US-MEX)

5876519

TES-INSERV-CSA Welding on In-Service Pipelines Specification (CDN) 3886791 TES-WL-AS-GL Welding of Assemblies and Station Piping Specification (CAN) 3670962 NON-DESTRUCTIVE EXAMINATION TEN-NDT NDT Standard (CDN-US-MEX) 1001828336 TEP-NDT-ADT Procedure for Non-destructive Examination (NDE) Audits (CDN-US-MEX) 3797402 TEP-NDT-VT Visual Examination 7381161 TES-NDT-PA Phased Array & TOFD Inspections of Welds and Materials 9219103 TES-NDT-RT Radiographic Examination of Welds Specification (CDN) 3671368 TES-NDT-UT Ultrasonic Examination of Girth Welds Specification (CDN) 1001829033 HYDROSTATIC TESTING TEN-PRES Pressure Testing Standard (CDN) 1001810598 TEP-PRES Pipeline and Facility Piping Pressure Testing Procedure (CDN) 1001810622 TES-PRES Pipeline and Facility Piping Pressure Testing Specification (CDN) 1001810638 DRAFTING TES-DR-3DSTD-GLE 3D Model Specification 1004347387 TES-DR-2DSTD-GLE 2D Drawings Specification 1003041252 TEP-DR-REDLN-GLE Engineering Drawings Redlining Specification 1003041205

Page 17 of 17