T1 - DWA Construct

Transcript of T1 - DWA Construct

NO

TE

3

NO

TE

5

"D

"

NO

TE

3

NO

TE

5

NOTE 3NOTE 5

NOTE 5

NOTE 3

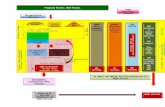

TYPICAL HORIZONTAL WALL

REINFORCING AS SHOWN ON

DRAWINGS, LAP WITH

CORNER AND INTERSECTION

REINFORCING

NOTE 3

NOTE 5

"D"

STD HOOK OR AS

NOTED ON THE DWGS

"D"

STD ACI-318 90°

HOOK OR AS NOTED

ON THE DWGS

"A" BARS SEE PLANS

"B" BARS

"C" BARS

"E" BARS

"D" BARS

"F" BARS

"G" BARS

© COPYRIGHT DESIGN WEST ARCHITECTS 201854321

A

B

D

C

desi

gn w

est

arch

itect

s25

5 SO

UTH

300

WES

T79

5 NO

RTH

400

WES

TLO

GAN

UT

843

21SA

LT L

AKE

CITY

UT

841

03

PROJECT #:

DRAWN BY:

CHECKED BY:

ISSUED:

MARK

:DA

TE:

DESC

RIPT

ION:

THE

CHUR

CH O

F JE

SUS

CHRI

ST O

F LA

TTER

-DAY

SAI

NTS

218036

05.08.2019

BID

SET

S

STE

TA

UTRS CT

R P

UR

F OE

G

OF UT HA

ERE

NI

NISO

L

EN

A LA

No. 295553RASMUSSENCRAIGL.

05/08/19

GARD

EN C

ITY

ASSE

MBL

Y HA

LL10

0 SO

UTH

PARA

DISE

PAR

KWAY

, GAR

DEN

CITY

, UT

1. ALL DESIGN, CONSTRUCTION, AND INSPECTION SHALL BE IN CONFORMANCE

WITH THE 2015 INTERNATIONAL BUILDING CODE (IBC) AND REFERENCED

STANDARDS.

2. THE CONTRACTOR SHALL VERIFY ALL DIMENSIONS AND CONDITIONS AT THE

SITE.

3. ALL OMISSIONS OR CONFLICTS BETWEEN THE VARIOUS ELEMENTS OF THE

WORKING DRAWINGS AND/OR SPECIFICATIONS SHALL BE BROUGHT TO THE

ATTENTION OF THE ENGINEER BEFORE PROCEEDING WITH ANY WORK

INVOLVED.

4. DRAWINGS INDICATE THE FINISHED PRODUCT. THEY DO NOT INDICATE A

METHOD OF CONSTRUCTION. CONTRACTOR SHALL TAKE ALL PRECAUTIONS

NECESSARY TO PROTECT THE STRUCTURE DURING CONSTRUCTION. SUCH

PRECAUTIONS SHALL INCLUDE, BUT NOT BE LIMITED TO, BRACING, SHORING

FOR CONSTRUCTION EQUIPMENT, ETC..

5. THE CONTRACTOR SHALL BE RESPONSIBLE FOR COMPENSATING THE OWNER

FOR ANY CHANGES MADE AS A RESULT OF A DEVIATION FROM THE CONTRACT

DOCUMENTS, DEVIATION FROM THE SPECIFICATIONS, FAULTY MATERIALS, OR

FAULTY WORKMANSHIP.

6. OPTIONS ARE FOR THE CONTRACTOR'S CONVENIENCE. THE CONTRACTOR

SHALL BE RESPONSIBLE FOR COORDINATING ALL REQUIRED DESIGN CHANGES.

COST ASSOCIATED WITH ANY DESIGN WORK INITIATED BY THE OPTION SHALL

BE BORN BY THE CONTRACTOR.

7. CONTRACTOR SHALL BE RESPONSIBLE FOR SAFETY AND PROTECTION WITHIN

AND ADJACENT TO THE JOB SITE.

8. TEMPORARY SHORING AND BRACING SHALL BE PROVIDED WHEREVER

NECESSARY TO TAKE CARE OF ALL LOADS TO WHICH THE STRUCTURE MAY BE

SUBJECTED INCLUDING WIND. SUCH BRACING SHALL BE LEFT IN PLACE AS

LONG AS MAY BE REQUIRED FOR SAFETY OR UNTIL ALL THE STRUCTURAL

ELEMENTS ARE COMPLETE.

9. DURING AND AFTER CONSTRUCTION THE CONTRACTOR AND/OR OWNER SHALL

KEEP LOADS ON THE STRUCTURE WITHIN THE LIMITS OF THE DESIGN LOADS.

10. THE GENERAL CONTRACTOR SHALL HAVE SHOP DRAWINGS REVIEWED BY THE

ENGINEER PRIOR TO THE FABRICATION OR ERECTION FOR THE FOLLOWING

ITEMS: REINFORCING STEEL, STRUCTURAL STEEL, AND MISCELLANEOUS

METALS.

11. ALL DETAILS, SECTIONS, AND NOTES ARE INTENDED TO BE TYPICAL AND SHALL

APPLY TO SIMILAR SITUATIONS UNLESS NOTED OR SHOWN OTHERWISE.

12. OBSERVATION VISITS TO THE JOB SITE BY THE OWNER, ENGINEER OR FIELD

REPRESENTATIVES OF THE ENGINEER SHALL NEITHER BE CONSTRUED AS

INSPECTION NOR APPROVAL OF CONSTRUCTION.

13. SIZES, LOCATIONS, AND ANCHORAGE'S OF EQUIPMENT SHALL BE VERIFIED IN

THE FIELD WITH EQUIPMENT MANUFACTURERS (SUPPLIERS) PRIOR TO PLACING

CONCRETE OR FABRICATING STEEL.

1. FOOTING ELEVATIONS SHOWN ON PLAN ARE TOP OF FOOTINGS AND ARE

MINIMUM DEPTH. DIFFERENT OR UNUSUAL CONDITIONS SHALL BE REPORTED

TO THE ENGINEER.

2. EXTERIOR WALL FOOTINGS SHALL BEAR AT A MINIMUM DEPTH OF 36" BELOW

FINISHED EXTERIOR GRADE.

3. NO FOOTINGS SHALL BE PLACED IN WATER OR ON FROZEN GROUND.

4. ANY SOIL CONDITION ENCOUNTERED DURING EXCAVATION THAT IS CONTRARY

TO THE CONDITIONS USED FOR DESIGN OF FOOTINGS, OR ON THE DRAWINGS

SHALL BE BROUGHT TO THE ATTENTION OF THE ENGINEER BEFORE

PROCEEDING.

5. WHERE 6" DIAMETER OR LARGER PIPE PASSES THROUGH AN INTERIOR OR

EXTERIOR FOUNDATION WALL, STEP THE FOOTING DOWN TO PASS BELOW PIPE

AND THEN STEP BACK UP TO INDICATED ELEVATION. PROVIDE PIPE SLEEVE

THROUGH FOUNDATION WALL. PLACE BOTTOM OF PIPE SLEEVE 12" ABOVE TOP

OF FOOTING.

6. COMPACT SOIL UNDER FOOTINGS TO AT LEAST 90% OF MAXIMUM DRY DENSITY

AS DETERMINED BY (MODIFIED PROCTOR) ASTM D1557.

7. FOUNDATION SUBGRADE SHALL BE PREPARED IN ACCORDANCE WITH THE

RECOMMENDATIONS OF THE GEOTECHNICAL EVALUATION REPORT PREPARED

BY GSH GEOTECHNICAL DATED DECEMBER 17, 2018.

8. ALLOWABLE BEARING CAPACITY = 3000 PSF

1. ALL CONCRETE SHALL MEET THE REQUIREMENTS OF ACI-301, “SPECIFICATION

FOR STRUCTURAL CONCRETE FOR BUILDINGS.” PROPORTIONING OF

INGREDIENTS FOR EACH CONCRETE MIX SHALL BE BY METHOD 2 OR THE

ALTERNATE PROCEDURE GIVEN IN ACI-301. PLACE CONCRETE PER ACI-304 AND

CONFORM TO ACI-604 (306) FOR COLD WEATHER PLACEMENT AND ACI-605 (305)

FOR HOT WEATHER PLACEMENT, USE INTERIOR MECHANICAL VIBRATORS WITH

7,000 RPM MINIMUM FREQUENCY. DO NOT OVER-VIBRATE. CONCRETE SHALL BE

PLACED MONOLITHICALLY BETWEEN CONSTRUCTION AND CONTROL JOINTS.

PROTECT ALL CONCRETE FROM PREMATURE DRYING, EXCESSIVE HOT OR COLD

TEMPERATURE FOR SEVEN DAYS AFTER PLACING.

2. STRENGTH

TWENTY-EIGHT DAY COMPRESSIVE STRENGTH SHALL BE:

4000 PSI

SLUMP: 4 INCH + 1 INCH.

MAX. WATER/CEMENT RATIO: 0.45

3. STRUCTURAL CONCRETE EXPOSURE CLASS: F2

4. MATERIALS

CEMENT: ASTM 150, TYPE I.

COARSE AND FINE AGGREGATE: ASTM C33.

WATER SHALL BE CLEAN AND POTABLE.

5. ADMIXTURES

WATER REDUCING ADMIXTURE: ASTM C494, ADMIXTURES SHALL BE USED IN

EXACT ACCORDANCE WITH MANUFACTURER'S INSTRUCTIONS.

SYNERGIZED PERFORMANCE SYSTEMS: CONCRETE USING ADMIXTURES TO

PRODUCE FLOWABLE CONCRETE MAY BE USED SUBJECT TO

ENGINEER'S APPROVAL.

6. AIR ENTRAINMENT:ASTM C260 AND ASTM C494, ENTRAIN 6% PLUS/MINUS 1 1/2%

BY VOLUME IN ALL EXPOSED CONCRETE.

7. NO OTHER ADMIXTURE PERMITTED UNLESS APPROVED BY THE ENGINEER OF

RECORD.

8. THE FLATNESS AND LEVELNESS OF CONCRETE FLOORS SHALL BE MEASURED

PER ASTM E 1155:STANDARD TEST METHOD FOR DETERMINING FLOOR FLATNESS

AND LEVELNESS USING THE F-NUMBER SYSTEM.

SPECIFIED OVERALL F-NUMBER FF 25/FL 20

MINIMUM LOCAL F-NUMBER FF 15/FL 12

9. A STATEMENT OF MIX DESIGN FOR ALL CONCRETE SHALL BE SUBMITTED TO AND

REVIEWED BY THE ENGINEER PRIOR TO COMMENCING WORK.

10. ALL CONCRETE WORK SHALL BE PLACED, CURED, STRIPPED, AND PROTECTED

AS DIRECTED BY THE SPECIFICATIONS AND ACI STANDARDS AND PRACTICES.

11. DOWEL VERTICAL BARS THE DEVELOPMENT LENGTH INTO STRUCTURE ABOVE

AND FOOTINGS BELOW. PROVIDE 90 DEGREE HOOK WHERE DEVELOPMENT

LENGTH IS NOT POSSIBLE. LAP ALL REINF. IN CONCRETE THE LISTED LENGTH

U.N.O.

12. BEFORE CONCRETE IS POURED CHECK WITH ALL TRADES TO ENSURE PROPER

PLACEMENT OF ALL OPENINGS, SLEEVES, CURBS, CONDUITS, BOLTS, INSERTS,

ETC. RELATIVE TO WORK.

13. REFER TO DRAWINGS FOR TYPICAL CONSTRUCTION JOINT DETAILS. UNLESS

NOTED IN DRAWINGS, ALL REINFORCEMENT SHALL BE CONTINUOUS THROUGH

JOINTS AND EACH CONSTRUCTION JOINT SHALL BE KEYED.

14. WHERE EXTERIOR SLABS ON GRADE ABUT FOUNDATIONS OR COLUMNS PROVIDE

3/8" PREFORMED EXPANSION JOINT WITH SEALANT.

1. ALL REINFORCEMENT SHALL BE DETAILED AND PLACED IN ACCORDANCE WITH

BP-66(04): ACI DETAILING MANUAL - 2004, ACI 350-06, AND ACI 318-14.

2. REINFORCING STEEL SHALL BE ASTM A615 GRADE 60. WELDED WIRE FABRIC

SHALL CONFORM TO ASTM A82 AND ASTM A185.

3. ALL REINFORCEMENT SHALL BE SECURELY TIED AND HELD IN PLACE.

4. REINFORCING BARS THAT ARE TO BE WELDED, INCLUDING DEFORMED BAR

ANCHORS (D.B.A.) SHALL COMPLY WITH ASTM A706 OR ANOTHER APPROVED

WELDABLE GRADE AND SHALL BE WELDED IN ACCORDANCE WITH THE A.W.S.

RECOMMENDATIONS.

5. ALL CONTINUOUS REINFORCEMENT SHALL TERMINATE WITH A 90 DEG. TURN OR

A SEPARATE CORNER BAR. ALL SPLICES IN CONCRETE SHALL LAP THE LISTED

LAP LENGTH.

6. THE FOLLOWING CONCRETE COVER SHALL BE PROVIDED FOR

REINFORCEMENT:

A. CONCRETE CAST AGAINST AND PERMANENTLY EXPOSED TO EARTH: 3"

B. ALL OTHER CONCRETE:2"

7. PRIOR TO FABRICATION AND PLACEMENT, SHOP DRAWINGS FOR ALL

REINFORCING STEEL SHALL BE REVIEWED BY THE ENGINEER.

8. REFER TO WALL CORNER AND WALL INTERSECTION REINFORCING DETAIL. IN

GENERAL, THE WALL CORNER REINFORCING SIZES AND SPACING SHALL BE

CALLED OUT ON THE PLANS AND REFERENCED TO THESE DETAILS AND THE

TYPICAL HORIZONTAL WALL REINFORCING SHALL LAP WITH THE HORIZONTAL

REINFORCING.

9. ALL BENDS, UNLESS OTHERWISE SHOWN, SHALL BE A 90 DEGREE STANDARD

HOOK. REFER TO STANDARD CONCRETE HOOK DETAILS.

10. ALL WALL CORNER AND WALL INTERSECTION REINFORCEMENT BARS SHALL BE

CONTINUOUS AROUND CORNERS AND THROUGH COLUMNS OR PILASTERS.

REINFORCEMENT SHALL BE EXTENDED INTO CONNECTING WALLS AND LAPPED

ON THE OPPOSITE FACE OF THE CONNECTING WALLS.

11. UNLESS INDICATED OTHERWISE, CONTRACTOR MAY SPLICE CONTINUOUS SLAB

OR LONGITUDINAL BEAM BARS AT LOCATION OF HIS CHOOSING, EXCEPT THAT

TOP BAR SPLICES SHALL BE LOCATED AT MIDSPAN AND BOTTOM BAR SPLICES

SHALL BE LOCATED AT SUPPORTS. STAGGER SPLICES IN HORIZONTAL WALL

BARS SO THAT NO TWO ADJACENT BARS IN THE SAME OR OPPOSITE CURTAIN

ARE SPLICED AT THE SAME LOCATION. ALL REINFORCEMENT BENDS AND LAPS,

UNLESS OTHERWISE NOTED, SHALL SATISFY THE REQUIREMENTS OF THE STD.

CONCRETE HOOK SCHEDULE AND THE CONCRETE REINFORCEMENT LAP AND

DEVELOPMENT SCHEDULES.

THE FOLLOWING STRUCTURAL DESIGN LOADS APPLY U.N.O.:

ROOF LIVE LOAD . . . . . . . . . . . . . . . . . . . . . . . . . L

r

= 20 PSF

MEZZANINE LIVE LOAD . . . . . . . . . . . . . . . . . . . . L = 40 PSF

STRUCTURE RISK CATEGORY . . . . . . . . . . . . . . III

SNOW LOAD:

GROUND SNOW LOAD. . . . . . . . . . . . . . . . P

g

= 80 PSF

SNOW IMPORTANCE FACTOR. . . . . . . . . I

s

= 1.1

SNOW EXPOSURE FACTOR. . . . . . . . . . . C

e

= 1.0

SNOW THERMAL FACTOR . . . . . . . . . . C

t

= 1.0

FLAT ROOF SNOW LOAD. . . . . . . . . . . . . P

f

= 62 PSF

SLOPED ROOF SNOW LOAD . . . . . . . . . . P

s

= 62 PSF

WIND:

BASIC WIND SPEED . . . . . . . . . . . . . . . . . . V = 120 MPH

WIND IMPORTANCE FACTOR. . . . . . . . . . . Iw = 1.00

WIND EXPOSURE. . . . . . . . . . . . . . . . . . . . C

SEISMIC:

SEISMIC IMPORTANCE FACTOR. . . . . . . . . . . . I

E

= 1.25

SPECTRAL RESPONSE ACCELERATION. . . . . S

S

= 1.121

SPECTRAL RESPONSE ACCELERATION. . . . . S

1

= 0.339

SEISMIC SOIL SITE CLASS . . . . . . . . . . . . . . . . D

SPECTRAL RESPONSE COEFFICIENT . . . . . . S

DS

= 0.786

SPECTRAL RESPONSE COEFFICIENT . . . . . . S

D1

= 0.389

SEISMIC DESIGN CATEGORY . . . . . . . . . . . . . D

ANALYSIS PROCEDURE USED: EQUIVALENT LATERAL FORCE

BASIC SEISMIC FORCE RESISTING SYSTEM:

LIGHT FRAME (WOOD) WALLS SHEATHED WITH WOOD PANELS

RESPONSE MODIFICATION COEFFICIENT. . . . . R = 6.5

OVERSTRENGTH FACTOR . . . . . . . . . . . . . . . . . . Ω

0

= 3

GENERAL CONCRETE

REINFORCING STEEL

FOOTINGS

DESIGN CRITERIA

PLYWOOD DIAPHRAGM FASTENERS

1. SUBSTITUTION OF FASTENERS OTHER THAN THOSE SPECIFIED IN THE

STRUCTURAL NOTES OR THE PLYWOOD DIAPHRAGM SCHEDULE IS NOT

ALLOWED.

2. NAILS SHALL BE PLACED NOT LESS THAN 3/8" FROM THE EDGE OF PLYWOOD

PANELS. STAGGER NAILS EACH SIDE OF PANEL EDGE.

3. AT ROOF AND FLOOR DIAPHRAGMS, APPLY NAILS AT PANEL EDGE SPACING TO

ALL DRAG STRUTS, TENSION CHORDS, BLOCKING OVER BEARING AND SHEAR

WALLS, AND ANY OTHER SPECIAL DIAPHRAGM MEMBERS NOTED ON PLANS.

4. AT PLYWOOD SHEAR WALLS, APPLY NAILS AT PANEL EDGE SPACING TO TOP

AND BOTTOM PLATES, END POSTS, ALL VERTICAL ELEMENTS AT HOLD DOWN

ANCHORS, AND HORIZONTAL BLOCKING.

5. ALL PANEL EDGES OF PLYWOOD SHEAR WALLS MUST BE BLOCKED.

6. NAILS SHALL BE COATED AND SHALL COMPLY WITH THE REQUIREMENTS OF

ASTM F 1667 NLCMS AND IBC SECTION 2303.6.

1. REFER TO STRUCTURAL DRAWINGS AND SPECIFICATIONS FOR DETAILS,

ADDITIONAL NOTES AND SCHEDULES PERTAINING TO PLYWOOD ROOF.

2. STRUCTURAL FRAMING LUMBER SHALL BE CLEARLY MARKED AND MEET THE

FOLLOWING MINIMUM GRADES AS DEFINED BY THE 2015 EDITION OF THE

NATIONAL DESIGN SPECIFICATION:

A. 2" TO 4" THICK

5" AND WIDER: DOUGLAS FIR-LARCH GRADE NO.2

3. ALL ROOF AND FLOOR JOISTS SHALL BE SUPPORTED LATERALLY AT THE ENDS

AND AT EACH SUPPORT BY SOLID BLOCKING 2" THICK AND THE FULL DEPTH OF

THE JOIST, EXCEPT WHERE THE END OF THE JOIST IS ATTACHED TO A HEADER

OR BOND BEAM WITH METAL ANCHORS OR HANGERS.

4. ALL NAILS SPECIFIED ON DETAILS OR SCHEDULED SHALL BE COMMON STEEL

WIRE NAILS (COATED) UNLESS NOTED OTHERWISE AND SHALL COMPLY WITH

REQUIREMENTS OF ASTM F 1667 AND IBC SECTION 2303.6.

5. HOLES FOR NAILS, WHERE NECESSARY TO PREVENT SPLITTING, SHALL BE

BORED OF A DIAMETER SMALLER THAN THAT OF THE NAILS.

6. ALL JOISTS AND BEAM HANGERS, FRAMING ANCHORS, STRAP TIES, AND OTHER

METAL FASTENERS FOR WOOD FRAMING SHALL BE SIMPSON BRAND (OR

EQUIV.).

7. UNLESS NOTED OTHERWISE, ANCHOR ALL TRUSSES, RAFTERS AND JOISTS TO

SUPPORTS WITH GALVANIZED FRAMING ANCHORS.

8. UNLESS NOTED OTHERWISE, PROVIDE 2 X CONTINUOUS BLOCKING BETWEEN

MAIN MEMBERS AT ALL RIDGES, HIPS AND VALLEYS.

9. CUTTING AND NOTCHING OF STUDS. IN EXTERIOR WALLS AND BEARING

PARTITIONS, ANY WOOD STUD IS PERMITTED TO BE CUT OR NOTCHED TO A

DEPTH NOT EXCEEDING 25% OF ITS WIDTH. CUTTING OR NOTCHING OF STUDS

TO A DEPTH NOT GREATER THAN 40% OF THE WIDTH IS PERMITTED IN

NONBEARING PARTITIONS SUPPORTING NO LOADS OTHER THAN THE WEIGHT

OF THE PARTITION.

10. BORED HOLES IN STUDS. A HOLE NOT GREATER IN DIAMETER THAN 40% OF THE

STUD WIDTH IS PERMITTED TO BE BORED IN ANY WOOD STUD. BORED HOLES

NOT GREATER THAN 60% OF THE WIDTH OF THE STUD ARE PERMITTED IN

NONBEARING PORTIONS OR IN ANY WALL WHERE EACH BORED STUD IS

DOUBLED, PROVIDED NOT MORE THAN TWO SUCH SUCCESSIVE DOUBLED

STUDS ARE SO BORED.

11. IN NO CASE SHALL THE EDGE OF THE BORED HOLE BE NEARER THAN 5/8" TO

THE EDGE OF THE STUD.

12. NAILING AND CONNECTION SHALL BE IN CONFORMANCE W/ IBC AND AITC.

REFER TO IBC 2015, TABLE 2304.10.1 FOR FASTENING SCHEDULE.

13. P.T. LUMBER SHALL BE IN CONFORMANCE WITH IBC SECTION 2303.1.9

14. NAILS IN CONTACT WITH P.T. LUMBER SHALL BE STAINLESS STEEL.

15. GLUE-LAMINATED BEAMS SHALL CONFORM TO I.B.C COMBINATION 24F-V4 FOR

SIMPLE SPANS, 24F-V8 FOR MULTIPLE SPANS OR CANTILEVERED BEAMS PER

ICBO REPORT 2519 (UNLESS SHOWN OR NOTED OTHERWISE ON DRAWINGS).

LUMBER SHALL BE DOUGLAS FIR 2400 PSI. CAMBER FOR DEAD LOAD AS SHOWN

ON DRAWINGS. WATERPROOF GLUE ALL BEAMS.

WOOD FRAMING

STRUCTURAL STEEL

1. ALL STEEL SHALL BE FABRICATED AND ERECTED IN ACCORDANCE WITH

AMERICAN INSTITUTE OF STEEL CONSTRUCTION SPECIFICATION FOR THE

DESIGN, FABRICATION AND ERECTION OF STRUCTURAL STEEL FOR BUILDING,

LATEST EDITION. OBTAIN APPROVAL OF THE ENGINEER OF RECORD PRIOR TO

SITE CUTTING, MAKING ADJUSTMENTS OR PERFORMING FIELD WELDS NOT

SCHEDULED OR SHOWN ON PLANS OR DETAILS. ALL ASTM A325 BOLTING

MATERIAL SHALL BE PROVIDED WITH CERTIFIED DIRECT TENSION INDICATOR

WASHERS AND HARDENED WASHERS FOR FIELD BOLTED CONNECTIONS.

2. STRUCTURAL L SHAPED STEEL TO MEET ASTM A36 GRADE 36.

1. FOLLOW RECOMMENDED PRACTICE FOR CONCRETE FORMWORK (ACI-347-14).

2. ALL SHORING SHALL BE THE RESPONSIBILITY OF THE CONTRACTOR.

FORMWORK SUPPORTS AND SHORING SHALL BE DESIGNED TO PROVIDE

FINISHED CONCRETE SURFACES OF ALL FACES LEVEL, PLUMB, AND TRUE TO

THE DIMENSIONS AND ELEVATIONS SHOWN. TOLERANCES AND VARIATIONS

SHALL BE AS SPECIFIED.

FORM WORK

1. CONCRETE ANCHOR RODS SHALL MEET THE QUALITY OF ASTM F1554 GRADE 36 KSI,

GALVANIZED (ASTM A153, CLASS C) RODS AND SHALL HAVE A STANDARD BOLT HEAD OR AN

EQUAL DEFORMITY IN THE EMBEDDED PORTION.

2. MACHINE BOLTS SHALL BE ASTM A307 BOLTS, UNLESS NOTE AS ASTM A307 ON THE DRAWINGS

OR DETAILS.

3. WELDED-HEADED STUDS SHALL BE “NELSON” STUDS CONFORMING TO ASTM A108.

ANCHOR BOLTS

S-000

STRUCTURAL

NOTES

9 5 W E S T 1 0 0 S O U T H , S T E . 1 1 5 , L O G A N , U T 8 4 3 2 1

PH: 435.227.0333 FAX: 435.227.0334

DLB

CLR

NOTES FOR CORNER AND INTERSECTION REINFORCING DETAILS

1. TYPICAL HORIZONTAL WALL CORNER AND INTERSECTION REINFORCING LAYOUT IS SHOWN TO AVOID CONGESTION AND PERMIT PROPER PLACEMENT, FOR SIZE AND

SPACING SEE PLANS. ALL HORIZONTAL REINFORCING AT CORNERS AND INTERSECTIONS SHALL BE FABRICATED AND INSTALLED WITH SPLICES LOCATED WHERE

SHOWN REGARDLESS OF BAR SIZE AND SPACING.

2. WHERE THE CORNER OR INTERSECTION REINFORCING SIZE AND SPACING IS NOT SHOWN, NOTED OR TABULATED ON THE PLANS, THE SIZE AND SPACING SHALL BE THE

SAME AS THE WALL HORIZONTAL REINFORCING SHOWN ON THE WALL SECTIONS OR AS NOTED FOR THE REINFORCING BETWEEN THE CORNERS OR INTERSECTIONS.

3. EXCEPT WHERE OTHERWISE SHOWN ON THE DRAWINGS, THE LENGTH INDICATED AS "NOTE 3" SHALL BE THE LESSER OF D/4, 10 FEET, OR 1.0 TIMES THE HEIGHT OF THE

WALL, EXCEPT THAT IN NO CASE SHALL IT BE LESS THAN THE SPLICE LENGTH.

4. D = LENGTH OF WALL PARALLEL TO THE BAR LENGTH IN QUESTION.

5. EXCEPT WHERE OTHERWISE SHOWN ON THE DRAWINGS, THE LENGTH INDICATED AS "NOTE 5" SHALL BE EQUAL TO ONE "LAP LENGTH" AS REQUIRED BY THE GENERAL

STRUCTURAL NOTES. USE THE LAP LENGTH AS REQUIRED FOR THE SMALLER OF THE TWO REINFORCING BARS BEING SPLICED.

6. HORIZONTAL BARS IN WALLS SHALL HAVE SPLICES STAGGERED ONE LAP LENGTH AS DEFINED IN NOTE 5.

7. ALTERNATE SPLICE LOCATIONS OF HORIZONTAL BARS IN WALLS BETWEEN THE TWO CURTAINS SO THAT NO SPLICES AT THE SAME ELEVATION ARE LOCATED

TOGETHER.

ALL SHEAR WALLS TO HAVE 3” X 3” X 1/4” (MINIMUM SIZE, GALVANIZED WHEN IN CONTACT WITH PRESSURE TREATED WOOD) PLATE

WASHER AT EACH ANCHOR BOLT.

MINIMUM FOR CAST IN PLACE ANCHOR BOLT EMBEDMENT SHALL BE 7”.

PROVIDE A MINIMUM OF 2 ANCHOR BOLTS PER FOUNDATION PLATE MEMBER WITH ONE BOLT LOCATED NOT MORE THAN 12” OR

LESS THAN 4” BOLT DIAMETERS FROM EACH END OF EACH PLATE MEMBER.

USE HOT DIPPED GALVANIZED NAILS WITH SIZE AND SPACING AS LISTED IN THE SHEAR WALL SCHEDULE FOR NAILING TO

PRESSURE TREATED MATERIAL. CONNECTORS IN CONTACT WITH PRESSURE TREATED WOOD SHALL BE CORROSION RESISTANT

WITH FINISHES PER THE MANUFACTURES RECOMMENDATIONS.

1. MAXIMUM SHEAR = 260 P.L.F.

USE 7/16” APA RATED SHEATHING ONE SIDE OF WALL WITH FRAMING MEMBERS AT 16” O/C MAXIMUM SPACING. NAIL ALL

PANEL EDGES WITH 8D COMMON NAILS (D=.131”, MIN. FASTENER PENETRATION INTO FRAMING 1 3/8”) AT 6” O.C. FOR FRAMING

USE 2” NOMINAL WIDTH DF #2. PROVIDE 5/8” DIAMETER ANCHOR BOLTS AT 32” O.C. MAXIMUM SPACING AT THE

FOUNDATION. SEE PLANS FOR LOCATIONS AND SIZES OF HOLDOWNS.

2. MAXIMUM SHEAR = 350 P.L.F.

USE 7/16” APA RATED SHEATHING ONE SIDE OF WALL WITH FRAMING MEMBERS AT 16” O/C MAXIMUM SPACING. NAIL ALL

PANEL EDGES WITH 8D COMMON NAILS (D=.131”, MIN. FASTENER PENETRATION INTO FRAMING 1 3/8”) AT 4” O/C. FOR FRAMING

USE 2” NOMINAL WIDTH DF#2. PROVIDE 5/8” DIAMETER ANCHOR BOLTS AT 32” O/C MAXIMUM SPACING AT THE

FOUNDATION. SEE PLANS FOR LOCATIONS AND SIZES OF HOLDOWNS.

3. MAXIMUM SHEAR = 490 P.L.F.

USE 7/16” APA RATED SHEATHING ONE SIDE OF WALL WITH FRAMING MEMBERS AT 16” O/C MAXIMUM SPACING. NAIL ALL

PANEL EDGES WITH 8D COMMON NAILS (D=.131”, MIN. FASTENER PENETRATION INTO FRAMING 1 3/8”) AT 3” O/C. FOR FRAMING

AT VERTICAL AND HORIZONTAL PANEL EDGES USE 3” NOMINAL OR WIDER DF#2. ALTERNATIVELY, AT ABUTTING PANEL EDGES

DOUBLE 2” NOMINAL MEMBERS MAY BE USED WHEN FASTENED (FACE NAILED) WITH 10D COMMON OR 16D

SINKER (D=.148”) NAILS AT 3-1/2” O.C. STAGGERED. USE A 2” NOMINAL SILL PLATE WITH 5/8” DIAMETER ANCHOR BOLTS

AT 32” O/C MAXIMUM SPACING AT THE FOUNDATION. SEE PLANS FOR LOCATIONS AND SIZES OF HOLDOWNS.

SHEAR WALL SCHEDULE

CORNER AND INTERSECTION REINFORCING DETAIL

1

10

5-1

6-2

01

9A

DD

EN

DU

M #

1

© COPYRIGHT DESIGN WEST ARCHITECTS 201854321

A

B

D

C

desi

gn w

est

arch

itect

s25

5 SO

UTH

300

WES

T79

5 NO

RTH

400

WES

TLO

GAN

UT

843

21SA

LT L

AKE

CITY

UT

841

03

PROJECT #:

DRAWN BY:

CHECKED BY:

ISSUED:

MARK

:DA

TE:

DESC

RIPT

ION:

THE

CHUR

CH O

F JE

SUS

CHRI

ST O

F LA

TTER

-DAY

SAI

NTS

218036

05.08.2019

BID

SET

S

STE

TA

UTRS CT

R P

UR

F OE

G

OF UT HA

ERE

NI

NISO

L

EN

A LA

No. 295553RASMUSSENCRAIGL.

05/08/19

GARD

EN C

ITY

ASSE

MBL

Y HA

LL10

0 SO

UTH

PARA

DISE

PAR

KWAY

, GAR

DEN

CITY

, UT

1. SPECIAL INSPECTION SHALL BE PROVIDED ACCORDING TO IBC

CHAPTER 17 FOR THE ITEMS IDENTIFIED IN THIS SECTION AND ON

THE CONTRACT DOCUMENTS.

2. THE NAMES AND CREDENTIALS OF SPECIAL INSPECTORS TO BE

USED SHALL BE SUBMITTED TO THE BUILDING DEPARTMENT WHEN

APPLYING FOR A BUILDING PERMIT.

3. SPECIAL INSPECTION REPORTS SHALL BE DELIVERED TO THE

OWNER BI-WEEKLY OR MORE FREQUENTLY AS REQUIRED BY THE

INSPECTOR OR BUILDING OFFICIAL.

4. OFF-SITE FABRICATION: WHERE FABRICATION OF STRUCTURAL

LOAD-BEARING MEMBERS AND ASSEMBLIES IS BEING PERFORMED

ON THE PREMISES OF A FABRICATORS SHOP, SPECIAL INSPECTION

OF THE FABRICATED ITEMS SHALL BE IN ACCORDANCE WITH IBC

SECTION 1704.2.5 UNLESS THE FABRICATOR IS APPROVED

ACCORDING TO IBC SECTION 1704.2.5.1.

5. CONCRETE CONSTRUCTION: SPECIAL INSPECTIONS AND

VERIFICATIONS SHALL BE PROVIDED IN ACCORDANCE WITH TABLE

1705.3.

6. THE FOLLOWING ELEMENTS OF THE SEISMIC-FORCE-RESISTING

SYSTEM IN ACCORDANCE WITH IBC SECTION 1705.12:

A. STRUCTURAL WOOD (IBC 1705.12.2)

7. SOILS: SPECIAL INSPECTION SHALL BE PROVIDED FOR PLACEMENT

OF FILL 12 INCHES OR MORE DEEP IN ACCORDANCE WITH SECTION

1705.6.

8. EPOXY ANCHORS: PRIOR TO AND DURING EPOXY INJECTION TO

INSURE PROPER INSTALLATION AS PER MANUFACTURERS

REQUIREMENTS. CONTRACTOR SHALL SUBMIT PROPOSED EPOXY

MANUFACTURERS I.C.B.O. REPORT TO ENGINEER PRIOR TO

INSTALLATION.

EACH CONTRACTOR RESPONSIBLE FOR THE CONSTRUCTION OF A

SEISMIC-FORCE-RESISTING SYSTEM, DESIGNATED SEISMIC SYSTEM,

OR COMPONENT LISTED IN THE QUALITY ASSURANCE PLAN SHALL

SUBMIT A WRITTEN CONTRACTOR'S STATEMENT OF RESPONSIBILITY

TO THE BUILDING OFFICIAL AND TO THE OWNER PRIOR TO THE

COMMENCEMENT OF WORK ON THE SYSTEM OR COMPONENT IN

ACCORDANCE WITH IBC SECTION 1704.4. THE CONTRACTOR'S

STATEMENT OF RESPONSIBILITY SHALL CONTAIN THE FOLLOWING:

A. ACKNOWLEDGMENT OF AWARENESS OF THE SPECIAL

REQUIREMENTS CONTAINED IN THE QUALITY ASSURANCE

PLAN.

B. ACKNOWLEDGMENT THAT CONTROL WILL BE EXERCISED TO

OBTAIN CONFORMANCE WITH THE CONSTRUCTION

DOCUMENTS APPROVED BY THE BUILDING OFFICIAL.

C. PROCEDURES FOR EXERCISING CONTROL WITHIN THE

CONTRACTOR'S ORGANIZATION, THE METHOD AND

FREQUENCY OF REPORTING, AND THE DISTRIBUTION OF

REPORTS.

D. IDENTIFICATION AND QUALIFICATIONS OF THE PERSON(S)

EXERCISING SUCH CONTROL AND THE POSITION(S) IN THE

ORGANIZATION.

QUALITY ASSURANCE

CONTRACTOR RESPONSIBILITY

QUALITY ASSURANCE PLAN

NOTES

NO

FASTENERS

BOUNDARY

40/2019/32"

SHEATHING

DIAPHRAGM SCHEDULE

MARK

WD-1

ALL GRADES OF STEEL (MIN. YIELD STRENGTHS)

D = FINISHED INSIDE BEND DIAMETER

d = BAR DIAMETER

D = 6d FOR #3 THROUGH #8

D = 8d FOR #9, #10 AND #11

D = 10d FOR #14 AND #18

d

B

4d or

2

1

2

" MIN.

D

HOOK A

DETAILING

DIMENSION

180° HOOK

d

12

d

A

D

DETAILING

DIMENSION

90° HOOK

RECOMMENDED END HOOKS

BAR

SIZE

D

180° HOOKS

A B

90° HOOKS

A

#3 2

1

4

" 5" 3" 6"

#4 3" 6" 4" 8"

NOTES:

1. ALL REINFORCEMENT LAPS, UNLESS OTHERWISE NOTED, SHALL SATISFY THE MINIMUM

REQUIREMENTS SHOWN IN THE TABLE "REINFORCEMENT LAP LENGTHS."

2. TOP BARS SHALL BE DEFINED AS ANY HORIZONTAL BARS PLACED SUCH THAT MORE THAN 12"

OF FRESH CONCRETE IS CAST IN THE MEMBER BELOW THE BAR, IN ANY SINGLE POUR.

HORIZONTAL WALL BARS ARE CONSIDERED TOP BARS.

CONCRETE REINFORCEMENT LAP & DEVELOPMENT SCHEDULES

NTS

DIAPHRAGM LAYOUT

TYPICAL PLYWOOD ROOF

BLOCKING IF REQ'D

FRAMING, SEE PLAN

INTERMEDIATE SUPPORTS

DIAPHRAGM

BOUNDARIES (SHEAR

WALLS, TENSION

CHORDS)

CONT. PANEL EDGE

PANEL EDGES

NOTES:

1. USE ONLY APA RATED SHEATHING MEETING THE REQUIREMENTS

OF IBC SECTION 2303.1.4.

2. USE ONLY COMMON WIRE NAILS FOR FASTENERS.

3. FACE GRAIN OF PLYWOOD PANELS TO BE PERPENDICULAR TO

SUPPORTS.

4. NAILS SHALL BE PLACED NOT LESS THAN 3/8" IN FROM PANEL

EDGES.

MINIMUM

FASTENER

PENETRATION

IN FRAMING

MINIMUM

NOMINAL

PANEL

THICKNESS

CONTINUOUS

PANEL EDGE

OTHER

PANEL

EDGES

BLOCKING

DIAPHRAGM

1 1/2"

HOOK EMBED

DEPTH

7"

9"

#5 3

3

4

" 7" 5" 10"

#6 4

1

2

" 8" 6" 1'-0"

1'-7"11

3

4

"1'-3"9

1

2

"#9

1'-4"8"11"6"#8

1'-2"7"10"5

1

4

"#7

1'-10"1'-1

1

4

"1'-5"10

3

4

'#10

#11 12" 1'-7" 1'-2

3

4

" 2'-0"

#14 18

1

4

" 2'-3" 1'-9

3

4

" 2'-7"

#18 24" 3'-0" 2'-4

1

2

" 3'-5"

(IN ACCORDANCE WITH ACI 318-14)

NTS

STD. CONCRETE HOOK SCHEDULE

12"

14"

23"

21"

18"

26"

31"

41"

16"

NOTE: EMBED BARS WITH HOOKS TO THE DEPTH

SHOWN.

SPAN

RATING

PANEL

FIELD

10d @ 4"

D=.148"

10d @ 6"

D=.148"

10d @ 6"

D=.148"

10d @ 12"

D=.148"

VERIFICATION AND INSPECTION

CONTINUOUS DURING

TASK LISTED

PERIODICALLY DURING

TASK LISTED

1. VERIFY MATERIALS BELOW SHALLOW FOUNDATIONS ARE ADEQUATE TO ACHIEVE THE

DESIGN BEARING CAPACITY.

2. VERIFY EXCAVATIONS ARE EXTENDED TO PROPER DEPTH AND HAVE REACHED PROPER

MATERIAL.

3. PERFORM CLASSIFICATION AND TESTING OF COMPACTED FILL MATERIALS.

-- X

4. VERIFY USE OF PROPER MATERIALS, DENSITIES AND LIFT THICKNESSES DURING

PLACEMENT AND COMPACTION OF COMPACTED FILL.

5. PRIOR TO PLACEMENT OF COMPACTED FILL, OBSERVE SUBGRADE AND VERIFY THAT SITE

HAS BEEN PREPARED PROPERLY.

-- X

-- X

X --

-- X

TABLE 1705.6 REQUIRED SPECIAL INSPECTIONS AND TESTS OF SOILS

VERIFICATION AND INSPECTION CONTINUOUS PERIODIC

REFERENCED

STANDARD

IBC

REFERENCE

1. INSPECTION OF REINFORCING STEEL, INCLUDING PRESTRESSING TENDONS, AND

VERIFY PLACEMENT.

3. INSPECT ANCHORS POST-INSTALLED IN HARDENED CONCRETE MEMBERS.

a. ADHESIVE ANCHORS INSTALLED IN HORIZONTALLY OR UPWARDLY INCLINED

ORIENTATIONS TO RESIST SUSTAINED TENSION LOADS.

b. MECHANICAL ANCHORS AND ADHESIVE ANCHORS NOT DEFINED IN 4.a.

4. VERIFYING USE OF REQUIRED DESIGN MIX.

-- X ACI 318 CH. 20,

25.2, 25.3,

26.6.1-26.6.3

1908.4

--X

ACI 318:17.8.2.4

--

-- X

ACI 318: CH. 19,

26.4.3, 26.4.4

1904.1,

1904.2,

1908.2,

1908.3

5. PRIOR TO CONCRETE PLACEMENT, FABRICATE SPECIMENS FOR STRENGTH

TESTS, PERFORM SLUMP AND AIR CONTENT TESTS, AND DETERMINE THE

TEMPERATURE OF THE CONCRETE.

X --

ASTM C172,

ASTM C31,

ACI 318: 26.4, 26.12

1908.10

6. INSPECT CONCRETE AND SHOTCRETE PLACEMENT FOR PROPER APPLICATION

TECHNIQUES.

X --ACI 318: 26.5

1908.6,

1908.7,

1908.8

7. VERIFY MAINTENANCE OF SPECIFIED CURING TEMPERATURE AND TECHNIQUES.

-- X

ACI 318:

26.5.3-26.5.5

1908.9

8. INSPECT FORMWORK FOR SHAPE, LOCATION AND DIMENSIONS OF THE

CONCRETE MEMBER BEING FORMED. -- X

ACI 318:

26.11.1.2(b)

--

TABLE 1705.3 REQUIRED SPECIAL INSPECTIONS AND TESTS OF CONCRETE CONSTRUCTION

2. INSPECT ANCHORS CAST IN CONCRETE.

-- X

ACI 318:17.8.2

--

-- X

ACI 318: 17.8.2

--

VERIFICATION AND INSPECTION

CONTINUOUS DURING

TASK LISTED

PERIODICALLY DURING

TASK LISTED

1. VERIFY APPROPRIATE SHEATHING, FRAMING MEMBERS AT PANEL EDGES AND

FASTENERS ARE USED

2. VERIFY PROPER NAILING, BOLTING, ANCHORING AND OTHER FASTENING OF ELEMENTS

OF LATERAL FORCE RESISTING SYSTEM INCLUDING WOOD SHEAR WALLS, WOOD

DIAPHRAGMS, DRAG STRUTS, BRACES AND HOLD-DOWNS.

-- X

-- X

IBC SECTION 1705.11.1 REQUIRED SPECIAL INSPECTIONS FOR STRUCTURAL WOOD FRAMING

3. VERIFY THAT PROPER BOLTING AND SPACING ARE USED ON TIMBER TRUSSES

-- X

5'-7"5'-1"4'-6"4'-0"3'-6"2'-5"2'-0"1'-7"1'-3"

7'-3"6'-7"5'-10"5'-2"4'-6"3'-1"2'-7"2'-1"1'-7"

#11#10#9#8#7#6#5#4#3

OTHER BAR

TOP BAR

BAR SIZE

REINFORCEMENT LAP LENGTHS

CONCRETE DESIGN STRENGTH - 4000 PSI

NO40/2023/32"WD-2 1 1/2"

10d @ 6"

D=.148"

10d @ 6"

D=.148"

10d @ 6"

D=.148"

10d @ 12"

D=.148"

S-001

STRUCTURAL

NOTES

9 5 W E S T 1 0 0 S O U T H , S T E . 1 1 5 , L O G A N , U T 8 4 3 2 1

PH: 435.227.0333 FAX: 435.227.0334

DLB

CLR

VERIFICATION AND INSPECTION CONTINUOUS PERIODIC IBC SECTION

TMS 402/ACI

530/ASCE 5"

TMS 602/ACI

530.1/ASCE 6"

1. VERIFY COMPLIANCE WITH THE APPROVED SUBMITTALS

2. AS MASONRY CONSTRUCTION BEGINS, VERIFY THAT THE FOLLOWING ARE IN COMPLIANCE:

5. OBSERVE PREPARATION OF GROUT SPECIMENS, MORTAR

SPECIMENS, AND/OR PRISMS.

-- X -- -- ART. 1.5

--

ART.

1.4 B.2.a.3,

1.4 B.2.b.3,

1.4 B.2.c.3,

1.4 B.3,

1.4 B.4

ACI 530-13, TABLE 3.1.2 - LEVEL B QUALITY ASSURANCE MINIMUM TESTS & SPECIAL INSPECTIONS

--

MINIMUM SPECIAL INSPECTIONS

MINIMUM TESTS

VERIFICATION OF SLUMP FLOW AND VISUAL STABILITY INDEX (VSI) AS DELIVERED TO THE PROJECT SITE IN ACCORDANCE WITH SPECIFICATION

ARTICLE 1.5 B.1.b.3 FOR SELF-CONSOLIDATING GROUT.

VERIFICATION OF f'

m

AND f'

AAC

IN ACCORDANCE WITH SPECIFICATION ARTICLE 1.4 B PRIOR TO CONSTRUCTION, EXCEPT WHERE SPECIFICALLY

EXEMPTED BY IBC 2015.

A. PROPORTIONS OF SITE-PREPARED MORTAR AND GROUT.

B. CONSTRUCTION OF MORTAR JOINTS.

C. LOCATION OF REINFORCEMENT AND CONNECTORS.

-- X -- --

ART. 2.1,

2.6 A

-- X -- -- ART. 3.3 B

X-- -- --ART. 3.4,

3. PRIOR TO GROUTING, VERIFY THAT THE FOLLOWING ARE IN COMPLIANCE:

A. GROUT SPACE

B. GRADE, TYPE, AND SIZE OF REINFORCEMENT AND ANCHOR

BOLTS.

C. PLACEMENT OF REINFORCEMENT AND CONNECTORS.

D. PROPORTIONS OF SITE-PREPARED GROUT.

E. CONSTRUCTION OF MORTAR JOINTS.

-- X -- --

ART. 3.2 D,

3.2 F

-- X -- SEC. 6.1ART. 2.4, 3.4

-- X --

ART. 3.2 E,

3.4

X-- -- -- ART. 2.6 B

X-- -- -- ART. 3.3 B

4. VERIFY DURING CONSTRUCTION:

A. SIZE AND LOCATION OF STRUCTURAL ELEMENTS

B. TYPE, SIZE, AND LOCATION OF ANCHORS, INCLUDING OTHER

DETAILS OF ANCHORAGE OF MASONRY TO STRUCTURAL

MEMBERS, FRAMES, OR OTHER CONSTRUCTION.

C. WELDING OF REINFORCEMENT

D. PREPARATION, CONSTRUCTION, AND PROTECTION OF

MASONRY DURING COLD WEATHER (TEMPERATURE BELOW

40°F) OR HOT WEATHER (90°F).

F. PLACEMENT OF GROUT.

G. PLACEMENT OF MASONRY UNITS.

-- X -- -- ART. 3.3 F

-- X --

SEC. 1.2.1(e),

6.1.4.3, 6.2.1

--

SEC. 8.1.6.7.2,

9.3.3.4 (c),

11.3.3.4 (b)

-- --

ART. 1.8 C,

1.8 D

-- -- ART. 3.5

--

ART. 3.3 B.9, 3.3

F.1.b

SEC. 6.1, 6.2.1,

6.2.6-7

X --

X --

-- X

-- X

XX

--

--

--

PRE-CAST CONCRETE LINTEL TO BE PROVIDED AT DOORS AND WINDOWS FOR BRICK VENEER

SUPPORT AT LOCATIONS SHOWN ON ARCHITECTURAL PLANS. PRE-CAST LINTEL TO BE 6" WIDE BY

8" TALL WITH (2) #3 LONGITUDINAL REINFORCEMENT BARS LOCATED 2" FROM BOTTOM OF

CONCRETE LINTEL.

MAX SPAN = 6'

PROVIDE 6” (MIN.) OF BEARING AT EACH END.

USE 7/8” 22 GA. GALVANIZED MASONRY TIES PER IBC 2103.4 AT 16” O/C HORIZONTAL AND 16” O/C

VERTICAL. 9 GA ANNEALED WIRE SHALL BE INSTALLED IN EACH HORIZONTAL COURSE CONTAINING

MASONRY TIES. LAP WIRE 3” MINIMUM. ANCHOR TIES SHALL HAVE A LIP OR HOOK ON THE

EXTENDED LEG THAT WILL ENGAGE OR ENCLOSE A HORIZONTAL JOINT REINFORCEMENT WIRE.

CONCRETE LINTELS FOR FASCIA BRICK

BRICK VENEER

1

10

5-1

6-2

01

9A

DD

EN

DU

M #

1

T

1

T

3

T

2

T

3

T

4

BW

2

14'-0"

BW

310'-0"

C2C2

C2C2

PRE-ENGINEERED,

PRE-MANUFACTURED

TRUSSES AT OVERBUILD

PRE-ENGINEERED,

PRE-MANUFACTURED

TRUSSES AT OVERBUILD

H1H1 H1 H1

H1

H4

H3

H1 H1

H1H1 H1 H1

H1

H4

H1

H1

H1

H1

10'-0"

14'-0"

TYP, AT ENTRY

SEE SHEET

S-502 FOR

LOADS TO

TRUSS

T

2

APPROXIMATE LOCATION

OF CAP TRUSS PER

PRE-ENGINEERED,

PRE-MANUFACTURED

TRUSSES

© COPYRIGHT DESIGN WEST ARCHITECTS 201854321

A

B

D

C

desi

gn w

est

arch

itect

s25

5 SO

UTH

300

WES

T79

5 NO

RTH

400

WES

TLO

GAN

UT

843

21SA

LT L

AKE

CITY

UT

841

03

PROJECT #:

DRAWN BY:

CHECKED BY:

ISSUED:

MARK

:DA

TE:

DESC

RIPT

ION:

THE

CHUR

CH O

F JE

SUS

CHRI

ST O

F LA

TTER

-DAY

SAI

NTS

218036

05.08.2019

BID

SET

S

STE

TA

UTRS CT

R P

UR

F OE

G

OF UT HA

ERE

NI

NISO

L

EN

A LA

No. 295553RASMUSSENCRAIGL.

05/08/19

GARD

EN C

ITY

ASSE

MBL

Y HA

LL10

0 SO

UTH

PARA

DISE

PAR

KWAY

, GAR

DEN

CITY

, UT

SCALE: 1/8"=1'-0"

ROOF FRAMING PLAN

NOTES:

HEADER & BEAM SCHEDULE

MARK MEMBER

(2) 2x8 DF #2

H2

H1

H3 (2) 1 3/4X 9 1/2 MICROLAM LVL 1.9 E

ALL HEADERS H1 U.N.O.

BEARING WALLS & COLUMNS

NOTES:

ALL COLUMNS ARE C1 U.N.O.

ALL BEARING WALLS ARE BW1 U.N.O.

BW3

2X6 DF #2 AT 12" O.C.

1 3/4"X5 1/2" MICROLAM LVL 1.9E AT 16" O.C.

BW1 2X6 DF #2 AT 16" O.C.

BW2

MemberMark

PRE-ENGINEERED/PRE-MANUFACTURED TRUSSES AT 19.2" O.C. w/ CAP TRUSS

PRE-ENGINEERED/PRE-MANUFACTURED GIRDER TRUSS

TRUSS, RAFTER, & GIRDER TRUSS SCHEDULE

NOTES:

T1

GT

STRUCTURAL KEY NOTES

1. 2x10 DF#2 OUTLOOKERS AT 24" O.C.

2. INSTALL SIMPSON CMSTC12 AT RIDGE PER DETAIL 12

SHEET S500.

3. INSTALL L6X3 1/2X1/2 STEEL LINTEL OVER FRONT

ENTRY. STEEL LINTEL TO BEAR ON A MINIMUM 6

INCHES OF MASONRY.

4. SEE DETAIL 1 SHEET S-501 FOR MEZZANINE FLOOR

FRAMING.

5. INSTALL SIMPSON CMSTC12 AT ALL TOP PLATE

SPLICES ALONG THE LENGTH OF WALL NOTED.

6. PRE-MANUFACTURED STEEPLE.

7. SEE DETAIL 1 SHEET S502 FOR SPACING AND LOADING

FOR PRE-ENGINEERED, PRE-MANUFACTURED

TRUSSES UNDER PRE-MANUFACTURED STEEPLE.

8. PROVIDE BLOCKING AT ROOF PANEL DIAPHRAGM

EDGES w/ 4" BOUNDARY NAILING AND 4" EDGE

NAILING.

9. PROVIDE LGT4-SDS3 AT BOTH ENDS OF EACH (4) PLY

TRUSS w/ (4) 2x6 DF #2 BUILT-UP COLUMN BELOW

TRUSSES.

10. PROVIDE H2.5A AT (2) PLY TRUSS.

#

GENERAL NOTES

1. REFER TO ARCHITECTURAL DRAWINGS FOR ADDITIONAL

DIMENSIONS AND ELEVATIONS NOT SHOWN.

2. REFER TO SHEET S-000 FOR SHEAR WALL SCHEDULE AND

NOTES. ALL SHEAR WALLS ARE TO BE TYPE 1 U.N.O.

3. REFER TO SHEET S-001 FOR WOOD DIAPHRAGM SCHEDULE

AND NOTES. ALL DIAPHRAGMS ARE TO BE TYPE 1 U.N.O.

4. ALL DOUBLE TOP PLACE SPLICES TO BE SPLICE TYPE 1

U.N.O. SEE DETAIL 10 SHEET S5OO FOR SPLICE SCHEDULE.

5. PROVIDE 2x NAILER AT EACH TRUSS FOR ANCHORING SHEET

VAPOR RETARDER. SEE DETAIL D2 SHEET A-561 FOR NAILER

LOCATION ON TRUSS.

C2

C1 (2) 2X6 DF #2

(3) 2X6 DF #2

(2) 1 3/4X5 1/2 MICROLAM LVL 1.9 E

PRE-ENGINEERED/PRE-MANUFACTURED TRUSSES AT 24" O.C.T2

PRE-ENGINEERED/PRE-MANUFACTURED MONO TRUSSES AT 19.2" O.C.T3

PRE-ENGINEERED/PRE-MANUFACTURED TRUSSES AT 19.2" O.C.T4

S-101

ROOF

FRAMING

PLAN

9 5 W E S T 1 0 0 S O U T H , S T E . 1 1 5 , L O G A N , U T 8 4 3 2 1

PH: 435.227.0333 FAX: 435.227.0334

7

S-500

6

S-500

6

S-500

2

S-501

4

S-501

8

S-500

6

S-500

9

S-500

H4 (2) 1 3/4X11 7/8 MICROLAM LVL 1.9 E

11

S-500

2

3

1

1

3

S-501

22

4

5

6

7

TYP ALL EXT. CORNERS

1

8

8

1

1

4

S-502

DLB

CLR

8 8

13

S-500

N

TYP AT OPP. SIDE

1

S-502

9

9

10

10

1

10

5-1

6-2

01

9A

DD

EN

DU

M #

1

3" M

IN

.

6"

MIN

.

FINISHED

GRADE

36" M

IN

FOOTING AND

REINF. PER PLAN

#4 VERT. AT 18" O.C.

EACH FACE. STD.

HOOK AT END

1'

(3) EQUALLY SPACED

#4 HORIZ. EACH FACE

ARCHITECTURAL

VENEER

P.T SILL PLATE

SLAB PER PLAN

ANCHOR BOLTS PER PLAN

WALL PER PLAN

NOTE: AT ROSTRUM AREA,

TOP OF FOUNDATION WALL

2" ABOVE TOP OF SLAB

3" M

IN

.

P.T SILL PLATE

6"

MIN

.

FINISHED

GRADE

36

" M

IN

.

FOOTING AND

REINF. PER PLAN

#4 VERT. AT 18" O.C.

EACH FACE. STD.

HOOK AT END

SLAB PER PLAN

ANCHOR BOLTS PER PLAN

WALL PER PLAN

1'-1"

(3) EQUALLY SPACED

#4 HORIZ. EACH FACE

ARCHITECTURAL

VENEER

NOTE: AT ROSTRUM AREA,

TOP OF FOUNDATION WALL

2" ABOVE TOP OF SLAB

FOOTING

WIDTH PER

PLAN

P.T SILL PLATE

WALL PER PLAN. AT SIMILAR -

SEE ARCH. PLAN FOR WALL

TYPE

THICKENED SLAB

FOOTING AND REINF.

PER PLAN

SLAB AND REINF.

PER PLAN

ANCHOR BOLT PER

SHEAR WALL

SCHEDULE

ST

EP

P

ER

P

LA

N

6"

SLAB AND REINF.

PER PLAN

SLAB AND REINF.

PER PLAN

4

5

°

8"

EXTERIOR SLAB

PER PLAN

THICKENED SLAB

AT DOOR OPENING

FOOTING AND STEM

WALL PER PLAN

STD. HOOK

EXPANSION

JOINT

FOOTING AND

REINF. PER PLAN

6"

SLAB AND REINF.

PER PLAN

SLAB AND REINF.

PER PLAN

4

5

°

SLOPE RAMP PER PLAN

#4 AT 18" O.C. EACH WAY#4 AT 18" O.C. EACH WAY

MIN LAP

LENGTH

MIN LAP

LENGTH

2x10 OUTLOOKER

TYP.

2x10

(3) 16d

(2) SIMPSON LS50'S

AT CORNERS

2x FASCIA, MUST BE

8'-0" MIN CONTINUOUS

AT CORNERS

SIMPSON H1

TYP. AT

OUTLOOKERS

SIMPSON A34 AT

CORNER & EACH

TRUSS

BLOCKING

NOTE: ALL 2x10'S ARE DF #2

FOR ROOF CORNER

2x10

ROOF TRUSS

PER PLAN

SIMPSON

H2.5A AT

TRUSS

SIMPSON A34

TYP. AT ALL

OUTLOOKER

SPACES

SIMPSON

LS50'S TYP.

2x FASCIA, MUST BE

8'-0" MIN CONTINUOUS

AT CORNERS

SOLID

BLOCKING

SOLID

BLOCKING

SIMPSON

A34 TYP.

BOUNDARY NAILING

PER PLAN (2) ROWS

SHEATHING PER PLAN

PRE-ENGINEERED,

PRE-MANUFACTURED TRUSS

BLOCKING PER PLAN

PRE-ENGINEERED,

PRE-MANUFACTURED TRUSS

SIMPSON H1 EACH

OUTLOOKER

BOUNDARY NAILING

PER PLAN

2X10 DF#2

OUTLOOKER

SHEATHING PER PLANSIMPSON A34 AT EACH BLOCKING

DROP CHORD TRUSS

TRUSS BRACING AS

REQUIRED BY

TRUSS MANUFACTURER

PROVIDE 2x BLOCKING FOR

SHEAR WALL BOUNDARY NAILING

NUMBER FASTENER

EACH SIDE OF SPLICE

NUMBER FASTENER

EACH SIDE OF SPLICE

SPLICE TYPE

STAGGER ROWS

OF FASTENERS

END DIST.

ED

GE

D

IS

T.

OTHER DIST.

DIS

T.

BE

TW

EE

N

RO

WS

34 1 1/4

MINIMUM DISTANCES

(INCHES)

FASTENER

FASTENERS

EA. SIDE

OF SPLICE

END EDGE ROWS OTHER

DIA.

(INCH)

0.1621 16d COMMON 1/41/4 3/4

SIMPSON CMSTC12

AT RIDGE

DOUBLE TOP PLATE

WALL PER PLAN

SHEATHING AND

NAILING PER PLAN

BOUNDARY NAILING

PRE-ENGINEERED,

PRE-MANUFACTURED TRUSS

SIMPSON A34 AT

EACH TRUSS BLOCK

SIMPSON H1 AT

EACH TRUSS

PRE-ENGINEERED,

PRE-MANUFACTURED TRUSS

BLOCKING TO MATCH HEEL

HEIGHT

TRUSS BLOCKING

SHEAR TRANSFER

LOAD = 180 PLF

(ASD SEISMIC)

2x NAILER FOR ANCHORAGE

OF SHEET VAPOR RETARDER.

SEE DETAIL D2 SHEET A-561

PRE-ENGINEERED,

PRE-MANUFACTURED TRUSS

SIMPSON H1 EACH

OUTLOOKER

BOUNDARY NAILING

PER PLAN

2X10 DF#2 OUTLOOKERSIMPSON A34 EACH

OUTLOOKER

SHEATHING PER PLAN

SIMPSON A34 AT EACH BLOCK

INSTALL BLOCKING

AT SHEATHING JOINT

SHEATHING PER PLAN

PRE-ENGINEERED,

PRE-MANUFACTURED

CAP TRUSS

PRE-ENGINEERED,

PRE-MANUFACTURED TRUSS

PROVIDE 2x6 NAILER PLATE w/

(2) SDS25300 SCREWS AT

EACH TRUSS TOP CHORD

SHEATHING TO RUN

CONTINUOUS AT CAP

TRUSS TRANSITION

SIMPSON H3 AT EACH END

OF EACH CAP TRUSS

2x NAILER FOR ANCHORAGE

OF SHEET VAPOR RETARDER.

SEE DETAIL D2 SHEET A-561

© COPYRIGHT DESIGN WEST ARCHITECTS 201854321

A

B

D

C

desi

gn w

est

arch

itect

s25

5 SO

UTH

300

WES

T79

5 NO

RTH

400

WES

TLO

GAN

UT

843

21SA

LT L

AKE

CITY

UT

841

03

PROJECT #:

DRAWN BY:

CHECKED BY:

ISSUED:

MARK

:DA

TE:

DESC

RIPT

ION:

THE

CHUR

CH O

F JE

SUS

CHRI

ST O

F LA

TTER

-DAY

SAI

NTS

218036

05.08.2019

BID

SET

S

STE

TA

UTRS CT

R P

UR

F OE

G

OF UT HA

ERE

NI

NISO

L

EN

A LA

No. 295553RASMUSSENCRAIGL.

05/08/19

GARD

EN C

ITY

ASSE

MBL

Y HA

LL10

0 SO

UTH

PARA

DISE

PAR

KWAY

, GAR

DEN

CITY

, UT

1A

EXTERIOR FOUNDATION WALL

SCALE: 3/4"=1'-0"

S-500

STRUCTURAL

DETAILS

9 5 W E S T 1 0 0 S O U T H , S T E . 1 1 5 , L O G A N , U T 8 4 3 2 1

PH: 435.227.0333 FAX: 435.227.0334

1B

EXTERIOR FOUNDATION WALL

SCALE: 3/4"=1'-0"

3

INTERIOR THICKENED SLAB

SCALE: 3/4"=1'-0"

4

STEP IN SLAB

SCALE: 3/4"=1'-0"

2

THICKENED SLAB AT OPENINGS

SCALE: 3/4"=1'-0"

5

CONCRETE RAMP

SCALE: 3/4"=1'-0"

11

ROOF FRAMING AT SHEAR WALL

SCALE: 3/4"=1'-0"

9

ROOF CORNER FRAMING

SCALE: 3/4"=1'-0"

7

DROP CHORD TRUSS

SCALE: 3/4"=1'-0"

10

TOP PLATE SPLICE

SCALE: 3/4"=1'-0"

12

TENSION STRAP AT RIDGE

SCALE: 3/4"=1'-0"

6

TYP TRUSS CONNECTION

SCALE: 3/4"=1'-0"

8

OUTLOOKER AT EXT. BEARING WALL

SCALE: 3/4"=1'-0"

13

CAP TRUSS CONNECTION

SCALE: 3/4"=1'-0"

DLB

CLR

10

5-1

6-2

01

9A

DD

EN

DU

M #

1

1

1

1

1