T ADDENDUM Nº: 02 · 2018. 10. 12. · A. Steel Roof Deck — Max 3 in. (76 mm) deep galv steel...

Transcript of T ADDENDUM Nº: 02 · 2018. 10. 12. · A. Steel Roof Deck — Max 3 in. (76 mm) deep galv steel...

RFT ADDENDUM Nº: 02

Project Number: Project Name: Location Address: Project Manager:

UC 18-008 Aboriginal Initiatives University Centre - Lakehead University Campus 955 Oliver Road, Thunder Bay, ON. James McKillop

To: Date:

October 11, 2018 All Bidders The following changes in the Request for Tenders documents are effective immediately. This Addendum will form part of the Contract Documents: (N.B: The Contractor shall acknowledge receipt of this Addendum on “Schedule B – Fixed Fee Proposal Form” of the Request for Quotations)

Item Description 1.

1.

2.

3.

4.

5. 2.

1.

QUESTIONS and ANSWERS QUESTION: Is there a demolition drawing showing the scope of work for the existing plumbing, venting and water piping to be removed and capped?

1) ANSWER: All of the remaining plumbing will be cut below floor level, capped and abandoned. The Contractor currently finishing demolition & abatement is responsible for this scope of work.

QUESTION: After measuring where the new sink is to be installed the plumbing drawing notes to tie into existing drain and water in the tunnel below. The tunnel is on the other side of the partition wall under Starbucks. The existing piping that needs to removed and capped and new piping seems to be located above basement corridor ceiling. This also looks to be asbestos containing by the patchwork that has been previously completed.

2) ANSWER: This is being reviewed with the Consultants and Owner and a response will be provided in the next addendum.

QUESTION: What remaining electrical, fire alarm and devices that should be removed as part of this contract?

3) ANSWER: All electrical will already be removed prior to the commencement of construction, with the exception of life safety devices and electrical/data continuations through the space.

QUESTION: Can you find out if D100 is supposed to be a fire frame by TGP?�It can't be made as drawn with regular hollow metal doors and a pressed steel frame.

4) ANSWER: The fire rated frame is to be a pressed steel frame and the fire rated glazing is to the TGP Pilkington Pyrostop fire rated glazing. Refer to the sketches attached to this addendum for the updated frame types and layout at the main entrance. Also refer to Specification Section 08 80 50 Glazing for the revisions to the fire rated glazing product included in this addendum.

QUESTION: It was noticed during site visit that there were numerous drains, vents and water lines in the existing space. Is the piping going to be removed or are we to carry this demolition work as part of this contract?

1) ANSWER: See response to Question#1 above. CLARIFICATIONS ARCHITECTURAL

1) All flooring surfaces inclusive of all glues, adhesives, mastic associated with the flooring surfaces have been removed and bare concrete surface will be left. The Successful Bidder will be

3.

1.

2.

4.

1.

2.

3.

4.

5.

6.

responsible for the floor levelling, grinding, patching of all holes, feathering and all floor preparation so the flooring surfaces are ready to receive the resilient sheet flooring.

2) All walls in File Rm#104 are to be furred out with resilient channel since the tile that has been removed has left all wall surfaces quite rough. 5/8” gypsum is to be installed and all surfaces are to be painted and made good. The existing mechanical chase access hatch is to be removed and replaced with a new painted fire rated access hatch (20”wide x 36”high). The plumbing from the former sink in this room is to be capped in the wall and an access hatch installed & painted for future access to the plumbing.

3) Spray fireproofing with a fire resistance rating of 1 hr is to be installed on all the existing steel structure and metal deck in the entire space. Please refer to the spray-applied fireproofing specification section attached to this addendum.

4) The gap between the top of the concrete block/brick and underside of structure along the entire length of the west demising wall of the Agora (west wall of Lounge Area#105/Seating Area#110/Multipurpose Area#111) is to be filled with the Hilti Firestop System No. HW-D-1037. See cut sheet attached to this addendum.

DRAWINGS ARCHITECTURAL DRAWINGS

1) Refer to sketches AD2.01-04 attached to this addendum for changes to the main entrance walls, frame types and additional wall type.

ELECTRICAL DRAWINGS

1) Refer to the attached sketch ESK-1 for the emergency exit signage locations and specifications. SPECIFICATIONS Section 00-21-14 BID FORM:

1) REPLACE: Section 00-21-14 Bid Form with the revised Bid Form attached to this addendum, which includes the mechanical & electrical subcontractors on the List of Subcontractors.

Section 00-21-14A OWNERS DOCUMENTS:

1) REPLACE: Appendix Item 1. General Liability Insurance, as follows: General liability insurance shall be provided by the contractor with limits of not less than $5,000,000 per occurrence and with a property damage deductible not exceeding $2,500. Contractor's policy shall be endorsed to include Lakehead University as a "Additional Named Insured" only with respect to this project and for liability arising out of the contractor's operations.

Section 00-61-00 AGREEMENT TO BOND: 1) REPLACE: Section 00-61-00 Agreement to Bond with the revised Agreement to Bond attached to

this addendum, which has the correct name of the project. Section 07-81-00 SPRAY-APPLIED FIREPROOFING:

1) ADD: Section 07-81-00 Spray-Applied Fireproofing attached to this addendum for the fireproofing of the existing steel structure and metal deck.

Section 07-84-00 FIRESTOPPING:

1) ADD: Section 07-84-00 Firestopping attached to this addendum. Section 08-80-50 GLAZING:

1) REPLACE: Item 2.1.1.3 Laminated Safety Wired Glass, as follows: i. Fire-Rated & Impact Safety-Rated Glass: to ANSI Z97.1 and CPSC 16 CFR1201 (Cat. I

and II) i. Fire-Rated, impact safety-rated transparent wall panels, ¾” (19mm) thick. All

glazing in interior fire-rated doors and screens to be impact safety-rated glass, unless specifically noted otherwise. 45-minute rating required.

ii. Acceptable Product: TGP Pilkington Pyrostop

7.

8. 5. 6.

2) REPLACE: Item 2.1.2.3 GL-3, as follows: i. GL-3: (for use in interior fire-rated doors and windows)

i. Fire-Rated & Impact Safety-Rated Glass, suitable for 60 minute rated assemblies / 45-minute fire-rated closure, TGP Pilkington Pyrostop

Section 09-22-16 METAL STUD FRAMING:

1) ADD: Item 1.1.3.8 Shaft Wall System, as follows: Shaft Wall System: CGC Sheetrock® Brand Glass-Mat Liner Panels—ASTM C1658, 25.4 mm (1") CGC Sheetrock® Brand Glass-Mat Liner Panels, moisture- and mould-resistant gypsum core encased in a moisture and mould-resistant glass mat on�both sides, 610 mm (24") wide, lengths as required. Stamped with UL or ULC Classification label documenting�UL or ULC Classifications for re resistance, surface burning characteristics and noncombustibility. Panels should also be identified with the following language: “CGC Sheetrock® Brand Glass-Mat Liner Panel, a Component of CGC Inc. Fire-Rated Systems.”

Section 09-30-13 TILING: 1) REPLACE: Item 2.1.1 CERAMIC WALL TILE, as follows:

WALL TILING: ANSI A137.1. .1 WT Olympia: Tile+Stone

Series: Colour & Dimension Collection, Glazed Wall Colour: One (1) colour to be selected by Architect Size: 3” x 6” (7.5cm x 15.2cm) Note: Refer to interior elevations for locations

APPROVED EQUALS The following requests for equal have been submitted prior to this Addendum.

SPECIFIED PRODUCT ALTERNATE / EQUAL APPROVAL Armstrong “Woodworks” Linear Veneered Panels – Model#6692W1 – Tapered Planks

ACGI Linear Open Series 3 (Tapered Planks) YES

“Ultra Touch” by Bonded Logic Inc. EcoTouch PINK Fiberglas Insulation YES Roxul: AFB Sound Attenuation Fire Blanket Thermafiber Mineral Wool Insulation YES Any and all additional costs associated with the use of approved equals is to be included in the Base Bid.

ATTACHMENTS - Hilti Firestop Product Cutsheets (23 pages attached / 8.5x11) - 2017-68 Aboriginal Initiatives - Addendum No-2 Sketches AD2.01-04 (4 pages attached / 11x17) - A114-18-007 LU Aboriginal Initiative Renovation Elec ESK-1 (1 page attached / 11x17) - 00 21 14 Bid Form (5 pages attached / 8.5x11) - 00 21 14A Owners Documents (2 pages attached / 8.5x11) - 00 61 00 Agreement to Bond (1 page attached / 8.5x11) - 07 81 00 Spray-Applied Fireproofing (8 pages attached / 8.5x11) - 07 84 00 Firestopping (14 pages attached / 8.5x11)

End of Addendum #02

Project Manager James McKillop

Telephone (807) 708-3609

Email [email protected]

Table Of Contents

UL Listings HW-D-1037 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

CFS-SP WB Product Data Sheet for CFS-SP WB Firestop Joint Spray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 Product Data Sheet for CFS-SP WB Firestop Joint Spray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 UL Certificate of Compliance for CFS-SP WB Firestop Joint Spray . . . . . . . . . . . . . . . . . . . . . . . . . . 5 LEED Information for CFS-SP WB Firestop Joint Spray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 LEED information for CFS-SP WB Firestop Joint Spray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

CP 777 Product Data Sheet for CP 767 and CP 777 Speed Plugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 Product Data Sheet for CP 767 and CP 777 Speed Plugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 UL Certificate of Compliance for CP 767 and CP 777 Speed Plugs . . . . . . . . . . . . . . . . . . . . . . . . . . 10 LEED Information for CP 767 Speed Strips and CP 777 Speed Plugs . . . . . . . . . . . . . . . . . . . . . . . . 11 LEED information for CP 767 Speed Strips and CP 777 Speed Plugs . . . . . . . . . . . . . . . . . . . . . . . . 12

Mineral wool Product Data Sheet for Mineral Wool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 Product Submittal Sheet for Mineral Wool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 UL Certificate of Compliance (CA-EN) Certificate of Compliance for Mineral Wool . . . . . . . . . . . . . . 18 LEED Information for Mineral Wool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 LEED information for Mineral Wool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

System No. HW-D-1037

SECTION A-A

HWD

1037

Page: 1 of 2

1. Floor Assembly — The fire-rated fluted steel floor unit/concrete floor assembly shall be constructed of the materials and in the manner describedin the individual Floor-Ceiling Design in the Fire Resistance Directory and shall include the following construction features:

A. Steel Floor and Form Units* — Max 3 in. (76 mm) deep galv steel fluted floor units.B. Concrete — Min 2-1/2 in. (64 mm) thick reinforced concrete, as measured from the top plane of the floor units.C. Spray-Applied Fire Resistive Materials* — (Optional)—(Not Shown)—Prior to the installation of the forming material and fill, void or cavity

material (Items 3A, 3B) the steel floor units may be sprayed with a min 5/16 in. (8 mm) to max 1-3/4 in. (44 mm) thickness of fire resistivematerial.W R GRACE & CO - CONN — Type MK-6-HY

1A. Roof Assembly (Not Shown) — As an alternate to the floor assembly, a fire rated fluted steel deck roof assembly may be used. The roofassembly shall be constructed of the materials and in the manner described in the individual P900 Series Roof-Ceiling Design in the UL FireResistance Directory. The hourly rating of the roof assembly shall be equal to or greater than the hourly rating of the wall assembly. The roofassembly shall include the following construction features:

A. Steel Roof Deck — Max 3 in. (76 mm) deep galv steel fluted roof deck.B. Roof Insulation — Min 2-1/4 in. (57 mm) thick poured insulating concrete, as measured from the top plane of the floor units.

1B. Roof Assembly — As an alternate to Items 1 and 1A, a fire rated protected fluted steel deck roof assembly may be used. The roof assemblyshall be constructed of the materials and in the manner described in the individual P700 Series Roof-Ceiling Design in the UL Fire ResistanceDirectory. The hourly rating of the roof assembly shall be equal to or greater than the hourly rating of the wall assembly. The roof assembly shallinclude the following construction features:

A. Steel Roof Deck — Max 3 in. (76 mm) deep galv steel fluted roof deck.B. Spray-Applied Fire Resistive Materials* — (Not Shown) - Prior to the installation of the steel ceiling runners, Forming Material and Fill, Void or

Cavity Material (Items 2A, 3A, 3B), the roof assembly shall be sprayed with the type and thickness of fire resistive material indicated in theindividual P700 Series design.

2. Wall Assembly — Min 8 in. (203 mm) thick steel reinforced lightweight or normal weight (100-150 pcf) (1600 -2400 kg/m3) structural concrete.Wall may also be constructed of any UL Classified Concrete Blocks*.

See Concrete Blocks (CAZT) category in the Fire Resistance Directory for names of manufacturers.

Reproduced by HILTI, Inc. Courtesy ofUnderwriters Laboratories, Inc.

June 07, 2010

Assembly Rating - 2 HrNominal Joint Width - 3-1/2 In.

Class II Movement Capabilities - 14% Compression and Extension

23B

3A

1

CCL

ASS IF IED

Classified byUnderwriters Laboratories, Inc.to UL 2079 and CAN/ULC-S115

US

1

Page: 2 of 2

3. Joint System — Max separation between bottom of floor units and top of concrete wall at time of installation is 3-1/2 in. (89 mm). The joint systemis designed to accommodate a max 14 percent compression or extension from its installed width. The joint system shall consists of the following:

A. Forming Material* — Nom 4 in. (102 mm) thick pieces of nom 4 pcf (64 kg/m3) forming material sized to attain a min compression rate of 50percent in the thickness direction firmly packed to completely fill the flutes. Additional pieces of batt insulation, min 8 in. (203 mm) wide, shallbe compressed 50 percent in thickness and installed edge first into joint opening between bottom of fluted floor or roof units and top ofconcrete wall.THERMAFIBER INC — Type SAF

A1. Forming Material*—Plugs — Optional-Not Shown) Performed mineral wool plugs, formed to the shape of the fluted floor units, friction fit tocompletely fill the flutes above the ceiling runner. The plugs shall be flush with both wall surfaces. Additional forming material, described inItem 3A, to be used in conjunction with the plugs to fill the gap between the top of the wall and the bottom of the steel floor units.HILTI CONSTRUCTION CHEMICALS, DIV OFHILTI INC — CP777 Speed Plugs

A2. Forming Material — As an alternate to Item 3A, min 6 pcf (96 kg/m3) ceramic blanket insulation installed in joint as a permanent form.Nominal 4 in (102 mm) thick pieces of nominal 6 pcf (96 kg/m3) forming material sized to attain a min compression rate of 50 percent in thethickness direction firmly packed to completely fill the flutes. Additional pieces of batt insulation, min 8 in. (203 mm) wide, shall be compressed50 percent in thickness and installed edge first into joint opening between bottom of fluted floor or roof units and top of concrete wall.

B. Fill, Void or Cavity Material* - Sealant — A 1/8 in. (3.2 mm) wet thickness of fill material sprayed of trowled on each side of wall to completelycover mineral wool forming material and to overlap a min 1/2 in. (13 mm) onto steel floor units and concrete wall. When spray-applied fireresistive material* is applied to the steel deck, the fill material is to overlap the wall a min ½ in. and the spray-applied fire resistive material amin of 2 in. (51 mm) on both sides of the wall.HILTI CONSTRUCTION CHEMICALS, DIV OFHILTI INC — CP672 Firestop Spray or CFS-SP WB Firestop Joint Spray

*Bearing the UL Classification Mark

System No. HW-D-1037

HWD

1037

Reproduced by HILTI, Inc. Courtesy ofUnderwriters Laboratories, Inc.

June 07, 2010

Assembly Rating - 2 HrNominal Joint Width - 3-1/2 In.

Class II Movement Capabilities - 14% Compression and Extension

CCL

ASS IF IED

Classified byUnderwriters Laboratories, Inc.to UL 2079 and CAN/ULC-S115

US

2

Product Information

Hilti. Outperform. Outlast.Hilti (Canada) Corp. 1-800-363-4458 • www.hilti.ca • Hilti Firestop Systems Guide — Canada

Firestop Joint Spray (CFS-SP WB)

Product description ■ A sprayable fire-rated mastic for construction joints where

maximum movement is required

Product features ■ Sprayable or apply by brush ■ Maximum flexibility, meets 500 cycle requirements (Class II and III

Approval) (ASTM E 1966 and UL 2079) ■ Quick and easy installation with the Titan 600 or 1100 Sprayers

can help save you time and money ■ Contains no halogens, solvents or asbestos ■ Water based formulation so spills and over-spray clean up quickly

and easily ■ Paintable ■ Meets LEED™ requirements for indoor environmental quality credit

4.1 Low Emitting Materials, Sealants and Adhesives and 4.2 Paints and Coatings

Areas of application ■ Top-of-wall joints ■ Curtain wall/edge of slab ■ Expansion joints

For use with ■ Concrete, masonry and gypsum wall assemblies ■ Wall and floor/wall assemblies rated up to 4 hours

Examples ■ Where a gypsum wall assembly meets the underside of a metal or

concrete deck ■ Where a concrete floor assembly meets with non-rated exterior

wall (concrete, glass, etc.) ■ Where two concrete floor/wall assemblies meet

Technical Data* CFS-SP WBDensity Approx. 10.8 lb/gal (1.3 g/cm3)Color Available in red, white and gray**Application temperature 39°F to 104°F (4°C to 40°C)Temperature resistance -40°F to 176°F (-40°C to 80°C)Consistency Sprayable liquidChemical basis Acrylic-water-based-dispersionCuring time Approx. 24 hours @ 73°F,

50% humidity for 1/8" depthAverage volume shrinkage (ASTM C1241)

51.1%

Ph-value Approx. 8-9Movement capability Up to 50%Surface burning characteristics (CAN/ULC-S102)

Flame spread: 15 Smoke development: 10

Sound transmission classification (ASTM E 90-99)

59(per tested construction type)

Tested in accordance with• UL 2079 • ASTM E 1966 • ASTM E 84 • ASTM E 2837 • UL 1479 • ASTM E 814 • ASTM E 2307 • CAN/ULC-S115 • CAN/ULC-S102

*At 73°F (23°C) and 50% relative humidity**Gray color requires six (6) weeks lead time

Installation instructions for Firestop Joint Spray CFS-SP WB

FILL, VOID OR CAVITY MATERIAL FOR USE IN THROUGH-PENETRATION FIRESTOP SYSTEMS, AND/OR JOINT

SYSTEMS, AND/OR PERIMETER FIRE CONTAINMENT SYSTEMS

SEE UL FIRE RESISTANCE DIRECTORY 66Y7

FM

R

FILL, VOID OR CAVITY MATERIALS CLASSIFIED BY

UNDERWRITERS LABORATORIES, INC.FOR USE IN TROUGH-PENETRATION

FIRESTOP SYSTEMS SEE UL FIRE RESISTANCE DIRECTORY

66Y7

Notice • Before handling, read Material Safety Data Sheet and

product label for safe usage and health information. • Instructions below are general guidelines — always

refer to the applicable drawing in the UL Fire Resistance Directory or Hilti Firestop Systems Guide for complete installation information

Opening1. Clean the opening. Surfaces to which Firestop Joint

Spray will be applied should be cleaned of loose debris, dirt, oil, wax and grease. The surface should be moisture and frost free.

Application of Firestop Joint Spray2. Mineral wool packing: Install the prescribed back

filling material type and depth to obtain desired rating.

3. Application of Firestop Joint Spray: Apply Firestop Joint Spray to the required depth in order to obtain the desired rating. Make sure Firestop Joint Spray contacts all surfaces and overlaps beyond all surrounding surfaces (Refer to UL System). Titan Sprayers have been successful in applying Firestop Joint Spray. Hilti recommends the use of the Titan 600 (for application temperatures above 50°F) or

Firestop Joint Spray may also be brushed on with a paint brush. Contact Hilti Technical Support for more information.

4. Curing time: Allow approx. 24 hours for typical application thickness (@ 73°F / 23°C) 50% humidity for 1/8" depth for the Firestop Joint Spray to fully cure.

5. Identification: For maintenance reasons all Firestop Joint Spray applications can be permanently marked with an identification plate and fastened in a visible position next to the seal.

Not for use• In areas immersed in water• On hot surfaces (above 176°F)

Storage• Store only in the original packaging at temperatures

39°F to 77°F (4°C to 25°C)• Observe expiration date on package

1. Clean opening 2. Pack in mineral wool compressed per UL System

3. Spray or brush on Firestop Spray

4. Allow Firestop Spray to cure

5. Fasten identification plate (if required)

3

IntroductionApplications/Produits

Selector Guide

Through-PenetrationJoint

Estimating Tables/Tech D

ata

25

Information sur les produits

Hilti (Canada) Corporation 1-800-363-4458 • www.hilti.ca • Guide des coupe-feu Hilti — dition Canada 2011

Hilti. Plus performant. Plus durable.

Aérosol pour joints coupe-feu CFS-SP WB

Description du produit ■ Mastic coupe-feu pulv riser servant au colmatage des joints dynamiques

tr s mobiles

Caractéristiques du produit ■ Pulv risable ou applicable au pinceau ■ Souplesse maximale, r pondant l exigence de 500 cycles (homologation

classe II et classe III) (ASTM E 1966 et UL 2079) ■ Installation rapide et facile avec les pulv risateurs Titan 600 ou 1100 pour

conomiser temps et argent ■ Sans halog ne, solvant ou amiante ■ Composition base d eau qui acc l re et facilite le nettoyage des

d versements et de l exc dent de pulv risation ■ Peut tre peint ■ Satisfait aux exigences LEEDMC pour la qualit de l environnement int rieur

cr dit 4.1 pour les mat riaux, mastics et adh sifs faible mission et 4.2 pour les peintures et enduits

Zones d’application ■ Joints de couronnement du mur ■ Mur-rideau /bordure de la dalle ■ Joints de dilatation

Utiliser avec ■ Assemblages de murs en b ton, en ma onnerie et en plaques de pl tre ■ Assemblages de murs et de murs/planchers cot s jusqu 4 heures

Exemples ■ l intersection d un assemblage de murs en plaques de pl tre et de la face

inf rieure d un tablier de m tal ou de b ton ■ l intersection d un assemblage de plancher en b ton et d un mur ext rieur

non cot (b ton, verre, etc.) ■ l intersection de deux assemblages de planchers/murs en b ton

Fiche technique* CFS-SP WBDensité Environ 1,3 g/cm3 (10,8 lb/gal) Couleur Offert en rouge, blanc et gris**Température d’application 4°C 40°C (39°F 104°F)Résistance de température -40°C 80°C (-40°F 176°F)Consistance Liquide pulv risableBase chimique Dispersion base d eau et de r sines

acryliquesTaux de durcissement Environ 24 h 23 °C (73 °F), 50 %

d humidit pour une paisseur de 1/8 poRétrécissement moyen (ASTM C1241) 51,1 %Valeur du Ph Environ 8-9Capacité de mouvement Jusqu 50 %Caractéristiques de la surface de combustion (CAN/ULC-S102)

Propagation des flammes estim : 5 Classification du d gagement de fum e: 10

lassification d la transmission sonore (ASTM E 90-99)

59 (construction particuli re)

Essais en conformité avec• UL 2079 • ASTM E 1966 • ASTM E 84 • CAN/ULC-S115• UL 1479 • ASTM E 814 • ASTM E 2307 • CAN/ULC-S102

* 23 °C (73 °F) et 50 % d humidit relative**Couleur grise : d lai d approvisionnement de six (6) semaines

MAT RIAU POUR REMPLISSAGE DE CAVIT ET ESPACE VIDE UTILIS DANS LES SYSTÈMES COUPE-FEU TRAVERSANTS, LES SYSTÈMES DE JOINTS ET LES SYSTÈMES DE

CONFINEMENT D INCENDIEVOIR LE R PERTOIRE 66Y7 SUR LA

R SISTANCE AU FEU DES UL

Directives d'installation de l'aérosol pour joints coupe-feu CFS-SP WBAvertissement • Avant de manipuler, lire la fiche technique de s curit

du mat riau ainsi que l tiquette du produit pour une utilisation s curitaire et obtenir de l information sur la sant .

• Les directives ci-dessous sont des principes g n raux r f re -vous toujours l illustration correspondante dans le R pertoire sur la r sistance au feu des UL/cUL ou au Guide des syst mes coupe-feu de Hilti pour l information compl te quant l installation

Ouverture1. Nettoye l ouverture. limine les d bris, la salet ,

l huile, la cire et la graisse des surfaces sur lesquelles l a rosol pour joints coupe-feu est appliqu . La surface doit tre exempte d humidit et de givre.

Application de l'aérosol pour joints coupe-feu 2. Bourrage de laine min rale : installe l paisseur

requise du mat riau de remplissage prescrit pour obtenir le degr de r sistance au feu d sir .

3. Application de l a rosol pour joints coupe-feu : applique l paisseur d a rosol pour joints coupe-feu requise pour obtenir le degr de r sistance au feu d sir . Assure -vous que l a rosol pour joints coupe-feu touche toutes les surfaces et chevauche les surfaces avoisinantes (reporte -vous au syst me UL). Les pulv risateurs Titan sont excellents pour appliquer l a rosol pour joints coupe-feu. Hilti recommande l utilisation des pulv risateurs Titan 600 (pour des temp ratures de mise en uvre sup rieures 10 °C 50 °F ) l a rosol

pour joints coupe-feu peut aussi tre appliqu au pinceau. Communique avec le soutien technique de Hilti pour plus d information.

4. Temps de durcissement : Pr voye environ 24 heures pour une paisseur standard ( 23 °C 73 °F ), 50 % d humidit pour une paisseur de 1/8 po et pour un durcissement complet de l a rosol pour joints coupe-feu.

5. Marquage : Pour faciliter l entretien, on peut marquer les diff rentes applications de l a rosol pour joints coupe-feu au moyen d une plaque signal tique permanente fix e un endroit visible pr s du joint

Ne pas utiliser• Dans des espaces submerg s par l eau• Sur des surfaces chaudes (au-dessus de 176 °F)

Entreposage• Entrepose dans l emballage original des

temp ratures situ es entre 4°C to 25°C (39°F to 77°F)• Respecte la date d expiration indiqu e sur

l emballage1. Ouverture propre 2. Remplisse de laine

min rale compress e par le syst me UL tel que sp cifi par le syst me UL

3. Applique l a rosol coupe-feu au pulv risateur ou au pinceau

4. Laisse durcir l a rosol coupe-feu

5. Fixe la plaque signal tique (au besoin)

4

C E R T I F I C A T E O F C O M P L I A N C E

Certificate Number 20170203 – R13240 Report Reference R13240 - 20100527

Issue Date 2017-FEBRUARY-03

Bruce Mahrenholz, Director North American Certification Program UL LLC Any information and documentation involving UL Mark services are provided on behalf of UL LLC (UL) or any authorized licensee of UL. For questions, please contact a local UL Customer Service Representative at http://ul.com/aboutul/locations/

Page 1 of 1

Issued to: HILTI CONSTRUCTION CHEMICALS, DIV OF HILTI INC 7250 Dallas Pky, Legacy Tower Suite 1000 Plano, TX 75024 USA

This is to certify that representative samples of

Fill, Void or Cavity Materials CFS-SP WB Firestop Joint Spray

Have been investigated by UL in accordance with the Standard(s) indicated on this Certificate.

Standard(s) for Safety: ANSI/UL 1479, "Fire Tests of Penetration Firestops,"

ANSI/UL 2079, "Tests for Fire Resistance of Building Joint Systems," ANSI/ASTM E2307, "Standard Test Method for Determining Fire Resistance of Perimeter Fire Barriers Using Intermediate-Scale, Multi-story Test Apparatus" and CAN/ULC-S115, "Standard Method of Fire Tests of Firestop Systems."

Additional Information: See the UL Online Certifications Directory at www.ul.com/database for additional information

Only those products bearing the UL Certification Mark should be considered as being covered by UL's Certification and Follow-Up Service. Look for the UL Certification Mark on the product.

5

Hilti, Inc. 5400 South 122nd East Avenue

Tulsa, OK 74146

1-800-879-8000 www.hil ti.com

August 26, 2015 To Whom It May Concern: Re: Hilti CFS-SP WB Firestop Joint Spray – LEED Information Item Numbers:

430792 430793 430802

The Hilti CFS-SP WB Firestop Joint Spray is manufactured in Florida. The CP 572 pail is made of polyethylene and can be completely recycled. There is no post-consumer or post-industrial content in CFS-SP WB Firestop Joint Spray and it cannot be recycled. The CFS-SP WB does not contain any Rapidly Renewable Materials. The VOC content for CFS-SP WB Firestop Joint Spray is 34 g/l. CFS-SP WB Firestop Joint Spray is not regulated as hazardous waste by the Federal EPA Standards. The regulations for the disposal of non-regulated industrial waste can vary from state to state and even city to city. For this reason, you should consult your local and state regulatory agencies for direction on disposal. Please feel free to contact me at (918) 872-3704 if you have questions. Sincerely,

Jerry Metcalf MPH, CHMM Sr. Manager, Safety/Environmental Hilti Inc. 918 872 3704 [email protected] Rev. Date: 8/14/15 The manufacturing plant location on this certificate has been provided for LEEDS reporting purposes only. It should never be used for Country of Origin certification or a representation of compliance/non-compliance with Buy American or Buy America requirements, as those requirements differ. The manufacturing plant location(s) identified on the certificate represent standard Hilti catalog products only. “Specially” produced non-catalog Hilti products may have differing manufacturing plant locations. Contact your Hilti representative in cases of “specially” produced products for a custom LEEDS certificates.

6

Hilti, Inc. 5400 South 122nd East Avenue

Tulsa, OK 74146

1-800-879-8000 www.hilti.com

August 13, 2013 Madame, Monsieur, Objet : Aérosol pour joints coupe-feu CFS-SP WB Hilti – Données LEED L'aérosol pour joints coupe-feu CFS-SP WB Hilti est fabriqué en Floride. Le seau contenant l'aérosol pour joints coupe-feu CFS-SP WB Hilti est en polyéthylène et peut être complètement recyclé. L'aérosol pour joints coupe-feu CFS-SP WB ne renferme aucune matière recyclée après consommation ou après utilisation dans l'industrie et ne peut pas être recyclé. L'aérosol pour joints coupe-feu CFS-SP WB ne renferme pas de matériaux renouvelables rapidement. La teneur en COV de l'aérosol pour joints coupe-feu CFS-SP WB est de 34 g/L. L'aérosol pour joints coupe-feu CFS-SP WB Hilti n'est pas réglementé comme déchet dangereux en vertu des normes environnementales canadiennes. Les règlements pour l'élimination des déchets industriels non réglementés peuvent varier d'une province à l'autre et même d'une ville à l'autre. C'est pourquoi vous devriez consulter les agences de réglementation municipales et provinciales pour connaître les méthodes d'élimination. Si vous avez des questions, n'hésitez pas à communiquer avec moi au 918-872-3704. Veuillez agréer, Madame, Monsieur, l'expression de mes sentiments distingués.

Jerry Metcalf MPH, CHMM Premier directeur – Sécurité, environnement et installations Hilti Inc. 918-872-3704 [email protected] Date de révision : 28/6/2011

7

Hilti FirestopSaving livesthrough innovationand education

Product Information

Hilti. Outperform. Outlast.Hilti (Canada) Corp. 1-800-363-4458 • www.hilti.ca • Hilti Firestop Systems Guide — Canada

IntroductionApplications and Products

Selector Guide

Through-PenetrationJoint

Reference D

ata

Technical Data CP 767 and CP 777Tested in accordance with • UL 2079

• ASTM E 1966 • ASTM C G12 Type I-IUB• CAN/ULC-S115

FORMING MATERIAL FOR USE IN JOINT SYSTEMS

SEE UL FIRE RESISTANCE DIRECTORY 17RL

Easy one step installation — simply cut to length and install.

Full coverage pre-cut flute configuration leaves no gaps or voids.

Superior finish smooth surface allows quick and cost effective coverage with Hilti CFS-SP WB Firestop Joint Spray.

Easy to utili e — Speed Strips in joints between wall substrate and bottom of deck. Compress per UL System.

Installation instructions for CP 777Notice • Before handling, read Material Safety Data Sheet

and product label for safe usage and health information.

• Instructions below are general guidelines — always refer to the applicable drawing in the UL Fire Resistance Directory or Hilti Firestop Systems Guide for complete installation information

Saves time and money!

Castle cutting 50 MINUTES

Conventional mineral wool 35 MINUTES

Hilti speed plugs 20 MINUTES

60% Faster than castle cutting43% Faster than conventional mineral wool

*Based upon 40 linear feet of installation. Actual results may vary.

Speed Strips (CP 767)

Speed Plugs (CP 777)

Product description ■ CP 777: Pre-formed mineral wool plugs for 1.5", 2" and 3" decks ■ CP 767: Pre-formed mineral wool strips suitable for joint

applications

Product features ■ Pre-cut to industry standard si e decking flutes ■ Reduces material waste ■ 3 si es available ■ Pre-cut — leaves no gaps or voids ■ Smooth surface provides cost effective spray coverage ■ Safe to use — no asbestos/inorganic, will not mildew ■ Up to 60% faster than castle cutting

Areas of application ■ Top-of-wall

Tested and approved ■ UL Classified when used in conjunction with CP 606 Flexible

Firestop Sealant, CP 601S Elastomeric Firestop Sealant, CP 672 Speed Spray, or CFS-SP WB Firestop Joint Spray

8

26

Information sur les produits

Hilti (Canada) Corporation 1-800-363-4458 • www.hilti.ca • Guide des coupe-feu Hilti — dition Canada 2011

Hilti. Plus performant. Plus durable.

Coupe-feu de HiltiSauver des viesgr ce l innovationet l ducation

Fiche technique CP 767 et CP 777Essais en conformité avec • UL 2079

• ASTM E 1966 • ASTM C G12 Type I-IUB• CAN/ULC-S115

MAT RIAU DE FORMAGE UTILISER DANS LES SYSTÈMES DE JOINTS VOIR LE R PERTOIRE DE LA R SISTANCE AU

FEU 17RL

Facile Installation en une tape...Coupe simplement la longueur et installe .

Pleine couverture La cannelure pr -coup e ne laisse aucun vide ou espace de jointFini .

Fini sup rieur. La surface lisse permet un recouvrement rapide et conomique avec l a rosol pour joints coupe-feu CFS-SP WB.

Facile Utilise des bandes rapides dans les joints entre le substrat du mur et le bas de la plate-forme

Directives d’installation du CP 777Avertissement • Avant de manipuler, lire la fiche technique de

s curit du mat riau ainsi que l tiquette du produit pour une utilisation s curitaire et obtenir de l information sur la sant .

• Les directives ci-dessous sont des principes g n raux r f re -vous toujours l illustration correspondante dans le R pertoire sur la r sistance au feu des UL/cUL ou au Guide des syst mes coupe-feu de Hilti pour l information compl te quant l installation

Économisez temps et argent!

Couper des formes 50 MINUTES

Laine min rale conventionnelle 35 MINUTES

Bouchons rapides Hilti 20 MINUTES

60 % plus rapide que de couper des formes43 % plus rapide que la laine min rale conventionnelle

*Bas sur une installation lin aire de 40 pieds. Les r sultats peuvent varier.

CP 767 Bandes rapides

CP 777 Bouchons rapides

Description du produit ■ CP 777 : bouchons pr -coup s de laine min rales pour des plate-formes de

1,5 po, 2 po et 3 po ■ CP 767 : bandes pr -coup es de laine min rale convenant aux applications

de joints

Caractéristiques du produit ■ Pr -coup es aux tailles standard de l industrie pour les cannelures de

platelage ■ Diminue le gaspillage de mat riau ■ 3 grandeurs disponibles ■ Pr -coup — ne laisse aucun vide ou espace de joint ■ Une surface lisse permet une pulv risation couvrante conomique ■ S curitaire — sans amiante / inorganique, ne moisira pas ■ Jusqu 60 % plus rapide que de couper des formes

Zones d’application ■ Couronnement du mur

Testé et approuvé ■ Classifi UL lorsqu il est utilis avec le mastic coupe-feu flexible CP 606, le

mastic coupe-feu lastom re CP 601S, l a rosol rapide CP 672 ou l a rosol pour joints coupe-feu CFS-SP WB.

9

C E R T I F I C A T E O F C O M P L I A N C E

Certificate Number 20160829-R13081 Report Reference R13081

Issue Date 2016-August-29

Bruce Mahrenholz, Director North American Certification Program UL LLC Any information and documentation involving UL Mark services are provided on behalf of UL LLC (UL) or any authorized licensee of UL. For questions, please contact a local UL Customer Service Representative at http://ul.com/aboutul/locations/

Page 1 of 1

Issued to: Hilti Construction Chemicals, Div of Hilti Inc. 7250 Dallas Pky, Legacy Tower Ste 1000 Plano, TX 75024 USA

This is to certify thatrepresentative samples of

Forming Materials Forming Materials Certified for Canada CP767 Speed Strips and CP777 Speed Plugs Speed Strips for use in Joint Systems as currently decribed in the UL Fire Resistance Directory and in the Products Certified for Canada Directory.

Have been investigated by UL in accordance with the Standard(s) indicated on this Certificate.

Standard(s) for Safety: ANSI/UL 2079, "Tests for Fire Resistance of Building Joint

Systems." CAN/ULC-S115, "Standard Method of Fire Tests of Firestop Systems."

Additional Information: See the UL Online Certifications Directory at www.ul.com/database for additional information

Only those products bearing the UL Certification Mark should be considered as being covered by UL's Certification and Follow-Up Service. Look for the UL Certification Mark on the product.

10

Hilti, Inc. 5400 South 122nd East Avenue

Tulsa, OK 74146

1-800-879-8000 www.hilti.com

January 27, 2016 To Whom It May Concern: Re: Hilti CP767 Speed Strips and CP777 Speed Plugs – LEED Information Item Numbers:

CP 767 CP 777 374505 374506 374507 374508

340998 340999 371925

The Hilti CP767 Speed Strips and CP777 Speed Plugs are manufactured in North Carolina. Post-consumer recycled content of Hilti CP767 Speed Strips and CP777 Speed Plugs is 0%. Pre-consumer recycled content of Hilti CP767 Speed Strips and CP777 Speed Plugs is 0%. There is no detectable VOC content either product. Hilti CP767 Speed Strips and CP777 Speed Plugs are not regulated as a hazardous waste by the Federal EPA Standards. The regulations for the disposal of non-regulated industrial waste can vary from state to state and even city to city. For this reason, you should consult your local and state regulatory agencies for direction on disposal. Please feel free to contact me at (918) 872-3704 if you have questions. Sincerely,

Jerry Metcalf MPH, CHMM Sr. Manager, Safety/Environmental Hilti Inc. 918 872 3704 [email protected] Rev. Date: 1/27/16

The manufacturing plant location on this certificate has been provided for LEEDS reporting purposes only. It should never be used for Country of Origin certification or a representation of compliance/non-compliance with Buy American or Buy America requirements, as those requirements differ. The manufacturing plant location(s) identified on the certificate represent standard Hilti catalog products only. “Specially” produced non-catalog Hilti products may have differing manufacturing plant locations. Contact your Hilti representative in cases of “specially” produced products for a custom LEEDS certificates.

11

Hilti, Inc. 5400 South 122nd East Avenue

Tulsa, OK 74146

1-800-879-8000 www.hilti.com

Le 26 juillet 2013 Madame, Monsieur, Objet : Bandes rapides CP 767 et lingots rapides CP 777 Hilti – Données LEED Les bandes rapides CP 767 et les lingots rapides CP 777 Hilti sont fabriqués à Sophia, en Caroline du Nord. Les matières premières sont extraites à Phoenix, en Alabama. Le contenu recyclé après consommation des bandes rapides CP 767 et des lingots rapides CP 777 Hilti est de 0 %. Le contenu recyclé avant consommation des bandes rapides CP 767 et des lingots rapides CP 777 Hilti est de 0 %. Ces deux produits ne contiennent aucun COV détectable. Les bandes rapides CP 767 et les lingots rapides CP 777 de Hilti ne sont pas réglementés comme déchets dangereux en vertu des normes environnementales canadiennes. Les règlements pour l'élimination des résidus industriels non réglementés peuvent varier d'une province à l'autre et même d'une ville à l'autre. C'est pourquoi vous devriez consulter les agences de réglementation municipales et provinciales pour connaître les méthodes d'élimination. Si vous avez des questions, n'hésitez pas à communiquer avec moi au 918-872-3704. Veuillez agréer, Madame, Monsieur, l'expression de mes sentiments distingués.

Jerry Metcalf MPH, CHMM Premier directeur – Sécurité et environnement Hilti Inc. 918-872-3704 [email protected]

12

Hilti, Inc. 5400 South 122nd East Avenue

Tulsa, OK 74146

1-800-879-8000 www.hilti.com

Date de révision : 26/7/2013

13

Thermafiber® Safing™Fire Containment Insulation

Exceptional performance in Perimeter Fire Containment Systems

Provides life saving fire protection in rated assemblies

Fire resistant to temperatures above 2,000°F (1,093°C)

Easy to fabricate for through penetrations and firestopping

Conserves energy, reduces greenhouse gas emissions

Resists moisture

Controls noise and sound

+

+

+

+

+

+

+

Thermafiber Safing and FireSpan® insulation provide the critical components of the perimeter fire containment system in the 111 South Wacker Building in Chicago, IL. Thermafiber insulation also contributed to the building’s LEED® Gold Rating.

Thermafiber® SafingTM is compression fitted between FireSpan® insulation and the concrete slab edge to create a perimeter fire containment system.

LEED® v2009 Green Building CreditsEnergy & Atmosphere

Materials & Resources

Indoor Environmental Quality

Innovation in Design

1 2.1, 2.2 9 1 4.1, 4.2 5.1, 5.2

Minimum

70%RecycledContent1

14

Thermafiber® SafingTM InsulationDescription:

Thermafiber® Insolutions®:

For Further Information:

Notice:

Submittal Approvals:

THERMAFIBER SafingTM products are designed to provide life saving fire protection in perimeter fire containment systems, floor and wall penetrations, construction joints, and other firestopping applications. These products are noncombustible, moisture-resistant, noncorrosive, nondeteriorating, mildew-proof and vermin-proof. Thermafiber Safing provides thermal insulation, fire protection, and acoustical control in many different UL and Intertek (formerly OPL) listed fire containment assemblies of 1, 2, and 3-hr ratings.

Thermafiber offers industry leading technical and engineering assistance to architects, specifiers, and contractors. These services include CAD drawings, engineering judgments, LEED® Credit Information, product recommendations, and customized products. Contact our technical services department at 1-888-834-2371, or email [email protected] For additional information about these or other Thermafiber products contact us at 1-888-834-2371 or visit our website www.thermafiber.com.THERMAFIBER, Inc. shall not be liable for incidental and consequential damages, directly or indirectly sustained, nor for any loss caused by application of these goods not in accordance with current printed instructions or for other than the intended use. THERMAFIBER liability is expressly limited to replacement of defective goods. Any claim shall be deemed waived unless made in writing within thirty (30) days from date it was or reasonably should have been discovered.

Job Name

Contractor Date

3711 Mill Street | Wabash, IN 46992 | 888-TFIBER1 [834-2371] | [260] 563-2111 | www.thermafiber.com

Standard Sizes:

Standards Compliance: SafingTM Insulation meets the following:ASTM C 665 Non-corrosive, Type I, IIIASTM C 612 Type IA, IB, IIASTM E 136 Rated Non-combustible per NFPA Standard 220CAN/ULC S114 CompliesASTM E 96 Unfaced, 50 Perms as testedASTM E 96 Foil Faced, 0.02 Perms as testedASTM C 1104 Absorbs less than 1% by volumeCAN/ULC S102 Flame Spread 0, Smoke Developed 0ASTM E 814 or UL 1479 Safing Insulation used in conjunction with an approved fill, void, or cavity material sealant or other approved material in through – penetration firestop systems - CompliesUL 2079 Safing Insulation used in conjunction with an approved fill, void or cavity material in construction joint systems - CompliesCAN/ULC S115 CompliesSafing products are approved by: New York City Board of Standards & Appeals – (under BSA 39-74-SM & accepted by MEA-209-82-M, Vol. 4).

Thickness* Widths** Lengths** Safing 4.0 pcf 1”- 7” 16”, 24”, 36” 48”, 60” Safing 6.0 pcf 1”- 7” 16”, 24”, 36” 48”, 60” Tolerances +1/4” - 1/8” ±1/8” ±1/2” *Thicknesses are available in ½” increments. **Custom sizes are available upon request.

Product Options: • Safing 4.0 pcf, 2” or greater thickness, is available with or without a vapor retarding foil facing.• Safing 6.0 pcf, 1.5” or greater thickness, is available with or without a vapor retarding foil facing.• Recycled Content Options1: EPA Choice Fiber (US Government Buildings) ........Minimum 75% Standard Fiber .................................................................... 70% 1Recycled content options other than Standard must be specified at time of order.

Installation: All firestopping insulation should be installed per the architectural specification or system specific test description. All compressed Safing insulation should be installed per the listed assembly.• Perimeter Installation: SafingTM insulation should be compression fitted between the slab edge and the FireSpan curtain wall insulation, leaving no voids.• Penetration Application: Safing insulation should be cut slightly larger than the opening and compression fitted into the opening, leaving no voids. • Construction Joint Application: Safing insulation should be compression fitted into the joint opening, leaving no voids.

Technical Data:

TF61

2/R

ev 0

3-15

Cop

yrig

ht 2

015,

The

rmafi

ber,

Inc.

All

Rig

hts

Res

erve

d. L

EED

® is

a re

gist

ered

trad

emar

k of

U.S

. Gre

en B

uild

ing

Cou

ncil.

SafingTM insulation is a critical component of any perimeter fire containment system. Thermafiber® has performed decades of testing in all of the containment systems listed below. For more complete test information, see SA707, THERMAFIBER Life-Safety Fire Containment Systems technical catalog or UL® and Intertek® (formerly OPL) Directories. For a full listing of containment systems visit www.thermafiber.com and click on Fire Rated Assemblies. UL Reference = TYPE SAF• Aluminum Spandrel Curtain Wall Fire Containment• Steel Stud-Framed/Gypsum Sheathing Curtain Wall Fire Containment• Glass Spandrel Curtain Wall Fire Containment• Granite Spandrel Curtain Wall Fire Containment• Precast Concrete Spandrel

Fire-Containment Tests Per ASTM E 2307

Product Actual “k” @ 75° [24°C] “R” value per Designation Density inch of thickness***

Safing 4.0 pcf 0.24 ‘R’= 4.2 0 0 25 0

Safing 6.0 pcf 0.24 ‘R’= 4.2 0 0 25 0

BTU.in/hr.sq. ft. °F

Tested to ASTM C 518 Tested to ASTM E 84

Unfaced Foil Faced

Flame Spread

Flame Spread

Smoke Developed

Smoke Developed

***R = thickness divided by ‘k’

15

THERMAFIBER® Safing Insulation is a mineral-wool-type insulation that resists temperatures up to 2,000 °F (1,093 °C), thus offering superior fire protection in a wide variety of fire-rated applications. It isa UL- and OPL-labeled product especially intended for tested UL and OPL Designs, as well as many otherfire- and smoke-tested assemblies. This product is noncombustible per Standard NFPA 220 when testedin accordance with ASTM E 136, and moisture-resistant, noncorrosive, nondeteriorating, mildew-proofand vermin-proof. It permits dry construction for all-year-round work. Also, THERMAFIBER SafingInsulation is available plain, or with scrim-reinforced foil facing (FSP) that serves as a vapor retarderand/or smoke barrier.

THERMAFIBER Safing Insulation is compatible with both THERMAFIBER® Curtain Wall CW Insulations andTHERMAFIBER FIRESPAN™ Insulations.

THERMAFIBER Safing Insulation is a key element in a wide variety of fire-tested construction assemblies.It is used with THERMAFIBER Curtain Wall and FIRESPAN Insulations in applications to contain both fireand smoke to the area of origin. Especially for mid- and high-rise buildings, where fire and smoke mustbe prevented from spreading to the next floor. Since the floor assembly is typically fire-rated, one routefor the fire spread is through and up the exterior curtain wall system. THERMAFIBER Safing Insulation isalso used in conjunction with various sealants and caulks, in wall and floor penetration (poke-through)applications, head-of-wall construction joints, and other construction joints.

It is important to note that one of the most valuable yet misunderstood applications of THERMAFIBER Safing Insulation is its use in exterior curtain wall assemblies to safe-off the openingbetween concrete floor slabs and the curtain wall assemblies. Many people still believe the myth that allthermal insulations are the same when used in the curtain wall spandrel panels as long as THERMAFIBER Safing Insulation is used in the assembly. This is simply not true. Actual fire tests haveproven that low-melt-point insulations, such as glass fiber types, will disintegrate quickly once exposedto fire, leaving the curtain wall unprotected. Then, as the now-unprotected curtain wall disintegrates orfalls away, the safing insulation will no longer be supported, and the fire will spread to the floor(s) above.Effective perimeter fire containment can only be achieved when a fire-compatible product with the abilityto resist high temperatures (such as THERMAFIBER Curtain Wall Insulations or THERMAFIBERFIRESPAN Insulations) is used in conjunction with the THERMAFIBER Safing Insulation, acting together asa system. (See TF685, TF686 and TF871 for additional information).

In curtain wall fire-containment applications, THERMAFIBER Safing Insulation fills the void between theslab edge and the curtain wall insulation to contain fire. Foil-faced insulation impedes the passage ofsmoke and noxious gases. Install THERMAFIBER Safing Insulation, of proper width (2" to 8" max. opening), compression fit in safe-off area (foil side up, if required) between THERMAFIBER FIRESPAN orCW Curtain Wall Insulation and floor slabs, on safing "Z" clips spaced as required in the design (24" or12" o.c. maximum), leaving no voids. Compression fitting the safing insulation is critical to assuring atight seal. See specific test description for proper installation details. Install proper topping material,such as THERMAFIBER SMOKE SEAL Compound, or other approved smoke sealants as indicated in the spe-cific test description or architectural specification.

THERMAFIBER Safing Insulation provides a noncombustible, fire-resistant forming/packing material formany types of penetrations in walls and floor/ceilings. In all poke-through penetrations, clean substrateof dirt, dust, grease, oil, efflorescence, loose material or other matter. With a serrated knife, cut THERMAFIBER Safing Insulation slightly wider than the opening. Compress and tightly fit the minimumthickness and density of insulation required (per system specification) completely around penetrant. Forfloor slab openings, compress or install THERMAFIBER Safing Insulation according to details indicated inthe specific test description or architectural specification to seal completely around cables, ducts, pipingor other utilities.

THERMAFIBER Safing Insulation is also used as a forming material in head-of-wall, floor to floor, floor towall, and wall to wall construction joints. It is compressed and slid into joint openings to completely fillthe gap between the intersection of the walls, floor, etc.

THERMAFIBER® Safing InsulationUL- and OPL-labeled* safing insulation for firestops and fire-containment systems • Firestop product for curtain wall fire and smoke containment systems, floor and wall penetrations,

head-of-wall, and other construction joint systems. • Fire resistant and noncombustible. • Economical; installs quickly and easily. • Aids sound control in many assemblies. • Available in unfaced felt (plain) or with a tough scrim-reinforced foil facing (FSP). • Durable; nondeteriorating and noncorrosive.

Description

Perimeter Fire Containment,Penetrations and Construction Joints

Installation Perimeter Installation

Penetration Application

Construction JointApplication

* UL is an abbreviation for Underwriters Laboratories Inc.; OPL is an abbreviation for Omega Point Laboratories, Inc.

Submittal Sheet07840

16

Trademarks THERMAFIBER, FIRESPAN and THENAME IN MINERAL WOOL are trade-marks of Thermafiber Inc. SMOKESEAL is a trademark of United StatesGypsum Company.

NoteProducts described here may not beavailable in all geographic markets.Consult your local sales office or rep-resentative for information.

Notice THERMAFIBER INC. shall not beliable for incidental and consequentialdamages, directly or indirectlysustained, nor for any loss caused byapplication of these goods not inaccordance with current printedinstructions or for other than theintended use. THERMAFIBER’Sliability is expressly limited toreplacement of defective goods. Anyclaim shall be deemed waived unlessmade in writing within thirty (30)days from date it was or reasonablyshould have been discovered.

Safety First!Follow good safety and industrialhygiene practices while handling andinstalling products and systems.Take necessary precautions and wearthe appropriate personal protectiveequipment as needed. Read materialsafety data sheets and related litera-ture on products before specificationand/or installation.

Health AspectsInformation about health aspects ofusing THERMAFIBER® Curtain WallInsulation products are thoroughlyexplained in North AmericanInsulation ManufacturersAssociation’s (NAIMA) Health andSafety facts for rock and slag woolinsulation document #63. ContactThermafiber, Inc. for more details.

Product Designation Flame Spread Smoke Developed Safing, Regular (Unfaced) 0 0 Safing (Foil-Faced) 25 0 Products have a class A interior finish rating per NFPA 101, life safety code.

Product Actual Density Minimum ApplicationDesignation Density Tolerance-pcf(1) Thickness MethodSafing 4.0 -0.5 +1.0 1" safing clips and/or compression fitSafing 6.0 -0.75 +2.0 1-1/2" safing clips and/or compression fit Safing 8.0 -1.0 +2.0 1" safing clips and/or compression fit(1) On packaging weight basis.

THERMAFIBER Safing Insulation meets the following:

ASTM C 665 - Federal Specification HH-I-521F–Safing insulation as Types I and III, Class A, Category 1.

ASTM C 612-00 - Federal Specification HH-I-558B–Safing insulation as Types IA, IB and II.

ASTM E 136 - Rated noncombustible as defined by NFPA Standard 220 when tested according to ASTM E 136.

ASTM E 814 or UL 1479 - Safing insulation used in conjunction with SMOKE SEAL Compound, or other approved material in through - penetration firestop systems.

UL 2079 - Safing insulation used in conjunction with various sealants and caulks in construction jointsystems.

ASTM C 553 - THERMAFIBER Insulations absorb less than 1% moisture by weight and volume.

Safing insulation products are approved by: New York City Board of Standards & Appeals– 39-74-SM &MEA 209-82-M, Vol. II.

THERMAFIBER blankets are a mineral fiber material manufactured from blast furnace slag, a by-product ofiron ore reduction, and naturally occurring rock. THERMAFIBER blankets contain greater than 80% post-industrial recycle content. This product contains No Asbestos.

System performance following substitution of materials or compromise in assembly design cannot becertified and may result in failure of fire performance under certain conditions. Products and systemsprovided by Thermafiber Inc. are warranted to be free from defects in material workmanship. ContactThermafiber Inc. for complete warranty details.

Store in a cool, dry place.

Surface BurningCharacteristics (According to ASTM E 84)

Product Density

Standards Compliance

Composition andMaterials

Warranty

Storage

Submittal Approvals:

Product Data

Job Name

Contractor Date

™

INC

3711 West Mill Street Wabash, IN 46992-8687 1-888-TFIBER1 (834-2371)www.thermafiber.com

TF612/Rev 11/06Copyright 2004, Thermafiber Inc. Printed in U.S.A.

Technical Data

MMAADDEE IINN UUSSAATTHHEERRMMAAFFIIBBEERR MMAADDEE FFRROOMM

RREECCYYCCLLEEDD MMAATTEERRIIAALLSS

For the most up-to-date technical data, please refer to our website at www.thermafiber.com

17

C E R T I F I C A T E O F C O M P L I A N C E

Certificate Number 20151218-R10905 Report Reference R10905

Issue Date 2015-December-18

Bruce Mahrenholz, Director North American Certification Program UL LLC Any information and documentation involving UL Mark services are provided on behalf of UL LLC (UL) or any authorized licensee of UL. For questions, please contact a local UL Customer Service Representative at http://ul.com/aboutul/locations/

Page 1 of 3

Issued to: Thermafiber Inc. 3711 Mill St Wabash, IN 46992 USA

This is to certify thatrepresentative samples of

Forming Materials Forming Materials Certified for Canada

Have been investigated by UL in accordance with the Standard(s) indicated on this Certificate.

Standard(s) for Safety: ANSI/UL 1479, "Fire Tests of Through-Penetration Firestops,"

ANSI/UL 2079, "Tests for Fire Resistance of Building Joint Systems," and ANSI/ASTM E2307 (2010), "Standard Test Method for Determining Fire Resistance of Perimeter Fire Barriers Using Intermediate-Scale, Multi-story Test Apparatus." CAN/ULC-S115 (2005), "Standard Method of Fire Tests of Firestop Systems."

Additional Information: See the UL Online Certifications Directory at www.ul.com/database for additional information

Only those products bearing the UL Certification Mark should be considered as being covered by UL's Certification and Follow-Up Service. Look for the UL Certification Mark on the product.

18

C E R T I F I C A T E O F C O M P L I A N C E

Certificate Number 20151218-R10905 Report Reference R10905

Issue Date 2015-December-18

Bruce Mahrenholz, Director North American Certification Program UL LLC Any information and documentation involving UL Mark services are provided on behalf of UL LLC (UL) or any authorized licensee of UL. For questions, please contact a local UL Customer Service Representative at http://ul.com/aboutul/locations/

Page 2 of 3

This is to certify that representative samples of the product as specified on this certificate were tested according to the current UL requirements. Type SAF mineral wool batts for use in Joint System Nos. BW-S-0029, FF-D-0002, FF-D-0011, FF-D-0013, FF-D-0014, FF-D-0015, FF-D-0016, FF-D-0017, FF-D-0019, FF-D-0022, FF-D-0023, FF-D-0025, FF-D-0026, FF-D-0028, FF-D-0073, FF-D-0074, FF-D-0096, FF-D-0097, FF-D-0109, FF-D-1001, FF-D-1002, FF-D-1003, FF-D-1004, FF-D-1006, FF-D-1007, FF-D-1008, FF-D-1010, FF-D-1015, FF-D-1016, FF-D-1020, FF-D-1021, FF-D-1024, FF-D-1025, FF-D-1027, FF-D-1036, FF-D-1039, FF-D-1040, FF-D-1041, FF-D-1042, FF-D-1045, FF-D-1047, FF-D-1098, FF-D-1125, FF-D-1158, FF-D-3003, FF-D-3004, FF-S-1031, FF-S-1033, FW-D-0001, FW-D-0004, FW-D-0007, FW-D-0009, FW-D-0010, FW-D-0011, FW-D-0012, FW-D-0014, FW-D-0017, FW-D-0018, FW-D-0020, FW-D-0021, FW-D-0023, FW-D-0024, FW-D-0027, FW-D-0050, FW-D-0051, FW-D-0067, FW-D-0068, FW-D-1001, FW-D-1002, FW-D-1003, FW-D-1005, FW-D-1006, FW-D-1007, FW-D-1009, FW-D-1010, FW-D-1016, FW-D-1017, FW-D-1020, FW-D-1024, FW-D-1033, FW-D-1035, FW-D-1037, FW-D-1038, FW-D-1039, FW-D-1040, FW-D-1044, FW-D-1047, FW-D-1055, FW-D-1070, FW-D-1089, FW-D-1092, FW-D-1093, FW-D-1102, FW-D-1103 FW-S-1016, FW-S-1019, HW-D-0001, HW-D-0002, HW-D-0006, HW-D-0009, HW-D-0013, HW-D-0016, HW-D-0017, HW-D-0020, HW-D-0021, HW-D-0022, HW-D-0023, HW-D-0025, HW-D-0026, HW-D-0027, HW-D-0028, HW-D-0029, HW-D-0030, HW-D-0031, HW-D-0034, HW-D-0038, HW-D-0039, HW-D-0040, HW-D-0042, HW-D-0043, HW-D-0044, HW-D-0045, HW-D-0046, HW-D-0047, HW-D-0049, HW-D-0050, HW-D-0051, HW-D-0052, HW-D-0054, HW-D-0055, HW-D-0058, HW-D-0059, HW-D-0062, HW-D-0064, HW-D-0067, HW-D-0069, HW-D-0072, HW-D-0073, HW-D-0075, HW-D-0079, HW-D-0086, HW-D-0087, HW-D-0088, HW-D-0089, HW-D-0091, HW-D-0092, HW-D-0099, HW-D-0100, HW-D-0101, HW-D-0102, HW-D-0103, HW-D-0104, HW-D-0105, HW-D-0106, HW-D-0107, HW-D-0108, HW-D-0118, HW-D-0122, HW-D-0123, HW-D-0127, HW-D-0128, HW-D-0131, HW-D-0136, HW-D-0137, HW-D-0139, HW-D-0140, HW-D-0143, HW-D-0146, HW-D-0149, HW-D-0152, HW-D-0153, HW-D-0154, HW-D-0156, HW-D-0157, HW-D-0160, HW-D-0166, HW-D-0168, HW-D-0170, HW-D-0171, HW-D-0172, HW-D-0173, HW-D-0174, HW-D-0177, HW-D-0178, HW-D-0185, HW-D-0186, HW-D-0187, HW-D-0188, HW-D-0190, HW-D-0192, HW-D-0199, HW-D-0200, HW-D-0201, HW-D-0204, HW-D-0205, HW-D-0206, HW-D-0208, HW-D-0211, HW-D-0218, HW-D-0220, HW-D-0221, HW-D-0222, HW-D-0246, HW-D-0248, HW-D-0252, HW-D-0253, HW-D-0258, HW-D-0259, HW-D-0263, HW-D-0265, HW-D-0278, HW-D-0279, HW-D-0297, HW-D-0298, HW-D-0299, HW-D-0335, HW-D-0336, HW-D-0337, HW-D-0338, HW-D-0354, HW-D-0357, HW-D-0358, HW-D-0359, HW-D-0363, HW-D-0365, HW-D-0366, HW-D-0367, HW-D-0377, HW-D-0378, HW-D-0380, HW-D-0381, HW-D-0384, HW-D-0385, HW-D-0388, HW-D-0389, HW-D-0391, HW-D-0395, HW-D-0396, HW-D-0404, HW-D-0405, HW-D-0406, HW-D-0407, HW-D-0408, HW-D-0409, HW-D-0410, HW-D-0411, HW-D-0412, HW-D-0413, HW-D-0414, HW-D-0415, HW-D-0416, HW-D-0417, HW-D-0441, HW-D-0442, HW-D-0447, HW-D-0456, HW-D-0457, HW-D-0460, HW-D-0465, HW-D-0467, HW-D-0468, HW-D-0478, HW-D-0479, HW-D-0524, HW-D-0531, HW-D-0536, HW-D-0538, HW-D-0539, HW-D-0540, HW-D-0542, HW-D-0546, HW-D-0547, HW-D-0548, HW-D-0549, HW-D-0553, HW-D-0560, HW-D-0561, HW-D-0562, HW-D-0564, HW-D-0566, HW-D-0567, HW-D-0568, HW-D-0569, HW-D-0570, HW-D-0571, HW-D-0572, HW-D-0577, HW-D-0578, HW-D-0580,

19

C E R T I F I C A T E O F C O M P L I A N C E

Certificate Number 20151218-R10905 Report Reference R10905

Issue Date 2015-December-18

Bruce Mahrenholz, Director North American Certification Program UL LLC Any information and documentation involving UL Mark services are provided on behalf of UL LLC (UL) or any authorized licensee of UL. For questions, please contact a local UL Customer Service Representative at http://ul.com/aboutul/locations/

Page 3 of 3

Type SAF mineral wool batts for use in Joint System Nos. HW-D-0582, HW-D-0583, HW-D-0584, HW-D-0590, HW-D-0591, HW-D-0597, HW-D-0612, HW-D-0614, HW-D-0617, HW-D-0619, HW-D-0631, HW-D-0633, HW-D-0634, HW-D-0635, HW-D-0636, HW-D-0639, HW-D-0640, HW-D-0642, HW-D-0643, HW-D-0644, HW-D-0645, HW-D-0649, HW-D-0650, HW-D-0661, HW-D-0662, HW-D-0687, HW-D-0697, HW-D-0698, HW-D-0702, HW-D-0703, HW-D-0704, HW-D-0725, HW-D-0726, HW-D-0735, HW-D-0740, HW-D-0741, HW-D-0742, HW-D-0743, HW-D-0747, HW-D-0748, HW-D-0750, HW-D-1001, HW-D-1002, HW-D-1003, HW-D-1004, HW-D-1005, HW-D-1006, HW-D-1007, HW-D-1010, HW-D-1013, HW-D-1014, HW-D-1015, HW-D-1016, HW-D-1020, HW-D-1021, HW-D-1022, HW-D-1023, HW-D-1024, HW-D-1028, HW-D-1032, HW-D-1033, HW-D-1034, HW-D-1037, HW-D-1040, HW-D-1042, HW-D-1044, HW-D-1045, HW-D-1050, HW-D-1060, HW-D-1066, HW-D-1067, HW-D-1068, HW-D-1069, HW-D-1070, HW-D-1073, HW-D-1074, HW-D-1075, HW-D-1076, HW-D-1077, HW-D-1079, HW-D-1080, HW-D-1089, HW-D-1094, HW-D-1097, HW-D-1102, HW-D-1103, HW-D-1104, HW-D-1110, HW-S-0001, HW-S-0009, HW-S-0010, HW-S-0053, HW-S-0054, HW-S-0080, HW-S-0083, HW-S-1015, WW-D-0013, WW-D-0018, WW-D-0019, WW-D-0020, WW-D-0063, WW-D-1001, WW-D-1002, WW-D-0022, WW-D-0089, WW-D-0090, WW-D-0103, WW-D-0171, WW-D-0140, WW-D-0141, WW-D-1003, WW-D-1004, WW-D-1005, WW-D-1006, WW-D-1007, WW-D-1010, WW-D-1015, WW-D-1016, WW-D-1023, WW-D-1027, WW-D-1036, WW-D-1037, WW-D-1042, WW-D-1047, WW-D-1089, WW-D-1090, WW-D-1091, WW-D-1128, WW-D-1129, WW-S-0064, WW-S-1035. TYPE SAF MINERAL WOOL BATTS FOR USE IN PERIMETER FIRE CONTAINMENT SYSTEM NOS. CW-D-1001, CW-D-1002, CW-D-1003, CW-D-1004, CW-D-1005, CW-D-1006, CW-D-1007, CW-D-1008, CW-D-1009, CW-D-1010, CW-D-1011, CW-D-1012, CW-D-1013, CW-D-1014, CW-D-1015, CW-D-1016, CW-D-1017, CW-D-1018, CW-D-1019, CW-D-1020, CW-D-1021, CW-D-1022, CW-D-1023, CW-D-1028, CW-D-1029, CW-D-1030, CW-D-2001, CW-D-2002, CW-D-2003, CW-D-2005, CW-D-2006, CW-D-2008, CW-D-2009, CW-D-2010, CW-D-2011, CW-D-2012, CW-D-2013, CW-D-2036, CW-D-2037, CW-D-2038, CW-D-2039, CW-D-2040, CW-D-2041, CW-D-2042, CW-D-2046, CW-D-2047, CW-D-2048, CW-D-2049, CW-D-2050, CW-D-2051, CW-D-2052, CW-D-2055, CW-D-2056, CW-D-2057, CW-D-2058, CW-D-2059, CW-D-2063, CW-D-2064, CW-D-2065, CW-D-2066, CW-S-0001, CW-S-0002, CW-S-0003, CW-S-0004, CW-S-1001, CW-S-1002, CW-S-1003, CW-S-1007, CW-S-1010, CW-S-1016, CW-S-1017, CW-S-1020, CW-S-1022, CW-S-1023, CW-S-1024, CW-S-1025, CW-S-1026, CW-S-2001, CW-S-2002, CW-S-2003, CW-S-2006, CW-S-2008, CW-S-2014, CW-S-2021, CW-S-2022, CW-S-2023, CW-S-2025, CW-S-2029, CW-S-2034, CW-S-2035, CW-S-2036, CW-S-2058, CW-S-2059, CW-S-2060, CW-S-2061, CW-S-2062, CW-S-2064, CW-S-2065, CW-S-2066. TYPE SAF MINERAL WOOL BATTS FOR USE IN THROUGH-PENETRATION FIRESTOP SYSTEM NOS. C-AJ-1020, C-AJ-1081, C-AJ-3045, W-L-1027, W-L-1039, W-L-1064, W-L-1065, W-L-2023, W-L-2036, W-L-3023, W-L-3034, W-L-7001, W-L-7002. TOPSTOP MINERAL WOOL DECK PLUGS TYPE SAF BATTS FOR USE IN JOINT SYSTEM NOS. HW-D-0001, HW-D-0002, HW-D-0020, HW-D-0022, HW-D-0034, HW-D-0039, HW-D-0043, HW-D-0086, HW-D-0088, HW-D-0160, HW-D-0161, HW-D-0456, HW-D-0612, HW-D-0644.

20

Hilti, Inc. 5400 South 122nd East Avenue

Tulsa, OK 74146

1-800-879-8000 www.hilti.com

September 24, 2015 To Whom It May Concern: Re: Hilti Mineral Wool-LEED Information Item Number:

236993 The Hilti Mineral Wool is manufactured in Wabash, Indiana. The post-consumer recycled content in the Hilti Mineral Wool is 0%. The pre-consumer recycled content in the Hilti Mineral Wool is 90%. There is no detectable VOC content in this product. Hilti Mineral Wool is not regulated as a hazardous waste by the Federal EPA Standards. The regulations for the disposal of non-regulated industrial waste can vary from state to state and even city to city. For this reason, you should consult your local and state regulatory agencies for direction on disposal. Please feel free to contact me at (918) 872-3704 if you have questions. Sincerely,

Jerry Metcalf MPH, CHMM Sr. Manager, Safety/Environmental Hilti Inc. 918 872 3704 [email protected] Rev. Date: 9/24/15 The manufacturing plant location on this certificate has been provided for LEEDS reporting purposes only. It should never be used for Country of Origin certification or a representation of compliance/non-compliance with Buy American or Buy America requirements, as those requirements differ. The manufacturing plant location(s) identified on the certificate represent standard Hilti catalog products only. “Specially” produced non-catalog Hilti products may have differing manufacturing plant locations. Contact your Hilti representative in cases of “specially” produced products for a custom LEEDS certificates.

21

Hilti, Inc. 5400 South 122nd East Avenue

Tulsa, OK 74146

1-800-879-8000 www.hilti.com

August 13, 2013 Madame, Monsieur, Objet : Laine minérale Hilti – Données LEED La laine minérale Hilti est fabriquée à Wabash, en Indiana. Le contenu recyclé après consommation de la laine minérale Hilti est de 0 %. Le contenu recyclé avant consommation de la laine minérale Hilti est de 90 %. La laine minérale Hilti ne contient aucun COV détectable. La laine minérale Hilti n'est pas réglementée comme déchet dangereux en vertu des normes environnementales canadiennes. Les règlements pour l'élimination des déchets industriels non réglementés peuvent varier d'une province à l'autre et même d'une ville à l'autre. C'est pourquoi vous devriez consulter les agences de réglementation municipales et provinciales pour connaître les méthodes d'élimination. Si vous avez des questions, n'hésitez pas à communiquer avec moi au 918-872-3704. Veuillez agréer, Madame, Monsieur, l'expression de mes sentiments distingués.

Jerry Metcalf MPH, CHMM Directeur – Sécurité et environnement Hilti Inc. 918-872-3704 [email protected] Date de révision : 13/8/2010

22

A5.0

2

1

A5.0 4

7A2.0 A5.0

A5.06

3

4'-0"

MANAGER OFFICE103

RECEPTION101

COMMUNITY PARTNERPROGRAM ROOM

108

STORAGE109

LOUNGE AREA105

FHC

SEATING AREA110

MULTI PURPOSE AREA111

COUNSELOR'S OFFICE106

ELDER'S ROOM107

9'-0 1/2"

9'-11

"

4'-7

1/2"

6'-1 1/2"

RELOCATED BULLETIN BD CABINET

D106

B

D107

D108

D109

D106A

D101

D100

12'-0

1/2

"O/F STUD

12'-1 1/4" 3 5/8"

O/F STUD

12'-1 1/4" 3 5/8"

O/F STUD

9'-0 5/8" 3 5/8"

O/F STUD

7'-1 3/4"

15'-10 1/8"

P3HS

P3HS

P3H

P24H

P24H

P24H

22'-0

"

P3HS

P3HS

P3HS

4'-0"

3'-9"

6'-8"

EXIST'G DRINKING FOUNTAINS

EXIST'G MOP SINK

MECH CHASE

P3HS

P3HS

CLEA

R

3'-0"

CN-01

CN-02

2'-1 1/2"

16'-3

3/4

"

2'-1 1/2" 18'-1 3/8" 3'-0" 3'-0" 13'-0 1/4"

SV CPT

3'-6"

12'-2

3/8

"

P3H

59'-7" (FIELD VERIFY)

FILE RM104

JAN / ELEC RM102

WAITING AREA100

3'-8"

CLE

AR

D105

D102

D103

5'-6"

CN-01

P3HS

P40DH

P40DH

CN-01

CN-02 CN-02 CN-02

DISHWASHER

FRIDGE

2'-6

1/4"

6'-8

1/4"

GROMMETS

2'-6"

2'-1

1/2"

2'-8" 1'-0" 1'-6" 4'-11" 2'-1"

7'-7

5/8"

3'-6"2'-10" CLEAR

4'-0"

3'-7

5/8"

8"

P40DH

P3DHS

P3DHS

12 St Paul St.Thunder Bay, ON, CAP7A 4S5

807.346.2277 (office)8555.558.1459 (fax)i4a.ca

Project Name

Project Address

Sheet Name

COPYRIGHT NOTICE:

Copyright of this electronic document belongs to Cory R. Stechyshyn Architect Inc o/a

i4architecture.

This electronic document may not be forwarded to others, transmitted, downloaded or reproduced in any format, whether print or

electronic, without the express, written permission of the copyright owner.

Scale

Drawn by

Project number

Professional Seal

Sheet Number

DRAWINGS ARE NOT TO BE USED FOR CONSTRUCTION UNLESS ARCHITECTS SEAL IS AFFIXED, SIGNED AND DATED.

3/16" = 1'-0"

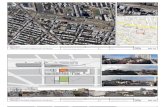

Lakehead UniversityAboriginal Initiatives -Interior Renovation

955 Oliver Road, ThunderBay, ON, P7B 5E1

Renovated Floor Plan

2017-68

NCM

AD2.01

No. Description DateA ISSUED FOR ADDENDUM

NO-211-OCT-2018

Scale = 3/16" = 1'-0"AD2.011 Renovation Plan - AD2.01

11-OCT-2018

GYP 8' - 0"

GYP 7' - 6"

ACT-1 8' - 0"

ACT-1 8' - 0"

ACT-1 8' - 0" ACT-1 8' - 0"

ACT-1 8' - 0" ACT-1 8' - 0"

ACT-1 8' - 0"

LOUNGE AREA105

SEATING AREA110

MULTI PURPOSE AREA111

RECEPTION101

COUNSELOR'S OFFICE106

ELDER'S ROOM107

COMMUNITY PARTNERPROGRAM ROOM

108

STORAGE109

MANAGER OFFICE103

ACT-1 8' - 0"

4'-7

1/2"

6"4'-

7"1'-

2"4'-

6 1/

4"4

7/8"

10'-9

7/8

"12

'-4 5

/8"

6'-2

5/8"

45'-2

5/8

"

2'-0" 15'-9 1/2"

4 7/8"

41'-4 5/8"

11'-1

1 7/

8"4

7/8"

21'-1

1 3/

8"

34'-4

1/8

"

19'-1 1/8" 4 7/8" 12'-0" 4 7/8" 12'-0" 4 7/8" 8'-11 3/8" 4 7/8" 7'-1 1/8"

9'-5"

60'-9 1/8"

3'-8 1/2" 6" 6'-1 1/2" 1'-0" 9'-0 1/2"

3'-4 1/8" 6'-4 7/8" 9'-6"

VALANCE UNDER CABINET LIGHITNG

VALANCE UNDER CABINET LIGHITNG

EXIST TO REMAIN

FILE RM104

MECH CHASE

JAN / ELEC RM102

WAITING AREA100

WD-L 7'-9" +/-

GYP BLKHD

1A2.0 AD2.04

12 St Paul St.Thunder Bay, ON, CAP7A 4S5

807.346.2277 (office)8555.558.1459 (fax)i4a.ca

Project Name

Project Address

Sheet Name

COPYRIGHT NOTICE:

Copyright of this electronic document belongs to Cory R. Stechyshyn Architect Inc o/a

i4architecture.

This electronic document may not be forwarded to others, transmitted, downloaded or reproduced in any format, whether print or

electronic, without the express, written permission of the copyright owner.

Scale

Drawn by

Project number

Professional Seal

Sheet Number

DRAWINGS ARE NOT TO BE USED FOR CONSTRUCTION UNLESS ARCHITECTS SEAL IS AFFIXED, SIGNED AND DATED.

3/16" = 1'-0"

Lakehead UniversityAboriginal Initiatives -Interior Renovation

955 Oliver Road, ThunderBay, ON, P7B 5E1

Renovated RCP

2017-68

NCM

AD2.02

No. Description DateA ISSUED FOR ADDENDUM

NO-211-OCT-2018

Scale = 3/16" = 1'-0"AD2.021 Renovation Reflected Ceiling Plan - AD2.02

11-OCT-2018

FRAME TYPE "F1"

50 VARIES 50

VARI

ES50

FRAME TYPE "F2"

50 500 50 VARIES 50

VARI

ES50

FRAME TYPE "F4"FRAME TYPE "F3"

Frame Type Legend

8'-0"

7'-0"

1'-0"

10"

8'-0"

5'-1 5/8"

1'-6"

1'-0"

7'-0"

10"

3'-0"

2"1'-7 5/8"2"

8"10

"

2" 1'-9" 2" 1'-9" 2" 2" 3'-1" 2" 3'-1" 2"4 7/8"

3'-2 1/8" 2"

10'-5"

FRAME TYPE "F1A"

10"

1'-6"

8"

4'-0"

12 St Paul St.Thunder Bay, ON, CAP7A 4S5

807.346.2277 (office)8555.558.1459 (fax)i4a.ca

Project Name

Project Address

Sheet Name

COPYRIGHT NOTICE:

Copyright of this electronic document belongs to Cory R. Stechyshyn Architect Inc o/a

i4architecture.

This electronic document may not be forwarded to others, transmitted, downloaded or reproduced in any format, whether print or

electronic, without the express, written permission of the copyright owner.

Scale

Drawn by

Project number

Professional Seal

Sheet Number

DRAWINGS ARE NOT TO BE USED FOR CONSTRUCTION UNLESS ARCHITECTS SEAL IS AFFIXED, SIGNED AND DATED.

1 : 50

Lakehead UniversityAboriginal Initiatives -Interior Renovation

955 Oliver Road, ThunderBay, ON, P7B 5E1

Frame Type Legend

2017-68

NCM

AD2.03

No. Description DateA ISSUED FOR ADDENDUM

NO-211-OCT-2018

Scale = 1 : 50Frame Type Legend

11-OCT-2018

3'-4 1/8" TO FACE OF GYP BULKHEAD

GYP 8' - 0" ACT-1 8' - 0"

FIEL

D VE

RIFY

TO

U/S

MTL

DEC

K

P3DHS

5/8" GYP ON 2 1/2" MTL STUD FRAMING

NEW PREFIN MTL TRIMCOLOR TO MATCH CLG

EXIST CORRIDOR CLG

U/S MTL DECK NEW 1HR FRR BLKHD TO U/S OF MTL DECK CTS AROUND FRAMES F1 & F1AFIRE STOP AS REQ'D AROUND EXISTSTRUCTURE

FIRE RATED HM DOOR/SCREENWAITING AREA

100

Interior Partition Assemblies - New Construction - Metal Stud

TAG ASSEMBLY THICKNESS

P3

16 GYPSUM BOARD92 METAL STUDS @ 400 O/CSOUND ATTENUATION BATT INSUL16 GYPSUM BOARD

124

4 7/8"

5/8" GYPSUM BOARD3 5/8" METAL STUDS @ 16" O/CSOUND ATTENUATION BATT INSUL5/8" GYPSUM BOARD

UNITSVISUAL

M

SI

COMMENTS

ULC REFERENCE: ULC W4071 HOUR MAXIMUM FIRE RESISTANCE RATING (F.R.R.) BASED ON ULC DESIGN. REFER TO FIRE RATING DESIGNATIONS AND FIRE SEPARATION PLANS FOR REQUIRED RATING & LOCATIONS.

FIRE STOP CAULKING AT TOP AND BOTTOM OF WALL + PENETRATIONS

12 St Paul St.Thunder Bay, ON, CAP7A 4S5

807.346.2277 (office)8555.558.1459 (fax)i4a.ca

Project Name

Project Address

Sheet Name

COPYRIGHT NOTICE:

Copyright of this electronic document belongs to Cory R. Stechyshyn Architect Inc o/a

i4architecture.

This electronic document may not be forwarded to others, transmitted, downloaded or reproduced in any format, whether print or

electronic, without the express, written permission of the copyright owner.

Scale

Drawn by

Project number

Professional Seal

Sheet Number

DRAWINGS ARE NOT TO BE USED FOR CONSTRUCTION UNLESS ARCHITECTS SEAL IS AFFIXED, SIGNED AND DATED.

As indicated

Lakehead UniversityAboriginal Initiatives -Interior Renovation

955 Oliver Road, ThunderBay, ON, P7B 5E1

Section Detail @ GYPBulkhead

2017-68

NCM

AD2.04

No. Description DateA ISSUED FOR ADDENDUM

NO-211-OCT-2018

Scale = 1 1/2" = 1'-0"AD2.04A2.01 Section Detail @ GYP Bulkhead

11-OCT-2018

LakeheadUniversity Section002114AboriginalInitiativesInteriorRenovation BIDFORMSeptember2018 Page1of5

LakeheadUniversity,ThunderBay,Ontario

Project:#UC18-008

LakeheadUniversity

AboriginalInitiativesInteriorRenovation1. NAME OF BIDDER

Thisbidissubmittedby:

NameofCompany

StreetAddress

CityorTown

PostalCode

Telephone

Facsimile

Signatures

PrintNameofSigningOfficer SignatureofOfficer(Ihaveauthoritytobindthecompany)

PrintNameofWitness SignatureofWitness

Date(dd/mm/yyyy)

LakeheadUniversity Section002114AboriginalInitiativesInteriorRenovation BIDFORMSeptember2018 Page2of5

LakeheadUniversity,ThunderBay,Ontario

BIDPRICE