Systems Level Design Review Project #10715 1/15/09 Rev 011.

-

Upload

francine-harmon -

Category

Documents

-

view

216 -

download

0

Transcript of Systems Level Design Review Project #10715 1/15/09 Rev 011.

Rev 01 2

Helen Jervey (ISE), Project Lead Charles Nicolosi (ME), Chief Engineer Brandon Sbordone (ME) George Kilger (EE) Ian Baker (ME) Ben Bouffard (EE)

Advised by John Kaemmerlen

Project Team

Rev 01 3

Provide background information about the current system at the Culinary Innovation Center

Detail the progress made by the team from RIT

Receive feedback from faculty and Wegmans staff

Discuss the next steps in the process

Goals of this presentation

Rev 01 5

Wegmans is a food market with more than 70 stores in five states

The Culinary Innovation Center, or CIC, provides all premade sauces and marinated meat products to Wegmans stores

About Wegmans

Rev 01 6

The current factory line requires seven people performing repetitive, injury prone tasks

Injuries have cost Wegmans more than $20,000 in the marinade area since the opening of the CIC

Unreliable labeling technology leads to rework, wasting the time of the employees

What are the problems?

Rev 01 7

Reallocate direct labor from flipping, labeling◦ Allow employees to move to other areas of the

CIC Reduce ergonomic risks on line Perform all work within safety and quality standards

Project Goals

Rev 01 8

Primary◦ Meet AMA, OSHA, USDA and other relevant

standards◦ Maintain integrity of product

Secondary◦ Reallocate direct labor from flipping, aligning◦ Automate or improve flipping, aligning, and

labeling processes◦ Maintain or improve takt time

Priorities

Rev 01 9

◦ Need 1: Product & Process are Safe Need 1.1: Product integrity is maintained Need 1.2: Equipment satisfies USDA Regulations as

well as the AMI Checklist Need 1.3: OSHA Safety requirements are met

Need 1.3A: Remove ergonomic issues and concerns

◦ Need 2: Reallocate Direct Labor Need 2.1: Reallocate direct flipping labor Need 2.2: Reallocate direct alignment labor Need 2.3: Reallocate direct labeling labor

Detailed View

Rev 01 10

◦ Need 3: Improve Processing Time Need 3.1: Maintain or decrease takt time Need 3.2: All packages get scanned by the x-ray at desired

belt speed Need 3.3: Control flow to scaling operation. (Control flow-

rate variance) Need 3.3A: Meet x-ray specs of one piece at a time in machine

◦ Need 4: Control orientation and flow-mechanics Need 4.1: Packages are in the proper orientation

Need 4.1A: Label is in proper orientation position relative to the package

Need 4.1B: All packages are centered in the x-ray beam Need 4.1C: Packages are conveyed in single-file

o Need 4.2: Avoid impact on other projects Need 4.2A: Keep allocation of floor space constant

Detailed View

Constraints◦ Space◦ Feasibility◦ Alignment ◦ Efficiency◦ Mechanical/“Intelligent

”

System Selection

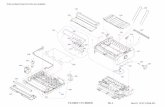

Align Flip X-Ray Label

Rev 01 12

Mechanical Process Allows for basic single file flow Engineered for product inconsistencies Will need future testing for jam concerns Basic frictional analysis shows it is feasible

Aligner Selection

Concept Improvement(Though Testing)

• Rollers• Belts• Actuated

Rev 01 14

Mechanical process Reliably performs a uniform flip Handles different package sizes and configurations Handles constant stresses of use Need component life cycle analysis

Flipper Selection

Concept Improvement(Through Testing)

• Adjustable Tray• Motor Choice• Tray Angle

Rev 01 16

Must consistently apply identifyer label Controlled label orientation and position Imaging/sensing system Implementation and modification of current

labelers to fit project Research has found feasible camera systems in

industry

Labeler Selection

Concept Improvement• Professor Meetings• Camera Selection

Rev 01 17

Align

• Align product mechanically

• Guide rails or rollers

• Push products to center of conveyor

Flip

• Flip product mechanically

• Offset belt system (upper and lower)

• Flipper arm or tray

• One piece at a time

X-Ray

• Automatic accept/reject

Label

• Add identifier label

• Fully/partially automated or manual

• Ability to reorient based on product angle and displacement offsets

Proposed Systems Architecture

Rev 01 19

Pieces enter in 2 or 3 wide

Adjustable, offset guides

Actuated guides to align

pieces/accelerate alignment process

Proximity/contact sensors to

ensure guide return

Laser sensor for piece(s)

entering guide path

Guide actuates and pushes pieces

to center

Pieces align with belt friction

Piece Alignment

Rev 01 20

Rev 01 21

Fixed/Adjustable Guides◦ Solid rail◦ Roller guide◦ Belt guide

Powered/Adjustable Guides◦ Solid rail/roller guide◦ Hinge mount for guide◦ Actuator/Actuators◦ Proximity sensors◦ Laser sensors for track

Alignment Components

Piece flows into flip tray

Laser sensor indicates

piece in tray

Stop arm for next piece

Motor/actuator

rotates flip tray

Piece is pushed out of tray

Sensor indicates no piece in tray

Motor/actuator rotates flip tray

Stop arm retracts

Automated Flipper

Rev 01 22

Rev 01 23

Flipper Tray◦ Grated◦ Solid

Stop Arm◦ Actuator◦ Hinge◦ Proximity Sensor(s)

Flipper◦ Motor/Actuator◦ Mounting/Hinges◦ Piece sensor (laser)◦ Proximity sensors (up/down)◦ Product pusher

Fixed Mechanical

Proximity sensor Actuator

Flipper Components

Single piece enters

Vision system identifies package

System outputs θ and

offset (x,y)

Motors align label head based on

output

Laser sensor

(possibly stops belt

and) activates

vision system

Label application

Label head retracts/

Returns to home

(Belt resumes)

Identifier Label Applicator

Rev 01 24

Rev 01 25

Vision System◦ Laser product sensor◦ Visual comparator system

Camera Comparison logic controller

Label Applicator system◦ X-axis motor◦ Y-axis motor◦ θ motor◦ Label applicator head

Head actuator Labeler Foam presser

◦ Label loader Belt motion controller

Identifier Labeler Components

Pieces From

Multivac

Trip Laser sensor(s)

Guide Returns

Piece leaves beam

Single file flow to flip

Piece enters

flip tray

Piece prox.

sensor trigger

Stop arm

actuates

Tray actuator trigger

Tray rotates down

Trigger push prox.

Piece prox.

Trigger off

Tray rotates

up

Stop arm

retracts

Piece to lower

conveyer

Piece through

x-ray

Piece trips laser

Belt stops

Camera shoots image

Calculates θ, x, y

Labeler assembly offsets

x

Labeler assembly offsets

y

Labeler assembly offsets

θ

Remove label from spool

Label head

actuates down

Label head

retracts

Belt resumes

Guide actuator(s) activate

Rev 01 26

ID Risk Item Effect CauseLikelihood

Severity

Importance Action to Minimize Risk Owner

1 Upstream process changes downstream variables

Engineering specs become obsolete, device may no longer meet customer requirements

P10711 1 2 2 Project managers meet to discuss changes several times during quarter (week 4, rest TBD)

PM

2 Device requires many on-floor adjustments

Deliverables not met, client may discontinue use of device

Wide package spec range, overly specialized device

2 2 4 Device will be set to one, “best” setting; if not possible team will devise as few as possible device settings and develop easy-to-use documentation

ME, ISE

3 Modified work tasks are ergonomically risky

Workers are injured, slowed production

Frequent, repetitive tasks; lifting; flipping

2 2 4 Proposed tasks evaluated using ergo risk assessment tool; tasks modified to be less than 24 on scale

Helen

4 Device does not meet cleanliness standards

Device cannot be used by client

Inappropriate materials used, incompatible with cleaning methods

2 3 6 AMI Sanitary Design Checklist used to drive all applicable design decisions; device designed to work with current sanitizing methods

Helen

5 Device does not work with lightest or heaviest packages

Device cannot be used by client

Weak design, inappropriate materials

3 3 9 Packages beyond dimensions of product range will be tested (TBD)

ME

6 Device cannot perform at current takt (6 sec)

Device cannot be used by client

Weak design, mechanical limitations

2 3 6 Device will be tested at quicker takt (TBD)

All

Technical Risk Assessment

Rev 01 28

ID Risk Item Effect CauseLikelihood

Severity

Importance Action to Minimize Risk Owner

7 Device damages or compromises packages

Device cannot be used by client

Excessive speed/force; sharp edges; pinch points

2 3 6 Device tested at range of speeds and forces; test package puncture force?

All

8 Labeler jams frequently Slowed production, rework

Inadequate hardware

2 3 6 Sensing system tested at wider range of speeds and package sizes than expected

EE

9 Labeler applies misaligned labels frequently

Added visual inspection, rework

Weak design; inadequate hardware

2 2 4 Sensing system tested at wider range of speeds and package sizes than expected

EE

10 Flipping task frequently misaligns package

Slowed production, direct manual labor, x-ray misses parts of package

Weak design; inadequate hardware

2 2 4 Sensing system tested at wider range of speeds and package sizes than expected

Brandon

11 Flipper jams frequently Slowed production, direct manual labor

Weak design; inadequate hardware

2 3 6 Sensing system tested at wider range of speeds and package sizes than expected

Brandon

12 Aligner frequently places packages outside x-ray beam

Slowed production, direct manual labor, x-ray misses parts of package

Weak design; inadequate hardware

2 2 4 Sensing system tested at wider range of speeds and package sizes than expected

Charlie

13 Aligner jams frequently Slowed production, direct manual labor

Weak design; inadequate hardware

3 2 6 Sensing system tested at wider range of speeds and package sizes than expected

Charlie

Technical Risk Assessment cont’d

Rev 01 29

Project Risk Assessment

ID Risk Item Effect CauseLikelihood

Severity

Importance Action to Minimize Risk Owner

1 Team member has extended absence

Critical chain affected Illness, personal issues

3 1 3 Thorough documentation during absence to reduce “catch up” time; team will communicate as much as reasonable during absence

All

2 Resource over-allocated Deliverables delayed or contain errors

Improper resource allocation, over-volunteering

3 1 3 PM will check in with all team members weekly to ensure workload is balanced

PM

3 Parts delayed from supplier Critical chain affected, deliverables delayed

Special parts, clerical errors, parts lost

2 2 4 Use approved vendors, have multiple vendors, use off-the-shelf parts

PM

4 Customer priorities change Customer needs, specs become obsolete

Business environment change

1 3 3 Constant communication with customers regarding needs

All

5 Insufficient risk assessment Slow response to problems, critical chain affected, deliverables delayed

Insufficient thought process

2 2 4 Constantly reexamine project and technical risks to ascertain changes

All

6 Team member leaves MSD Critical chain affected, deliverables delayed

Illness, personal issues

1 3 3 None. Keep in communication with all team members to plan for reallocation ASAP

PM

7 End users unhappy with device

Customer needs not met, device cannot be used by client

User input not considered during design, design not suited to users

3 3 9 Include end user input in all phases of design; practice active listening; ask “Why?” when concerns are raised to find root cause

All

8 Budget changes during project

Engineering specs may be infeasible, customer needs change

Business environment change

1 3 3 Adjust project goals, demonstrate cost savings of project and return on investment

PM

Rev 01 30

Evaluate analyzing methods for the labeling device Gather data on packaging durability Research optimal methods of flipping and aligning Draft circuit designs for controls and sensors Draft schematics for mechanical devices Investigate costs of long lead time devices Physically implement designs Test "first run" designs on product Revise and improve designs

Detailed Design Review: Friday 2/12 (4 weeks)

Next Steps

32Rev 01