SY and SL Series - INFOCOM Ltd · D-2C/A439 1020/A108 1020/A108(nickel-plated) Malleable iron Steel...

Transcript of SY and SL Series - INFOCOM Ltd · D-2C/A439 1020/A108 1020/A108(nickel-plated) Malleable iron Steel...

Globe ValvesSY and SL Series

GS0420409

www.fitokgroup.com

FITOK GroupFITOK GmbH Sprendlinger Landstr. 115, 63069 Offenbach, GermanyTel.: +49 69 8900 4498 Fax: +49 69 8900 4495

FITOK, Inc.13000 Murphy Road, Suite 116, Stafford, TX 77477, USATel.: +1 281 888 0077 Fax: +1 281 888 0033

FITOK Middle East Oil Equipment Trading LLC208-209, Makateb Tower, Airport Road, P.O.Box 185412, Deira, DUBAI, United Arab Emirates Tel.: +971 4 2959 853 Fax: +971 4 2959 854

FITOK IncorporatedYingtailong lndustrial Park, Shenzhen, 518109, ChinaTel.: +86 755 2803 2500 Fax: +86 755 2803 2619

(Headquarter)

SL Series

Index

05

Forged Steel Globe Valves

01

Forged steel Y-pattern bonnetless globe valves

SY Series

Globe Valves 1

Forged Steel Y-pattern Bonnetless

Globe Valves

SY Series

Features

Specifications

◎

◎

◎

◎

◎

◎

Design: ASME B16.34

Testing: ASME B16.34 and API 598

Marking: MSS-SP-25

Socket weld ends: ASME B16.11

Butt weld ends: ASME B16.25

Threaded ends: ASME B1.20.1

◎

◎

Size: 1/2 ~ 4" (15 ~ 100 mm)

Classes: 1500, 1690, 2500, 2680 and 4500

◎

◎

◎

◎

◎

◎

◎

◎

◎

◎

◎

◎

◎

◎

◎

◎

◎

◎

◎

◎

One-piece, forged, bonnetless globe valves eliminate the potential for body-to-bonnet

joint leakage, and not require cut or disassemble the bonnet for servicing.

65 inclined body reduces pressure drop compared with T-type.

Splined bushing guides the stem allows quick and easy maintenance by removing

all working parts at one time.

The non-rotating stem hardened and polished to reduce operating torque.

Linearly instead of helical movement of the non-rotating stem reduces the total

friction area between the packing and stem.

Packing chamber burnished and combination graphite rings individually pre-stressed

for tight seal.

Two-piece gland ensures gland and packing self-aligning.

Stellite disc, seat and backseat provide excellent long service life even in severe services.

Fully guided disc assures seat and disc precise alignment in spite of side thrust caused

by high velocity flow, and prevents stem from scoring and galling, and provides longer

disc seal and body life.

Double orifice design Protects seating faces because part of the erosive flow energy

dissipates through disc.

Two flat slots design at the internal bottom of the disc prevent the disc from rotating,

so avoid high-speed rotating disc and seat contact, damage to disc and seat.

Backseat bevel on the stem, not on the disc, meet specifications API-602.

Large clearance between stem and disc allows disc to move freely.

Dust cover and sleeve protect stem threads from dirt, dust and sand.

Fully enclosed stem driving lubrication system with two needle roller bearings ensures

low operating torque.

Upper stem position indicates if valve is open or closed.

Optional live-loading packing, disc springs keep packing tight for long periods of time

without maintenance.

Stop, regulating, and stop check discs are available.

Handwheel is rugged and knobbed to make sure the grip even when wearing gloves.

Optional handwheel colors are available.

°

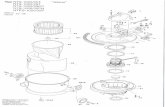

Tab washer

Snap ring

Thrust bearing

Gland stud

Gland nut

Packing washer

Spline bushing

Backseat

Stem protector

Yoke bushing

Stem nut

Packing flange

Split gland bushing

Handwheel

Name plate

Packing

O-Ring

Holder

Dust cover

Indicator

Springs

Disc

Body

Seat

Stem

A105N

410 SS/A276

CA15

304 SS

630 SS

A105

F22/A182 F316/A182

316 SS/A276

F304/A182

S17700

410 SS/A276

F91/A182

B7 B M8 2

2H 8M

304 SS

316 SS/A276

304 SS

304 SS

19

18

17

20

10

9

11

12

16

15

13

14

6

5

7

8

4

3

1

2

21

24

25

22

23

F9 /A1822

316 SS 580/A

Stellite 6

Stellite 6

Stellite 6

Graphite

Nitrile rubber

Steel teelS

Steel

D-2C A439/

(nickel-plated)1020/A108 1020/A108

Malleable iron

Steel

Valve MaterialPartItem

Standard Materials of Construction

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

23

21

24

22

2019

1817

25

live-loaded

Disc type

Stop CheckNeedleStop

Note:

Contact the authorized representative or for valves of other materials.FITOK Group

Acc. ANSI B -

Working Pressure by Classes, psig

16.34 2004

1. A105 permissible but not recommended for prolonged usage above about 800 F (425 C).

2. Please contact the authorized representative or for Pressure - Temperature ratings of other valve material.

° °

FITOK Group

1 . Sizes and types listed are standard. Other sizes and types are available upon request.

Dimensions

2 Globe Valves Globe Valves 3

2. All dimensions are for reference only and are subject to change. For dimensions not shown above,

please contact the authorized representative or FITOK Group.

A105 F22 F91 F92 F316

45001500~2680

1500~2680

45001500~2680

12680500~ 1

2680500~ 1

2680500~

4500 4500 4500 4500

0.3759.5

0.55914.2

1/215

4.88124

5.75146

9.63245

11.75298

6.00152

6.00152

3.6392

3.2583

3.2081

4.19106

3/420

0.55914.2

0.55914.2

4.88124

7.00178

9.63245

14.20361

6.00152

8.00203

3.6392

6.00152

3.2081

3.8899

4.19125

0.83321.2

0.55914.2

5.75146

7.00178

13.19335

14.20361

8.00203

8.00203

5.13130

6.00152 106

3.8899

1.501.6883 12.00 12.00 20.69 20.75 16.00 16.00 7.25 7.25 8.00 8.0038.1 42.9 80 305 305 526 527 406 406 184 184 203 203

1.501.6884 12.00 12.00 20.69 20.75 16.00 16.00 7.25 7.25 8.00 8.0038.1 42.9 100 305 305 526 527 406 406 184 184 203 203

1.125 0.833 7.25 10.13 16.63 18.88 12.00 12.00 7.57 7.00 4.94 6.571 1/4

28.6 21.2 184 257 422 480 305 305 192 178 125 167 32

50 42.9 38.1 257 305 505 527 305 457 190 203 167 203 1.688 1.50 10.13 12.00 19.86 20.75 12.00 18.00 7.50 8.00 6.57 8.002

1.125 1.125 7.25 12.00 16.63 20.75 12.00 18.00 7.57 8.00 4.94 8.001 1/228.6 28.6 184 305 422 527 305 457 192 203 125 203 40

1.501.688 12.00 12.00 20.69 20.75 16.00 16.00 7.25 7.25 8.00 8.002 1/238.1 42.9 305 305 526 527 406 406 184 184 203 203 65

F mmin.E mm

in.C mmin.B mm

in. D mmin.A mm

in.

Clearance Open Center to EndSizeNPSDN

Center to Top OpenEnd to EndPort Handwheel

735 1230

45002680250016901500

3600

925

1185

1525

1720

1750

2090

2110

2135

2170

2390

1930

2075

2220

2255

2570

2795

3095

6000

1545

1970

2545

2865

2915

3480

3520

3560

3620

3980

3220

3460

3700

3760

4280

4660

5160

2680 450016904500

4010

6170

7560

7990

8055

8210

8980

9505

9845

10120

11110

2680

2390

3675

4500

4760

4795

4890

5350

5660

5865

6030

6615

1250

1200

1150

1100

1050

1000

950

850

700

400

300

200

900

800

750

650

600

500

A105

16901500 1500

F22 F316

psig

4175

1510

2320

2840

3005

3375

3025

3080

3570

3695

3805

3705

1340

2060

2520

2665

2995

2685

2735

3170

3280

3375 5625

5470

5280

4560

4475

4990

4440

4200

3430

2230

6170

2500 2500

4055

829

1040

1330

1715

1935

1970

2350

2375

2405

2445

2690

2175

2338

2500

2540

2895

3150

3485 5530

4995

4585

4030

3965

3705

3450

4265

3880

3815

3770

3730

3125

6430 10800

3070

2725

2110

1655

1315

9290

8390

7705

7165

6770

6660

6515

6410

6335

6265

6230

5795

5245

5155

4575

3550

2775

2210

3750

3750

3325

2940

3025

3530

3640

1305

2435

2540

2660

2840

1885

2245

875

550

6250

6250

5540

4730

4905

5880

6070

1455

3745

4060

4230

4430

2170

3145

915

5040

1125067004225

4225

3745

3310

3405

3975

4100

1470

2740

2860

2995

3200

2125

2530

985

620 980

1550

2325

112506700

6505

6300

5935

5400

5255

5070

4745

4530

4350

4010

3370

10925

10585

9965

9070

8825

8515

7970

7610

7305

6740

5665

3910

2625

1645

2680 450016901500 2500

F91

3750

3750

3325

2940

3025

3530

3640

1820

2435

2540

2660

2840

1930

2245

1800

1510

6250

6250

5540

4730

4905

5880

6070

3000

3745

4060

4230

4430

3030

2515

5040

1125067004225

4225

3745

3310

3405

3975

4100

2050

2740

2860

2995

3200

2175

2530

2030

1700 2695

3215

3245

112506700

6505

6300

5935

5400

5255

5070

4745

4530

4350

4010

3450

10925

10585

9965

9070

8825

8515

7970

7610

7305

6740

5795

5450

5400

4525

1115

720 810

1255

3220

1855

1200

1990

1285

3345

2160

Material

Class

Temp. oF

-20 to 100

B

F

E

C

Do

65

A

Temperature -

Pressure Ratings

Forged Steel Globe Valves

SL Series

Features

Specifications

◎

◎

◎

◎

◎

◎

◎

Design: ANSI B16.34, API 602

Testing: ANSI B16.34 and API 598

Marking: MSS-SP-25

Socket weld ends: ASME B16.11

Butt weld ends: ASME B16.25

Threaded ends: ASME B1.20.1

Flanged: ASME B16.5

Globe Valves 5

◎

◎

Size:1/4 ~ 2" (8 ~ 50 mm)

Class:150 ~ 4500

F316L

6L

YG RB

F92

92

LLLF

3LF

3

LF2

LF2

F51

D5

HCM

3

X

TPTFE

HK

91

F91

FRT

FNS

F321

S1

F304

S4

232

20

116

3/4

12

4500

C

L

2680

C

L

2500

C

L

CS

A105

248

1/2

PS

PB

M22

F22

F316

SS

SY

2

1 1

/2

1 1

/4

464

40

48

32 1

/2

1690

C

L

1500

C

L

GJF

F316H

6HB

od

y M

ate

rial

Seri

es

Typ

e O

f C

on

nect

ion

Siz

e O

f C

on

nect

ion

Fem

ale

BSP

T

Fem

ale

NPT

Pip

e B

utt

Weld

Pip

e S

ock

et

Weld

Mo

nel

(Allo

y 400)

Fem

ale

BSP

PFR

P

AN

SI

Cla

ssD

isc

an

d S

eat

Mate

rial

Hast

ello

y

C 2

76

Cu

sto

mer

Speci

fied

Stellit

e

Sto

p

Ch

eck

Sto

p

Need

le

Dis

c Ty

pe

Pack

ing

M

ate

rial

Live-L

oad

ing

Han

dw

heel

Co

lor

Gra

ph

ite

Yes

No

Bla

ck

Blu

e

Red

Gre

en

Yello

w

4 Globe Valves

◎

◎

◎

◎

◎

◎

◎

◎

Three types of bonnet designs:

Bolted Bonnet, Outside Screw and Yoke Class to Class * Stronger and leakproof body bonnet encases fully a spiral wound gasket.

Welded Bonnet Outside Screw and Yoke Class to Class * For welded bonnet valves the bonnet is threaded in and torqued to an engineered

torque value and the body bonnet joint is strength-welded offering double

protection against leakage body/bonnet threads and strength-weld

Pressure Seal Bonnet Outside Screw and Yoke Class to Class *

Pressure seal bonnet the body bonnet joint is threaded packing rings are compressed

to provide a high integrity seal by the drawing-in stud.

Fully guided disc assures seat and disc precise alignment in spite of side thrust caused by

high velocity flow, and prevents stem from scoring and galling and provides longer

seal and body life.

Large clearance between stem and disc allows disc to move freely.

Packing chamber burnished and combination graphite rings individually prestressed for

tight seal.

Two-piece gland ensures gland and packing self-aligning.

Solid Stellite disc, seat ring (optional) ensures long service life even in severe services.

Handwheel is rugged and knobbed to make sure the grip even when wearing gloves.

Optional handwheel colors are available.

( 150 1500)

( 150 1500)

. ( ).

( 1500 4500)

,

,

,

,

, ,

, disc

WB

36

WB

36

Mo

nel

(400)

Allo

y

SYSS

-PS8

GM

2TLL

R

-

Ord

eri

ng

In

form

ati

on

Materials of ConstructionStandard Materials of ConstructionStandard

Bolted Bonnet Welded Bonnet

316 SS/276 410 SS/A276

F316/A182 F22/A182

2H

B7

A105

Graphite

304 SS + Graphite

A105N

A105N F22/A182 F316/A182

B7 B8M2

410 SS/A276

F11/A182

F11/A182 F91/A182

F304/A182

B8M

8M

410 SS

F91/A182

316 SS/276

316 + SS Graphite

410 SS/A276

410 SS/A276 316 SS/276

F316/A182

304 SS

Steel

Malleable iron

PartItemValve Materials

Bolt

Bonnet

Gasket

Stem Nut

Packing

Handwheel

Name Plate

Seat

Body

Disc

Stem

Hex Nut

Gland Bolt

Gland Flange

Gland

2

1

3

4

8

7

5

6

9

14

13

15

16

12

11

10

SS304

Malleable iron

A1081020/

410 SS/A276

Graphite

304 SS/A276

304 SS/A276

A105

410 SS/A276

F91/A182

SS/276304

F91/A182 F11/A182

F11/A182 F316/A182 F22/A182A105N

18

17

19

20

16

9

8

10

11

15

14

12

13

6

5

7

4

3

1

2

A105N

304 SS/A276

A1081018/

F22/A182 F316/A182

Item Part

Stem Nut

Draw-in Stud

Packing

P.S Seat

P.S Ring

Handwheel

Thrust Bearing

Seal Ring Gasket

Bonnet

Yoke Bushing

Disc

Body

Seat

Stem

Gland

Packing Flange

Anti Rotation

Gland Bolt

Gland Nut

Name Plate

WCB

B7

Steel

410 SS/A276

410 SS/A276

316 SS/276

316 SS/276

316 SS/276

316 SS/276

316 SS/276

316 SS/276

2H

Contact the authorized representative or for valves of other materials.FITOK Group

6 Globe Valves Globe Valves 7

Contact the authorized representative or for valves of other materials.FITOK Group

410 SS/A276 SS/276316

F304/A182

CF8/A351

B8M

8H

304SS/276

Pressure Sealing

F92/A182

F92/A182

Handwheel Nut

A105 F11 F22 F91 F316

Valve Materials

A105 F11 F22 F91 F316 F92

1

2

3

4

5

6

8

9

10

11

12

13

14

15

7

16

9

8

6

4

3

2

1

16

15

14

13

12

11

10

9

1

2

3

4

5

6

8

9

10

11

12

13

14

15

7

16

17

18

19

20

Threaded or weldASME Class 800ASME Class 1500

Flanged ASME Classes

150,300,600,1500

B

Bolted Bonnet Globe Dimensions and Weights

600 1500300150

Flanged Valves

1500800

NPSDN

SizeHandwheel

Center to Top OpenEnd to EndPort

lbkg

Weight

Socket Weld Depth

Socket Weld Bore

7.00178

7.50190

4.62117

11.005.0

0.5013

1.06527.05

6.0152

8.40213

7.10180

5.00127

3.2583

0.5013

0.5013

5.002.3

9.00229

3/420

4.0102

8.50216

6.50165

4.00102

6.00152

0.3810

8.10206

4.80122

1/48

3.001.4

8.003.6

0.5013

0.318

3.0076

4.00102

2.5064

6.0152

0.55514.10

3.0076

8.50216

6.50165

4.00102

6.00152

3.001.4

8.003.6

0.3810

6.0152

2.5064

8.10206

4.80122

4.00102

0.5013

0.318

3/810

0.69017.53

3.0076

8.50216

6.50165

6.00152

4.25108

3.001.4

8.003.6

0.3810

6.0152

2.5064

8.10206

4.80122

4.00102

0.5013

0.318

1/215

0.85521.72

8.50216

21.009.5

0.5013

4.0102

10.0254

7.30185

6.00152

0.7519

6.002.7

10.00254

8.00203

5.00127

125

0.7519

3.5089

8.0203

1.33033.78

11.50292

10.50266

2.40661.11

12.3312

11.2285

9.00229

1.538

27.0012.2

49.0022.2

14.50368

8.00203

250

1.538

8.00203

8.0203

12.0305

0.6316

9.00229

8.50216

0.5013

8.0203

6.0152

11.0279

8.90226

7.00178

5.00127

1.2532

14.006.4

31.0014.0

11.00279

5.50140

1.2532

1.67542.5532

9.50241

31.0014.0

14.006.4

6.0152

8.0203

11.0279

8.90226

5.00127

7.00178

1.2532

1.2532

12.00305

9.00229

6.50165

1.91548.64

0.501340

Threaded or weldASME Class 1500ASME Class 2500

Threaded or weldASME Class 800

ASME Class 1500

Welded Bonnet Globe Dimensions and Weights

40

32

1500 2500 1500 2500 1500 2500 1500 2500 1500 2500

0.5514

3/420

0.5514

1.06527.05

0.5013

5.50140

7.25185

8.0203

8.0203

2411

2411

12.6320

14.8375

0.85521.72

1/215

0.4311

5.50140

7.25185

12.6320

14.8375

0.3810

8.003.6

8.0203

8.0203

2511

0.5013

1.67542.55

17.3440

1.128

5726

7.00178

9.25235

0.5013

11.0279

11.0279

4420

19.3490

125

0.5013

1.91548.64

1.3835

11.0279

6228

7.00178

9.25235

11.0279

4420

17.3440

19.3490

1.128

0.6316

12.0305

21.3540

19.3490

8.50216

1.538

250

13260

12255

11.00279

2.40661.11

12.0305

1.3835

A mmin. B mm

in. C mmin. Dmm

in. K mmin. L mm

in.

C mmin.B mm

in. L mmin.A mm

in. D mmin. K mm

in.

C mmin. D mm

in. K mmin. L mm

in.B mmin.A mm

in.

1500800 1500800 1500800 1500800

1500800 1500800 1500800 1500800 1500800

NPSDN

SizeHandwheel

Center to Top OpenEnd to EndPort

WeightlbkgSocket

Weld Depth

Socket Weld Bore

SizeNPSDN

HandwheelCenter to Top

OpenEnd to EndPort

WeightlbkgSocket

Weld Depth

Socket Weld Bore

8 Globe Valves Globe Valves 9

1. The constructions and dimensions of ASME Class 150, Class 300, Class 600 valves with threaded or welded ends are same with Class 800 valve.

2. The construction and dimension of Class 900 valve is same with Class 1500 valve.

Bolted Bonnet Welded Bonnet Pressure Sealing

Pressure Sealing Globe Dimensions and Weights

0.7519

1.33033.78

8.0203

125

0.7519

0.5013

5.50140

7.25185

8.0203

12.6320

15380

2411

2411

3.0076

0.69017.53

0.3810

7.22183

4.84123

3.001.4

6.002.7

2.5064

6.0152

3.5089

3/810

0.318

0.5013

3.0076

0.85521.72

0.3810

3.5089

6.0152

2.5064

6.002.7

3.001.4

4.84123

7.22183

1/215

0.318

0.5013

6.0152

0.6316

12.0305

5.25133

1.538

250

45.0020.4

13.005.9

1.538

10.00254

10.00254

14.00356

2.40661.11

6.002.7

7.22183

3.5089

4.0102

3/420

4.502.0

0.5013

0.5013

3.2583

6.90175

6.0152

1.06527.05

0.5013

3.0076

0.55514.10

6.0152

2.5064

3.5089

0.318

0.5013

6.002.7

3.001.4

1/48

4.84123

7.22183

0.3810

6.0152

1.33033.78

3.5089

0.7519

125

5.002.3

0.7519

5.00127

7.20183

8.84225

4.0102

0.5013

12.005.4

17.007.7

10.004.5

8.0203

6.0152

10.76273

8.93227

5.25133

5.00127

1.2532

1.2532

0.5013

1.91548.6440

1.67542.55

1.2532

17.007.7

10.004.5

1.2532

5.00127

5.25133

8.93227

10.76273

6.0152

8.0203

0.501332

1 1/4

1 1/2

1 1/4

1 1/2

1 1/4

1 1/2

L

K

A

B

D

C

A

B

C

D

D

LAB

K

C C

L

B

A

K

D

Materials of ConstructionStandard

16

7

15

14

13

12

11

10

9

8

6

5

3

4

2

1

10

11

12

13

14

15

16

1

2

3

4

6

8

9

Y Type Bolted Bonnet Y Type Welded Bonnet

316 SS/276 410 SS/A276

F316/A182 F22/A182

2H

B7

A105

Graphite

304 SS + Graphite

A105N

A105N F22/A182 F316/A182

B7 B8M2

410 SS/A276

F11/A182

F11/A182 F92/A182

F304/A182

B8M

8M

410 SS

316 SS/276

316 SS + Graphite

410 SS/A276

410 SS/A276 316 SS/276

F316/A1822

1

3

4

8

7

5

6

9

14

13

15

16

12

11

10

F91/A182

F92/A182 F 1/A1829

Materials of ConstructionStandard

Contact the authorized representative or for valves of other materials.FITOK Group

PartItem

Bolt

Bonnet

Gasket

Stem Nut

Packing

Handwheel

Name Plate

Seat

Body

Disc

Stem

Hex Nut

Gland Bolt

Gland Flange

Gland

304 SS

Steel

Malleable iron

10 Globe Valves Globe Valves 11

Contact the authorized representative or for valves of other materials.FITOK Group

Valve Material

SS304

Malleable iron

A1081020/

420 SS/A276

Graphite

304 SS/A276

304 SS/A276

A105

410 SS/A276

F91/A182

SS/276304

F92/A182 F11/A182

F11/A182 F316/A182 F22/A182A105N

18

17

19

20

16

9

8

10

11

15

14

12

13

6

5

7

4

3

1

2

A105N

304 SS/A276

A1081018/

F22/A182 F316/A182

Item Part

Stem Nut

Draw-in Stud

Packing

P.S Seat

P.S Ring

Handwheel

Thrust Bearing

Seal Ring Gasket

Bonnet

Yoke Bushing

Disc

Body

Seat

Stem

Gland

Packing Flange

Anti Rotation

Gland Bolt

Gland Nut

Name Plate

WCB

B7

Steel

410 SS/A276

410 SS/A276

316 SS/276

316 SS/276

316 SS/276

316 SS/276

316 SS/276

316 SS/276

2H

410 SS/A276 SS/276316

F304/A182

CF8/A351

B8M

8H

304 SS/276

F91/A182

F92/A182

Valve Materials

A105 F11 F22 F91 F316 F92 A105 F11 F22 F91 F316 F92

Handwheel Nut

Y Type Pressure Sealing

1

2

3

4

5

6

8

9

10

11

12

13

14

15

7

16

17

18

19

20

Y Type Bolted Bonnet

Threaded or weldASME Class 800ASME Class 1500

Y Type Bolted Bonnet Globe Dimensions and Weights

A mmin. B mm

in. C mmin. Dmm

in. K mmin. L mm

in.

1500800 1500800 1500800 1500800 1500800

Y Type Welded Bonnet Y Type Pressure Sealing

Threaded or weldASME Class 800ASME Class 1500

Threaded or weldASME Class 12500ASME Class 2500

Y Type Welded Bonnet Globe Dimensions and Weights

1500800

A mmin. B mm

in. C mmin. Dmm

in. K mmin. L mm

in.

1500800 1500800 1500800 1500800

Y Type Pressure Sealing Globe Dimensions and Weights

45002500

A mmin. B mm

in. C mmin. Dmm

in. K mmin. L mm

in.

45002500 45002500 45002500 45002500

SizeNPSDN

HandwheelCenter to Top

OpenEnd to EndPort

WeightlbkgSocket

Weld Depth

Socket Weld Bore

NPSDN

SizeHandwheel

Center to Top OpenEnd to EndPort

WeightlbkgSocket

Weld Depth

Socket Weld Bore

NPSDN

Size

HandwheelCenter to Top

OpenEnd to EndPort

WeightlbkgSocket

Weld Depth

Socket Weld Bore

12 Globe Valves Globe Valves 13

D

KA

LB

C

1. The constructions and dimensions of ASME Class 150, Class 300, Class 600 valves with threaded or

welded ends are same with Class 800 valve.

2. The construction and dimension of Class 900 valve is same with Class 1500 valve.

1. Sizes and types listed are standard. Other sizes and types are available upon request.

2. All dimensions are for reference only and are subject to change. For dimensions not shown above,

please contact the authorized representative or FITOK Group.

C

D

L

B

K

A

C

D

L

B

K

A

8.003.6

0.5013

1.06527.05

6.50165

8.15207

8.15207

4.00101

4.00102

0.5013

0.5013

8.003.6

3/420

5.00127

3.5089

4.502.0

8.003.6

0.3810

5.00127

4.00102

8.15207

7.80198

4.00102

0.5013

0.318

1/215

0.85521.72

18.008.1

0.5013

6.50165

11.0279

11.0279

5.50140

0.7519

18.008.1

125

0.7519

5.50140

6.50165

1.33033.78

0.5013

6.50135

6.50165

11.0279

11.0279

5.50140

5.50140

1.2532

18.008.1

18.008.1

1.2532

1.67542.55

27.0012.2

27.0012.2

7.00178

7.00178

11.5292

11.5292

6.00153

6.00153

1.2532

1.2532

1.91548.64

0.5013

2.40661.11

13.8305

13.8350

6.70170

1.538

35.0016.0

35.0016.0

250

1.538

6.70170

8.00203

8.00203

0.6316

32

40

0.3810

7.80198

1/48

4.001.8

0.318 76

4.00102

0.55514.10

3.00

4.001.8

4.001.8

0.3810

4.00102

4.00102

7.00178

7.80198

3.5089

0.5013

0.318

3/810

0.69017.5376

3.00

32

40

7.25185

24.0011

66.0030.0

0.3810

0.4311

0.4311

1/215

0.85521.72

11.0279

8.00203

16.0406

13.00330

7.875200

80.0036.0

57.0025.8

9.25235

1.0226

1.1028

1.91548.64

0.5013

12.0305

11.0279

18.0460

16.0406

9.85250

0.5013

9.25235

0.7920

62.0028.0

66.0030.0

1.0025

1.67542.55

12.0305

11.0279

18.0460

13.0330

9.85250

66.0030.0

0.5013

1.06527.05

7.25185

0.55

14

0.43

11

27.0012.3

3/420

11.0279

8.00203

16.0406

13.00330

7.875200

66.0030.0

0.5013

0.5915

27.0012.3

125

0.7519

7.25185

1.33033.78

11.0279

8.00203

16.0406

13.00330

7.875200

2.40661.11

1.128

97.0043.9

129.0058.0

250

1.3835

12.2310

0.6316

12.6320

12.0305540

20.5521

13.0330

21.25

10.004.5

0.5013

1.06527.05

5.00127

8.50216

7.30185

4.37111

4.37111

0.5013

0.5013

10.004.5

3/420

5.00127

3.8598

6.002.7

6.002.7

0.3810

4.00102

4.00102

7.00178

7.00178

3.8598

0.5013

0.318

3/810

0.69017.53

3.8598

8.003.6

10.004.5

0.3810

5.00127

4.00102

7.00178

7.00178

4.37187

0.5013

0.318

1/215

0.85521.72

21.009.5

0.5013

6.50165

8.50216

11.0279

5.50140

0.7519

21.009.5

125

0.7519

5.50140

6.50165

1.33033.78

0.5013

6.50135

6.50165

10.0254

11.0279

5.50140

5.50140

1.2532

21.009.5

21.009.5

1.2532

1.67542.55

31.0014.0

31.0014.0

7.00178

7.00178

12.0305

11.5292

6.00153

6.00153

1.2532

1.2532

1.91548.64

0.5013

2.40661.11

12.0305

13.8350

6.70170

1.538

44.0020.0

44.0020.0

250

1.538

6.70170

8.00203

8.00203

0.6316

32

40

0.3810

7.00178

1/48

6.002.7

0.318

3.8598

4.00102

0.55514.10

1 1/4

1 1/2

1 1/4

1 1/2

1 1/4

1 1/2

Pressure - Temperature RatingsASME B16.34 - Class 150,300,600 1500,2500, 4500.,

API Std 602 Class 800 -

6L

Fem

ale

BSP

P

Fem

ale

BSP

T

Pip

e S

ock

et

Weld

Pip

e B

utt

Weld

92

LF3

LF2

D5

91

S1

S4

CS

M22

F316L

F92

LF3

LF2

F51

F91

F321

F304

A105

F22

F316

SS

Yel

low

YG R

Gre

en

Red

Blu

e

BB

lack

Han

dw

heel

Co

lor

Siz

e O

f C

on

nect

ion

Typ

e O

f C

on

nect

ion

Bo

dy M

ate

rial

Seri

es

2500

C

LG

PS

Weld

ed

Bo

nn

et

Bo

dy a

nd

Bo

nn

et

Co

nn

ect

ion

BW

Bo

lted

Bo

nn

et

FFSm

oth

Fin

ish

Flat

Face

Fla

ng

ed

RF

Smo

th F

inis

h

Fa

ce F

lan

ged

Rais

ed

RFS

Spir

al Fi

nis

h

Fa

ce F

lan

gedR

ais

ed

RJ

Rin

g T

ype

Flan

ged

Join

t

H

800

C

L

150

C

L

300

C

L

600

C

L

900

C

L

1500

C

L

A B C D E F

SL

PB

PS

1/4

D

N8

()

4

3/8

(D

N10)

6 8 24

12

3/4

(D

N20)

16

1 (

DN

25)

1 1

/4 (

DN

32)

20

32

2 (

DN

50)

MTS

FRT

FRP

(DN

15)

2

1/

4500

C

L

YW

Y T

ype

Weld

ed

Bo

nn

et

Y T

ype

Bo

lted

Bo

nn

et

YB

YS

Y T

ype

Pre

ssu

re S

ea

lin

g

14 Globe ValvesGlobe Valves 15

Cla

ss

Mo

nel

(Allo

y 400)

Metr

ic T

ub

eSo

cket

Weld

Metr

ic T

ub

e B

utt

W

eld

M

TB

Fem

ale

NPT

FNS

42 M

Pa

26 M

Pa

15 M

Pa

11

MPa

6.3

MPa

4.0

MPa

2.5

MPa

1.6

MPa

PN

16

PN

25

PN

40

PN

63

PN

110

PN

150

PN

260

10 M

pa

PN

100

PN

20

2.0

MPa

PN

50

5.0

MPa

Speci

al

X

PN

420

Pre

ssu

re S

ealin

g

1. A105 permissible but not recommended for prolonged usage above about 800 F (425 C).

2. F11 and F22 permissible but not recommended for prolonged usage above about 1100 F (593 C).

3. Please contact the authorized representative or for Pressure - Temperature ratings of other valve material.

° °

° °

FITOK Group

1.

Cla

ss8

00

sh

ou

ld b

e s

ele

cte

d f

or

Cla

ss 1

50

, C

lass

30

0,

Cla

ss 6

00

Glo

be

va

lve

s

wit

h t

hre

ad

ed

or

we

lde

d e

nd

s.

2.

Cla

ss1

50

0 s

ho

uld

be

se

lect

ed

fo

r C

lass

90

0 G

lob

e v

alv

es.

(DN

40)

1

2

1/

WB

36

WB

36

2500

5160

4660

4280

3760

3700

3460

3220

3980

3620

3560

3520

3480

2915

2865

2545

1970

1545

1230

6000

2500

11250

10925

10585

9070

8825

6740

5795

9965

8515

7970

7610

7305

5450

5400

4525

3345

2160

11250

2500

6000

5540

5120

4640

4800

6250

6250

6250

6015

2500 2500

6070

6250

6250

2500

6170

5470

5625

3095

2795

2570

2255

2220

2075

1930

2390

2170

2135

2110

2090

1750

1720

1525

1185

925

735

36001920

390

495

630

815

915

935

1115

1125

1140

1160

1275

1030

1105

1185

1205

1370

1495

16551240

1120

1025

900

890

830

775

955

870

855

845

835

700

685

610

475

370

295

1440720

145

185

235

305

345

350

420

420

425

480

385

415

430

450

515

560

620

445

65

80

95

110

170

125

140

235

275

195

215

20

35

50

20

20

20

20

20

F316

72038529014520

20

1250

1200

1150

1100

1050

1000

950

850

700

400

300

200

900

800

750

650

600

500

150

F51

260

230

200

140

170

290

720

665

615

555

575

750

300 600

1500

1150

1115

1230

1330

1440 1920

1770

1640

1480

1535

2000

800

3750

2880

2785

3070

3325

3600

1500 150 300 600 800 1500

F91

65

80

95

110

170

125

140

260

290

200

230

20

35

50

20

20

750

730

705

605

590

665

570

530

510

750

300

360

485

385

365

225

1500

1500

1330

1175

1210

1410

1455

720

975

1015

1065

1135

775

900

605

445

450

725

805

960

1200

1030

1515

1420

1355

1300

970

1940

1880

1615

1570

1775

2000

2000

595

1510

1800

2245

1930

2840

2660

2540

2435

1820

3640

3530

3025

2940

3325

3750

3750

1115

1500800600300150

psig

psig

3640

3750

3750

2000

2000

19401455

1500

1500

750

730

750

230

290

260

150 300 600 800 1500

F22

3750

3750

3610

1900

2000

17951455

1500

1500

750

720

750

230

290

260

F11

15008006003001501500

3375

3280

3705

800

1975

1750

18001350

1315

1480

600300

740

655

675

285

230

260

-20 100 to

150

200

300

4500

11110

9845

10120

4500

5040 50404560 302516151210605140302516151210605140273514601095550140600 8210 9070

800 9155502952201102048022519095201100 1645

2655 314518851005755375351595100564032035950 5665

1800 21701305695520260201080595430215201000 3910

4430 44304200 266014201065505952660142010655309525201345101050595750 7560 7970

4230 42303430 25401355101553080254013551015510802060110082541080800 6170 7610

4060 40602230 24351300975510652435130097548565134071553527065850 4010 7305

3745 3745224512009004505022451200450 90050900 6740

1200 145587546535017520720365290145201050 2625

10925

5775 58805280 353018801410705200346517551385695200317016901270635200400 9505 10585

4905 49054475 294015701175590125294015701175590125268514301075535125650 8055 8825

4730 47304440 284015151135570110284015151135570110266514201065535110700 7990 8515

5540 55404990 332517751330665170332517101330665170299515951200600170500 8980 9965

11250

11250

570515 70 135 180 345310140125601150

3451108240 2051200

4500

6250

6070

5880

5040

4905

3745

3220

5540

4730

4430

4230

4060

3030

3000

2515

1855

1200

6250

4500

8390

7705

6770

6660

6230

5795

7165

6515

6410

6335

6265

5245

5155

4575

3550

2775

2210

10800

A105 A350-LF2&

ClassoTemp. F

Materials

-20 100to

Class

oTemp. F

Materials

SLSS

FNS8

D16B

WB

-

-

Part

Nu

mb

er

Desc

rip

tio

n

9290

Dis

c Su

rface

18

Cr

8N

i%

,%

Stellit

e

13

Cr

%

Seat

Surf

ace

Stem

Mate

rial

F304

A182

/

F6a/A

182

13%

Cr

18

Cr

8N

i%

,%

Stellit

eF6

aA

182

/

Mo

nel

18

Cr

8N

i%

,%

F316

A182

/18

Cr

8N

i%

,%

Mo

nel

Ni

Cu A

llo

y M

on

el

Sym

bo

l

Stellit

eF6

aA

182

/13

Cr

%

Tri

m M

ate

rial

Stellit

e

Allo

y 20

19%

Cr,

29%

Ni

AST

M B

473

18

Cr

8N

i%

,%

F316

A182

/

Allo

y 20

19%

Cr,

29%

Ni

92 51

108

13

12

16

Stellit

eF3

16

A182

/St

ellit

e

Stan

dard

No

te:

"Part

Nu

mb

er

Desc

rip

tio

n" is

use

d f

or

com

po

siti

on

ru

les

of

FITO

K p

rod

uct

mo

del, N

ot

suit

ab

le f

or

sp

eci

fic

pro

du

ct p

art

nu

mb

er

sele

ctio

n, n

ot

ran

do

m

co

mb

inati

on

s. If

in d

ou

bt,

ple

ase

co

nta

ct F

ITO

K

co

mp

an

y o

r au

tho

rize

d a

gen

ts.