Swing Lo 2012 Product Book

description

Transcript of Swing Lo 2012 Product Book

ProductCatalog

INSPECTION • CONSTRUCTION • REPAIR • MAINTENANCE Swing-Lo Suspended Scaffold Company PO Box 128 Covert Michigan 49043

Designers, Engineers & Manufacturers of Special Overhead ScaffoldingCustomer Service (866) 764-8989 Office (269) 764-8989 FAX (269) 764-8897

www.swing-lo.com E-mail: [email protected]

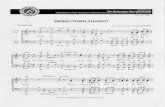

THE SCAFFOLDING

SYSTEM THAT BEGINS RIGHT AT THE TOP

* BRIDGES * POWER PLANTS * RAILROADS * REFINERIES * AUDITORIUMS * CUSTOM DESIGN

SINCE 1955

All products must be used in accordance with Swing-Lo Suspended Scaffold Company’s Safety Instructions, and all Local, State, and Federal Safety Regulations.

●●

●●●●

VER21JAMEMBER

SCAFFOLDING DEVICES CLASSIFIED BYUNDERWRITERS LABORATORIES INC.

ONLY AS TO LOAD CAPACITY NO. 419M

All products must be used in accordance with Swing-Lo Suspended Scaffold Company’s Safety Instrutions, and all Local, State, and Federal Safety Regulations.

2

Date______________________________________

Project____________________________________

Customer Service: 866-764-8989 Tel: (269) 764-8989 Fax: (269) 764-8897

TABLE OF CONTENTS

Our Heritage 4 Application Photographs 5-12 Permanent Suspended Scaffold Application 13 Bascule Bridge Scaffold 14 Rig Scaffold Systems 15

3Customer Service: 866-764-8989 Tel: (269) 764-8989 Fax: (269) 764-8897

INTRODUCTION

MOBILE SUSPENDED SCAFFOLD SYSTEMS

Scissors CHD-140 & HD-801 Hangers 16 Winch Frame Hanger Scaffold 17 I-Beam Clamp, Truss, & Hanger 18 Prestressed Concrete I-Beam Clamp 19-20 By-Pass Scaffold System 21-23 Multi-Level Scaffold 24 Drop-Through Scaffold 25 Traveller Scaffold 25 Spreader Scaffold 25 Bottom Flange Steel Riding Scaffold 26 Top Flange Steel & Concrete Riding Scaffold 26 Suspended Stripping Scaffold 27 Between Girder Stripping Scaffold 28 Tank Scaffold 32 Girder-Edge Scaffold 50

Grid Scaffold (“Dance Floor”) 29 Beam Clamp & Truss Scaffold 30 Beam Clamp & Hanger Scaffold 30 Waler Beam Clamp Scaffold 31 Waler Fascia Beam Scaffold 31 Tank Scaffold 32 Pier Cap Scaffold 33 Pier I-Beam Scaffold 34 H-Beam Chord Scaffold 34 Box Chord Scaffold 35 Box Chord & Parapet Scaffold 35 Box Chord Single, Double, and Center Sides 36 Box Chord Cantilever Scaffold 36 I-Beam Saddle Scaffold 37 Single-Side I-Beam Scaffold 37 Elevated Rail Scaffold 37 H-Beam Pile Scaffold 38 Extended Girder Scaffold 38

STATIONARY SUSPENDED SCAFFOLD SYSTEMS

PARAPET SCAFFOLD

RAILROAD SCAFFOLD Mobile Rail Scaffold (Subway Painting) 50 Thru-Girder Wrap-Around Scaffold 51

Open Deck Cantilever Platform 51 Railroad Scaffold System 52

CABLE SCAFFOLD Cable Scaffold Preview 53Cable Scaffold Components 54Cable Scaffold Packaged Platforms 55Wire Rope Installation (Choker & Beam) 53

Pipe Ladder Clamp 56 I-Beam Ladder Clamp 56 Concrete Parapet Ladder Clamp 56 Side-Mounted Ladder Clamps 56

ACCESS EQUIPMENT

Parapet Rail Types 39 Parapet Dimensions & Considerations 40 Parapet Scaffold Components 41 Single Deck Parapet Scaffold 42 Double Deck (2 Ft.)Parapet Scaffold 42 Double Deck (2 Ft. & 4 Ft.) Parapet Scaffold 43 Stationary Cat-Walk Parapet Scaffold 43 Extended Parapet Scaffold 44 Wrap-Around Parapet Scaffold 44 Expanded Wrap-Around Parapet Scaffold 45 Expanded Parapet Scaffold 45 Stationary Heavy Duty Parapet Scaffold 46 Wrap-Around & Connecting By-Pass System 47 Mobile Barrier & Median Barrier Scaffold 48 Mobile Counter-Weight Cart Scaffold 49

FALL PROTECTION Static Line Fall Protection System 57 Fall Protection I-Beam Clamps 57 Prestressed Concrete I-Beam Clamp 57 Concrete Parapet Fall Protection Clamp 57

Rolling Parapet Guardrail System 58 Mobile Train Rail Guardrail System 58

GUARDRAIL SYSTEMS

Perimeter Guardrail System 59 Static Line Guardrail System 59

CLAMPS Mobile I-Beam Clamps 60 Mobile Angle Clamps 60 Stationary I-Beam Clamps 61 Screw Type I-Beam Clamps 61 Scissor I-Beam Clamps 62 Sweet Heart Beam Clamps 62 Heavy Duty Stationary I-Beam Clamps 62 Stationary Angle Clamps 62

Vertical Stems 63 Aluminum Support Beams 63 Steel Support Trusses 63 Hangers 64 Connectors & Accessories 65 Wheels 65

Code of Safe Practices 69 Daily Inspection Checklist 70 Index 71

ADDENDUM

STEMS, ALUMINUM BEAMS, TRUSSES, HANGERS, CONNECTORS, WHEELS

Guardrail & Accessories 66,68 Aluminum Stages, Beams & Scaffold Plank 67

GUARDRAIL & ACCESSORIESALUMINUM STAGES,BEAMS,& PLANKS

All products must be used in accordance with Swing-Lo Suspended Scaffold Company’s Safety Instructions, and all Local, State, and Federal Safety Regulations.

→

→

The invention and introduction of Swing-Lo Suspended Scaffolds stemmed from the old adage, “necessity is the mother of invention”. That was the motivation behind the invention of Swing-Lo Suspended Scaffolds by H. George Leonard, a painting contractor whose bid was below his competitors. The idea was derived from the old ice tong and a pair of scissors. The combination of both items provided him with a model that would scissor and grip the bottom flanges of I-beams on bridges. This model, along with a connecting hanger component produced a simple suspended scaffold that could be easily erected and dismantled. The application and performance of this scaffold was well received, and soon became a demand by bridge and painting contractors. Thus, the painter became the manufacturer of a particular type of scaffold whose market has expanded from local to national to international.

Constant improvements in the design and fabrication of Swing-Lo Suspended Scaffolds have served to provide a safer, more efficient and economical scaffolding system for highway and utility contractors when access to work areas are a problem. Swing-Lo Suspended Scaffolds are patented with built-in, quick locking devices and fasteners for instant assembly. They have lessened the risks to the worker, lowered the cost, and increased safety in modern bridge and power plant construction and maintenance.

Today, Swing-Lo is a recognized designer and manufacturer of Suspended Scaffolding. We use the latest Computer-Aided (CAD) software to provide safe, quality solutions within budget and on-time delivery. Used by contractors and DOTs throughout the world, all Swing-Lo Systems meet or exceed OSHA safety standards and are fully supported by our technical consultants. Need suspended scaffolding NOW? Contact us and we will analyze your site to determine the most efficient design, then ship your scaffolding in as little as 5 to 10 working days.

Whether you’re working on new bridge or plant construction, planned outages, or ongoing maintenance, demand suspended scaffolding that comes in any size, suspends from any structure, and reaches any place.

Customer Service: 866-764-8989 Tel: (269) 764-8989 Fax: (269) 764-8897

We can help configure your suspended scaffold ranging from a 1000 lb safe working load (SWL) assembly to a 12000 lb or more safe working load assembly. We provide seminars covering the safe use of Swing-Lo Suspended Scaffolding. Upon request, we will come to your facility and provide a Competent Person Workshop.

With Swing-Lo Suspended Scaffold patented modular designs, scaffolding is easy to erect and totally versatile. Suspending is easy:

1. START AT THE TOP Swing-Lo Clamps or Scissors clamp on structural members (steel or concrete). Many products are available depending on your requirements.

2. ADD HANGER ASSEMBLY A working deck of almost any size can easily be suspended at any eight by adding to Clamps the Connectors Stems, and Hangers or Truss. A complete assembly will safely support a 1000 lb to 12000 lb distributed working load,

3. ADD DECKING, GUARDRAILS, AND TOE BOARDS

→→

1. CLAMP PAGES 59-61

→

2. CONNECTOR PAGE 62

3. RAIL BRKT PAGE 65

4. VERTICAL STEM PAGE 62

5. TRUSS (PAGE 62) HANGER (PAGE 63)

6. GUARDRAILS (PAGE 65) DECKING (PAGE 66)

OUR HERITAGE

1000 LB SWL ASSEMBLY

4

WE CAN HELP

All products must be used in accordance with Swing-Lo Suspended Scaffold Company’s Safety Instructions, and all Local, State, and Federal Safety Regulations.

Customer Service: 866-764-8989 Tel: (269) 764-8989 Fax: (269) 764-8897 5

Tight spots are no problem for Swing-Lo suspended scaffolding. More than a dozen clamp designs let you connect to channels, bar joists, I-beams, angles - even vertical columns - with equal ease, so you can get your skilled trades into those hard-to-reach places. And with multi-level platforms, several crews can work in the same area at one time.

Hundreds of modular configurations give you overhead access to areas from 4’ x 8’ to an entire football stadium. Rigid stems, trusses and platforms provide solid footing, less fatigue and greater worker safety. And that means more productivity per man hour.

● Put your crew to work on both sides and under neath the bridge simultaneously.

● Swing-Lo suspended systems permit inspections and repairs that don’t block activity above or below the bridge.

● Give your crew complete access to every inch of every bridge safely and economically.

● No tools needed to erect the systems. In fact, most systems can be assembled and erected in minutes. ● Systems can be installed permanently for periodic inspections and maintenance or disassembled and easily installed at another site.

Mobile By-pass Scaffold & Connecting Mobile Parapet ScaffoldPages 21-23, 39-47

Put your crew in a tight spot.

APPLICATIONS

Open Deck Railroad Bridge Scaffold Page 52

Mobile By-pass Scaffold & Connecting Mobile Parapet ScaffoldPages 21-23, 39-47

All products must be used in accordance with Swing-Lo Suspended Scaffold Company’s Safety Instructions, and all Local, State, and Federal Safety Regulations.

Stationary Parapet Scaffold (Pages 39-47)

Grid Scaffold Deck (“Dance Floor”) Page 29

Mobile Parapet ScaffoldPages 39-47

Cable ScaffoldPages 53-55

Mobile Wrap-Around Parapet ScaffoldPages 44,45,47

6 Customer Service: 866-764-8989 Tel: (269) 764-8989 Fax: (269) 764-8897

APPLICATIONS

All products must be used in accordance with Swing-Lo Suspended Scaffold Company’s Safety Instructions, and all Local, State, and Federal Safety Regulations.

Mobile By-pass Scaffold with Inverted Mobile Beam Clamps - Call

Top-Riding Flange Scaffold, Page 26 Mobile Beam Clamp Suspended Scaffold, Page 18

7Customer Service: 866-764-8989 Tel: (269) 764-8989 Fax: (269) 764-8897

APPLICATIONS

Extended Girder Scaffold, Page 38 Parapet Scaffold, Pages 39-47

All products must be used in accordance with Swing-Lo Suspended Scaffold Company’s Safety Instructions, and all Local, State, and Federal Safety Regulations.

Mobile Parapet Scaffold with Ladder ClampPages 39-47, 56

Mobile By-pass Scaffold Pages 21-23

Stationary Beam Clamp Suspended ScaffoldPages 29-30

Extended Parapet ScaffoldPage 44

8 Customer Service: 866-764-8989 Tel: (269) 764-8989 Fax: (269) 764-8897

APPLICATIONS

All products must be used in accordance with Swing-Lo Suspended Scaffold Company’s Safety Instructions, and all Local, State, and Federal Safety Regulations.

9

Mobile Mono-rail Parapet Scaffold - Call

Customer Service: 866-764-8989 Tel: (269) 764-8989 Fax: (269) 764-8897

APPLICATIONS

Mobile Parapet Scaffold, Pages 39-47 Bridged Mobile Parapet Scaffolds, Pages 39-47

Stationary Cat-Walk Parapet Scaffold, Page 43 Stationary Heavy Duty Parapet Scaffold, Page 46

All products must be used in accordance with Swing-Lo Suspended Scaffold Company’s Safety Instructions, and all Local, State, and Federal Safety Regulations.

Stationary Beam Clamp, Hanger & Aluminum Beam Support Scaffold, Page 30

Single Beam (Fixed Beam) SUSPENDED SCAFFOLD Page 37

Mobile Beam Clamp, Hanger & Aluminum Beam Support Scaffold, Page 18

Monorail Track SCAFFOLDCall

Pier Column Scaffold, Page 34

Customer Service: 866-764-8989 Tel: (269) 764-8989 Fax: (269) 764-8897

APPLICATIONS

10

All products must be used in accordance with Swing-Lo Suspended Scaffold Company’s Safety Instructions, and all Local, State, and Federal Safety Regulations.

Mobile Top Flange-Cart Scaffold, Page 26

Counter-Weighted Cart Scaffold, Page 49

Steel Girder Application Concrete Girder Application

Mobile Prestressed Concrete I-Beam Suspended Scaffold Pages 19-20

Mobile Thru-Girder Wrap-Around Scaffold, Page 51

Rai

l-Ind

epen

dent

Par

apet

Sca

ffold

C

all

Customer Service: 866-764-8989 Tel: (269) 764-8989 Fax: (269) 764-8897

APPLICATIONS

11

All products must be used in accordance with Swing-Lo Suspended Scaffold Company’s Safety Instructions, and all Local, State, and Federal Safety Regulations.

Mobile I-Beam Clamp & Hanger with Aluminum Beam Support Multi-Level Suspended Scaffold, Page 24

Stationary Box Chord & Hanger with Aluminum Beam Support Suspended Scaffold - Call

Stationary Box Chord & Hanger with Aluminum Beam Support Suspended Scaffold - Call(Interior View)

Customer Service: 866-764-8989 Tel: (269) 764-8989 Fax: (269) 764-8897

APPLICATIONS

12

All products must be used in accordance with Swing-Lo Suspended Scaffold Company’s Safety Instructions, and all Local, State, and Federal Safety Regulations.

13

Stainless Steel Construction

Customer Service: 866-764-8989 Tel: (269) 764-8989 Fax: (269) 764-8897

PERMANENT SUSPENDED SCAFFOLD APPLICATION

All products must be used in accordance with Swing-Lo Suspended Scaffold Company’s Safety Instructions, and all Local, State, and Federal Safety Regulations.

Customer Service: 866-764-8989 Tel: (269) 764-8989 Fax: (269) 764-8897

BASCULE BRIDGE SCAFFOLD

14

All products must be used in accordance with Swing-Lo Suspended Scaffold Company’s Safety Instructions, and all Local, State, and Federal Safety Regulations.

Inspect and maintain all areas of a Rig

Temporary or permanent suspended scaffold decks can be erected with attention given to a type of scaffold system best suited for a particular area. We will custom design and fabricate to meet a specific scaffold need

Swing-Lo Cable Scaffold is most effective where structural beams are not available for supporting a scaffold working deck. Cable trollies are anchored on both ends to support a rolling working deck. All Cable Scaffolds are equipped with brakes to maintain work-ing position.

Swing-Lo standard Beam Clamps (rolling or station-ary) attach and lock to structural beams to support a 1000lb. or more rated working deck. The By-Pass scaffold system enables the working deck to be moved around obstructions.

Swing-Lo Pier Column Scaffold is erected around pier columns to create a multi-level scaffold for reaching all areas of the pier column.Access to all scaffold decks is accomplished with a Swing-Lo Ladder Clamp and ladder.

Swing-Lo Scaffolds meet or exceed OSHA stan-dards.

Customer Service: 866-764-8989 Tel: (269) 764-8989 Fax: (269) 764-8897

RIG SCAFFOLD SYSTEMS

15

All products must be used in accordance with Swing-Lo Suspended Scaffold Company’s Safety Instructions, and all Local, State, and Federal Safety Regulations.

Package includes:

2 each HD-801 Hangers (29” Base, 38” high)4 each Scissor Beam Clamps

Package includes:

2 each CHD-140 Hangers (31” Base, 36” high)4 each Scissor Beam Clamps

CHD-140 PAINTERS SPECIAL

HD-801 HANGER ASSEMBLY

CHD-140 Painters Special is designed for painters of highway bridges and overpasses.

Customer Service: 866-764-8989 Tel: (269) 764-8989 Fax: (269) 764-8897

CHD-140ASSEMBLY

HD-801ASSEMBLY

HD-801 Grid Hanger is used for super-structure staging. The quick-attach swivel hook allows rotation and alignment to proper working position.

*SHD and CSHD models use 2 3/8” diameter rollers (see page 65)

SCISSOR BEAM CLAMP & HANGER

CHD-140 PAINTERS SPECIAL HANGER SWL (LBS)BEAM CLAMP EXPANSION

CBHD #6610006-10

CMHD #6610008-16

CKHD #66100010-18

CSHD #66*1000

14-24”

HD-801 GRID HANGER “COAT HANGER”SWL (LBS)BEAM CLAMP EXPANSION

CBHD #6610006-10

CMHD #6610008-16

CKHD #66100010-18

CSHD #66*1000

14-24”

*SHD and CSHD models use 2 3/8” diameter rollers (see page 65)

16

31”

29”

24”to

36”

38”

All products must be used in accordance with Swing-Lo Suspended Scaffold Company’s Safety Instructions, and all Local, State, and Federal Safety Regulations.

Package includes:2 each CHD-101 Hangers (29” Base, 36” high)4 each SL-71A32 32” Vertical Stem2 each W-20D Drum Winch with 5/16 X 100’ wire rope2 each SL-54C 1000 lb SWL Beam Clamps 8 each SL-35D Safety Rail Bracket (Bolt-Type)4 each SL-65A Scissor Insert Connector4 each Scissor Beam Clamps (choose model from above)

The CHD-101 Winch Frame Hanger System may be used at the piers with or without rolling on the beams. This system has a built in winch so that assembled scaffold can be raised to the desired working height. It is also ideal for working on the pier columns.

CHD-101 WINCH FRAMEHANGER SYSTEM

Customer Service: 866-764-8989 Tel: (269) 764-8989 Fax: (269) 764-8897

The CHD-101 Winch Frame Hanger Assembly is used at the piers while working on the Pier Columns.

WINCH FRAME HANGER SCAFFOLD

1000 LB SWL MOBILE APPLICATION

1000 LB SWL STATIONARY APPLICATION

CHD-101 WINCH FRAME HANGER SYSTEM

BEAM CLAMP EXPANSION

CBHD #666-10

CMHD #668-16

CKHD #66

10-18

CSHD #66*

14-24”

W-20D Drum Winch 5/16 x 100’ wire rope

WINCH FRAME HANGER SCAFFOLD

17

29”

24”

32” stemfor

adjust-ment

All products must be used in accordance with Swing-Lo Suspended Scaffold Company’s Safety Instructions, and all Local, State, and Federal Safety Regulations.

Customer Service: 866-764-8989 Tel: (269) 764-8989 Fax: (269) 764-8897

Mobile Beam Clamp & Truss Beam ExpansionSafe Working Load (SWL) lbPackage includes:

SL-54F5”- 18”1000

SL-54F2 6” - 18”

2000

4 ea Beam Clamps 4 ea Safety Hooks 4 ea Vertical Perforated Stems 2 ea 4 Ft. Horizontal Truss4 ea Stage Board Locks

SL-54FSL-65C

SL-71A72SL-70BSL-70L

SL-54F2SL-65CHDSL-71AA72

SL-70BSL-70L

PACKAGED WEIGHT (LBS) 218 262

Easy movement, no tools required for erection; add to that the expand-ability of the platform. Go to the appropriate page for quantity and length of Aluminum Stage. Go to pages 63-64 for width of deck re-quired. Adjust your working elevation along the Vertical Stem. Change the I-Beam Clamp for any other suitable model (see page 60).

Page 67 for Aluminum StagePage 66 for Guardrails, Posts, & LocksPage 56, 59 for fall protection I-Beam Clamps

I-BEAM ROLLER CLAMP, STEM & TRUSSALUMINUM STAGE CONFIGURATION

I-BEAM ROLLER CLAMP, STEM, HANGER, ALUMINUM BEAM & PLYWOOD DECK CONFIGURATION

MOBILE BEAM CLAMP & TRUSS

MOBILE BEAM CLAMP & HANGER

I-BEAM ROLLER CLAMP, STEM AND HANGER (SLP-702A) USING 4” X 6” WOOD BASE CONFIGURATION

MOBILE BEAM CLAMP & HANGER

18

Mobile I-Beam Clamp & Hanger Beam ExpansionSafe Working Load (SWL) lbPackage includes: 8’ X 20’ Deck

SL-54F5”- 18”1000

SL-54F2 6” - 18”

2000

4 ea Beam Clamps 4 ea Safety Hooks 4 ea Vertical Perforated Stems 4 ea Hangers (for aluminum beams)4 ea 6.5” X 114” Aluminum Beam 3 ea 5.5” X 252” Aluminum Beam18 ea Aluminum Beam Locking Clips3 ea 3/4” X 4’ X 96” Plywood (Rough)*

SL-54FSL-65C

SL-71A72SLP-702TSA1

SL-BM650X114SL-550X252

SL-70ALL

SL-54F2SL-65CHD2SL-71C72

SLP-702TSB4SL-BM650X114

SL-550X252SL-70ALL

PACKAGED WEIGHT (LBS) 382 426

*Plywood not included

Mobile I-Beam Clamp & Hanger Beam ExpansionSafe Working Load (SWL) lbPackage includes: 4’ X 8’ Deck

SL-54F5”- 18”1000

SL-54F2 6” - 18”

2000

4 ea Beam Clamps 4 ea Safety Hooks 4 ea Vertical Perforated Stems 4 ea Hangers (for 4” X 6” Wood)4 ea 2” X 10” X 10’ Scaffold Plank 1 ea 3/4” X 4’ X 8’ Plywood (Rough)*

SL-54FSL-65C

SL-71A72SLP-702ASL-210X10

SL-54F2SL-65CHDSL-71AA72SLP-702ASL-210X10

PACKAGED WEIGHT (LBS) 246 290

All products must be used in accordance with Swing-Lo Suspended Scaffold Company’s Safety Instructions, and all Local, State, and Federal Safety Regulations.

*Plywood not included

MOBILE PRESTRESSED CONCRETE BEAM CLAMP MODELSMODEL RATED LOAD EXPANSION WT E F

SL-74R45A 2000 Lbs. 14” - 28” 72 45 Deg. 9”

SL-74R64A 2000 Lbs. 14” - 28” 72 64 Deg. 9”

SL-74R45B 2000 Lbs. 26” - 32” 74 45 Deg. 9”

SL-74R64B 2000 Lbs. 26” - 32” 74 64 Deg. 9”

PRESTRESSED CONCRETE BEAM CLAMP MODELSMODEL RATED LOAD EXPANSION WT E F

SL-74S45A 2000 Lbs. 14” - 28” 78 45 Deg. 9”

SL-74S64A 2000 Lbs. 14” - 28” 78 64 Deg. 9”

SL-74S45B 2000 Lbs. 26” - 32” 80 45 Deg. 9”

SL-74S64B 2000 Lbs. 26” - 32” 80 64 Deg. 9”

The Prestressed Concrete I-Beam models are designed to attach and lock onto prestressed concrete I-beams, and to support a suspended platform. Use 4 clamps with safety hooks, stems, and truss or hanger for one complete scaffold assembly. Additional units may be added for a larger working deck.

SL-74S45

This model can be modified to fit custom specifications. See sketch at left for required dimensions when ordering a custom fit clamp.

ANGLE ADAPTER KIT

PRESTRESSED CONCRETE I-BEAM CLAMP ANGLE ADAPTER KITS

MODEL DESCRIPTION WT

SL-74K4555 KIT TO CONVERT 45 DEG TO 55 33

SL-74K4564 KIT TO CONVERT 45 DEG TO 64 33

1. AXLE2. COTTER PIN3. RIGHT HAND BRACKET4. LEFT HAND BRACKET

Rolling

Stationary

(2) Ea.(4) Ea.(1) Ea.(1) Ea.

This kit is designed to change the angle of your concrete Prestressed Beam Clamp with a simple axle connection and relocation of the wheels. These kits are available only for the 45 Degree Prestressed concrete I-Beam Clamps.

SL-74R45

LH Bracket

RH Bracket

Wheels, Thrust Bearings, Washers, and axles are used from existing assembly

Customer Service: 866-764-8989 Tel: (269) 764-8989 Fax: (269) 764-8897

MOBILE PRESTRESSED CONCRETE BEAM CLAMP

PRESTRESSED CONCRETE I-BEAM

SECTIONS

19

All products must be used in accordance with Swing-Lo Suspended Scaffold Company’s Safety Instructions, and all Local, State, and Federal Safety Regulations.

See page 64 for choice of an alternate Hanger. For example: SLP-702A when using4” X 6” Wood.

ROLLING PRESTRESSED CONCRETE I-BEAM ASSEMBLY MODEL DESCRIPTION Q WT

1

2345678

SL-74R45A

SL-D2412ASL-84SASL-71B48GWSL-35DSL-70L4SL-BM650X52SL-71AA72

2000 lb. Cap., 14”-28” exp., 45 deg., Rolling Prestressed Beam ClampStage Aluminum 24”X12’ 2-ManStage Post AdaptorGuardrail Post w/35D & TB LockSafety Rail Lock (2’X4” Wood Rail)Board Lock (Aluminum Beam)Beam Aluminum; 6.5” X 63” w/nailerStem Vertical; 1.75sq. X 72”

4

2668424

288

9618548

204456

910

SL-65CHDSL-70TCD

Safety Swivel Hook Connector; 2k Truss Connector (Aluminum Beam)Wood; 2” X 4” X 5’ (NOT Included)Wood 2” X 4” X 12’ (NOT included)

4444

2424

PACKAGED WEIGHT (LBS) 632

The Prestressed Beam Clamp System is ideal for installing and removing concrete forms. It is a fully adjustable platform along the Vertical Stem. When fully assembled, it provides a mobile platform that can be expanded to include By-Pass attachments when diaphragms, lateral bracing, or stiffners are present. The platform can be enlarged to include several bays.

NOTE:

Stationary Prestressed Beam Clamp (SL-74S series)can be converted to a mobile clamp by adding rollers.See page 19 for all models and conversion kits.

Attach clips and slotted bolt to lock beams at every loca-tion where the beams (top and bottom) intersect

Prestressed concrete I-beam application using aluminum truss and aluminum stagesing

Prestressed concrete I-beam application using aluminum beam and plywood decking

Customer Service: 866-764-8989 Tel: (269) 764-8989 Fax: (269) 764-8897

MOBILE PRESTRESSED CONCRETE I-BEAM

SCAFFOLD

20

DETAIL Aing

All products must be used in accordance with Swing-Lo Suspended Scaffold Company’s Safety Instructions, and all Local, State, and Federal Safety Regulations.

The By-Pass System is part of a revolutionary concept in scaffold engineering. Instead of using ground scaffolding, working decks are elevated by using clamp and hanger assemblies suspended from existing structural beams. This allows general contractors, painters, and maintenance crews to perform jobs over water, utility lines, high-ways, rugged terrains, and railroads without interrupting traffic and work operations below. Because suspended scaffolding requires few materials, no special tools and minimal labor to erect and assemble, savings of 50% or more are reported over conventional ground scaf-folding. The By-Pass System is designed to simplify the moving of

suspended working decks along the support beams. The suspended scaffold can be moved the entire length of the beam, by-passing cross beams without removing or leaving the working deck.This is accomplished by attaching ratchet binders and stems (com-plete with roller beam clamps) to the I-beam flange. The scaffold roller beam clamp and stem assembly which supports the working deck, is then lowered and the deck is rolled past the cross beam. Once repo-sitioned, the scaffold clamp and stem assembly are reclamped and locked to the beam flange. The ratchet binder and stem are lowered, and work can resume with minimum downtime.

Steel I-Beam Application Utilizing Plywood Decking

Steel I-Beam Application Utilizing Aluminum Stage Decking 1. Roll up to obstruction

←

2. Attach By-Pass Beam Clamp and Ratchet to Connector

4. Roll past obstruction

←

3. Use the Ratchet to take the weight off the outside Beam Clamp and detach outside beam Clamp

5. Re-attach outside Beam Clamp

6. Detach By-Pass Beam Clamp and advance deck

←

Attach clips and slotted bolt to lock beams at every location where the beams (top and bottom) intersect

SLP-702TS

←←←

Customer Service: 866-764-8989 Tel: (269) 764-8989 Fax: (269) 764-8897

MOBILE BY-PASS SCAFFOLD

21

All products must be used in accordance with Swing-Lo Suspended Scaffold Company’s Safety Instructions, and all Local, State, and Federal Safety Regulations.

LARGE BY-PASS PLATFORM SIZES

MODEL SL-706 LARGE BY-PASS SUSPENDED SCAFFOLDNO. PART NUMBER DESCRIPTION QTY

1 SL-BM650X014 Beam Alm; 6.5” X 14’ w/Nailer 4

2 SLP-702TSB1 Truss Hanger Support w/Pin (2” Stem) 8

3 SL-54F2 Roller Beam Clamp; 2k RL; 5”-18” Exp. 4

4 SL-71C72 Stem, 2” X 2” X 72” Perf. Pre-Galv. 8

5 SL-65CHD2 Safety Swivel Hook Connector (2” Stem) 4

6 SL-65BPF By-Pass Ratchet/Stem Connector (C-Stem) 4

7 CM-05 Load Transfer Ratchet - 10” Barrel 4

8 SL-54F2BP Roller Beam Clamp; 2k RL; 5”-18”, w/BP C 4

9 SL-DX2424 Alm Stage, 24” X 24’ - 3-Man 6

10 SL-70L4 Aluminum Beam/Aluminum Stage Lock 12

PACKAGED WEIGHT (LBS) 1788

MODEL SL-706

Pages 63-64 for Aluminum Beams and HangersPage 60 for beam clamp models

Guardrails not shown for clarity

LARGE BY-PASS SUSPENDED SCAFFOLD

MODELNUMBER OF

STAGESWIDTH

(INCHES)LENGTH(FEET)

SL-704 4 24/28 *SL-705 5 24/28 *SL-706 6 24/28 *

The Large By-Pass Scaffold System is a mobile platform equipped with four suspension points and four transfer points.

*The length of stages used will determine the quantity and length of guardrails, endrails, and toeboards.

By-Pass Configuration

Customer Service: 866-764-8989 Tel: (269) 764-8989 Fax: (269) 764-8897

LARGE MOBILE BY-PASS SCAFFOLD

22

Page 67 for Aluminum Stages

All products must be used in accordance with Swing-Lo Suspended Scaffold Company’s Safety Instructions, and all Local, State, and Federal Safety Regulations.

The Small By-Pass Scaffold System is a mobile platform equipped with four suspension points and four transfer points. The Vertical Stems come with triangular By-Pass Brackets that allow for going around Diaphrams, Stiffeners, and Lateral Braces. The standard packaged platform is four feet wide by the desired length of the platform.

Steel I-Beam Application Using Aluminum Stage Decking

MODEL SL-602 SMALL BY-PASS SUSPENDED SCAFFOLDNO. PART NUMBER DESCRIPTION QTY

1 SL-70B Truss, 48” w/Stage Board Lock 2

2 SL-71A72 Stem, 1.75” Sq. X 72”, Perf. Pre-Galv. 4

3 CM-05 Load Transfer Ratchet - 10” Barrel 4

4 SL-54FBPA Roller Beam Clamp; 1k RL; 5”-18” , w/BPC 4

5 SL-65BPB2 By-Pass Bracket for 1.75” Sq. Stem 4

6 SL-65C Safety Swivel Hook Connector -1.75” Stem 4

7 SL-54F Roller Beam Clamp; 1k RL; 5”-18” Exp. 4

8 SL-DX2416 Stage Aluminum; 24” X 16’ 3-Man (750#) 2

9 SL-84SAH Stage Post Adaptor w/ 1.38” Offset fr. web 6

10 SL-71B48M Guardrail Post, Perf. Pre-Galv. w/Locks 6

11 SL-16AL Aluminum Guardrail, 1.5” Sq. X 192” 4

12 SL-GR0540 Aluminum Guardrail, 1.5” Sq. X 54” 4

13 SL-84GRL Guardrail Lock, J-Bolt for 1.5” Sq. Stem 8

14 SL-70L Truss Board Lock 4

PACKAGED WEIGHT (LBS) 828

SMALL BY-PASS SUSPENDED SCAFFOLD

MODELNUMBER OF

STAGESWIDTH

(INCHES)LENGTH(FEET)

SL-602 2 24/28 *SL-603 3 24/28 *SL-604 4 24/28 *

Customer Service: 866-764-8989 Tel: (269) 764-8989 Fax: (269) 764-8897

SMALL BY-PASS ATTACHMENT

SMALL MOBILE BY-PASS SCAFFOLD

23

SMALL BY-PASS PLATFORM SIZES

MODEL SL-602

All products must be used in accordance with Swing-Lo Suspended Scaffold Company’s Safety Instructions, and all Local, State, and Federal Safety Regulations.

MOBILE MULTI-LEVEL SCAFFOLDPART # DESCRIPTION QTY

SL-54X 4k RL Roller Beam Clamp, 6-12”Exp., 1.5”J 6SL-65CHD20 Double Stem to Eye Connector 6SL-71CX120 2” Sq. X 10’ Stem 18SLP-702TSB4 Hanger for Aluminum Beam, Short Body 18SL-650X0035 Aluminum Beam 6.5 X 3’6” 20SL-DX2820 Aluminum Stage, 28” X 20’, 3-Man 3SL-10AL 1.5” Sq. X 10’ Alum Guardrail 12SL-GR0380 38” Aluminum Guardrail 12SL-70LWB Sliding Board Lock for Aluminum Beam 22SL-84GRL3 Guardrail Lock 24SL-70L4 Board Lock for Aluminum Beam 2SL-D2810 Aluminum Stage, 28” X 10’, 2-Man 1SLP-702TSB4A Hanger for Aluminum Beam, single 4SL-65ESP20 HD Stem Connector 12

The Mobile Multi-Level Scaffold offers adjustability, functionality, and mobility. The workman can reach areas at various elevations.

Customer Service: 866-764-8989 Tel: (269) 764-8989 Fax: (269) 764-8897

MOBILE MULTI-LEVEL SCAFFOLD

24

PACKAGED WEIGHT 1993

All products must be used in accordance with Swing-Lo Suspended Scaffold Company’s Safety Instructions, and all Local, State, and Federal Safety Regulations.

The Mobile Spreader Scaffold provides a single spreader expansion bar and two Roller Beam Clamp jaws, used in situations where there are stiffeners on one side of the girder, preventing movement of the rollers on a standard roller beam clamp.

The mobile Drop-Through Cart is designed for rolling on girder top flange (concrete and steel). It offers a platform that is adjustable, requiring no tools to erect. This modular platform is ideal when deep girders present an access problem in reaching the underside of the roadway. The scaffold is perfect for working between two bridge roadways. Easy erection, easy take down. Adjustable to girder depth above and below flanges. Can be used for various bridge applications.

The Swing-Lo Mobile Traveller Scaffold is designed to provide access to the crane rail. The scaffold can be made to the client’s specification. The Model SL-514CRA runs on a fourteen-foot track which, in turn, rolls on the crane rail. It comes complete with eight foot Vertical Stems, a thirty-eight inch wide by thirty-six inch long platform, access ladder brackets, and brakes.

SL-810DTC DROP-THROUGH ROLLING CART PART NO. DESCRIPTION QTYSL-7010 2 X 3 X 10’ Horizontal Traveller 2612PGC3 Roller Wheels with Brakes 415TSCSA-L Column Support Bracket w/Bumper 215TSCSA-R Column Support Bracket w/Bumper 271A096M 8’ Vertical Perforated Stem 4SL-70C 30” Truss w/Bolt Locks 2SL-D2808 28” X 8’ 2-Man Aluminum Stage 1SL-70L Stage/Truss Board Lock 2SL-15AB036C Horizontal Brace, 36” OC w/Lock CH 2SL-71B48M Perforated Steel Guardrail Post 4SL-84SA Stage Post Adapter 4SL-10AL 10’ Aluminum Guardrail 4SL-15CWA Horizontal Bumper Support 4

Customer Service: 866-764-8989 Tel: (269) 764-8989 Fax: (269) 764-8897

MOBILE SPREADER SCAFFOLD PART NO. DESCRIPTION QTYSL-56X15 Spreader Roll Beam Clamp, 1k 2SL-65CHD Safety Hook Connector 4SL-71A072 6’ Vertical Perforated Stem 4SL-DX2820 28” X 20’ 3Man Aluminum Stage 1SL-70L Board Lock 2SL-70C 30” Truss Support 2SL-71B48M Guardrail Post 8SL-84SAH Stage Post Adapter 8SL-20AL 20’ Aluminum Guardrail 4SL-03AL 3’ Endrail 4SL-84GRL8 Guardrail Lock J-Bolt 8

MOBILE DROP-THRU SCAFFOLD

MOBILE TRAVELLER SCAFFOLD

MOBILE SPREADER SCAFFOLD

* Ladder not included

SL-514CRA MOBILE TRAVELLER SCAFFOLD PART NO. DESCRIPTION QTY514CRA-1 Spreader 2 X 4 X 168” 2514CRA-2 Top Support Assembly 2514CRA-3 39” Truss Assembly 2514CRA-4 Horizontal Bumper Arm 4514CRA-5 Track Roller Assembly 4514CRA-6 Ladder Clamp Assembly 215AB037C 37” Horizontal Brace w/ lks 271A096M 96” Vertical Stem 4SL-D1903 19” X 3’ Stage w/Hooks 2SL-03AL 3’ Guardrail 4SL-84GRL Guardrail Lock J-Bolt 8

25

MODEL SL-810DTC

MODEL SL-514CRA

MODEL SL-56X15

All products must be used in accordance with Swing-Lo Suspended Scaffold Company’s Safety Instructions, and all Local, State, and Federal Safety Regulations.

SL-512BFS Bottom Flange Suspended ApplicationPART NO. DESCRIPTION QTYSL-15LAS Cart Wheels 4SL-70A72M Stage Support Truss 4SL-GB72 Vertical Stem w/Collar Locks 4SL-70CS Truss Support 4SL-70L Board Locks 4SL-4AL 4 ft. Aluminum Guardrail 4SL-12AL 12 ft. Aluminum Guardrail 4SL-84GRL Guardrail Bolt Locks 16SL-D2412 Aluminum Stage 24 in. x 12 ft. 2

SL-512BFR Bottom Flange Riding ApplicationPART NO. DESCRIPTION QTYSL-15LAS Cart Wheels 4SL-70A72M Stage Support Truss 2SL-84SA Stage Adapter 4SL-71B48M Perforated Guardrail Posts 4SL-70L Board Locks 4SL-4AL 4 ft. Aluminum Guardrail 4SL-D2412 Aluminum Stage 24 in. x 12 ft. 2

Designed for rolling on girder and beam flanges, working between two bridge roadways. Easy erection, easy take down. Adjustable to girder depth above and below flanges. Can be used for various bridge applica-tions.

Standard models are for spanning forty-eight inches between girders and designed to use twelve foot stages. This system is not suitable for bridges with stiffners. Please provide all applicable dimensions when inquiring.

The Swing-Lo Top Flange Mobile Scaffold is designed to fit types A, AA, and generic railroad bridges. The platform includes access hatch openings at each end, allowing the worker to step onto the girder for advancing the platform. Sliding gates allow for entry and exit. Foot Brakes, Anti-Tip, Adjust-able Locks, Guardrails (top and mid) on all sides. The inside lower bumper wheels track the girder.

Concrete Girder Application

TOP FLANGE MOBILE SCAFFOLD Rated Load... 500 lbsMODEL NO. DESCRIPTION WT

SL-610CGC 65” X 112” Top Flange Mobile Scaffold 270SL-614PGC 60” X 168” Top Flange Mobile Scaffold 300

Steel Girder Application

Customer Service: 866-764-8989 Tel: (269) 764-8989 Fax: (269) 764-8897

MOBILE FLANGE SCAFFOLD

MOBILE TOP FLANGE SCAFFOLD

26

MODEL SL-610CGC

MODEL SL-614PGC

All products must be used in accordance with Swing-Lo Suspended Scaffold Company’s Safety Instructions, and all Local, State, and Federal Safety Regulations.

MOBILE SUSPENDED STRIPPING SCAFFOLD # PART NO. DESCRIPTION QTY1 PSC72AN Prestressed Beam Cart Jaw Assembly 62 PSCB53 Expansion Bar 31” 32 PSCB72 Expansion Bar 50” 37 15AB096F Horizontal Brace 96” 45 SL-HLT55008 5 1/2” x 8’ Aluminum Beam w/nailer 38 SL-71A024M 1 3/4” Sq. x 24” Vertical Stem 64 SLP-702TS Truss Hanger Support for 1 3/4” Stem 63 PSCG24 Cart Scaffold Guardrail Bracket 46 SL-35D Safety Rail Bracket (for 2x4 wood rail) 4

Swing-Lo Mobile Stripping Scaffold is designed to roll along prestressed concrete I-beam flanges. Adjustable expansion bars expand from beam to beam with the wheel assemblies attached at both ends. The Scaffold is equipped with side rollers and brakes to help maintain scaffold stability and mobility. The working deck is adjust-able horizontally as well as vertically to adapt to beam spacing. When fully assembled the scaffold measures from 6 feet to over 10 feet wide and 16 feet long. Dimensions to consider

prior to ordering

Customer Service: 866-764-8989 Tel: (269) 764-8989 Fax: (269) 764-8897

MOBILE SUSPENDED STRIPPING SCAFFOLD

27

MODEL SL-PSC6285

All products must be used in accordance with Swing-Lo Suspended Scaffold Company’s Safety Instructions, and all Local, State, and Federal Safety Regulations.

SL- PSC9320 MOBILE STRIPPING CART ASSEMBLYPART NO. DESCRIPTION QTY

1 PC71E58 Prestress Cart Adhustable Arm As-sembly; 71 deg., 48-58” Expansion

3

2 SL-BM650X21 Beam Aluminum; 6.5” X 21’ Long with Plastic Nailer

3

3 SL-84ABA65 Post Support aluminum Beam adaptor with Detent Pin

4

4 SL-71B48M2 Guardrail Post: Perforated Steel 48” w/SL-35D & Toeboard Clamp

4

5 Plywood; 3/4”X4’X4.75” (NOT Incld) 26 Plywood; 3/4”X4’X21.5” (NOT Incld) 27 Plywood; 3/4”X4’X8’ (NOT Incld) 28 Wood; 2”X4”X6’ (NOT Incld) 4

BETWEEN GIRDERS APPLICATION

Between-the- girders application allows the worker to get closer to the bottom of the roadway. The Endrails are collapsable, allowing the platform to evade diaphrams and/or diagonal braces. Installation and removal of concrete forms proceeds uninterrupted. The width is adjustable forty-eight inches to fifty-eight inches, and up to twenty feet long.

Customer Service: 866-764-8989 Tel: (269) 764-8989 Fax: (269) 764-8897

MOBILE STRIPPING CART SCAFFOLD

28

MODEL SL-PSC9320

All products must be used in accordance with Swing-Lo Suspended Scaffold Company’s Safety Instructions, and all Local, State, and Federal Safety Regulations.

When wide-open, clear view suspended working platform is required for over-head construction or maintenance in auditori-ums, fieldhouses, hangers, etc., Swing-Lo beam clamp, stem, and hanger assemblies have proven to be a safe, versatile and economical solution. Configured in an eight foot by eight foot or ten foot by ten foot grid, the modular system can be expanded to any size platform. Rated live load can range from twenty-five pounds per square foot to fifty or more pounds per square foot.

1000 LB SWL ASSEMBLY

Pages 60-62 for beam clamp choicesPages 63-64 for stem and hanger choicesPage 67 for Aluminum Beams & Scaffold Plank

5000 LB SWL ASSEMBLY

SLP-702A USES 4” X 6” WOOD

SLP-702TS USES ALUMINUM BEAM

Customer Service: 866-764-8989 Tel: (269) 764-8989 Fax: (269) 764-8897

STATIONARY GRID SCAFFOLD

29

All products must be used in accordance with Swing-Lo Suspended Scaffold Company’s Safety Instructions, and all Local, State, and Federal Safety Regulations.

Increase the size of your platform in a number of con-figurations. Alternate decking materials are available.

BEAM CLAMP ASSEMBLY - STATIONARY SL-54C SL-54CE

EXPANSION 5” - 18” 5” - 20”

SWL (LBS) 1000 1000JAW OPENING 3.375” 6.875”Package includes:4 ea. Beam Clamps (6” - 18”) exp., 4 ea SL-65C Safety Swivel Hook Connectors, 4 ea. SL-71A072 (72” Vertical Stem), 4 ea. SLP-702TS Hanger, 8 SL-35D Safety Rail Bolt Lock (for 2” X 4” Wood Rail), 4 ea. SL-BM650X0085 Aluminum Beam

STEM & TRUSS WITH ALUMINUM STAGE CONFIGURATION

STATIONARY BEAM CLAMP, STEM & HANGER WITH ALUMINUM BEAM CONFIGURATION

SLP-702AHANGER

(For 4X6 wood) SLP-702TSB4

HANGER(For aluminum beam)

Customer Service: 866-764-8989 Tel: (269) 764-8989 Fax: (269) 764-8897

STATIONARY BEAM CLAMP & TRUSS SCAFFOLD

STATIONARY BEAM CLAMP AND HANGER

30

All products must be used in accordance with Swing-Lo Suspended Scaffold Company’s Safety Instructions, and all Local, State, and Federal Safety Regulations.

BEAM CLAMP ASSEMBLY - STATIONARY DECK SL-54C SL-54DT

EXPANSION 5” - 18” 5” - 28”

SWL (LBS) 1000 2000

JAW OPENING 3.5” 3.5”

Package includes:6 ea. Beam Clamps 6 ea Safety Swivel Hook Connectors 6 ea. 72” Vertical Stems 6 ea. SL-70TCD Connectors 3 ea. SL-BM650X008 6.5” X 6’ Aluminum Beam20 ea. SL-35D Safety Rail Bolt Lock (2X4 Wood) 6 ea. SL-70L4 Aluminum Beam Board Lock

Waler Beam Clamps, when used in pairs, provide an effective and efficient scaffold. Commonly used when forming and stripping operations on a bridge deck or fascia require a wider working platform.

Swing-Lo Waler Beam Clamps are used with 2” x 6”, 8”, 10”, or 12” wood beams. Aluminum Channel Trusses (two 2” x 6” spaced back-to-back) or two Steel Channel Trusses are similarly attached to create a cantilevered working deck. Waler Beam Clamps should be evenly spaced (24” - 30” apart) on both the fascia beam flange and a second interior beam flange to accomodate the wood, aluminum, or steel channels 10’ to 16’ long.

After Waler Beams are spaced and positioned, 2” x 10” x 14’ planks are stag-gered approximately 2’ on center and covered with plywood decking. Guard-rail Posts with Toeboards complete the Fascia Waler Scaffold Assembly.

WALER FASCIA BEAM BRACKET

MODEL DESCRIPTION BEAM WIDTH

BEAM THICKNESS

SL-03FBWA 3 ft. Waler Fascia Beam Bracket 8” - 18” 3/4” - 4”SL-03FBWB 3 ft. Waler Fascia Beam Bracket 14” - 24” 3/4” - 4”SL-04FBWA 4 ft. Waler Fascia Beam Bracket 8” - 18” 3/4” - 4”SL-04FBWB 4 ft. Waler Fascia Beam Bracket 14” - 24” 3/4” - 4”SL-05FBWA 5 ft. Waler Fascia Beam Bracket 8” - 18” 3/4” - 4”SL-05FBWB 5 ft. Waler Fascia Beam Bracket 14” - 24” 3/4” - 4”

The Waler Bracket is used as a temporary “cat-walk” support. The system provides a solid base for aluminum stages or planking and plywood decks. The Waler assembly includes guardrail post. See example below for obtaining proper spacing of the Waler Brackets.

Safe Working Load Limits:All Waler Fascia Beam Brackets are designed to support 250 lbs. per foot with 4:1 safety factor. Spacing and working loads are determined as follows:

EX: 4 ft. Waler Bracket = 4ft. X 250 Lbs. = 1000 lbs. 1000 lbs. divided by desired working load of 25 lbs./sq./ft =

1000 lbs. = 40 sq. ft. = 40 sq. ft. = 10 ft. spacing 25 lbs./sq./ft. 4 ft. Bracket

Leveler adjusts from 3/4” - 4” for beam thickness Jaw adjusts to fit a wide range of flange widths. See chart above.

Boardlocks secure aluminum stages.

Guardrail Posts (not shown) are easily removable.

Waler Brackets come in 3’ - 5’ lengths. The SL-05FBW is shown above.

Safe Working Load Specifications:

The Waler Beam Clamp is designed to support a pair of structural members as a cantilever, off a minimum of two (2) I-beams.

Determination of the decking support should be performed by a Licensed Engineer. Choice of structural members must consider the following:

1. Factor of safety of 4:1, based on desired distributed live load.2. End point concentrated load not more than 500 lbs. with 4:1 safety factor 3. Maximum deflection when fully loaded.

Total load shall not exceed Waler Clamp rated load of 2000 lbs., based on the square area of the support members and clamp. The ends of the structural support members should be braced adequately.

Swing-Lo Suspended Scaffold does not assume any liability for use of materials that have not been examined and approved by a certified engineer.

WALER BEAM CLAMPMODEL DESCRIPTION WTFB-C6S Waler Beam Clamp 35

Customer Service: 866-764-8989 Tel: (269) 764-8989 Fax: (269) 764-8897

WALER BEAM CLAMP SCAFFOLD

WALER FASCIA BEAM SCAFFOLD

31

All products must be used in accordance with Swing-Lo Suspended Scaffold Company’s Safety Instructions, and all Local, State, and Federal Safety Regulations.

The Tank Bracket Scaffold Assembly is designed to be used with clips welded to inside or outside of the tank surface. The Tank Bracket also includes Board Locks to be used with Scaffold Planks or Aluminum Stages. Perforated pre-galvanized guardrail post is included with each Tank Bracket to accomodate cable guardrails. The Tank Bracket comes in three sizes.

Tank Bracket (for Ring Girder)

The Tank Bracket for Ring Girder is used where a steel ribbon is welded to the circumference of a steel tank, providing a stable platform for the worker. The bracket is adjustable for various sizes in width and height.

Tank Bracket for Steel Tank

TANK SCAFFOLD PART NO. DESCRIPTIONSL-24TS 2’ wide Tank Scaffold Bracket w/1 ea Locking Clip,

guardrail post and board lock(s)SL-36TS 3’ wide Tank Scaffold Bracket w/1 ea Locking Clip,

guardrail post and board lock(s)SL-48TS 4’ wide Tank Scaffold Bracket w/1 ea Locking Clip, guard

rail post and board lock(s) SL-18RGB 1.5’ Tank Bracket for Ring GirderSL-71B48M 4’ Perforated Pre-Galvanized Guardrail Post

Guard Rail Post(for wire rope rail)

Number of Tank Brackets required = 3.14 X diameter, then divide by 8

The Mobile Tank Scaffold provides a rolling platform on the inside or outside of a tank wall for easy access to the work surface. The platform can be adjusted along the vertical stem for optimum working elevations. It can, also, be configured for your specific application. The scaffold comes complete with aluminum stage deck and guardrails. The ladder clamp can accommodate any standard ladder (not included in the pack-age). The Mobile Tank Scaffold is ideal for cleaning, re-lining, and re-surfacing of steel tanks.

MOBILE TANK SCAFFOLD

MODELLENGHT OFVERT. STEM

WIDTH(INCHES)

LENGHT(FEET)

SL-100MTS To 24 Ft. 24/28 7 OR 12SL-200MTS VARIES VARIES MODULAR

Customer Service: 866-764-8989 Tel: (269) 764-8989 Fax: (269) 764-8897

FORMULA

STATIONARY TANK SCAFFOLD

MOBILE TANK SCAFFOLD

32

MODEL SL-24TS

MODEL SL-18RGB

24”

14” 1.5”

MODEL SL-71B48MGC

MODEL SL-100MTS MODEL SL-200MTS

All products must be used in accordance with Swing-Lo Suspended Scaffold Company’s Safety Instructions, and all Local, State, and Federal Safety Regulations.

SL-20PSE PIER CAP SCAFFOLD - Pier Cap Width 2’ - 4’PART # DESCRIPTION QTY

1 20PS06A Pier Cap Top Assembly 22 15TSCSFN Lower Brace Bracket 43 20PS04 8’ Vertical Stem Assembly w/ 2” Channel 24 20PS02 8’ Vertical Stem Assembly w/ 2 1/4” Channel 25 SL-24SB 24” Stage Bracket 46 SL-71B48M Perforated Steel Pre-Galv Guardrail Post 47 SL-71B60M 1 1/2” Sq. X 5’ Perforated Steel Pre-Galv Stem 28 SL-35C Safety Rail Bracket 8

The Pier Cap Scaffold is designed to straddle pier caps at two points or more to provide the worker access to areas on both sides and ends of the pier. The standard package allows for twenty-four inch wide by twelve foot aluminum stages. Various sizes are available.

SL-20PTS PIER CAP SCAFFOLD - Saddle Style - Pier Cap Width 6’ - 8.5’ITEM MODEL DESCRIPTION1 SL-20PT085 Pier Cap Top Assembly2 SL-7012 2” X 3” X 12’ Vertical Perforated Stem3 SL-71B48M2 Perforated Steel Pre-Galv. Guardrail Post w/SL-35D Locks4 SL-84SAH Stage Post Adaptor5 SL-24SB 24” Stage Bracket6 SL-DX2430 Aluminum Stage, 24” X 30”; 3-Man7 SL-49B Stage Binder - 24”8 SL-15LAFW Lower Fixed Pad ; Wood Mount9 2” X 4” Wood Guardrail (customer supplied)

The SL-20PTS Pier Cap Scaffold is designed to straddle pier caps at two points or more to provide the worker access to areas on both sides and ends of the pier. Working decks are adjustable for width and length. This model adapts to slopes of eighty-five de-grees on the pier cap. The length of the Platform can be increased using the SL-49B Stage Binder.

2” X 4” Wood Rail

Customer Service: 866-764-8989 Tel: (269) 764-8989 Fax: (269) 764-8897

PIER CAP SCAFFOLD

33

MODEL SL-20PSE

MODEL SL-20PTS

All products must be used in accordance with Swing-Lo Suspended Scaffold Company’s Safety Instructions, and all Local, State, and Federal Safety Regulations.

BEAM CLAMPSMODEL ULTIMATE LOAD EXPANSION JAW WT

SL-54E 6000 Lbs. 6” - 14” 2 1/2” 11SL-1254SC 8000 Lbs. 5” - 12” 1 3/8” 17SL-1518SC 15 Ton 15” - 18” 2 3/4” 45SAFETY CONNECTOR

MODEL DESCRIPTION WTSL-65CHD H.D. Safety Insert Connector 6VERTICAL STEMS (2” X 2”) HEAVY DUTY SL-71C72 72” Stem 14SL-71C96 96” Stem 19SL-71C120 120” Stem 24SL-71C144” 144” Stem 27ACCESSORIESSL-30CC Corner Guardrail Connector 4SL-60A16 Truss Insert 10SL-30GRC Guardrail Collar 11SL-65ESP H.D. Collar Connector 3SL-70L Truss Board Lock 5SL-35CHD Safety Rail Bracket 2SLP-702CHD H.D. Hanger, 4” x 6” Needle Beams 8SL-B80TB Toeboard Bolt Lock 1

HEAVY DUTY PIER CAP SCAFFOLD MODEL NO. SL-30PS

Customer Service: 866-764-8989 Tel: (269) 764-8989 Fax: (269) 764-8897

The SL-84CC Chord Clamp Assembly is designed to lock onto bridge structures. Standard clamp has a rated load of 1000 lbs. and is 30 inches in width. Clamp comes with J-Bolts for anchoring and a lad-der clamp for easy access to the platform. Other widths available on request.

SL-84CC H-BEAM CHORD CLAMP ASSEMBLYMODEL DESCRIPTION QTY WT

SL-84CC Chord Clamp 2 102SL-71A72 72” Stems 4 50SL-70TS(CC) Truss Support 4 24SL-70C36M 36” Truss 2 20SL-70L Board Locks 2 9SL-35C Safety Rail Brackets 8 12Total Weight: 227 lbs.

PIER SCAFFOLD

H-BEAM CHORD SCAFFOLD

34

MODEL SL-84CC

MODEL SL-30PS

All products must be used in accordance with Swing-Lo Suspended Scaffold Company’s Safety Instructions, and all Local, State, and Federal Safety Regulations.

SL-54BCC10 BOX CHORD SCAFFOLD - DUAL DECK 24” X 32’PART NO. DESCRIPTION QTYSL-54BCC10 Box Chord Scaffold Assembly w/ Stabilizer Brace 1SL-71C96M Vertical Perforated Stem, 2” X 2” X 8’ 4SLP-702TSB4 Truss Hanger Support, Short Body, w/detent Pins 4SL-70L4 Board Lock for Aluminum Beam - 702TS 4SL-70LWB Board Lock for Aluminum Beam - 6.5” 12SL-BM650X008 Beam, Aluminum; 6.5” X 8’ w/ Plastic Nailer 4

The Swing-Lo Box Chord Scaffold Model SL-54BCC10 is designed to lock onto bridge box chords, providing two twenty-four inch wide by up to forty feet of suspended aluminum decks. Stabilizers limit swaying and provides a rigid platform for a secure working environment.

SL-15AMB67 Suspended ApplicationPART NO. DESCRIPTION QTY

1 SL-15UJF UPPER HEAD ASSEMBLY - FIXED 22 SL-65DM1 V-Stem Lift Connector Assembly 23 SL-15AB059C Horz. Brace 59” CC w/Chn Lock 14 SL-15AB059T Horz. Brace 59” CC w/Tub Lock 15 SL-15LAF Fixed Mid Wheel Assembly 26 SL-7008 2” X 3” X 8’ Vertical Perforated Stem 27 SL-15TSHB Truss Hanger Suppt; 2” X 3” Vertical Stem 28 15AMB67-1N Box Chord Beam Clamp Jaw Assembly 29 15AMB67-2N Box Chord Beam Clmp Assmbly w/set scrw 210 SL-D2407 Stage Aluminum 24” X 7”; 2-Man 311 SL-BM650X008 Beam Aluminum 6.5” X 8’ w/Plastic Nailer 212 SL-70L4 Aluminum Beam Board Lock 613 SL-84SA Stage Post Adaptor 414 SL-07AL 7’ Aluminum Guardrail 615 SL-71B48M Perforated Steel Guardrail Post w/Locks 416 SL-84GRL Guardrail Lock J-Bolt for 1.5” Sq. 4

The Swing-Lo Chord to Parapet Scaffold is designed to connect the Outside Chord to the Bridge Parapet, giving the worker a platform six feet by seven feet. The Scaffold can be modified to a rolling system by adding rollers where appropriate.

Customer Service: 866-764-8989 Tel: (269) 764-8989 Fax: (269) 764-8897

BOX CHORD SCAFFOLD

35

MODEL SL-54BCC10

MODEL SL-15AMB67

All products must be used in accordance with Swing-Lo Suspended Scaffold Company’s Safety Instructions, and all Local, State, and Federal Safety Regulations.

SL-54CSC10 CHORD PLATFORM - CENTER PART NO. DESCRIPTION QSL-54UH10 Box Chord Upper Head Assembly 2SL-15CTE Box Chord Bottom Support 2SL-71E120M Stem, 2.5” Sq. X 120” Perforated 4SL-70G Truss, 25” 2SL-70L Truss Board Lock 2

The Box Chord Scaffold comes in a variety of configurations. They are designed to provide a stable and sturdy working deck to any and all sides of the chord. Add more stirrups to expand the platform length.

SL-54CDS11 DOUBLE SIDE CHORD PLATFORM PART NO. DESCRIPTION QSL-54UH11 Box Chord Upper Head 2SL-15CDS Box Chord Bottom Support 2SL-71E096M Stem, 2.5” Sq. X 120” 4SL-24SBF Stage Bracket, 24” w/ Bd Lck 4SL-71B48M2 Guardrail Post, Perforated w/35D 4

SL-54CSS09 SINGLE-SIDE CHORD PLATFORM PART NO. DESCRIPTION QSL-54UH09 Box Chord Upper Head 2SL-SL-15CSD Box Chord Bottom Support 2SL-71D72M Stem, 2.25” Sq. X 72” 2SL-28SBD Stage Bracket, 28” w/Bd Lck 2

Customer Service: 866-764-8989 Tel: (269) 764-8989 Fax: (269) 764-8897

SL-54CSA1 ABOVE CHORD PLATFORM MODEL NO. DESCRIPTION WT

SL-54CSA1 66” X 12.5’ Stationary Scaffold 350

The Swing-Lo Above Box Chord Cantilever Scaffold offers access without limit-ing the size of the working platform. No tools are needed to erect this adjustable and modular platform. The deck may be expanded up to seven feet wide, and up to the desired lenght.; simply add components. The standard platform (as shown) is sixty-six inches wide by twelve and a half feet long. All components except plywood included.

ABOVE BOX CHORD

SINGLE SIDE BOX CHORD

CENTER BOX CHORD

DOUBLE SIDEBOX CHORD

BOX CHORD SCAFFOLD

BOX CHORD CANTILEVER SCAFFOLD

36

END VIEW

MODEL SL-54CSA1

MODEL SL-54CSC3

MODEL SL-54CSS1MODEL SL-54CSD2

All products must be used in accordance with Swing-Lo Suspended Scaffold Company’s Safety Instructions, and all Local, State, and Federal Safety Regulations.

The Fixed Beam Saddle Scaffold provides acces to both sides of the beam or girder. The deck is adjustable along the lenght of the vertical stem. The length of the platform can be increased by adding more stirrups.

The Single-Side Beam Scaffold is easily placed and removed where it is needed. It is used for splicing beams and bolting beam sections. Guardrails provided when requested. The platform deck is adjustable along the vertical Stem. Wheels on the base of the Vertical Stem allow the platform to be erected below and rolled into place.

SL-1015B1 SINGLE-SIDE BEAM SCAFFOLD # PART NO. DESCRIPTION QTY1 SL-15US9 Upper Head for pivoting Stem 22 SL-15BRFS2 Horizontal Brace Support 23 SL-71E096M Stem, 2.5” Sq. X 96” Perforated 44 SL-24SBF Stage Bracket, 24” with Board Lock 25 SL-54D5 Side-Mounted Ladder Clamp - 2.5” Sq. 16 15CWA-234N Caster 2

SL-20PSG I-BEAM SADDLE SCAFFOLD # PART NO. DESCRIPTION QTY1 20PSG-1N Top Hanger Body Assembly 22 AR0629 Rod Adj. .75” X 29” 23 SL-71E096M Stem, 2.5” Sq. X 96” Perforated 44 AR0621C Rod Adj. .75” x 21” 25 SL-24SBF Stage Bracket, 24” with Board Lock 46 20PSG-2N Lower Brace Bracket Assembly 2

Designed specifically for railroad bridge inspection and maintenance. The assembly clamps onto the top of the bridge girders. Upper and lower clamp assemblies adjust to top and bottom chords. Standard Vertical Stem lengths are 10 to 12 feet. Additional Stem lengths, Stage Brackets, and Guardrails can be purchased to provide a working platform on both sides and beneath the bridge structure. Guardrails are purchased separately according to job requirements. An alternate configuration can be achieved when Aluminum Stages are used instead of wood decking. In that case, the illustrated Horizontal Truss may be used. Specify width of desired platform.

SL-RRP20 ELEVATED RAIL SCAFFOLD MODEL DESCRIPTION QTY

SL-90ER 6” - 14” Beam Clamp 4SL-71A72 6’ Galvanized Stems 4SLP-702A Needle Beam Hanger 4SL-B80TB Toeboard Clamp 4Total Weight:138 lbs.

Truss option for Aluminum Stage

Customer Service: 866-764-8989 Tel: (269) 764-8989 Fax: (269) 764-8897

ELEVATED RAIL SCAFFOLD

SINGLE-SIDE BEAM SCAFFOLD

I-BEAM SADDLE SCAFFOLD

37

MODEL SL-20PSG

MODEL SL-1015B1

MODEL SL-RRP20

All products must be used in accordance with Swing-Lo Suspended Scaffold Company’s Safety Instructions, and all Local, State, and Federal Safety Regulations.

Designed specifically for railroad bridge inspection and maintenance. The assembly clamps onto the top of the bridge girders. Upper and lower clamp assemblies adjust to top and bottom chords. Standard Vertical Stem lengths are 10 to 12 feet. Additional Stem lengths, Stage Brackets, and Guardrails can be purchased to provide a working platform on both sides and beneath the bridge structure.

SL-4818HBP H-BEAM PILE SCAFFOLDPART # DESCRIPTION

1 SL-200CCB Column Bracket Assembly - 36” 22 SL-D2818 Stage Aluminum 28” X 18’ 500 lb 13 SL-71B48M Guardrail Post Steel w/Locks 84 SL-84SA Stage Post Adapter 85 SL-18AL 18’ Aluminum Guardrail 46 SL-28ER Endrail Aluminum 28” 47 SL-48SB 48” Stage Bracket w/Bd Lck 2

The Extended Girder Clamp Scaffold allows workers to gain easy and safe access to the girder’s fascia by way of a built-in ladder clamp. The 10 Ft. spaced and standard 10 Ft. hinged Vertical Stem makes it easy for one person to install. This modular scaffold allows for two foot by ten foot increments along the structure. Two sizes of the Extended Girder Clamp provides expansion from five to eleven inches, and twelve to eighteen inches. The platform is extended up to 26.5 in. away from the girder.

Customer Service: 866-764-8989 Tel: (269) 764-8989 Fax: (269) 764-8897

H-BEAM PILE SCAFFOLD

EXTENDED GIRDER SCAFFOLD

STATIONARY H-BEAM CLAMP The H-Beam Column Clamp is used in pairs. When attached and locked to a steel H-Beam, the clamps provide a sturdy and secure base for an Aluminum Stage 14 inches wide and up to 40 feet in length. No tools required.

H-BEAM COLUMN CLAMP Rated Load... 500 lbs.MODEL NO. DESCRIPTION WT

SL-100CC 6 in. - 10 in. Expansion 20SL-160CC 12 in. - 16 in. Expansion 35

38

MODEL SL-90EGC

SL-90EGC EXTENDED GIRDER SCAFFOLDPART # DESCRIPTION QTY

1 90EGC1-2 Upper Head Bracket 5-18” Exp. 22 SL-7010 2” X 3” X 10’ Vertical Stem 23 SL-15AAB-A 10’ Adjustable horizontal Brace 24 SL-24SB 24” Stage Bracket w/Bd Lck 25 SL-64DM Front Mounted Ladder Clamp 16 SL-10AL 10’ Aluminum Guardrail 2

MODEL SL-4818HBP

All products must be used in accordance with Swing-Lo Suspended Scaffold Company’s Safety Instructions, and all Local, State, and Federal Safety Regulations.

PARAPET SCAFFOLD

SL-15A Parapet Scaffold features a 24in. x 7ft. working deck that mounts to 8ft., 12ft., and 16ft. perforated vertical stems. Electro-plated steel upper assembly locks into position on most types of rails. Rollers allow you to move entire scaffold along parapet with ease.

Assemble and lock this SL-15A Parapet Scaffold to most bridge rails in minutes with quick-locking pins. Proper assembly saves material and labor costs AND meets or exceeds OSHA’s standards.

Vertical Stem8ft.,12ft. & 16ft.

Aluminum Guard Rails

Working deckwidth/length2ft. x 7ft. or2ft. x 12ft.

Horizontal Brace:5ft. & 10ft.

Ladder Support

Horizontal Standoff Brace.

TYPICAL RAIL DESIGNS

Jersey Concrete Rail Steel on Concrete Rail

Aluminum Pipe Rail Steel Post and Rail

Customer Service: 866-764-8989 Tel: (269) 764-8989 Fax: (269) 764-8897 39

The above rail designs are typical, however, the Upper Head Assembly is desinged to fit almost every type of parapet, including guardrails.

All products must be used in accordance with Swing-Lo Suspended Scaffold Company’s Safety Instructions, and all Local, State, and Federal Safety Regulations.

Lower Wheel Assembly

Steel Tube on Concrete Rail

D

E

A

B

C

When considering a Parapet Scaffold application, dimensions A, B, C, D, and E are critical in determining the appropriate model.

The Swing-Lo Parapet Scaffold is adaptable to most bridge parapets. The standard Upper Head Assembly will fit a 14 1/2” concrete parapet (A) up to 36 inches. The Upper Head Assembly can also adapt to a 4 inch and larger pipe rail. As in every case, a competent person must determine whether the structure is sufficiently strong to carry the live and dead load.

The Horizontal Bumper allows for up to 5 ft. horizontal support (B). The Horizontal Bumper allows for two types of support. The first application is to support the platform at the web of the girder. The second application allows for multiple platforms when the horizontal support is attached to the bottom flange of the girder.

The platform lengths (C) are 7ft. and 12ft. Only 24in width is provided. At a time of de-termining the number of decks required, please indicate how far under the sidewalk you would need to access.

Letter (D) specifies the length of the vertical stems. When considering the length of the vertical stem, you must determine the deck elevation. Typically 2 - 4 ft is subtracted from the vertical length, because of the stage bracket. The length of the vertical stem is pro-vided in 8, 12, and 16ft options.

Finally, consideration should be given to any obstruction such as, water pipe lines, cable lines, etc. along the bottom face of the parapet (E). In cases where these obstructions exist, a different Upper Head Assembly may be specified, along with a Stand-off pad for the Lower Wheel Assembly (SL-15LAS).

Following this page are several packaged units. Should these packages not meet your requirements, you may configure your own system by going to page 41.

Exterior Guardrails lock into position on Guardrail Posts to give you maximum protection while working. Four Guardrails and four Endrails are required.

Braces (2) hold and maintain the parallel distance of the Vertical Stems for a strong, rigid scaffold. This brace is positioned on the top of the Upper Head Assembly, the other is placed just below the Lower Wheel Assembly, or along the Vertical Stem as desired.

Vertical Stems (2 required) are available in lengths 8, 12, and 16 ft., to give you the right working eleva-tion. Custom lengths available.

Lower Wheel Assembly locks onto Vertical Stems at the elevation you need. Wheels add to scaffold’s mobility.

Stage Brackets (2 required) attach to vertical stems at the elevation you need. Simply add deck and you’re ready to work.

The included Ladder Support locks onto the Vertical Stem and adjusts to accomodate any working elevation. The ladder (not included) is held securely in place. The Lad-der Clamp comes in two sections: top and bottom.

Bumper Wheel Assem-blies add extra support at the lower end of the Vertical Stems and can be used in two different configurations. One is to roll against the web of the I-beam. Another can grip the bottom I-beam flange with two more adjust-able wheels that come standard with the Bum-per Wheel Assembly, as shown below.

The Interior Guardrails between the Vertical Stems are removable to form a 3-sided Guardrail System when access to deck below sidewalk is required.

The Working Platform comes in 2 sizes: 24in. wide x 7 ft. long, and 24 in. wide x 12 ft. long.

NOTE: The Parapet Scaffold can be configured to increase the length along the bridge by adding components.

Upper Wheel Assembly fits over concrete parapet and pipe rails. The Standard Head adjusts from 14.5 inches to 20 inches.

Customer Service: 866-764-8989 Tel: (269) 764-8989 Fax: (269) 764-8897

PARAPET SCAFFOLD

40

All products must be used in accordance with Swing-Lo Suspended Scaffold Company’s Safety Instructions, and all Local, State, and Federal Safety Regulations.

UPPER HEAD ASSEMBLIESMODEL DESCRIPTION

SL-15UJW Standard Upper Head Assembly w/wheels - 14 1/2”SL-15UHD Heavy Duty Upper Head Assembly w/wheels - 17 1/2”SL-15UHD20 Heavy Duty Upper Head Assembly w/wheels - 20”SL-15UHD36 Heavy Duty Upper Head Assembly w/wheels - 36”MID WHEEL STAND-OFF ASSEMBLIES

MODEL DESCRIPTIONSL-10LAS 3 1/4” x 4” Double Mid Wheel AssemblySL-15LAS 2” x 8” Double Mid Wheel AssemblySL-15LDW 2” x 6” Double Mid Wheel AssemblySL-15BRR1A 2” x 8” Inner Double Mid Wheel Stand-OffPERFORATED VERTICAL STEMSSL-7012 2” X 3” Vertical Perforated Stem 12’SL-7016 2” X 3” Vertical Perforated Stem 16’SL-7512 2” X 6” Vertical Perforated Stem 12’SL-7516 2” X 6” Vertical Perforated Stem 16’HORIZONTAL BRACESSL-15AB059T 1 1/2” Sq. x 5’ Tubing BraceSL-15AB059C 1 1/2” Sq. x 5’ Channel BraceSL-15AB120T 1 1/2” Sq. x 10’ Tubing BraceSL-15AB120C 1 1/2” Sq. x 10’ Channel BraceHORIZONTAL SUPPORTSSL-15CVR Support with 2 each 3 1/4” x 4” V-Rollers, 5’ StemSL-15CVS Support with 2 each 3 1/4” x 4” V-Rollers, 6’ StemSTAGE BRACKETSSL-24SB 2 Ft. Stage BracketSL-24SBB 2 Ft. Stage Bracket w/Clip LockSL-48SB 4 Ft. Stage BracketSL-72SB 6 Ft. Stage BracketALUMINUM STAGESSL-D2407 2 Ft. x 7 Ft. Aluminum Stage (2 Man)SL-D2412 2 Ft. x 12 Ft. Aluminum Stage (2 Man)GUARDRAILSL-GR0800 1 1/2” Sq. X 80” Aluminum GuardrailSL-GR0610B 1 1/2” Sq. X 61” Aluminum GuardrailSL-GR1410 1 1/2” Sq. X 141” Aluminum GuardrailSL-GR1220B 1 1/2” Sq. X 122” Aluminum GuardrailENDRAILSSL-24ERL Endrail 2 Ft., W/15ERL6SL-48ERL Endrail 4 Ft., W/15ERL6SL-72ERL Endrail 6 Ft., W/15ERL6GUARDRAIL POSTSSL-15GRP 1 1/2” Sq. X 48” Aluminum Guardrail PostSL-71B48M 1 1/2” Sq. X 48” Perforated Steel Guardrail PostSL-15GRPA 1 1/2” Sq. X 48” Aluminum Guardrail PostLADDER CLAMPSSL-64A Pipe Ladder ClampSL-64D Side-Mounted Ladder Clamp

SL-15AB059T

SL-15AB059C

SL-D2412

SL-15LAS

SL-15ERL6

SL-84GRC

SL-15GRP

SL-24SB

SL-15UHD

SL-15UJW

SL-64LC

SL-84GRL

SL-64D

SL-10LAS

SL-24ERL

SL-7512

SL-15CVR

SL-64A

SL-15UHD20

SL-15UHD36

Customer Service: 866-764-8989 Tel: (269) 764-8989 Fax: (269) 764-8897

PARAPET SCAFFOLD COMPONENTS

41

All products must be used in accordance with Swing-Lo Suspended Scaffold Company’s Safety Instructions, and all Local, State, and Federal Safety Regulations.

ROLLING PARAPET SCAFFOLD PARAPET SCAFFOLD MODEL NO. SL-15A12D20 2 Ft. x 7 Ft. 1 DeckNO. QTY. MODEL NO. DESCRIPTION

1 2 SL-15UJW Upper Head Assembly 14.5” - 20” EXP.2 2 SL-7012 2”x3”x12’ Vertical Perforated Stem3 2 SL-15LAS Adjustable Mid Wheel Assembly (2”x8”)4 2 SL-15CVR Horizontal Brace w/Rotating Vertical Rollers5 2 SL-24SBB 24” Stage Bracket w/Stage Lock Clip6 1 SL-15AB059C 1.5” sq. x 59” Channel Brace7 1 SL-15AB059T 1.5” sq. x 59” Tubing Brace8 2 SL-15GRPA 1.5” sq. x 48” Aluminum Guardrail Post9 2 SL-GR0800 1.5” sq. x 80” Aluminum Guardrail10 2 SL-GR0610B 1.5” sq. x 61” Aluminum Guardrail11 4 SL-24ERL 1.5” sq. x 24” Aluminum Endrail Assembly12 1 SL-64D Ladder Clamp13 1 SL-D2407 24” wide x 84” long Aluminum Stage (2 Man)

Total Weight: 350 lbs. 500 LB SWL

PARAPET SCAFFOLD MODEL NO. SL-15A12D22 2 Ft. x 7 Ft. 2 DecksNO. QTY. MODEL NO. DESCRIPTION

1 2 SL-15UJW Upper Wheel Assembly 14.5” - 20” EXP.2 2 SL-7012 2”x3”x12’ Vertical Perforated Stem3 2 SL-15LAS Adjustable Mid Wheel Assembly (2”x8”)4 2 SL-15CVR Horizontal Brace w/Rotating Vertical Rollers5 4 SL-24SBB 24” Stage Bracket w/Board Lock6 1 SL-15AB059C 1.5” sq. x 120” Channel Brace7 1 SL-15AB059T 1.5” sq. x 120” Tubing Brace8 4 SL-15GRPA 1.5” sq. x 48” Aluminum Guardrail Post9 4 SL-GR0800 1.5” sq. x 80” Aluminum Guardrail10 2 SL-GR0610B 1.5” sq. x 61” Aluminum Guardrail11 8 SL-24ERL 1.5” sq. x 24” Aluminum Endrails12 1 SL-64D Ladder Clamp13 2 SL-D2407 24” wide x 84” long Aluminum Stage (2 Man)

Total Weight: 450 lbs. 500 LB SWL

PARAPET SCAFFOLD MODEL NO. SL-15AA12D20 2 Ft. x 12 Ft. 1 DeckNO. QTY. MODEL NO. DESCRIPTION

1 2 SL-15UJW Upper Head Assembly 14.5” - 20” EXP.2 2 SL-7012 2” x 3” x 12’ Vertical Perforated Stem3 2 SL-15LAS Adjustable Mid Wheel Assembly (2”x8”)4 2 SL-15CVR Horizontal Brace w/Rotating Vertical Rollers5 2 SL-24SBB 24” Stage Bracket w/Stage Lock Clip6 1 SL-15AB120C 1.5” sq. x 120” Channel Brace7 1 SL-15AB120T 1.5” sq. x 120” Tubing Brace8 2 SL-15GRPA 1.5” sq. x 48” Aluminum Guardrail Post9 2 SL-GR1220B 1.5” sq. x 122” Aluminum Guardrail10 2 SL-GR1410 1.5” sq. x 141” Aluminum Guardrail11 4 SL-24ERL 1.5” sq. x 24” Aluminum Endrail Assembly12 1 SL-64D Ladder Clamp13 1 SL-D2412 24” wide x 144” long Aluminum Stage (2 Man)

Total Weight: 402 lbs. 500 LB SWL

PARAPET SCAFFOLD MODEL NO. SL-15AA12D22 2 Ft. x 12 Ft. 2 DecksNO. QTY. MODEL NO. DESCRIPTION

1 2 SL-15UJW Upper Head Assembly 14.5” - 20” EXP.2 2 SL-7012 2”x3”x12’ Vertical Perforated Stem3 2 SL-15LAS Adjustable Mid Wheel Assembly (2”x8”)4 2 SL-15CVR Horizontal Brace w/Rotating Vertical Rollers5 4 SL-24SBB 24” Stage Bracket w/Stage Lock Clip6 1 SL-15AB120C 1.5” sq. x 120” Channel Brace7 1 SL-15AB120T 1.5” sq. x 120” Tubing Brace8 4 SL-15GRPA 1.5” sq. x 48” Aluminum Guardrail Post9 2 SL-GR1220B 1.5” sq. x 122” Aluminum Guardrail10 4 SL-GR1410 1.5” sq. x 141” Aluminum Guardrail11 8 SL-24ERL 1.5” sq. x 24” Aluminum Endrail Assembly12 1 SL-64D Ladder Clamp13 2 SL-D2412 24” wide x 144” long Aluminum Stage (2 Man)

Total Weight: 500 lbs. 500 LB SWL

*

*

* Ladder not included

* Ladder not included

ROLLING PARAPET SCAFFOLD

Customer Service: 866-764-8989 Tel: (269) 764-8989 Fax: (269) 764-889742

All products must be used in accordance with Swing-Lo Suspended Scaffold Company’s Safety Instructions, and all Local, State, and Federal Safety Regulations.

SL-35AA STATIONARY BRIDGE RAIL SCAFFOLDPART NO. DESCRIPTION

SL-35BRC Stationary Upper Head Assembly ClampSL-7016 2” x 3” x 16’ Vertical Perforated StemSL-24SB 24” Stage Bracket w/Board LocksSL-48SB 48” Stage Bracket w/Board Locks

* Ladder not included

This assembly is designed for use as a “cat walk” system, and is adaptable to most structural bridge rail designs.

PARAPET SCAFFOLD MODEL NO. SLH-15A16D24 2 ft. & 4 ft. Decks, 7 ft. LongNO. QTY. MODEL NO. DESCRIPTION

1 2 SL-15UHD Upper Head Assembly 16.5” - 22” EXP.2 2 SL-7516 2” x 6” x 16’ Vertical Perforated Stem3 2 SL-15LAS Adjustable Mid Wheel Assembly (2”x8”)4 2 SL-15CVR Horizontal Brace w/Rotating Vertical Rollers5 2 SL-24SBB 24” Stage Bracket w/Stage Lock Clip6 1 SL-15AB059C 1.5” sq. x 59” Channel Brace7 1 SL-15AB059T 1.5” sq. x 59” Tubing Brace8 2 SL-15GRPA 1.5” sq. x 48” Aluminum Guardrail Post9 2 SL-15GRP 1.5” sq. x 48” Aluminum Guardrail Post10 4 SL-GR0800 1.5” sq. x 80” Aluminum Guardrail11 2 SL-GR0610B 1.5” sq. x 61” Aluminum Guardrail12 4 SL-24ERL 1.5” sq. x 24” Aluminum Endrail Assembly13 4 SL-48ERL 1.5” sq. x 48” Aluminum Endrail Assembly14 2 SL-48SB 48” Stage Bracket w/Board Locks15 1 SL-64D Ladder Clamp16 3 SL-D2407 24” wide x 84” long Aluminum Stage (2 Man)

Total Weight: 600 lbs. 750 LB SWL

PARAPET SCAFFOLD MODEL NO. SLH-15AA16D24 2 ft. & 4 ft. Decks, 12 ft. LongNO. QTY. MODEL NO. DESCRIPTION

1 2 SL-15UHD Upper Head Assembly 16.5” - 22” EXP.2 2 SL-7516 2” x 6” x 16’ Vertical Perforated Stem3 2 SL-15LAS Adjustable Mid Wheel Assembly (2”x8”)4 2 SL-15CVR Horizontal Brace w/Rotating Vertical Rollers5 2 SL-24SBB 24” Stage Bracket w/Stage Lock Clip6 1 SL-15AB120C 1.5” sq. x 120” Channel Brace7 1 SL-15AB120T 1.5” sq. x 120” Tubing Brace8 2 SL-15GRPA 1.5” sq. x 48” Aluminum Guardrail Post9 2 SL-15GRP 1.5” sq. x 48” Aluminum Guardrail Post10 2 SL-GR1220B 1.5” sq. x 122” Aluminum Guardrail11 4 SL-GR1410 1.5” sq. x 141” Aluminum Guardrail12 4 SL-24ERL 1.5” sq. x 24” Aluminum Endrail Assembly13 4 SL-48ERL 1.5” sq. x 48” Aluminum Endrail Assembly14 2 SL-48SB 48” Stage Bracket w/Board Locks15 1 SL-64D Ladder Clamp16 3 SL-D2412 24” wide x 144” long Aluminum Stage (2 Man)

Total Weight: 650 lbs. 750 LB SWL To configure a 6 ft. platform under sidewalk, deduct Item nos. 13 & 14, then add 2 each SL-72SB (6 ft. Stage Bracket) & 4 each SL-72ERL (6 ft. Endrail Assembly). This will change the model number to SLH-15AA16D26.

See page 66 for Guardrails and Accessories.

*

Customer Service: 866-764-8989 Tel: (269) 764-8989 Fax: (269) 764-8897

ROLLING PARAPET SCAFFOLD

STATIONARY RAIL SCAFFOLD

43

All products must be used in accordance with Swing-Lo Suspended Scaffold Company’s Safety Instructions, and all Local, State, and Federal Safety Regulations.

Cut the cost of stripping, sandblasting, and maintainence on bridges designed with overhangs. Swing-Lo model SL-25AA is ideal for removing forms. The Upper Assembly extends the scaffold up to 48 inches away from the parapet, positioning the working deck right where the job needs to be done. The scaffold clamps to most bridge rails or parapets, and is equipped with rollers for easy mobility.

This unit requires few components, no tools, and assembles in minutes. It pro-vides safe access to hard to reach areas. It does not interfere with traffic below. Compared to conventional scaffolding, the Parapet Scaffolding can save you up to 50 percent in scaffolding costs.

The SL-15WA Wrap-Around Parapet Scaffold lets you maxi-mize the efficiency of your work force. Wrap-Around design lets you simultaneously work along both sides of the bridge AND un-derneath it. Roller Clamps let you reposition the scaffold as work progresses.

SL-25AA EXTENDED PARAPET SCAFFOLDPART NO. DESCRIPTION QTYSL-25UA Upper Assembly With Wheels (6 in - 16 in. adj.) 2SL-7516 2” x 6” x 16’ Vertical Perforated Stem 2SL-48SB 48” Stage Bracket w/Board Locks 2SL-15AB120X 10 ft. X-Brace 1SL-15AB120C 10 ft. Horizontal Brace 2SL-12AL 1.5 in. sq. x 144 in. Aluminum Guardrail 4SL-48ER 1.5 in. sq. x 48 in. Aluminum Endrail 4SL-15GRP 1.5” sq. x 48” Aluminum Guardrail Post 2SL-64LC Ladder Clamp 1SL-D2412 24” wide x 144” long Aluminum Stage, 500 lb. 2Total Weight: 882 lbs. 500 LB SWL

SL-15WA WRAP-AROUND PARAPET SCAFFOLD PART NO. DESCRIPTION QTYSL-15UJW Upper Assembly With Wheels (6 in - 16 in. adj.) 4SL-7016 2” x 3” x 16’ Vertical Perforated Stem 4SL-15LAS Adjustable Mid Wheel Assembly (2”x8”) 4SL-15CVR Horizontal Brace w/Rotating Vertical Rollers 4SL-24SBB 24” Stage Bracket w/Board Lock 4SL-15AB059C 1.5” sq. x 59” Channel Brace 2SL-15AB059T 1.5” sq. x 59” Tubing Brace 2SL-15GRPA 1.5” sq. x 48” Aluminum Guardrail Post 4SL-GR0800 1.5” sq. x 80” Aluminum Guardrail 8SL-GR0610B 1.5” sq. x 61” Aluminum Guardrail 8SL-24ERL 1.5” sq. x 24” Aluminum Endrails 8SL-64D Ladder Clamp 2SL-D2407 24” wide x 84” long Aluminum Stage 2SL-15WB Diagonal Brace 4SL-15TS Horizontal Truss Support 4SL-70L Stage/Truss Board Lock 4SL-70A72M 6 ft. Stage Support Truss 2Total Weight: 900 lbs. 500 LB SWL

2 each 28 inch wide x desired length required decks under bridge. Guardrails, Guardrail Post, and Connectors, provided on pages 66-68. Determine quantity and add to package above.

Customer Service: 866-764-8989 Tel: (269) 764-8989 Fax: (269) 764-8897

EXTENDED PARAPET SCAFFOLD

WRAP-AROUND PARAPET SCAFFOLD

See pageL 57 for Mobile Parapet Fall Protection Clamps.

See pageL 57 for Mobile Parapet Fall Protection Clamps.

44

All products must be used in accordance with Swing-Lo Suspended Scaffold Company’s Safety Instructions, and all Local, State, and Federal Safety Regulations.

The Parapet Scaffold can be expanded to increase the deck size up to forty feet.

The Expanded Wrap-Around Parapet Scaffold can be expanded to increase the platform lenght and height.

SL-15WA3 WRAP-AROUND PARAPET SCAFFOLD PART NO. DESCRIPTION QTYSL-15UHD HD Upper Assembly With Wheels (9 -14.5” adj.) 6SL-7520 2” x 6” x 20’ Double-Back Vertical Perforated Stem 6SL-15LAS Adjustable Mid Wheel Assembly (2”x8”) 6SL-15CVR Horizontal Brace w/Rotating Vertical Rollers 6SL-24SB 24” Stage Bracket w/Board Lock 6SL-15AB120C 1.5” sq. x 120” Channel Brace 4SL-84SA Stage Guardrail Post Adapter 8SL-71B48M 1.5” sq. x 48” Aluminum Guardrail Post 8SL-GR1304 1.5” sq. x 130.44” Aluminum Guardrail 8SL-84GRC Guardrail Connector 4SLP-702TSB4A Aluminum Beam Truss Support 12SL-64D Ladder Clamp 2SL-D2422 24” wide x 22’ long Aluminum Stage 2SL-BM750X0240 Aluminum Beam 7.5” X 24’ W/Nailer 4Total Weight: 980 lbs.

Ladder NOT included

See page 41 to configure your platform; See pages 66-68 for aluminum stages and guardrails for connecting two Parapet Systems based on the width of the bridge.

See page 41 to configure your platformSee pages 66-68 for aluminum stages and guardrails

SL-15X320 PARAPET SCAFFOLD PART NO. DESCRIPTION QTYSL-15UJW Standard Upper Head Assembly w/wheels - 14 1/2” 3SL-7012 2” x 3” x 12’ Vertical Perforated Stem 3SL-15LAS Adjustable Mid Wheel Assembly (2”x8”) 3SL-15CVR Horizontal Brace w/Rotating Vertical Rollers 3SL-24SB 24” Stage Bracket w/Board Lock 3SL-15AB096C 1.5” sq. x 96” Channel Brace 2SL-106019700 1.5” sq. x 197” Tubing Brace 1SL-84SAH Stage Post Adapter w/ 1.38” offset from web 8SL-20AL 1.5” sq. x 240” Aluminum Guardrail 8SL-71B48M 1.5” sq. x 48” Aluminum Guardrail Post 8SL-03AL 1.5” sq. x 36” Aluminum Guardrail 4SL-15AK00ST Horizontal Brace Bracket - 5” 3SL-64D Ladder Clamp 1SL-DX2420 24” wide x 20’ long Aluminum Stage; 3-Man 1SL-84GRL8 Guardrail Lock; J-Bolt for 1.5” Endrail 8Total Weight: 980 lbs.

Customer Service: 866-764-8989 Tel: (269) 764-8989 Fax: (269) 764-8897

EXPANDED WRAP-AROUND PARAPET SCAFFOLD

EXPANDED PARAPET SCAFFOLD

45

All products must be used in accordance with Swing-Lo Suspended Scaffold Company’s Safety Instructions, and all Local, State, and Federal Safety Regulations.

750 LB SWL

500 LB SWL

See pageL 57 for Mobile Parapet Fall Protection Clamps.

The Heavy Duty Series SLH Parapet Models are ideal for situations where a longer platform is needed without the restrictions of using a fixed brace. By using the Stabilizer brace, the contractor can expand his platform lenght at wider spacing intervals. The platform may be positioned along the Vertical Stem at the desired elevation. The unit below is packaged with-out the aluminum stage so the contractor may make that determination. A twenty-four inch stage bracket is used in this configuration, however, a twenty-eight inch stage bracket may be substituted.

SLH-15X12D20 HD SCAFFOLD SWL 750MODEL DESCRIPTION QTY

1 SL-15UHDF Stationary HD Upper Head 22 SL-7512 2” X 6” X 12’ Double-Back Stem 23 SL-15LAF Fixed Mid Assembly 24 SLH-15ASB Fixed Stabilizer Brace 25 SL-64D Side-Mounted Ladder Clamp 1

Ladder NOT included; contractor may use any standard ladder

Customer Service: 866-764-8989 Tel: (269) 764-8989 Fax: (269) 764-8897