Sustainable Energy from Biomass Residues · Wood Remanufacturing Schools, College Campus, Hospitals...

Transcript of Sustainable Energy from Biomass Residues · Wood Remanufacturing Schools, College Campus, Hospitals...

Sustainable Energyfrom Biomass Residues

KMW ENERGY INC.LONDON, ONTARIOTel: (519) 686‐1771www.kmwenergy.com

KMW Energy Inc.

Long History in designing bioenergy systems. Founded in 1947 in Sweden withsubsidiaries in Canada (1979) and Australia (1980).

Independent Canadian Company since 1987, with 125+ installations in North,Central & South America. Design and manufacturing in Ontario and Quebec.

KMW Designs sustainable energy systems using unutilized biomass forrenewable energy.

Focus on thermal gasification technology to produce clean and efficientrenewable energy.

Proven Design for an easily maintained and operated energy system that willprovide years of dependable service.

System Applications range from commercial to power utility.Thermal energy: 2 MWth up to 55 MWth per unit.Electric energy: 1 MWe up to 12.5 MWe per unit.

Many different applications including:

Pulp & Paper Mills, Lumber Mills, Board PlantsWood RemanufacturingSchools, College Campus, HospitalsGreenhousesPower Utility PlantsDistrict HeatingMSW ProcessingBiosolids (Municipal Waste Water Treatment)Ethanol Plant

Electric Power Generation:

Systems installed with an electric capacity range from 1.1 MW to 25 MW.

KMW Installations

Examples of repeat customers:

JD Irving Limited, New Brunswick and Nova Scotia,7 Biomass Systems (1993 – 2008)

Eenou Companee, Quebec,2 Biomass Systems (1992 – 1998)

Abitibi Consolidated, Quebec,6 Biomass Systems (1992 – 1995)

Bowater Mersey Paper Co., Nova Scotia,2 Biomass Systems (1991 – 1996)

Spruce Products Ltd., Manitoba,3 Biomass Systems (1996 – 2006)

KMW Installations

KMW has a major presence in the Biomass Energy Industry based on 38 years experience and 125+ installations for a wide range of applications and large variety of biomass types.

KMW Installations

KMW Installations

Gasification

Clean gas-combustionby injection ofsecondary air

Final burningof fixed carbons

KMW Combustion TechnologyBased on Thermal Gasification

for Clean and Efficient Combustion

Wood Residues

Agricultural Residues

Cardboard

Wood Containers

Wood Pallets

Construction Waste

Sludge (all types)

Peat

Husks, Hulls, Shells

Non‐recyclable fraction of MSW

Waste water treatment – “bio‐solids”

Rice Husks

Wood Chips

RDF Pellets

Cardboard

Bark & Sawdust

Peat

Biomass

“carbon neutral,and renewable”

“creating energy, solving problems”

Corn Stover = Biomass

CO2

Fossil Fuels

Biomass Fuels:•Bark / Sawdust•Agricultural Waste•Fuel Pellets

Natural Decomposition

Biomass Fuel: The Renewable Energy Source Working With The Cycle of Nature

Nature in Balance

CO

H2O, nutrients

51% C6% H242% O20.3% N2<1%

minerals

CH4methane

Two slices of Douglas‐Fir glued together. One side is 12 years old and the other is 119 years old.

Same size means same amount of CO2 absorbed through the photosynthesis process.

The 12 year old tree was growing unrestricted with ample sunlight, while the 119 year old tree was in a “Natural” stand of trees competing for space and sunlight.

Conclusions:

Planting new trees are important to absorb excess CO2 in the atmosphere.

Equally important is to manage our forest resource to increase the absorption of CO2 for maximum positive climate change impact. This will also increase the yield from our forest.

Part of the forest management is to do thinning amongst the trees. This operation could be made profitable if the resulting biomass could be used as a renewable fuel source for energy production. Job opportunities are significant.

Well managed “active” forest

By managing our forests, vast amounts of “forest floor” biomass will be available for energy production. The removal of dead trees and branches will significantly reduce the risk of devastating forest fires.

Benefits of Biomass Energy: Utilizes many different types of biomass to produce heat and electricity.

Is considered renewable and carbon neutral energy which reduces greenhouse gases, compared with landfilling or burning fossil fuels.

Compared to other renewable energy sources, produces continuous dependable (24/7) heat and electricity.

Can utilize low cost fuels (unutilized residues). Is dispatchable and can produce energy were it is needed.

The world’s annual potential biomass supply is enormous; estimated by the IIASA to be approximately 254EJ/y, the equivalent of 44B bbl oil (worldwide consumption is 30B bbl/year).

Source: Biomass Energy Primer, A “Growing” Area of Interest. Jacob Securities, Toronto, November 2008

Benefits for Communities When Embracing Biomass Energy Technology

Self sustained energy generation

Creates long-term sustainable jobs

Becomes part of a waste management strategy

Stimulates local economy

Short-term: Construction

Long-term: Operation & fuel supply

Local investment opportunity

Automatic Fuel Handling

Steam To Turbine & Generator

Steam toDry Kiln

Emission Control

Steam Boiler

Combustion Chamber

Automatic Ash Handling

Typical Biomass Energy System

Steam boiler on rail siding (28 MWth)

Located in Kapuskasing, ON

3 KMW shop assembled combustion chamberswere installed in 1997.

Total boiler output 240,000 lbs/hr.

3 shop assembled package boilers are mounteddirectly above the combustion chambers.

At design, the plant utilizes approximately 1,000tons of fuel per day.

Sludge makes up approximately 27% of the fuelmixture with the balance of it consisting of barkand mill residue at 62% moisture content on a wetbasis.

Paper Mill Application

Automatic Ash Handling

Fuel Bin Fuel Bin

Combustion Chambers

Fuel Bin

Automatic Fuel Handling

Fluegas System

withEmission Control

Paper Mill ApplicationPaper Mill Application

This Power Utility Plant is located in Alberta.

The design includes two parallel wood firedpackaged boilers.

25 MW of electric power is produced.

Total boiler output is 226,000 lbs./hr.

At design capacity, the plant utilizesapproximately 950 tons of fuel per day,consisting of wood residue from sawmill.

Power is sold to the utility grid while thenearby sawmill also receives steam andpower.

Power Utility ApplicationPower Utility Application

Combustion System

Boiler

Economizer

MulticycloneESP

Ash Conveyor

Power Utility ApplicationPower Utility Application

Located in Middle Musquodoboit, NSproduces 8‐10 million board feet per year ofkiln dried and heat treated lumber.

In 1993 installed a Wood Fired Power Plantwhich produces 20,000 lb/hr of saturatedsteam@ 230 psig.

Supplies steam for kilns and creates all powerrequired for their operation. Any surplus ofelectric power is sold to a local UtilityCompany.

Approximately 25,000 wet tons of woodwaste is consumed annually

Producing 1,150 kW of electric power.

Lumber Mill Application

Native Community ApplicationIn 1992, construction began on the new community of Ouje Bougoumou located inNorthern Quebec, which included a unique district heating system utilizingalternative energy technology designed by KMW. In 1998 a second biomass firedboiler was added.

Represent the first village-wide application of a district heating system in NorthAmerica.

Also the continent’s first community to primarily utilize biomass as a fuel sourceand hot water as the energy transfer medium.

In 1995 the United Nations recognized Ouje Bougoumou, along with 50 othercommunities, as a community that best exemplifies the UN’s objectives.

Ouje Bougoumou

Canadian Geographic, 1994

The Village of Ouje Bougoumou

Energy dollars would be retained within the village. Future development project could then be financed internally.

Ability to control heating energy and domestic hot water costs.

Local employment created for the operation of the heating plant and maintenance of the district heating system and supplying the biomass fuel.

There was no employment opportunities connected to conventional heating.

Potential for positive community growth. Excess heating capacity could be used towards future development of a greenhouse and aqua culture.

A Community’s Decision

Located in Manitoba.

Hot water system.

Started up in November 2012.

Rural Farm Community

System sized for 8.4 million Btu/hour (250 BHP, 2.5 MWth).

100% of energy required for their operation is produced by the Biomass Energy System.

Fuel is bark, wood chips and sawdust from local wood recycling.

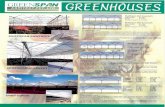

Located in Lawrencetown, NS, a 5 acre greenhouse operation.

Hot water system.

Started up in March 2006.

System sized for 8.4 million Btu/hour (250 BHP, 2.5 MWth).

Greenhouse Application

95% of energy required for their operation is produced by the Biomass Energy System.

Fuel is residues from local forestry operations.

Located in Northampton, NB, a 7.5 acre greenhouse operation.

Hot water system.

Started up in March 1998.

System sized for 15 million Btu/hour (450 BHP, 4.5 MWth).

90% of energy required for their operation is produced by the Biomass Energy System.

Fuel is bark and sawdust from nearby sawmill.

Greenhouse Application

Installed 2004 and located in the interior British Columbia

Developed a Community Energy Plan

1 steam consumer for lumber drying kilns, demand ~750 –1000 kW

9 hot water consumers, demand ~1700 – 1800 kW

Biomass consumption ~4000 GMT/year

Future plant expansion adding two new schools and the hospital

Community District Heating

Revelstoke, BC

Wood Pellet Mill, Quebec

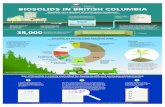

Municipal waste water facility.

Disposal of biosolids.

Started up in October 2007.

System sized for 5 million Btu/hour (150 BHP, 1.5 MWth).

Municipal Application

The system consumes 0.5 tons per hour.

The remaining ash (30%) contains <1% carbon and is used locally as aggregate for making bricks and concrete.

Belt Dryer for Biosolids

KMW Combustion System for Biosolids

Municipal Waste Processing, Iowa

KMW system providing heat for MSW drying

Transforming MSW into RDF pellets

MSW RDF pellets

VIDEO: Sweden Destination of Choice for Waste ExportsWaste to energy capacity is making Sweden the destination of choice for waste exports.

Less than 1% is landfilled due to recycling and Biowaste to energy plants.

32 Biowaste (MSW) to energy plants consume 2.2 million tonnes per year including importing 800,000 tonnes per year.

32% of all energy comes from Biomass thereby making it the single largest source of energy (2012).

Waste Management World Waste Weekly E-Digest |View online| August 30, 2014|

Skövde District Heating Plant, Sweden.Consuming 60,000 tonnes per year of Biowaste. 125 km of underground piping serves the city with heat. Plant capacity is 24 MW thermal + 1.7 MW electric.

Tibro District Heating Plant, Sweden.Consuming 20 tonnes per day of recycled biomass. District heating system provides the industrial park with heat. Plant capacity is 16 MW thermal.

The world is facing three major challenges.

How to dispose of our waste How to create sustainable energy How to deal with excess CO2 and the resulting climate change

Biomass energy technology can successfully be part of the solution to these challenges.

Government and industry has to work together for this to happen on a more significant scale.

• Kirkland Lake Power Corporation. 17 MWe 1990

• Taylor Lumber 1.1 MWe 1993

• Comeau Lumber 1 MWe 1993

• Canadian Gas & Electric 25 MWe 2006

• Ajax Energy 17 MWe 2014

• Hefler Forest Products 3.5 MW 2015

Projects Currently Underway

• ProBiomass - Portugal 14 MWe Fall 2017

• Georges River Electric – Maine 8.5 MWe Q3 2018

KMW InstallationsElectric Power Projects

Alberta

• Ainsworth Lumber Co. Ltd. Grande Prairie, AB 1995• Buchanan Lumber High Prairie, AB 2000• Canadian Gas & Electric Grande Prairie, AB 2006

British Columbia

• Western Pulp Partnership Limited Port Alice, BC 1993• Revelstoke Community Energy Project Revelstoke, BC 2004

Manitoba

• Spruce Products Ltd. Swan River, MB 1996, 1999, 2006

Newfoundland & Labrador

• Heritage Manufacturing Limited Glovertown, NL 1990• Cottles Island Lumber Co. Ltd. Summerford, NL 2003• Holson Forest Products Roddickton, NL 2010

Saskatchewan

• Northwest Terminals Unity, SK 2007

KMW Installations - Canada

Ontario

• Malette Corporation Timmins, ON 1978• Goulard Lumber Sturgeon Falls, ON 1980• Commonwealth Plywood Co. Ltd. Pembroke, ON 1981• Grenville Christian College Brockville, ON 1982• Chapleau Co-generation Ltd. Chapleau, ON 1986• Commonwealth Plywood Co. Ltd. North Bay, ON 1987• ORTECH (ON Research Foundation) Mississauga, ON 1987• Uniboard New Liskeard Inc. New Liskeard, ON 1988• Ministry of Natural Resources Angus, ON 1989• Kirkland Lake Power Corporation Kirkland Lake, ON 1990• Ajax Energy Corporation Ajax, ON 1990, 2013• Bogdon & Gross Furniture Co. Ltd. Walkerton, ON 1990• Weyerhauser Company Limited Chapleau, ON 1991• Cochrane Power Corporation Cochrane, ON 1991• IKO Industries Ltd. Brampton, ON 1992• Devlin Timber Co. (1992) Ltd. Kenora, ON 1995• Kizhaagimitay Nipi Community Utility Grassy Narrows, ON 1997• Spruce Falls Inc. Kapuskasing, ON 1997• Murray Bros. Lumber Company Limited Madawaska, ON 1998• Foothill Greenhouses Ltd. Kettleby, ON 2000, 2004 • Les Van Egmond & Sons Wholesale St Ann’s, ON 2003• Rosa Flora Limited Dunnville, ON 2003

KMW Installations - Canada

Nova Scotia

• Stockdijk Greenhouses Truro, NS 1988• Nova Scotia Agricultural College Truro, NS 1988• Digby Elementary School Digby, NS 1988• South Shore Regional Hospital Bridgewater, NS 1988• Bowater Mersey Paper Co. Ltd. Bridgewater, NS 1991, 1996• Russell White Lumber Ltd. Kennetcook, NS 1993• Taylor Lumber Ltd. Middle Musquodoboit, NS 1993• Comeau Lumber Ltd. Meteghan, NS 1993• Deniso Lebel Ltd. Scotsburn, NS 1994• N.F. Douglas Lumber Ltd. Caledonia, NS 1994• Elmsdale Lumber Ltd. Elmsdale, NS 1994• Scanwood Canada Ltd. Dartmouth, NS 1995• Ledwidge Lumber Co. Ltd. Enfield, NS 1997• Dewdrop Gardens Sheet Harbour, NS 2000• Hefler Forest Products Middle Sackville, NS 2015

Quebec

• Desencrage C.M.D. Inc. Cap-de-la-Madeleine, QC 1991• Domtar Inc. Ste-Marie de Beauce, QC 1993• Eenou Companee Ouje Bougoumou, QC 1992, 1998• Trebio Inc Portage-du-Fort, QC 2010• DG Forest Products Quebec City 2016

KMW Installations - Canada

New Brunswick

• Edmundston Correctional Center Edmundston, NB 1982• Shorewood Furniture Inc. Fox Creek, NB 1983• Belle Isle Regional High School Norton, NB 1983• Eastwind Speciality Veneer Miramichi, NB 1984• Skyway Wood Products Miramichi, NB 1985• Chaleur Regional Hospital Bathurst, NB 1986• Campbellton Regional Hospital Campbellton, NB 1987• University of Moncton Edmundston, NB 1989• Tracadie Hospital Tracadie-Shelia 1990• Miramichi Hospital Miramichi, NB 1993• Westmorland-Albert Solid Waste Corp. Moncton, NB 1995• H.J. Crabbe & Sons Ltd. Bristol, NB 1997• Jolly Farmer Products Ltd. Northampton, NB 1997• Groupe Savoie Inc. Saint Quentin, NB 1993, 2000• Twin Rivers Paper Inc. Plaster Rock, NB 2009

• Prince Edward Island

• PEI Energy Charlottetown, PEI 1984, 1992, 1996

* Please note this is a partial listing only.

KMW Installations - Canada

JD Irving, • Begin Lumber Ltd. Clair, NB 1993• Russell & Swim Sawmill Doaktown, NB 1997• Sproule Lumber Truro, NS 1997• Lewis Sawmill Weymouth, NS 1997• Georgetown Timber Georgetown, PEI 1999• Deersdale Sawmill Deersdale, NB 2008• St Leonard Sawmill St Leonard NB 2010

Bowater Mersey Paper Co. Ltd.• Bowater Mersey Paper Co. Ltd. Bridgewater, NS 1991• Bowater Mersey Paper Co. Ltd. Bridgewater, NS 1996

Eenou• Eenou Companee Ouje Bougoumou, QC 1992• Eenou Companee Ouje Bougoumou, QC 1998

KMW Installations – Repeat Customers

Abitibi• Abitibi Consolidated Inc. Champneuf, QC 1992• Abitibi Consolidated Inc. Baie-Comeau, QC 1993• Abitibi Consolidated Inc. Roberval, QC 1994• Abitibi Consolidated Inc. Senneterre, QC 1994• Abitibi Consolidated Inc. Baie-Comeau, QC 1995• Abitibi Consolidated Inc. La Tuque, QC 1995

Spruce Products• Spruce Products Ltd. Swan River, MB 1996• Spruce Products Ltd. Swan River, MB 1999• Spruce Products Ltd. Swan River, MB 2006

KMW Installations – Repeat Customers

California

• Cedar Mills EcoFarm, LLC Pioneer, CA 2003

Michigan

• Grandview Hospital Ironwood, MI 1983• James River Corporation Amasa, MI 1985• IKO Monroe Inc. Monroe, MI 1998

Minnesota

• Hi-Tech Milling Remer, MN 1979• Holasek & Sons Greenhouses Inc. Chanhasson, MN 1980• Hill City School Hill City, MN 1983• Ironworld Discovery Center Chisholm, MN 1985• Red Lake High School Red Lake, MN 1986• City of Buffalo (Bio-solids) Buffalo, MN 2007

KMW Installations – USA

New York

• Canfibre MDF Plant Lackawanna, NY 1999

Wisconsin

• Barron High School Barron, WI 1981• Rib Lake Middle School Rib Lake, WI 1982• Lake Holcombe School Holcombe, WI 1982• Rock Oil Refining, Inc. Stratford, WI 1984

Indiana

• Wood Parts International Elkohat, IN 1987

Iowa

• Lundell Enterprises Cherokee, IA 2006

KMW Installations – USA

Chile

• Foraction Chili S.A. Curanilahue, Chile 1999

Mexico

• Masisa S.A. Durango, Mexico 1995

Australia

• Easteel Australia PTY Ltd. Melbourne, Australia 2002

KMW Installations – International

KMW ENERGY INC.LONDON, ONTARIOTel (519) 686-1771

www.kmwenergy.com

KMW ENERGY INC.LONDON, ONTARIOTel (519) 686-1771

www.kmwenergy.com

THANK YOUTHANK YOU