Supplier Audit Program 2 2 - · PDF fileSupplier Audit Program Implementation Date: Version...

Transcript of Supplier Audit Program 2 2 - · PDF fileSupplier Audit Program Implementation Date: Version...

Company Name

Procedure Number:

Page 4 of 18

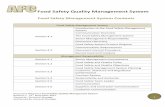

Title: Supplier Audit Program

Implementation Date:

Version Number 1.0

Contents copyrighted © GMP7.com Reproduction, photocopying, storage or transmission by magnetic or electronic means strictly prohibited. Authorization to photocopy items for internal or personal use is granted by GMP-Online-Consultancy. Violation of copyright will result in legal action, including civil and/or criminal penalties, and suspension of service.

1. Regulatory Basis, Reference Documents • Guide to Good Pharmaceutical Manufacturing Practice 1983. • Code of Federal Regulations, Food and Drug, 21.211. • EEC Guide to Good Manufacturing Practice for Medicininal Products, 1989. • Article 14 of the EU directives on GMP (91/356/EEC and 91/412/EEC).

2. Purpose The purpose for Auditing suppliers is to assess the effectiveness of their quality assurance system and to ensure that the requirements of the Good Manufacturing Practice are being met. The purpose of this document is to provide clear guidance for Quality and GMP personnel conducting Audits of suppliers, contract manufacturing, packaging/labeling operations, analytical/microbiological laboratory testing, stability testing and general cGMP facilities. 3. Scope This procedure pertains to GMP related Audits of suppliers of raw materials, excipients or components, contract manufacturing and services, contract laboratory testing, contract packaging or labeling facilities. All of these service providers are called in the SOP “suppliers”. 3.1 Types of Audits 3.1.1 Audits of new suppliers / Due Diligence An Audit conducted in order to assess the cGMP compliance of a potential provider of services and/or product. 3.1.2 Regular Audit An Audit conducted in order to assess the cGMP and/or Technical/Quality Contract compliance of an existing supplier (different material or service). 3.1.3 Re-approval Audit (Time Cycle) A re-approval Audit is an inspection of a previously approved supplier or contract manufacturer, already providing services and/or product. A time cycled Audit is conducted in order to assess the supplier’s facility and services continued cGMP and/or Technical/Quality Contract compliance. Re-approval will be conducted pending the intended use and the frequency of use. 3.1.4 For Cause Audit An Audit initiated as a result of a recognized problem in the services or product provided by a supplier or contract manufacturer.