Suburban Owners Manual DL3 0712 to 1622

-

Upload

daniel-kimia -

Category

Documents

-

view

81 -

download

19

description

Transcript of Suburban Owners Manual DL3 0712 to 1622

SUBURBAN MANUFACTURING COMPANY676 Broadway Street

Dayton, Tennessee 37321

DYNALINE™

MODELDL3-0712 • DL3-0912 • DL3-1220

DL3-1622PACKAGED TERMINAL AIR CONDITIONER

OWNER’S MANUALINSTALLATION, OPERATING AND SERVICE INSTRUCTIONS

This book contains instructions for installation and operation of your unit. Keep it in a safe place for ready reference.Should you require further information, contact your dealer.

WARNING: If the information in these instructions are not followed exactly, a fireor explosion may result causing property damage, personal injury or loss of life.

- Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or anyother appliance.

- WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.• Do not touch any electrical switch; do not use any phone in your building.• Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

instructions.• If you cannot reach a gas supplier, call the fire department.

- Installation and service must be performed by a qualified installer, service agency or the gassupplier.

Installer: Leave this manual with the appliance.

Consumer: Retain this manual for future reference.

WARNING! Improper installation, adjustment, alteration, service or maintenance cancause property damage, personal injury or loss of life. Refer to the installationinstructions and/or owners manual provided with this appliance. Installation and servicemust be performed by a qualified installer, service agency or the gas supplier.

FOREWORD

You have just purchased a Suburban Packaged Term inal Air Conditioner. Models0712, 0912, 1220 and 1622 are UL listed. Models 0912, 1220 and 1622 are alsocertified by the Canadian Standard Association to com ply with the latest editionof National Standard of Canada CSA 2.32.

To sim plify the proper installation and to assure that the unit will operate inconform ity with generally accepted safety regulations, it requires that you readcarefully and fully understand the step-by-step instructions outlined in this manual.

CAUTION: Due to the differences in vinyl siding, this appliance should notbe installed on vinyl siding without first consulting with the manufacturer ofthe siding or cutting the siding away from the area around the appliancevent.

NOTE: Do not deviate from the instructions as outlined in this manual. Failure tofollow the installation, operating and maintenance instructions will void theresponsibility of Suburban Manufacturing Com pany.

INSPECTING FOR FREIGHT DAM AGES

Your unit was carefully packed in a container which com plies with the NationalSafe Transit Test. This m eans that the packaged product, with norm al handling,

will withstand the load conditions encountered in norm al transit and in handling.Your unit should be inspected im m ediately after unpacking to determ ine if anydam age is present due to shipping or handling. If any dam age is discovered, donot install the unit. Notify the transportation company im m ediately and file adam age claim .

The m anufacturer can bear no responsibility for dam ages which occur in transitor for im proper operation of the unit as a result of shipping dam ages.

For future reference, you should record the following inform ation from the units.

M ODEL NUM BER _______________________________________________

SERIAL NUM BER ______________________________________________

STOCK NUM BER _______________________________________________

DATE OF PURCHASE ___________________________________________

2

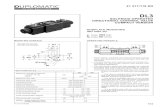

UNIT SPECIFICATIONS

Do not operate this unit during construction as this may violate yourwarranty.

HEATING

MODEL

DL3-0712 DL3-0912 DL3-1220 DL3-1622

BTU INPUT 12,000 12,000 18,000 20,000

VOLTS 208/230 208/230 208/230 208/230

AMPS 2.0 2.0 2.0 2.0

GASCONNECTION

3/8" IPS 3/8" IPS 3/8" IPS 3/8" IPS

COOLING

MODEL

DL3-0712 DL3-0912 DL3-1220 DL3-1622

COOLINGCAPACITY

7400/7500 9600/9800 11500/11700

15000/16000

VOLTS 208/230 208/230 208/230 208/230

W ATTS 680/710 920/960 1160/1170 1570/1590

REFRIGERANTCHARGE

SEE INFORMATIONSTICKER ON UNIT

REFRIGERANT FREON R-22

PRE-INSTALLATION TIPS AND CONSIDERATION

M inim um Operational Clearances

The following m inim um outside clearance from rear grille must bem aintained:

Rear of unit to nearest obstruction - 36"

Side of unit to nearest obstruction - 0"

CAUTION: This appliance should not be installed on or near adjacent walls withvinyl siding without first consulting with the manufacturer of the siding orcutting the siding away from the area around the appliance vent.

Bottom of unit to obstruction and/or ground - This requirem ent is determ ined bylocal clim ate and environmental conditions. The unit m ust be above ground andhigh enough off of the ground to prevent snow, water, leaves or any otherobstruction from blocking rear of unit.

The following m inim um ins ide clearances from cabinet front must bem aintained:

The flow of discharge air must not be obstructed for a m inim um of 12"Side of cabinet to nearest obstruction - 1"

Top of unit to ceiling - 12"Cabinet front to nearest obstruction - 12" *

*Obstruction must be rem ovable for service of unit.

Otherwise a m inim um clearance of 36" is required.Bottom of cabinet front to finished floor - 0"

M inim um Clearances to Com bustible Construction

Units are approved for 0" clearance to com bustible construction top, sides andbottom . Front and rear clearances not applicable as there can be noconstruction combustible or non-combustible to the front or rear of the opening.Keep burner and control com partm ent clean. See installation and operatinginstructions accompanying appliance.

TABLE 1

3

Figure 1

INTRODUCTION

W ARNING! Installation of this appliance m ust be m ade in accordance withthe written instructions provided in this m anual. No agent, representativeor employee of Suburban or other person has the authority to change,m odify or waive any provision of the instructions contained in thism anual.

This manual is intended to fam iliarize the installer, servicem an and user withthe installation, operation and maintenance of the heating and cooling unit.

The unit is designed for a wall thickness of 1" m inimum to 14-1/2" maxim um .NOTE: Maxim um wall thickness cannot exceed 12-5/8" if rear gas hook-up isto be used. The wall sleeves must be installed as illustrated in Figures 5 or 6so that the unit chass is when slid into the sleeve is vented to the outsideatm osphere.

Do not install in an alcove or recess.

Special sleeve and grille applications must be brought to the attention ofSuburban as they m ay impair the operation of the unit.

IM PORTANT: Installation of the rear grille m ust be m ade prior to installingthe chassis as it secures from inside the wall sleeve.

In the U.S.A., this appliance must be installed in accordance with local codesand regulations. In the absence of local codes and regulations, installation m ustcom ply with the latest edition of:

1. National Fuel Gas Code ANSI Z223.1.2. National Electrical Code ANSI/NFPA No. 70.

In Canada, the installation m ust be in accordance with local codes or in theabsence of local codes, with the current CANI-B149 Installation Code.

Requirem ents for installations in Com m onwealth of Massachusetts, Seepage 19.

1. W hen choosing a location for the sleeve, rem em ber that the unit chassism ust be vented to the outside atm osphere, therefore, the s leeve must bem ounted in the outside wall of the room . A location should be selected withconsideration for circulation of discharge (room) air. Generally, the locationwhich provides the most effective circulation is m idway along the wall of theroom the unit is to serve and away from a stairwell or other openings. Do notlocate sleeve behind a door or at a point where a door, if left open, would tendto obstruct the unit when installed into the sleeve.

2. In choosing a location for the sleeve, one must consider the m inim umoperation clearances as specified in Table 1. These clearances assureadequate accessibility for servicing and proper operation of the unit andtherefore, must be maintained.

3. The wall sleeve may be installed directly on fin ished floor as illustrated inFigure 2, however, considerations should be given to the location of gas linesand electrical service. NOTE: If mounted on top of floor, the gas connectionshould be made from rear of unit. For the best finished results, Suburbansuggests the wall sleeve be mounted a m inim um of 3-1/2" off of the finishedfloor, as illustrated in Figure 3. This allows sufficien t space for the gas andelectrical connections to be m ade below the wall case. An accessory basepanel, Suburban Kit #520873, m ay then be attached to the cabinet front toconceal these service connections. NOTE: This base panel is non-loadingbearing.

4. W hen installing below a window, the installer should consider the possibilityof curtains interfering with discharge air and/or accessory air discharge packageand take steps to elim inate these restrictions.

5. The ins taller should allow for drywall or other interior wall finishes whenlocating sleeve during rough-in. (See Figures 5 or 6.)

6. Prior to installing the wall sleeve, one must consider the m ethod to be usedto drain the condensate from the wall sleeve. Two methods m ay be used:

a. Free Drain (External)- A general acceptable alternative where thecondensate drains from the wall sleeve through three exterior drainholes and drops to open ground. (See Figure 4.) T he condenser fanis designed to p ick up norm al condensate and evaporate it offthe condenser coil.

b. Drain Kit - A condensate drain kit is recom m ended for positive drainagewhen specified or code requires or when condensate is heavy underconditions of extrem e hum idity for extended periods of tim e. The drain tubeassem blies m ay be installed externally on rear flange of the wall sleeve orunderneath the wall sleeve to the external side of building. (See Figure 7)The condensate can be freely drained to ground level or routed in tubing toa disposable location. Drain tube kits are des igned for 1/2" O.D. coppertubing.

NOTE: Excessive rain water entering the unit through the outside grille may notbe entirely rem oved during operation of the unit. Excessive rain water will drainthrough the raised weep holes provided on the rear of the wall sleeve.

7 . A fter selecting a location for wall sleeve, inspect the wall and floor areas todeterm ine that there are no hidden electrical wires, propane or other flam m ablegas-liquid piping or tubing, ducts, girders or wall studs that will interfere with theproper installation and safe operation of the unit or the proper installation of gassupply lines and electrical service

8. The cabinet front is shipped with the unit chassis. Side flanges on chassisare secured to sleeve from inside room to insure proper security and mounting.

INSTALLATION

Before beginning the installation, it is suggested that the cabinet front and airfilter be rem oved to avoid dam age during installation of the unit.

1. Cut an opening in the outside wall and fram e to the m inim um opening asillustrated in Figures 2 or 3. Refer to Table 1 for m inimum clearances toobstruction. Use conventional construction methods to fram e opening. Do notuse wall sleeve as a lintel. The fram ed opening should allow for the slopingof the sleeve toward outside wall as illustra ted in F igures 5 or 6, in order toassure proper drainage. Do not install wall sleeve level or slope towardroom .

2. Unfold the sides of the wall sleeve and assem ble the top, being sure that thesides wedge between the top flange on the top and the retaining angle asillustrated in Figure 4. Secure at top corners w ith screws provided. If theopening in the rear of the sleeve for rear gas hook-up is not used, you m ayblock the opening using the bird guard supplied with the sleeve. (See Figure4A for illustration.)

3. Install wall sleeve into fram ed opening with the three drain holes to theoutside. Minim um projection of wall sleeve into the room is flush with finishedwall or molding, as illustrated by “x” dim ension in Figures 5 or 6.

CAUTION: Be sure sleeve protrudes far enough into the room to allow forany interior wall studding, insulation and dry wall or finished wall to beadded during construction.

Do not install sleeve flush with finished exterior wall.

4

Figure 2

Figure 3

If sleeve installed with floor clearance from 0" to less than 3-1/2", the sleevem ust protrude a m inim um of 1-5/8" beyond finished surface of exterior wall.(See Figure 5.) This is to allow for rear gas hook-up. If sleeve is installed withfloor clearance of 3-1/2" or greater, the sleeve m ust protrude a m inim um of 1/4"beyond finished surface of exterior wall. (See Figure 6.)

NOTE: W all sleeve installations that protrude into the room 4" or more requirethe use of Leg Leveling Kit #520600 or other m eans of supporting the wallsleeve. (See Figure 8). Failure to support the wall sleeve front in suchinstallations may cause im proper sleeve slope(1/4" rear s lope required - seeStep 4 below), which m ay result in im proper condensate leakage into theinterior room space.

For installations in windows and/or curtain or panel walls of 2", it is suggestedthat a m inim um of two field supports be installed under wall sleeve since noscrews can be used in bottom of sleeve to the wall.

Field supplied wall sleeve angles 1" x 1" x .065/.055 are to be used on top,sides and bottom of wall sleeve. (See Figure 9).

CAUTIO N: Do not drill holes in bottom of sleeve. Bottom angle is forsupport only and is to be secured to wall.

4. Secure wall sleeve to wall as illustrated in Figures 5 or 6. Be sure wall caseis level (side to side-parallel to floor) and sloped 1/4" from front to rear. Do notput holes in bottom of sleeve, water dam age to wall and floor will occur.

5. Caulk around wall sleeve between the sleeve and building to form a weathertight seal against rain and snow. Use only weather proof caulking. (SeeFigures 5 or 6).

6. Seal around sleeve between finished interior wall and sleeve to m inim izeheat/cooling loss around sleeve. Seal may be caulking, or if preferred, installerm ay trim around sleeve with m olding or other suitable m aterials.

IM PORTANT: Installation of the rear grille m ust be m ade prior to installingthe chassis as it secures from inside the wall sleeve.

7. Slide unit into wall sleeve and secure it to s leeve using the four #10 x 1/2screws provided.

8. Connect gas and electrical supply. Refer to Figure 10 for centerline locationof gas connection and electrical connection when unit is installed into wallsleeve.

NOTE: This unit is factory set for 230 volt operation. If you wish to operate uniton 208 volts, the rocker switch located behind the cabinet front on the controlspanel (reference Item No. 25, Figure 15) must be switched to 208 volts.

NOTE: On occasions, the voltage on a 230 volt model may drop. If the voltagedrop is at or below 208 volts, the switch should be switched to 208 volts.

9. The operation of this unit is controlled by a built-in therm ostat. A d ig ita ltem perature read out will be displayed on the control panel.

For rem ote therm ostat operation, connect the therm ostat wiring to the term inalblock located on the m odule board. Move switch #1 on the therm ostat switchto "on". (See Figure 12.)

To reset controls, turn power off then back on.

NOTE: Connecting rem ote therm ostat overrides the built-in therm ostat and youwill not get a digital read out on the control panel. There is no need todisconnect the built-in therm ostat as shipped from factory.

10. Reinstall air filter.

11. Reinstall cabinet front. Do not operate unit with cabinet front rem oved.

5

Figure 4AFigure 4

Figure 5

Figure 6

6

Figure 7

Figure 8

Figure 9

7

Figure 10

TABLE 2

Maximum Capacity of Pipe in Cubic Feet of Gas per

Hour for Gas Pressures of 0.5 PSIG or Less and a

Pressure Drop of 0.3 Inch Water Column

(Based on a 0.60 Specific Gravity Gas)

NominalIron Pipe Internal Length of Pipe, Feet

Size, Diameter,Inches Inches 10 20 30 40 50 60 70 80 90 100 125 150 175 200

1/4 .364 32 22 18 15 14 12 11 11 10 9 8 8 7 6 3/8 .493 72 49 40 34 30 27 25 23 22 21 18 17 15 14 1/2 .622 132 92 73 63 56 50 46 43 40 38 34 31 28 26 3/4 .824 278 190 152 130 115 105 96 90 84 79 72 64 59 55

1 1.049 520 350 285 245 215 195 180 170 160 150 130 120 110 1001-1/4 1.380 1,050 730 590 500 440 400 370 350 320 305 275 250 225 2101-1/2 1.610 1,600 1,100 890 760 670 610 560 530 490 460 410 380 350 320

2 2.067 3,050 2,100 1,650 1,450 1,270 1,150 1,050 990 930 870 780 710 650 6102-1/2 2.469 4,800 3,300 2,700 2,300 2,000 1,850 1,700 1,600 1,500 1,400 1,250 1,130 1,050 980

3 3.068 8,500 5,900 4,700 4,100 3,600 3,250 3,000 2,800 2,600 2,500 2,200 2,000 1,850 1,7004 4.026 17,500 12,000 9,700 8,300 7,400 6,800 6,200 5,800 5,400 5,100 4,500 4,100 3,800 3,500

MAKING GAS CONNECTIONS

The unit is factory equipped with a 3/8" NPT gas connection. The size of thepipe should be computed according to the type of gas and the length of the run.Table 2 gives a reasonably accurate size for the service line. The quantitiesgiven in the table are for cubic feet per hour. To convert BTU capacity to cubicfeet, divide total BTU load by the BTU value of the gas being used. The tableis for natural gas only. To convert to liquefied petroleum (LP) gas, multiply by.633. The pressure drop caused by other gas appliances being served by anyportion of the line provided for this installation m ust be considered. If the newline is takeoff from an existing line to another app liance, pressure dropcomputation with the table must include the demand of the other appliance.

CAUTION: Suburban does not recomm end the use of flex tubing to m akethe gas connections to the unit unless the flex tubing is a high qualitystainless certified by AGA and approved for use by local codes.

Minimum gas supply pressure for purposes of input adjustment:

M inim um M axim umNatural Gas 5" W .C.* 7" W .C.Liquefied Petroleum (LP) Gas 11" W .C. 13" W .C.(*W ater Colum n)

Operating Pressure

All units for burning natural gas are equipped with a valve having a built-inregulator preset at 3.5" W .C. pressure. A ll units for burning liquefied petroleum(LP) gas are equipped with a valve having a built-in regulator preset at 10.5"W .C. pressure. Do not adjust the regulator set screw on the valve. Over firingof the unit may occur.

It is recom m ended that the installer install a m anual shut-off valve in the gassupply line to the unit. It is also recom m ended that a ground join t union beinstalled between the unit and this shut-off valve.

A condensate trap should also be installed in the gas supply line as close to theunit as possible.

In order to maintain a check on gas supply pressure to the unit, Suburbanadvises the installer to provide a 1/8" NPT plug tap for test gauge connectionimm ediately upstream of the gas supply connection to the unit.

The unit and its individual shut-off valve m ust be disconnected from the gassupply piping system during any pressure testing of the gas system at testpressures in excess of 1/2 PSIG. The unit must be isolated from the gas supplypiping system by clos ing its individual manual shut-off valve during anypressure testing of the gas supply system at test pressures equal to or less than1/2 PSIG.

W ARNING! A pipe thread com pound resistant to the action of liquefiedpetroleum (LP) and natural gas m ust be used on all pipe joints.

All gas piping should be tested with a soap and water solution to assure gas-tightconnections.

W ARNING! Do not use an open flam e to check for leaks!

MAKING ELECTRICAL CONNECTIONS(208 - 230 Volts)

If local codes perm it, the service cord as supplied with the unit m ay be used. Theservice cord is added at the factory for testing during production. If local codesdo not perm it the use of a service cord, it must be rem oved and the electricalconnections made in the junction box.

A ll external wiring m ust com ply with local codes or national electrical codes.

It is recom m ended that the wiring be on a separate perm anent line electrica lcircuit. The electrical circuit must be protected using dual 15 am p fuse or HACRtype circuit breaker.

In the U.S.A., the unit when installed, m ust be electrically grounded inaccordance with local codes or, in the absence of local codes, w ith the latestedition of National Electrical Code ANSI/NFPA No. 70. Proper operation of thisunit is dependent on adequate earth ground. If the installation is m ade using gaspiping of any m aterial other than m etal pipe, then adequate steps must be takento assure adequate earth ground.

In Canada, the unit m ust be electrically connected and grounded in accordancewith local codes or in the absence of local codes w ith the current CSA C22.1Canadian Electrical Code.

24 VAC EM ERGENCY POW ER CONNECTION (COM PRESSOR LOCK-OUT)

Two 1/4" m ale term inals labeled "PW R DOW N" are available on the m oduleboard. If 24 VAC is applied to these term inals, the compressor and condensorfan operation are disabled. During a call for cooling, the indoor blower will runand the "SERVICE SYSTEM" light will be on.

1. Rem ove the display panel (save the 5 screws for re-use (See Figure 13).

2. Route wiring from an external 24 VAC source through the bushing in the baseof the unit.

3. Term inate two wires with 1/4" fem ale pre-insulated term inals.

4. Connect wires to the "PW R DOW N" term inals on the m odule board (Seewiring diagram ).

5. Replace the display panel.

8

Figure 11

OPERATING INSTRUCTIONSA. HEAT MODE

Initial Lighting Instructions (See Figure 11)

NOTE: During initia l firing of this furnace, a burn-off of excess paint and oilsrem aining from manufacturing process m ay cause “sm oking” for 5 - 10 m inutes.

NOTE: If your unit has the optional air discharge package installed, werecom m end the room air blower be operated on high (Select high fan speed).

1. Open the manual shut-off valve. The valve is fully open when the handle islevel or parallel to the gas line. Never attem pt to operate unit w ith m anual valvepartially closed.

2. Depress "System " key pad until heat lam p is illum inated.

3. Depress "Fan" key pad until desired speed lam p is illum inated.

4. Set therm ostat to desired setting by depressing temperature indicating arrowsuntil desired tem perature is displayed.

5. If the therm ostat circuit is closed at the setting chosen in step 4, the ignitionsequence begins.

6. After ignition, the operation of the unit will be controlled autom atically by thetherm ostat.

To Shut Down for an Extended Period of Tim e

1. Depress "System " key pad until stand by lam p is illum inated.

2. C lose manual shut-off valve.

Sequence of Norm al Operation - Heat Mode

1. W hen heat is required, the therm ostat closes and energizes the combustionair m otor.

2. As the blower reaches approxim ately 90% of the norm al RPM, the pressurecreated by the com bustion air m otor causes the diaphragm in the pressure switchto move, closing the contacts. This completes the electrical circuit to the input ofthe m odule board and a 10 second warm -up period for the glo-bar is established.During the warm up period, the glo-bar com es on for 7 seconds, then the valveopens. The g lo-bar rem ains on another 3 seconds after the valve opens andthen goes off. W hen the valve opens, it will rem ain open for 6 seconds. Gas willflow to the burner and be ignited by the glo-bar.

3. If the m ain burner flam e is sensed, the burner will rem ain on until thetherm ostat is satisfied. If the flam e is not sensed, the gas valve closes and theignition sequence autom atica lly repeated two (2) tim es. If the burner does notlight during this trial for ignition period, the unit will lock-out for one (1) hour andthen re-set autom atically.

NOTE: If lock-out should occur, the unit can be re-set m anually by breaking thepower to the unit. W hen power is restored, the ignition procedures can berepeated. Should repeated lock-out occur, shut unit down and contact your gasservice agency.

4. After proof of ignition (burner lights and flam e properly sensed) a circuit iscompleted to the room air blower and the blower com es on.

5. W hen the therm ostat is satisfied, the valve closes. The com bustion air m otorwill rem ain on for a 20 second purge cycle, then goes off. The room air blowerwill continue to operate for approxim ately 90 seconds at which tim e the circuit isopened and the room air blower goes off.

NOTE: If your unit is controlled by a wall therm ostat, the ignition sequence is thesame as with built-in therm ostat; however, the tem perature setting and systemfunctions are selected at the wall therm ostat. The "Fan" speed is controlled in thesam e manner as with built-in therm ostat.

B. COOLING MODE

Norm al Operation (See Figure 11)

1. Depress "System " key pad until cool lam p is illum inated.

2. Depress "Fan" key pad until desired speed lam p is illum inated.

3. Set therm ostat to desired setting by depressing temperature indicating arrowsuntil desired tem perature is displayed.

4. If the therm ostat circuit is closed at the setting chosen in Step 3, the coolingcycle begins. NOTE: On initial start-up, the compressor will not be energized forfive (5) m inutes even though the system functions have been properly selected.

W henever the outside tem perature is below 65° and the hum idity is high, frostcould form on the evaporator coil during extended cooling operation. To elim inatefrost form ation, a de-ice switch in the com pressor circuit will sense a frostcondition and open the com pressor circuit. Upon tem perature rise, the switch willclose and the com pressor will again com e on provided the therm ostat is stillcalling for cooling.

NOTE: This unit has a built-in 5 m inute delay between compressor cycles. Anytim e the com pressor cycle is interrupted either m anually, through therm ostat, apower interruption, etc., the com pressor will not restart for 5 m inutes.

C. OPERATING TIPS - HEAT MODE OR COOLING MODE

1. At tim es it may be desirable to reduce the operating sound level. This ispossible by selecting “Low Cool” position. At this setting, the cooling capacity isnot reduced - only the blower speed and air movem ent is reduced.

2. Circulation of room air with no heat or cooling m ay be obtained if desired. Forfan only operation, depress "System " key pad until fan only lam p is illum inated.Depress "Fan" key pad until desired speed lam p is illum intaed.

9Figure 13

Figure 14

Figure 12

UNIT CONTROLS AND THEIR FUNCTION

Lim it Switch - The purpose of the lim it control is to turn off the gas to the mainburner if, for any reason, the heating section of the unit becom es hotter than thatwhich is safe. Cycling on lim it does not always indicate a defective lim it switch.If the circulating air is blocked or only partially so, the lim it control will functionand cause the m ain burner to go off. Cycling on lim it is not always undesirable -if it happens only occasionally. This is a good indication of safe operation and willm ost like ly happen on a warm day. If cycling happens too often or for anextended period, the circulating air system should be thoroughly cleaned. (See“Maintenance and Cleaning.”)

If for any reason, the lim it switch is found to be defective, it must be replaced.There is no recom m ended m ethod of repairing it. Because of the im portance ofthe lim it switch, for safety reasons, never shunt the lim it switch - even for onlytem porary operation.

Pressure Switch - The purpose of the pressure switch is to sense the airpressure generated by the com bustion air blower. W hen the pressure isadequate to support com bustion, the contacts in the switch close. This completesthe circuit to the input of the module board and the ignition sequence begins. Iffor som e reason the pressure is not sufficient to support com bustion, the switchwill not operate. Reasons for insufficient pressure: 1) slow com bustion air motor2) restriction in intake and 3) loose pressure switch tube or a blockage in thepressure switch tubing.

Fresh Air Vent - The purpose of the fresh air vent is to prov ide a m eans ofintroducing outside air into the living. The control rod is located in the lower leftfront corner of the unit. To gain access to the control rod, the cabinet front mustbe pivoted forward. (See Figure 13).

NOTE: Operating the unit with the vent open could reduce efficiency of the unitin both heat and cooling m odes.

Overload Protection - These units are equipped w ith an electrical safetyoverload which stops the com pressor in the event of electrical overload. Ifrepeated overload cycling occurs, call your dealer or a local repair agencyequipped to service air conditioning equipm ent.

REMOVING UNIT FOR SERVICE

1. Shut off gas supply to unit.

2. Break electrical circuit to unit at fuse box if wired perm anently. D isconnectwiring in junction box on unit. If service cord is used, unplug from wall receptacle.

3. Disconnect inlet gas line to unit.

4. Disconnect therm ostat wiring at term inal block on module board, if unit iswired for rem ote therm ostat.

5. Pull unit from wall case.

6. To reinstall, reverse above procedure.

7. Check gas connections for leaks using a soap and water solution. Do not usean open flam e to check for leaks. Correct any gas leaks imm ediately.

PREVENTIVE MAINTENANCE

W ARNING! If the user of this appliance fails to m aintain it in the conditionin which it was shipped from the factory or if the appliance is not usedsolely for its intended purpose or if appliance is not m aintained inaccordance with the instructions in this m anual, then the risk of a fireand/or the production of carbon m onoxide exists which can causepersonal injury, property damage or loss of life.

IMPORTANT: Always verify proper operation after servicing.

W ARNING! Always disconnect electrical supply before cleaning unit orperform ing any m aintenance.

The unit should be inspected by a qualified service person yearly before turningthe unit on heat for the winter. Particular attention should be given to the following:

1. Inspect all gaskets. If any gaskets show signs of leakage or deterioration, theym ust be replaced. Safe operation of the unit depends on all gaskets being tight.

2. Inspect com bustion cham ber and venting to assure that these com ponents arephys ically sound without holes or excessive corrosion. Replace if found to bedefective.

3. Inspect exhaust and intake for restrictions and for adequate sealing of anym ating parts. (See “Minimum Outside Clearances”.)

W ARNING! It is im perative that the products of com bustion be properlyvented to the outside atm osphere and that all com bustion air supplied tothe burner be drawn from the outside atm osphere.

4. Check outside grille to be sure it is clean and free of any obstructions.

5. Check the control com partm ent, burner and circulating air passageways of theunit. These areas must be kept clean. NOTE: More frequent cleaning m ay berequired due to excessive lint from carpeting, bedding m aterial, etc.

6. Check burner for proper operation. A proper flam e will have a blue inner conewith well defined pattern and an orange outer cone with slightly yellow tips. Aflam e that is yellow in appearance with an erratic flam e pattern indicates arestriction in the air supply. Shut the unit down and have the burner and airpassage ways checked and cleaned as needed. The surface of the burner andeach burner port should be cleaned with a steel wire brush and blown clean usingcompressed air. (See Figure 14 for illustration of a correct and incorrect burnerflam e.)

7. Check all gas connections and gas controls (electrical valves, manual shut-offvalves, regulators, etc.) for leaks.

8. This inspection should include a com plete operational check of the unitincluding all elec trical and mechanical com ponents. NOTE: If cabinet front wasrem oved in order to inspect the unit and controls, it must be reinstalled prior tooperating the unit.

10

You as the owner/user should inspect the unit periodically during theheating season. Particular attention should be given to the following:

A. Periodically observe the main burner flam e to assure it is burning with a hardblue flam e with well-defined burner ports. (See Figure 14.) If flam e appears yellowor burner has a lazy flame, shut furnace down and contact a qualified serviceperson.

B. Periodically inspect the vent for obstructions or presence of soot. Soot isform ed whenever com bustion is incom plete. This is your visual warning that thefurnace is operating in an unsafe manner. If soot is present, im m ediately shutfurnace down and contact your dealer or a qualified service person.

C. Circulating air through the front grille must not be blocked. Keep filter clean toassure adequate air flow.

The rem ovable, washable type filter should be cleaned or replaced several tim esduring the year. This will depend upon the usage and location of the unit. A dirtyfilter will reduce the air flow and the efficiency of the unit. Filter m ay be washed ina soapy solution and rinsed in clean water. Let the filter dry before reinstalling iton the unit.

The filter is located behind the cabinet front. The cabinet front pivots forward foreasy access to the filter. To rem ove the filter, rotate retaining arm free of filter, andlift filter up.

Listed below are several safety related item s that you should follow during theheating season to assure continued safe operation of the furnace.

1. Never operate the unit if you smell gas. Do not assum e that the smell of gasis norm al. Any tim e you detect the odor of gas, it is to be considered lifethreatening and corrected imm ediately. (See safety notice on front cover of thism anual.)

2. Im m ediately shut unit down and call a service agency if unit cycles erraticallyor delays on ignition.

W ARNING! Should overheating occur, or the gas supply fail to shut off,shut off the manual gas valve to the appliance before shutting off theelectrical supply.

3. Do not restrict the flow of com bustion air or the warm air circulation to the unit.To do so could cause personal injury and/or death.

W ARNING! Do not install screens over the vent for any reason. Screenswill becom e restricted and cause unsafe furnace operation.

4. Keep unit clean. More frequent cleaning m ay be required due to excessive lintfrom carpeting, bedding m aterial, etc. It is im perative that control com partm ents,burners and circulating air passageways of the appliance be kept clean.

5. Keep the furnace area clear of any com bustible materials, gasoline or otherflam m able vapor and liquids.

6. Do not use this appliance if any part has been subm erged under water.Im m ediately call a qualified service technician to inspect the appliance and toreplace any part of the control system and any gas control that has beensubm erged under water.

7. Always follow the operating instructions. Do not deviate from the step-by-stepprocedures.

8. Never attem pt to repair dam aged parts. A lways have them replaced by aqualified service agency.

9. Never attem pt to repair the furnace yourself. Seek the help of a qualifiedservice person.

10. The room air m otor, the condensor motor and the com bustion air m otor arem aintenance free m otors and require no oiling.

GENERAL NOTES

The efficiency rating of this unit is a product therm al efficiency rating determ inedunder continuous operating conditions and was determ ined independent of anyinstalled system .

Children and adults should be alerted to the hazards of h igh surfacetem peratures and should stay away to avoid burns or clothing ignition.

Young children should be carefully supervised when they are in the sam eroom as the unit.

Clothing or other flam m able material should not be placed on or near theunit.

Any safety screen or guard rem oved for servicing the unit m ust bereplaced prior to operating the unit.

Installation and repairs should be done by a qualified service person. Theappliance should be inspected before use and at least annually by aqualified service person. More frequent cleaning m ay be required due toexcessive lint from carpeting, bedding m aterial, etc. It is im perative thatcontrol compartm ents, burners and circulating air passageways of theappliance be kept clean.

Never operate unit with filter rem oved. Evaporator coil and/or drain panm ay becom e restricted.

11

Figure 15

Figure 16

12

Figure 17

Figure 18

All Models

DL3-0712, DL3-0912,DL3-1220

13

Figure 18A

Figure 19

DL3-1622

DL3-0712, DL3-0912, DL3-1220

14

Figure 19A

Figure 20

DL3-1622

DL3-0712, DL3-0912,DL3-1220

15

Figure 20A

DL3-1622

16

ORDERING REPAIR PARTSDo not attem pt to repair damaged parts. Only factory authorizedparts are to be used.

W hen ordering parts from your dealer or distributor, always give thefollowing inform ation:

1. Part Num ber (Not Item Num ber)2. Part Description3. Model No. And Serial No.4. Quantity

Item PartNo. Description Number1 Grille, Aluminum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0311232 Top, Wall Case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101621CB3 Gasket, Wall Case Top . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0708874 Gasket, Wall Case End . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0708855 Gasket, Wall Case Bottom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0708836 Wall case Bottom Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101549CB7 Screw 10 - 12 x 1" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1219538 Tinnerman . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1213789 Shoulder Screw #8-15 x 3/4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12186910 Fastener Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12172711 Name Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53002612 Tinnerman Flat Push-on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12144214 Control Plate and Decal Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 52091315 Tube Assembly, Gas Inlet (Rear Gas Models Only) . . . . . . . . . . . . . . 17166116 ELL 90/ Hi-Ear (Off-Set Mount) (Rear Gas Models Only) . . . . . . . . . . 17159817 Screw 8-32 x 3/8 (Rear Gas Models Only) . . . . . . . . . . . . . . . . . . . . . 12195819 Panel Assembly Complete (Left Side (Dl3-0712, 0912, 1220)) . . . . . . 10190020 Bushing, Universal 1 1/8" (Rear Gas Models Only) . . . . . . . . . . . . . . 07104621 Plug, Hole 1 1/8" (Front Gas Models Only) . . . . . . . . . . . . . . . . . . . . . 07107522 Bushing Strain Relief 7/8 (DL3-0712, 0912, 1220) . . . . . . . . . . . . . . . 510405

Bushing Strain Relief (DL3-1622) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 07118223 Module Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23278524 Control Rod, Vent Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14023525 Switch, Rocker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23224626 Label, 208/230 V. Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19190227 Plate, Mounting (Controls) (DL3-0712, 0912, 1220) . . . . . . . . . . . . . . 063402

Plate, Mounting (Controls) (DL3-1622) . . . . . . . . . . . . . . . . . . . . . . . . 06347928 Terminal Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23094430 Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23103232 Transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23263433 Switch, Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23290734 Filter (DL3-07-12, 0912, 1220) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 031097

Filter (DL3-1622) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 03117735 Evaporator Panel Assembly Complete (DL3-0712, 0912, 1220) . . . . 102053

Evaporator Panel Assembly Complete (DL3-1622) . . . . . . . . . . . . . . 10210036 Grille, Room Air (DL3-0712, 0912, 1220) . . . . . . . . . . . . . . . . . . . . . . 030656

Grille, Room Air (DL3-1622) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 03117637 Cover Assembly Complete (DL3-0712, 0912, 1220) . . . . . . . . . . . . . . 101905

Cover Assembly Complete (DL3-1622) . . . . . . . . . . . . . . . . . . . . . . . . 10208938 Panel Assembly Complete (Right Side) (DL3-0712, 0912, 1220) . . . . 101901

Panel Assembly Complete (Right Side) (DL3-1622) . . . . . . . . . . . . . . 10208340 Bottom Angle Seal Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 063430CB42 Spring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15009043 Rod Control Door Hinge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15008944 Controls Door Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 03109945 Washer, Nylon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12172646 Cabinet Front Assembly Complete (DL3-0712, 0912, 1220) . . . . 101920CB

Cabinet Front Assembly Complete (DL3-1622) . . . . . . . . . . . . . . 102097CB47 Coil, Evaporator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38023948 Cover Plate Assembly with Insulation (DL3-0712, 0912, 1220) . . . . . 063449

Cover Plate Assembly with Insulation (DL3-1622) . . . . . . . . . . . . . . . 06348749 Bushing, Universal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 07048650 Boot, Capacitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23268651 Clamp, Capacitor (DL3-0712, 0912, 1220) . . . . . . . . . . . . . . . . . . . . . 062925

Clamp, Capacitor (DL3-1622) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 06348352 Capacitor 15 :f (DL3-0712) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232949

Capacitor 25 :f (DL3-1220, 1622) . . . . . . . . . . . . . . . . . . . . . . . . . . . 232688Capacitor 30 :f (DL3-0912) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232744

53 Capacitor 1.5 :f (DL3-1220) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232712 Capacitor 2 :f (DL3-0712, 0912 1 each DL3-1622 2 each) . . . . . . . . 23290154 Bushing, Snap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23182755 Boot, Capacitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23268757 Top, Junction Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 09054459 Burner Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 01088860 Gasket, Burner Tube . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 07115661 Burner Tube Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 05140763 Tube, Combustion Air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 05140964 Orifice, Natural Gas (DL3-0712,0912) . . . . . . . . . . . . . . . . . . . . . . . . 180222

Orifice, Natural Gas (DL3-1220) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180314Orifice, Natural Gas (DL3-1622) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180187Orifice, LP Gas (DL3-0712, 0912) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180225Orifice, LP Gas (DL3-1220) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180296Orifice, LP Gas (DL3-1622) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180224

65 Manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17165666 Grommet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 071123

Item PartNo. Description Number67 Valve (Natural Gas) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161199

Valve (LP Gas) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16118368 Tube, Pressure Switch (DL3-0712, 0912, 1220) . . . . . . . . . . . . . . . . . 051484

Tube, Pressure Switch (DL3-1622) . . . . . . . . . . . . . . . . . . . . . . . . . . . 05201069 Elbow, Street (Brass) (Front Gas Models Only) . . . . . . . . . . . . . . . . . 17142770 Fitting 90/ 3/8 NPT x 3/8 Flare (Rear Gas Models Only) . . . . . . . . . . 17037471 Bracket, Valve Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 06350173 Gasket, Combustion Air Tube (Burner) . . . . . . . . . . . . . . . . . . . . . . . . 07111874 Motor, Room Air (DL3-0712, 0912) . . . . . . . . . . . . . . . . . . . . . . . . . . . 232753

Motor, Room Air (DL3-1220) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232635Motor, Room Air (DL3-1622) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232835

76 Blower Assembly with Insulation (Room Air) (DL3-0712, 0912, 1220) 390947Blower Assembly with Insulation (Room Air) (DL3-1622) . . . . . . . . . . 390916

78 Bearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35020379 Wheel, Room Air (DL3-0712, 0912, 1220) . . . . . . . . . . . . . . . . . . . . . 350193

Wheel, Room Air (DL3-1622) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35020280 Evaporator Pan Assembly Complete (DL3-0712, 0912, 1220) . . . . . . 380244

Evaporator Pan Assembly Complete (DL3-1622) . . . . . . . . . . . . . . . . 38026481 Thermostat Sensing Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23271682 Bracket (Thermostat Sensing Probe) . . . . . . . . . . . . . . . . . . . . . . . . . 06341784 Switch Assembly, Limit (DL3-0712, 0912, 1220) . . . . . . . . . . . . . . . . 232770

Switch Assembly, Limit (DL3-1622) . . . . . . . . . . . . . . . . . . . . . . . . . . 23288784A Spacer, Limit Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 06343386 Ignitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23268187 Gasket, Ignitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 07109787A Switch, Flue Limit *DL3-0712, 0912, 1220) . . . . . . . . . . . . . . . . . . . . . 520887

Switch, Flue Limit (DL3-1622) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23282388 Gasket, Flame Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 07109689 Electrode (Flame Probe) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23270190 Baffle (DL3-0712, 0912, 1220) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 04046791 Bushing, Strain Relief (DL3-0712, 0912, 1220) . . . . . . . . . . . . . . . . . 23021692 Combustion Chamber Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 02116993 Strap, Tie-Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 06342694 Cover Assembly, Evaporator Coil (DL3-0712, 0912, 1220) . . . . . . . . 38025695 Door Assembly Complete (Fresh Air Vent) . . . . . . . . . . . . . . . . . . . . . 03117596 Bracket Support, Capacitors (DL3-1622) . . . . . . . . . . . . . . . . . . . . . . 06348297 Brace, Condenser Housing (DL3-0712, 0912, 1220) . . . . . . . . . . . . . 063403

Brace, Condenser Housing (DL3-1622) . . . . . . . . . . . . . . . . . . . . . . . 06348198 Bracket (Blower to Base) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 06346199 Box Assembly, Exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 051419BK100 Gasket Exhaust Blower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 071153101 Vent Cap Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 051483102 Blower Assembly, Exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 390892105 Bracket, Condenser Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 063480106 Fan, Condenser Blower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 350200107 Wrap Assembly, Condenser Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . 380254108 Cover, Condenser Coil (DL3-0712, 0912, 1220 . . . . . . . . . . . . . . . . . 380240

Cover, Condenser Coil (DL3-1622) . . . . . . . . . . . . . . . . . . . . . . . . . . . 380261110 Baffle, Condenser Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 040484111 Coil, Condenser (Dl3-0712, 0912, 1220) . . . . . . . . . . . . . . . . . . . . . . 380279

Coil, Condenser (DL3-1622) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 380258112 Capillary Tube Assembly (DL3-0712) . . . . . . . . . . . . . . . . . . . . . . . . . 171714

Capillary Tube Assembly (DL3-0912) . . . . . . . . . . . . . . . . . . . . . . . . . 171606Capillary Tube Assembly (DL3-1220) . . . . . . . . . . . . . . . . . . . . . . . . . 171590Capillary Tube Assembly (DL3-1622) . . . . . . . . . . . . . . . . . . . . . . . . . 171648

114 Motor, Condenser Air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232636115 Tube, Suction (DL3-0712, 0912, 1220) . . . . . . . . . . . . . . . . . . . . . . . . 171605

Tube, Suction (DL3-1622) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171695116 Switch, De-Icer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232796117 Compressor (DL3-0712) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 380289

Compressor (DL3-0912) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 380186Compressor (DL3-1220) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 380195Compressor (DL3-1622) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 380259

118 Isolator, Compressor Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 380191119 Sleeve, Compressor Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 380192120 Nut 5/16 - 18 Hex Whiz Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121495121 Tube, Discharge (DL3-0712) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171713

Tube, Discharge (DL3-0912) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171608Tube, Discharge (DL3-1220) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171586Tube, Discharge (DL3-1622) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171649

123 Capacitor 2 :f . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232901 126 Bushing, Strain Relief 5/8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230216

128 Restrictor Plate (DL3-0712, 0912 Natural Gas) . . . . . . . . . . . . . . . . . 040495Restrictor Plate (DL3-1220 Natural Gas) . . . . . . . . . . . . . . . . . . . . . . 040493Restrictor Plate (DL3-1622 Natural and LP Gas) . . . . . . . . . . . . . . . . 040497Restrictor Plate (DL3-0712, 0912, 1220 LP Gas) . . . . . . . . . . . . . . . . 090494

Orifice and Pressure Switch Chart

Orifice (Part Number)

Pressure Switch(Part Number)

Unit Stock Number(See Model/Serial # Sticker)

180295 232685 1619, 1620

180296 232685 1617, 1618

180222 232685 1629, 1630, 1691, 1693

180225 232685 1627, 1628, 1692, 1694

17

Figure 21

Figure 22

OPTIONAL ACCESSORIES

ALUMINUM GRILLESTOCK NO. 1625

INTRODUCTION

The grille was specially designed for the DL3 Dynaline. Do not attem pt to bend or alter the design of the grille or the venting system of the Dynaline unit.

The grille will also work, as designed, for those models with rear gas hook-up. IMPORTANT: Installation of the rear grille m ust be m ade prior to installing the chassisas it secures from inside the wall sleeve.

ARCHITECTURAL STYLE GRILLES

INTRODUCTION

These architectural grilles are designed to be used as an optional/alternate for the standard aluminum grille #1625. They are to be installed so that the angle of the grille isin the downward position. Remember, these are special grilles. Do not attempt to bend or alter the design of the grille, the venting system or the Dynaline unit.

These grilles will also work, as designed, for those models with rear gas hook-up. IM PORTANT: Installation of the rear grille must be m ade prior to installing thechassis as it secures from inside the wall sleeve.

18

Figure 24

Figure 23

DL3 AIR DISCHARGE PACKAGE

STOCK NO. 1651 - ADAPTORSTOCK NO. 1623 - EXTENSIONSTOCK NO. 1624 - CONNECTOR

INTRODUCTION

This optional package allows for distribution of air into an adjacent zone requiring a controlled tem perature. This assem bly will discharge the conditioned air to either theright or left depending upon which end the cap is placed. (See Figure 23.)

This package, when installed on a DL3-0912 Series, cannot be lengthened. Maxim um length, not including adaptor, is 43 1/4". On the DL3-1220 Series, additional lengthm ay be added.

If additional length is required, connector assem bly (No. 1624) m ay be used. No more than two (2) connectors m ay be used. Maxim um length not including the adaptoris 130" (10.8 Feet). NOTE: Installer must provide wall support brackets for the connector and extension. Not recom m ended for use on m odels with built-in

therm ostats.

19

Requirements for InstallationCommonwealth of Massachusetts

For all side wall horizontally vented gas fueled equipment installed in every dwelling, building or structureused in whole or in part for residential purposes, including those owned or operated by the Commonwealthand where the side wall exhaust vent termination is less than seven (7) feet above finished grade in thearea of the venting, including but not limited to decks and porches, the following requirements shall besatisfied:

1. INSTALLATION OF CARBON MONOXIDE DETECTORS. At the time of installation of theside wall horizontal vented gas fueled equipment, the installing plumber or gas fitter shallobserve that a hard wired carbon monoxide detector with an alarm and battery back-up isinstalled on the floor level where the gas equipment is to be installed. In addition, the installingplumber or gas fitter shall observe that a battery operated or hard wired carbon monoxidedetector with an alarm is installed on each additional level of the dwelling , building or structureserved by the side wall horizontal vented gas fueled equipment. It shall be the responsibilityof the property owner to secure the services of qualified licensed professionals for theinstallation of hard wired carbon monoxide detectors.

a. In the event that the side wall horizontally vented gas fueled equipment isinstalled in a crawl space or an attic, the hard wired carbon monoxide detectorwith alarm and battery back-up may be installed on the next adjacent floorlevel.

b. In the event that the requirements of this subdivision can not be met at the timeof completion of installation, the owner shall have a period of thirty (30) daysto comply with the above requirements; provided, however, that during saidthirty (30) day period, a battery operated carbon monoxide detector with analarm shall be installed.

2. APPROVED CARBON MONOXIDE DETECTORS. Each carbon monoxide detector asrequired in accordance with the above provisions shall comply with NFPA 720 and be ANSI/UL2034 listed and IAS certified.

3. SIGNAGE. A metal or plastic identification plate shall be permanently mounted to the exteriorof the building at a minimum height of eight (8) feet above grade directly in line with theexhaust vent terminal for the horizontally vented gas fueled heating appliance or equipment.The sign shall read, in print size no less than one0half (½) inch in size, “GAS VENTDIRECTLY BELOW, KEEP CLEAR OF ALL OBSTRUCTIONS”.

4. INSPECTION. The state or local gas inspector of the side wall horizontally vented gas fueledequipment shall not approve the installation unless, upon inspection, the inspector observescarbon monoxide detectors and signage installed in accordance with the provisions of 248CMR 5.08(2)(a)1 through 4.(b) EXEMPTIONS: The following equipment is exempt from 248 CMR 5.08(2)(a)1 through 4:

1. The equipment listed in Chapter 10 entitled “Equipment Not Required To Be Vented” in themost current edition of NFPA 54 as adopted by the Board; and 2. Product Approved side wall horizontally vented gas fueled equipment installed in a roomor structure separate from the dwelling, building or structure used in whole or in part forresidential purposes.

Part Number 2042761-12-07

SUBURBAN LIMITED WARRANTYDYNALINE

ONE YEAR LIMITED WARRANTYThis SUBURBAN product is warranted to the original purchaser to be free from defects in material and workmanship under normal use andmaintenance for a period of one year from the date of installation whether or not actual use begins on that date. It is the responsibility of theconsumer/owner to establish the warranty period. Suburban does not use warranty registration cards for its standard warranty. You are requiredto furnish proof of installation date which may be a Bill of Sale or other payment records which verifies the original installation. A new orremanufactured part to replace any defective part will be provided to your dealer, service agency or local gas company, at Suburban’s sole option,without charge for the part itself, FOB the shipping point. THE EXCHANGED PART WILL BE WARRANTED FOR ONLY THE UNEXPIREDPORTION OF THE ORIGINAL WARRANTY. Defective parts must be returned to Suburban, transportation charges prepaid (Suburban is notresponsible for any freight charges), where Suburban will establish to its sole satisfaction that the part was or became defective under normal useand maintenance. Said first year repairs, made by a recommended Suburban service agency, will qualify for labor reimbursement (to the serviceagency only) up to a maximum as established by Suburban’s flat rate schedule effective at that time. No reimbursement will be made fortransportation, diagnosing, shipping or handling. THIS WARRANTY APPLIES ONLY TO THE PRODUCT IN ITS ORIGINAL INSTALLATIONLOCATION AND IS VOIDED IF THE PRODUCT IS REINSTALLED ELSEWHERE.

FOUR YEAR LIMITED WARRANTY ON HEAT EXCHANGER AND COMPRESSORDuring the second through fifth years after the date of original installation, Suburban further warrants the heat exchanger against defects in materialand workmanship under normal use and maintenance. A replacement heat exchanger will be provided under the same conditions as stated inthe one year warranty EXCEPT no labor reimbursement will be provided.During the second through fifth years after the date of original installation, Suburban further warrants the compressor against defects in materialor workmanship under normal use and maintenance. A new or re-manufactured compressor will be provided at Suburban’s sole option under thesame conditions as stated in the one year warranty EXCEPT no labor reimbursement will be provided.

LIMITATION OF WARRANTIESALL IMPLIED WARRANTIES (INCLUDING IMPLIED WARRANTIES OF MERCHANTABILITY) ARE HEREBY LIMITED IN DURATION TO THEPERIOD FOR WHICH EACH LIMITED WARRANTY IS GIVEN. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIEDWARRANTY LASTS SO THE ABOVE LIMITATIONS MAY NOT APPLY TO YOU. THE EXPRESSED WARRANTIES MADE IN THIS WARRANTYARE EXCLUSIVE AND MAY NOT BE ALTERED, ENLARGED, OR CHANGED BY ANY DISTRIBUTOR, DEALER OR OTHER PERSONWHOMSOEVER.ALL WORK UNDER THE TERMS OF THIS WARRANTY SHALL BE PERFORMED DURING NORMAL WORKING HOURS. ALL REPLACEMENTPARTS ASSUME AS THEIR WARRANTY PERIOD ONLY THE REMAINING TIME PERIOD OF THIS WARRANTY.

SUBURBAN WILL NOT BE RESPONSIBLE FOR:1. Normal maintenance as outlined in the owner’s installation, operating and service instructions manual including cleaning of component parts;such as, orifices and burners.2. Failure to start and/or operate due to voltage or gas conditions, blown fuses, open circuit breakers, loose or disconnected wires, low gaspressure or other damages due to inadequacy or interruption or electrical service or gas supply.3. Damage or repairs required as a consequence of faulty or incorrect installation not in conformance with Suburban instructions.4. Damage as a result of floods, winds, lightning, accidents, corrosive atmosphere or other conditions beyond the control of Suburban.5. Costs incurred in gaining access to the furnace.6. Parts or accessories not supplied by Suburban.7. Damage or repairs needed as a consequence of any misapplication, abuse, unreasonable use, unauthorized alteration, improper service,improper operation or failure to provide reasonable and necessary maintenance.8. Freight charges incurred from parts replacements.9. Fuel or electricity costs or increases in such costs from any reason whatsoever.10. Suburban products whose serial number has been altered, defaced or removed.11. Suburban products installed or warranty claims originating outside the Continental U.S.A., Alaska, Hawaii and Canada.12. ANY SPECIAL, INDIRECT OR CONSEQUENTIAL PROPERTY, ECONOMIC OR COMMERCIAL DAMAGE OF ANY NATUREWHATSOEVER. Some states do not allow the exclusion of incidental or consequential damages, so the above limitation may not apply to you.NO REPRESENTATIVE, DEALER OR OTHER PERSON IS AUTHORIZED TO ASSUME FOR SUBURBAN MANUFACTURING COMPANY ANYADDITIONAL, DIFFERENT OR OTHER LIABILITY IN CONNECTION WITH THE SALE OF THIS SUBURBAN PRODUCT.This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

IF YOU HAVE A PRODUCT PROBLEMFIRST:Contact the installer of the equipment or the selling dealer for warranty service. You may find his name on the product or with your homeownersmanual. If his name is not known, call your builder or general contractor if yours is a new structure.SECOND:Contact the Suburban distributor who supplied the product to the installer/dealer.THIRD:Contact: Suburban Manufacturing Company

Customer Service Department676 Broadway StreetDayton, Tennessee 37321(423) 775-2131, Ext. 1Fax: (423) 775-7015

![Model-dependent...Descriptive Technical Documentation - Model-dependent - DTD no. 22-1622 Model(s): HR 1622 [USA], HR 1622 [CAN], HR 1622 [MEX] 21.01.2015, US_am This information should](https://static.fdocuments.us/doc/165x107/5f1c026a363694191974885c/model-dependent-descriptive-technical-documentation-model-dependent-dtd.jpg)