STUDY ON THE EFFECT OF DIFFERENT CURING METHODS IN COMPRESSIVE STRENGTH OF CONCRETE

description

Transcript of STUDY ON THE EFFECT OF DIFFERENT CURING METHODS IN COMPRESSIVE STRENGTH OF CONCRETE

STUDY ON THE EFFECT OF DIFFERENT CURING METHODS IN COMPRESSIVE STRENGTH OF CONCRETE

IAN JUN F. CARLOS

A RESEARCH STUDY SUBMITTED TO THE FACULTY OF THE COLLEGEOF ENGINEERING AND TECHNOLOGY, WESTERN PHILIPPINES UNIVERSITY, SAN JUAN, ABORLAN, PALAWAN IN PARTIALFULFILLMENT OF THE REQUIREMENTS FOR THE DEGREE OF

BACHELOR OF SCIENCE IN CIVIL ENGINEERING

MARCH 2015

Republic of the PhilippinesWESTERN PHILIPPINES UNIVERSITYCOLLEGE OF ENGINEERING AND TECHNOLOGYAborlan, Palawan

APPROVAL SHEETThe research study attached hereto entitled, STUDY ON THE EFFECT OF DIFFERENT CURING METHODS IN COMPRESSIVE STRENGHT OF CONCRETE, prepared and submitted by IAN JUN F. CARLOS in partial fulfillment of the Requirements for the degree of Bachelor of Science in Civil Engineering is hereby accepted.

RYAN A. LIMCO, CE BERNARDO S.OCAMPO, CEMember, Advisory Committee Member, Advisory Committee

________________________________ ___________________________Date Signed Date Signed

DHEVIE A. MADARCOS, CEChair, Advisory Committee

____________________________ Date Signed

Accepted as partial fulfillment of the requirements for the degree of Bachelor of Science in Civil Engineering.

MIRRIAM P. BANLAWE, RPAEDean, College of Engineering and Technology

_________________________________Date Signed

WESTERN PHILLIPINES UNIVERSITYMISSION AND VISION

WPU VISION 2020Western Philippines University: the leading knowledge Center for sustainable development of west Philippines and beyond.

WPU MISSION 2020Western Philippines University commits itself to develop quality human resource and Green technologies for a dynamic economy and sustainable development Through relevant instruction, research and extension services.

Republic of the PhilippinesWESTERNPHILIPPINES UNIVERSITYCollege of Engineering and TechnologyAborlan, Palawan

CET GOALTo produce technically skilled professionals who will be leaders of sustainable development and key personalities in the national and international resource management.

CIVIL ENGINEERING OBJECTIVES To train students to be capable of applying basic computer system and associated engineering application software including mathematics, physical sciences and other engineering sciences in the practice of civil engineering. To develop the students communication skills they need both in writing and orally in the implementation of civil engineering projects and in the preparation of contracts, specifications and other necessary papers and documents. To train students to be advocate of ethical, legal and professional engineers. To produce civil engineering graduates that are able to manage materials, manpower, machineries, and financial resources used in infrastructures projects, evaluate quality of materials and workmanship employed in the implementation of the projects. To prepare students to be a good planner capable of conducting survey and investigation and undertakes economic, technical, financial and environmental feasibility studies. To train students to be capable of conducting research and development works and pursue a life-long learning or post graduate studies.

BIOGRAPHICAL SKETCHThe author was born on February 14, 1992 at Sandoval, Narra, Palawan. He presently resides at Barangay Sandoval, Narra, Palawan. He is the eldest child of Bobby M. Carlos and Norma F. Carlos. He has two (2) brothers and two (2) sisters named Ariel, Jayson, Kristine Joy, and Krezel kate. He finished his elementary education at Sandoval, Elementary School and his secondary education at Sandoval National High School. As he dreams to pursue his studies and become a professional, he enrolled his tertiary education at the western Philippines University (WPU) Aborlan, Palawan with the degree of bachelor of Science in Civil Engineering and is about to graduate in April 2015. He wants to become a successful Civil Engineer someday.

IAN JUN FRANCISCO CARLOS

ACKNOWLEDGEMENTThe author wishes to acknowledge every individual who had been part of this study. First and foremost, the almighty God, who is the source of all strength, wisdom and knowledge;To his adviser, Engr. Dhevie A. Madarcos, for seriously sharing her knowledge and ideas, for the patience, advices and corrections that made this study possible;To his project study instructor, Engr. Bernardo S. Ocampo, for the advice, suggestions and encouragements that made this study successful;To his statistician, Dr. Noel L. Gauran, for guiding and checking statistical data;To his English Critic, Mr. Ryan Madarcos, for the effort and patience checking and editing his manuscript;Engr. Mirriam P. Banlawe for the advice, approval, concern and for the time she spent in checking his manuscript;To the technician of Universal Testing Machine (UTM), Mr. Angelo T. Toto for the effort and time he spent during testing of samples;To his friends and boardmates, John Christian Pamado, David Maniquis, Jose Ryan Latosa, Richard Pendon, Arnold Villanueva, Jerald Villones, Feterson Tabujara, Defrey, Joriel and Mac-Mac for sharing happy moments and laughter together;The author wants to express his gratitude to his friends Jessica Labrador, Nequita Joyce Escala, and Rose Ann Arimado, for inspiring and being his companions, for the support, love and care, for the encouragements, reminders and motivations, and for those happy moments, thoughts and trials shared together;And also, his utmost gratitude and sincerity to his family, to his brothers and sisters, Ariel, Jayson, Kristine Joy, and Krezel Kate for being his inspiration. to his father and mother, Bobby M. Carlos and Norma F. Carlos, for unending support, love, care and advice that mould the author to become more responsible;To his aunt, Virginia Calunsag for being there in times of financial shortage, and for giving advice and support;To his Uncle, Fernando Calunsag and his cousin Nancy Briza Calunsag for their support; andTo his classmates, for their advices and reminders.The author never forgets you.

I.J.F.C

ABSTRACT

CARLOS, IAN JUN F., College of Engineering and Technology, Western Philippines University, Aborlan Palawan, March 2015. STUDY ON THE EFFECT OF DIFFERENT CURING METHODS IN COMPRESSIVE STRENGTH OF CONCRETE

Adviser; Engr. Dhevie A. MadarcosThis study entitled Study on the Effect of Different Curing Methods in Compressive Strength of Concrete was conducted from December 2014 to February 2015. The general objective of the study was to determine the effects of different curing methods applied on concrete. The specific objectives were: to determine the effects of different curing methods in compressive strength of concrete; and to determine the most effective curing methods that would give the highest result for the compressive strength of concrete.The materials used in the study were collected and prepared. Common course and fine aggregates, Ordinary Portland cement, and potable water were used in concrete mixture. Ordinary Polyvinyl Chloride (PVC) pipe served as cylindrical moulds. Concrete cylindrical samples were cured for 28 days using three (3) curing methods. The samples were subjected to compressive test using the Universal Testing Machine (UTM) at the College of Engineering and Technology, Western Philippines University, Aborlan Palawan. Data were analyzed using analysis of variance (ANOVA) to test the difference among the treatment means.The result for compressive test revealed that the highest compressive strength of 15.79 N/mm2 was obtained by Treatment 3 (water sprinkling method) followed by treatment 2 (plastic sheeting method) with a mean of 12.87 N/mm2 and lastly the treatment 1 (Air drying method) with a mean of 12.10 N/mm2. Statistical analysis revealed that treatment 3 which is water sprinkling method had a highest compressive strength of 15.79 N/mm2 which was significantly different from the other treatments but showed no significant difference from Treatment 2 (plastic sheeting method).Therefore, the results of the study proved that curing of concrete using water increases its compressive strength. Based on the result, the researcher recommends the following; (a) using Treatment 3 (water sprinkling method) in curing the concrete to increase the compressive strength; and (b) further study about the other curing techniques and their proper application on concrete be conducted.

TABLE OF CONTENTS

TITLE PAGEiAPPROVAL SHEETiiWPU MISSION AND VISSIONiiiCEAT GOAL AND CIVIL ENGINEERING OBJECTIVESivBIOGRAPHICAL SKETCHviACKNOWLEDGEMENTviiABSTRACTixTABLEOF CONTENTSxiLIST OF TABLESxiiiLIST OF FIGURESxivLIST OF APPENDICES xv

CHAPTER PAGEI. INTRODUCTION1Background of the study1Significance of the study3Statement of the problem3Objectives of the study4Scope and limitation of the study4Operational definition of terms5II. REVIEW OF RELATED LITERATURE6Conceptual Framework7Literatures7III. METHODOLOGY8Time and place of the study8The research paradigm9Materials, Tools and Equipment used in the study10Determination of curing methods11Collection and preparation of materials11Mixing of concrete11Preparation of samples11Curing 12Analysis12IV. RESULTS AND DISCUSSION13V. SUMMARY, CONCLUSION AND RECOMMENDATION15Summary15Conclusion16Recommendation16BIBLIOGRAPHY17APPENDICES18

LIST OF TABLES

TABLEPAGE1. Compressive strength (in N/mm2) concrete samples14

LIST OF FIGURESFIGUREPAGE1. The conceptual paradigm of the study62. Paradigm of research activities113. Curing of concrete by plastic sheeting 134. Concrete by air drying method145. Samples after sprinkling of water 15

LIST OF APPENDICESAppendix A. Letter of Request Appendix B. Test Result Summary Compressive test of concrete cylinder samplesAppendix C. Computations Appendix D. Pictorials

Chapter IINTRODUCTION

Background of the Study

Curing can be described as keeping the concrete moist and warm enough so that the hydration of cement can continue. More elaborately, it can be described as the process of maintaining a satisfactory moisture content and a favorable temperature in concrete during the period immediately following placement, so that hydration of cement may continue until the desired properties are developed to a sufficient degree to meet the requirement of service.Concrete curing is one of the most important and final steps in concrete construction though it is also one of the most neglected and misunderstood procedures. Curing is the treatment of newly placed concrete during the hardening period so that it retain enough moisture to immunize shrinkage and resist cracking (Lambert Corporation, 1999). The process serves two major purposes: it prevents or replenishes the loss of moisture from the concrete, and it maintains a favorable temperature for hydration to occur for a definite period.Water Curing Curing concrete with waterprevents excessive loss of moisturewhen the concrete is covered with a layer of water for a predetermined period of time. Curing concrete with water controls the evaporation of moisture from the surface. Gradually, the concrete produces its chemical reaction that will eventually harden the concrete.Water curing can be done through different techniques; Immersion, ponding, fogging, and wet covering. The scope of this paper will focus only on fogging or sprinkling. It is a curing method wherein a fine fog mist is frequently applied on the surface of the concrete through a system of sprayers or nozzles. It is an effective method of curing when the humidity is low or the ambient temperature is well above the freezing point. This method requires ample of water and constant proper supervision. Membrane CuringMembrane curing is a process ofcontrollingthe curing ofconcretebysealing in the moisture that usually is lost toevaporation. The process is accomplished either by spraying a sealer on the surface or by covering the surface with asheetfilm.Curing concrete with membrane or plastic sheeting is the most practical and efficient wayto cure concrete in today's construction industry. Sometimes, water is unavailable to cure concrete or if done using an incorrect procedure can alter thesurface finishing of the concreteproduct. Sometimes, adding water to concrete that has not finished its hardening process could adversely affect the hydration process, thus altering the concretes properties. Air Drying CuringDry curing is a curing method wherein the concrete samples are left in open air to be cured at room temperature. Researchers have been working on the natural air drying of concrete since long.This research study aimed to gather information related to curing methods and their effects in compressive strength of concrete.

Compressive Strength is the maximum stress a material can sustain under crush loading. The compressive strength of a material that fails by a shattering fracture can be defined within fairly narrow limits as an independent property. However, the compressive strength of materials that do not shatter in compression must be defined as the amount of stress required to distort the material an arbitrary amount. Compressive strength is calculated by dividing the maximum load by the original cross-sectional area of a specimen in a compression test.Significance of the StudyThis research would provide information about the effect of different curing methods in compressive strength of concrete.Statement of the ProblemThis research was conducted to study about the effectivity of different curing methods applied on concrete.Specifically, it sought answers to the following questions:1. What are the effects of different curing methods in the compressive strength of concrete?2. What is the most effective curing method that will give the highest result for the compressive strength of concrete?

Objectives of the StudyThe general objectives of the study were to determine the effects of different curing methods applied on concrete.Specific Objectives1. To determine the effects of different curing methods in the compressive strength of concrete; and2. To determine the most effective curing method that will give the highest result for the compressive strength of concrete.Scope and Limitations of the StudyThis research focused only on determining the effects of different curing methods in the compressive strength of concrete. Curing methods were limited only to air drying method, plastic sheeting method, and water sprinkling method.

Operational Definition of TermsCompressive strength. It is the capacity of a material or structure to withstand loads tending to reduce size. It can be measured by plotting applied force against deformation in a testing machine. Some materials fracture at their compressive strength limit; others deform irreversibly, so a given amount of deformation may be considered as the limit for compressive load. Compressive strength is a key value for design of structures.Concrete. -is acomposite materialcomposed mainly ofwater,aggregate, andcement. Often, additives and reinforcements are included in the mixture to achieve the desired physical properties of the finished material. When these ingredients are mixed together, they form a fluid mass that is easily molded into shape. Over time, the cement forms a hard matrix which binds the ingredients together into a durable stone-like material with many uses.Curing. - is the process in which concrete is protected from loss of moisture and kept within a reasonable temperature range. The result of this process is increased strength and decreased permeability. Curing is also a paramount in mitigating cracks in the concrete, which severely impacts durability. Cracks allow open access for harmful materials to bypass the low permeability concrete near the surface. Adequate curing can mitigate the appearance of unplanned cracking.Slump test. - is an empiricaltest that measures the workability and consistency of fresh concrete. More specifically, it measures the consistency of the concrete in that specific batch.Universal testing machine (UTM). -also known as auniversal tester,materials testing machineormaterials test frame, is used totestthetensile stressandthe compressive strengthofmaterials. It is named so because it can perform many standard tensile and compression tests on materials, components, and structures.

Chapter IIREVIEW OF RELATED LITERATURE

Curing concrete can be defined as a chemical process that ensures the hydration of cement in newly placed concrete. The curing process is part of the chemical reaction between Portland cementand water to hydrate the product, creating a gel that can be laid down only in water-filled space. It usually involves the control of moisture loss and the temperature affecting the hydration process.Concrete must be placed, ideally between 50 degrees and 75 degreesFahrenheit, or between 10 degrees and 22 degrees Centigrade. And this temperature must be maintained during concrete curing. The curing process is vital to quality and has a strong influence on concrete properties such as durability, strength, water tightness, resistance, volume, and freezing and thawing resistance. (http://inventors.about.com/library/inventors/blconcrete.htm)Curing concrete is required to allow a transitional and constantevaporation of waterfrom the concrete mix. How soon should it start the concrete to be cured?It all depends on the environmental conditions in which the concrete was placed and whether it was placed in between forms, directly over ground, submerged in water, and others.The best practice is to cure the concrete shortly after the chemical reaction has started allowing the concrete to be hardened.Concrete should not be allowed to dry fast in any situation, and the curing conditions are likely to be maintained during the first 24 hours or at least until the final setting time of cement has passed.

Water Curing Curing concrete with waterprevents excessive loss of moisturewhen the concrete is covered with a layer of water for a predetermined period of time. Curing concrete with water allows for the control of the evaporation of moisture from the surface as the concrete gradually produces its chemical reaction that will eventually harden the concrete. Water curing can be done using the following techniques:Immersion-Immersion curing is usually done inconcrete testingfor curing concrete test specimens.Ponding- Ponding is used to cure flat surfaces on jobs or controlled areas where water could be easily ponded.Fogging- Fogging is used in circumstances where thetemperatures are above freezing and there is low humidity.Wet Covering- Curing concrete with wet covering is done after concrete has hardened sufficient enough where the covering will not damage concretes surface.

Membrane CuringMembrane curing is a process ofcontrollingthe curing ofconcretebysealing in the moisture that would be evaporate. The process is accomplished either by spraying a sealer on the surface or by covering the surface with asheetfilm.Curing concrete with membrane or plastic sheeting is the most practical and efficient wayto cure concrete in today's construction industry. Sometimes water is unavailable to cure concrete or if done using an incorrect procedure can alter thesurface finishing of your concreteproduct. Sometime adding water to concrete that has not finished its hardening process could adversely affect the hydration process, thus altering the concretes properties. A minimum thickness is required to ensure adequate strength in the sheet;ASTMC 171 Sheet Materials for Curing Concrete specifies 0.01 mm.(http//construction.about.com/od/glossary/g/astm-american-society-for-testing-and-materials.htm) Concrete should be covered with a membrane, either plastic or chemical compound that will likely seal off the pores and retard the evaporation of water from concrete.

Dry-Air CuringDry-air curing is a curing method wherein the concrete cubes are left in open air to be cured at room temperature. Researchers have been working on the natural air drying of concrete since long.

CONCEPTUAL FRAMEWORKThe conceptual model of the study is shown in the form of paradigm in figure 1. It utilizes the input, the throughput, and the output approach.The INPUT of the study consisted of information and facts from related literature, materials, tools and equipment use for casting of concrete.The THROUGHPUT covers the different process involved in determination of the effect of different curing methods in the compressive strength of concrete.The OUTPUT covers the application of different curing methods to finished concrete.The Research Conceptual Model INPUT THROUGHPUT OUTPUT-Finished concrete-determination of curing methods-curing process-information and facts from related literature-materials-tools and equipment

FEED BACK

Figure 1. The conceptual paradigm of the study

Chapter IIIMETHODOLOGYTime and Place of the studyThis research study was conducted at Barangay Sandoval, Narra, Palawan. Samples were tested at the College of Engineering and Technology, Western Philippines University, San Juan, Aborlan, Palawan.Paradigm of Activities

Determination of curing methods

Collection and preparation of materials

Mixing of concrete

Preparation of samples

Curing

Analysis

Figure 2. The Research Paradigm`

Materials, Tools and Equipment Used in the StudyMaterials:0.254 bags of Ordinary Portland Cement (40 kg)0.1413 cubic meter of sand (fine aggregates)0.2826 cubic meter of gravel (course aggregates)WaterUsed oilTools:9 pcs. 4 x 8 Polyvinyl Chloride (PVC) pipe1 pc. Shovel1 pc. Mason trowel1 pc. Polyethylene sheetEquipment:Universal testing machine (UTM)

Determination of Curing MethodsThe three curing methods used in concrete were as follows; Sprinkling Method Plastic sheeting Method Air drying MethodCollection and Preparation of MaterialsOrdinary Portland cement, course aggregates (gravel), fine aggregates (sand), and water were collected. Nine (9) pieces of four (4) inches in diameter and eight (8) inches in length polyvinyl chloride (PVC) pipe and thirty (30) inches by forty (40) inches of polyethylene sheet were also prepared.Mixing of ConcreteOrdinary Portland cement was used as the main binder. Common course aggregates and fine aggregates were also used. Lastly, fresh potable water was used to prepare the concrete and for curing purposes.Preparation of SamplesA total of (9) nine cylindrical moulds having dimensions of four (4) inches in diameter and eight (8) inches in length lubricated with oil were prepared. They were filled with Class-A mixture of concrete tamped for 25 times to expel the entrapped air and to prevent voids, and marked with initials for identification purposes. Samples were settled for 24 hours, then removed from the moulds to subject to its curing process.

Curing Curing started after removing the concrete samples from the moulds. The concrete samples were cured for 28 days. They were then subjected to air drying method where the concrete samples were left in an open air to be cured at a room temperature; plastic sheeting method, a curing method which covers the concretes surface with a polyethylene sheet which prevents the evaporation; and water sprinkling curing method where water prevents excessive loss of moisture.AnalysisAnalysis of data covers overall performance and results of the test. It was analyzed using Analysis of Variance (ANOVA) to determine the effects of different curing methods in the compressive strength of concrete.

Chapter IVRESULTS AND DISCUSSION

The samples in every treatment were cured for 28 days. After curing, the samples were subjected to Compression Test to measure their compressive strength. It was tested at the College of Engineering and Technology, Western Philippines University, Aborlan, Palawan using Universal Testing Machine (UTM).Compressive StrengthCompressive strength of concrete is the most common performance measure used by engineers in designing every structures to determine the concretes strength. This study was able to determine the effects of different curing methods in the compressive strength of concrete at the maximum curing period. Table 1.0 presents the compressive strength attained by the cylindrical concrete samples. The results revealed that the highest compressive strength of 15.79 N/mm2 was obtained by treatment 3 (Water sprinkling method) followed by treatment 2 (Plastic sheeting method) with a mean of 12.87 N/mm2 and lastly the treatment 1 (Air drying curing method) with a mean of 12.10 N/mm2.Statistical Analysis revealed that treatment 1 (Air drying curing method) and treatment 2 (Plastic sheeting method) were significantly different from treatment 3 (Water sprinkling method) but not significantly different from each other. This implies that curing of concrete with water treatment produces higher compressive strength on concrete.This implies that water curing produces higher compressive strength compare to other curing methods.Among the three curing methods used in the study water curing, for as long as sprinkling method is used, is the most effective method to cure the concrete.

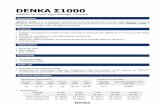

Table 1. Maximum strength for 28 days curing period.Treatment ReplicationTotalMean

1 2 3

Dry-air12.9212.3511.0536.3212.10a

Plastic sheeting14.5912.1211.9238.6312.87a

sprinkling 16.9015.2615.2147.3715.79b

Grand Total

Grand Mean

122.3113.59

Cv= 14.27%

ANOVASources of variationDegrees of freedom (DF)Sum of squares (SS)Mean of squares (MS)Computed F - valueF Tabulated5% 1%

Treatment222.9211.468.81*5.14% 10.92%

Error67.821.30

Total830.74

* = Significant Cv = 8.39%

Chapter VSUMMARY, CONCLUSION AND RECOMMENDATIONSummaryThis research study entitled Study on the Effect of Different Curing Methods in the Compressive Strength of Concrete was conducted at Sandoval, Narra, Palawan from December 2014 to February 2015. Testing of samples were done at the College of Engineering and Technology, Western Philippines University, Aborlan Palawan using Universal Testing Machine (UTM). This study was conducted to determine the effectiveness of different curing methods applied on concrete. The specific objectives were; to determine the effects of different curing methods in the compressive strength of concrete, and to determine the curing method, that will give the highest compressive strength on concrete. There were three (3) treatment used, the treatment 1 (air drying method) treatment 2 (plastic sheeting method), and treatment 3 (water sprinkling method) with three (3) replications. The proportion of cement, sand, and gravel was 1:2:4. The results revealed that the highest compressive strength of 15.79 N/mm2 was obtained by treatment 3 (water sprinkling method) followed by treatment 2 (plastic sheeting method) with a mean of 12.87 N/mm2, and treatment 1 (air drying method) with a mean of 12.10 N/mm2. Statistical analysis revealed that treatment 3 which is water sprinkling method was significantly different from other treatments but not significantly different from treatment 2 which is plastic sheeting method Therefore, concrete should be cured with water to prevent excessive loss of moisture and to increase its maximum compressive strength.ConclusionBased on the result of the study, the author concludes that water curing is the best method to cure the concrete. Proper treatment on a newly placed concrete should also be practiced.RecommendationBased from the results of the study, the researcher came up with the following Recommendations:1. The use of treatment 3 (water sprinkling method) in curing the concrete to increase the compressive strength.2. Further Study about the other curing techniques and their proper application on concrete be conducted.

BIBLIOGRAPHY

THESIS Abadines, Monica P., 2014. A study on the effect of palm bunch ash as admixture on the compressive and flexural strength of concrete

PDF FILESKholia et al., Effect on concrete by different curing method and efficiency of curing compounds -a review.

WEBSITESLambert Corporation (1999): Concrete Curing, www.lambertusa.com, 11-30-2014; 9:41 PM.www.engineeringcivil.com/assessment-of-the-properties-of-self-cured-concrete, 12-11-2014; 8:17 AM

http://www.google.com.ph/search?sclient=psyab&site=&source=hp&q=diferent+curing+methods+on+concrete&btnK=Google+Search# , 12-11-2014; 5:46 PM

http://www.google.com.ph/search?sclient=psyab&site=&source=hp&q=study+on+the+different+curing+methods+applied+on+concrete&btnK=Google+Search, 12-16-2014; 1:55 PM

APPENDICES

Computation for compressive strength Given; Diameter =100 mm Height = 200 mm Area = 7853.98 mm2For treatment 1 (Dry-air method)Replication 1: P= 101,410 NSolution; fc = P/A = 101,410 N/7853.98 mm2fc = 12.91 N/mm2 Replication 2: P = 97.020 NSolution; fc = P/A = 97,020 N/7853.98 mm2 fc = 12.35 N/mm2

Replication 3: P = 86,790 NSolution; fc = P/A = 86,790 N/7853.98mm2 fc = 11.05 N/mm2

For treatment 2 (Water Sprinkling Method)Replication 1: P = 132,770 NSolution; fc = P/A = 132,770 N/mm2 fc = 16.90 N/mm2

Replication 2: P = 11,985 NSolution; fc = P/A = 11, 985 N/7853.90 mm2 fc = 15.26 N/mm2 Replication 3: P = 124,210 NSolution; fc = P/A = 124,210 N/7853.98 fc = 15.21 N/mm2

For treatment 3 (Plastic sheeting method)Replication 1: P= 114,620 NSolution; fc = P/A = 114,620 N/7853.98 mm2 fc = 14. 59 N/mm2

Replication 2: P = 95,180 NSolution; fc = P/A =95,180 N/mm2 fc = 12.12 N/mm2

Replication 3: P = 93,600 NSolution; fc = P/A = 93,600 N/7853 mm2 fc =11.91 N/mm2

PICTORIALS

Figure 3. Curing of Concrete by Plastic Sheeting

Figure 4. Air drying of concrete samples

Moulds filled with concrete

Figure 5. Samples after sprinkling of water (water sprinkling method)

Figure 6. Samples subjected to Compressive Testxxxvii