Studio Air 2014

-

Upload

stephanie-anton -

Category

Documents

-

view

221 -

download

3

description

Transcript of Studio Air 2014

F I N A L P R E S E N T A T I O N

D E S I G N S T U D I O

A I R

S I T E C O N T E X T

D E S I G N C O N C E P T

C O P E N H A G E Nl o o k i n g t o w a r d s

a c a r b o n n e u t r a l f u t u r e

B I O M I M I C R Y C O P E N H A G E N

a growing ce l l mul ip ly ing and creat ing one ent i ty

growing knowlage of a carbon neut ra l area

I D E A O F G R O W T H A N D A D A P T A T I O N

In order to sat is fy the LAGI br ie f , as a group we sought to create an ins ta l la t ion that was re levant to the s i te . We conducted ex tens ive research on Copenhagen ’s people , c l imate , cur rent env i ronmenta l i ssues as wel l as producing energy for Copenhagen through the ins ta l la t ion o f so lar f i lm wi th in our scu lptura l des ign .

P R O J E C T D E S C R I P T I O N

In a rap id ly advancing env i ronment , we are faced wi th a problem of how to be e f f ic ient . Our pro ject successfu l ly takes the idea o f e f f ic ient energy sav ing look ing towards a carbon neut ra l env i ronment . In address ing th is issue , the panels were created on the most e f f ic ient areas o f the model a t the most appropr ia te angles . S i t t ing f la t or a t 90 degrees is a lmost use less so our des ign a l lows for the th in ‘Power F i lm ’ so lar f i lm to be p laced on the open faces o f the s tee l s t ructure . The s t r ips o f f i lm come on a ro l l however can be custom made to su i t a par t icu lar s t ructure such as ours . Fur thermore , our s tee l s t ructure is 250mm th ick pre fabr icated s tee l co lourbond panels which wi l l be jo ined on s i te wi th L imcon Angle C leat connect ions for s t ructura l in tegr i ty .

T H E T O W E R S

M A T E R I A L S

250mm th ick ga lvanised s tee l Pre fabr icated Panels 200mm th ick above 20m ta l l

B iggest : 24 .8x15 .73x16 .91m (131 .44m 2)Smal les t : 4 .88x4 .28x3 .72m (7 .65m 2))

Co lourbond f in ishEvening Haze

Expans ion jo in ts A long r idges

L imcon Angle C leats

Power F i lm Organic Photovol ta ic F i lm Customised 0 .3 wide x 730m long

D I M E N S I O N S

P R O T O T Y P ETESTING: UHU vs PVA Tab S izes Colour o f Colourbond

300 vs 200 GSM card S ize o f ho les Pos i t ion ing o f ho les Taper ing o f s t ructures for s tab i l i t y and l ive wind loads

S H A D O W T R I A L S

E X P E R I M E N T A T I O N WITH POSISIT IONING DUE TO SHADOW OVERLAP

Sun path o f C o p e n h a g e n ut i l i sed in order to p lace towers dependant upon shaddows

S T R U C T U R E

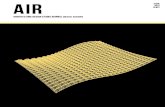

YOSHIMURA PATTERN

We researched s t ructura l e f f ic ient ways o f combin ing form wi th funct ion and found that the Yoshimura pat tern u t i l i ses in terest ing fo lds that were both s t ructura l and aesthet ic . Th is concept t ies back to the idea o f e f f ic iency expl ic i t in b iomimic sys tems and how des ign can adopt form and funct ion equal ly and s imul taneous ly .

Pat tern ing that is v is ib le in h igh ly complex b iomimic sys tems was adopted through the use o f the Yoshimura d iagonal d iamond pat tern to create an ex t remely e f focoent s t ructure that a lso has necessary sur face area for so lar sk in sheets to produce energy .

Our s t ructura l sys tem and des ign aesthet ic are in tegrated to form one

S T R U C T U R E

Prefabr icated Galvanised Stee l Panel

Power F i lm Organic Photovol ta ic F i lm Customised

C O N S T R U C T I O N D E T A I L

I M A G E O N E

Unders ide o f Pre fabr icated Stee l Panel

Power F i lm Organic Photovol ta ic customised f i lm Transparent conductor P- I -N dev ice Back meta l contact

L imcon Angle C leats

I M A G E T W O

Limcon Angle C leats

Weld ing o f pre fabr icated panels

I M A G E T H R E E

O N E

T W O

T H R E E

E N E R G Y

PowerF i lm is the f i rs t and the on ly company now that use ro l l - to - ro l l manufactur ing process to fabr icate f lex ib le so lar panels . These panels consis t o f severa l layers : t ransparent conductor , P- I -N dev ice , back meta l contact , and polymer subst ra te .

The poly imide subst ra te used for the panel makes panels f lex ib le , l ightweight , and as th in as 0 .025 mm.

The Col lectors are welded to the steel forms and a l l l ink to an underground gr id which is then connected to the main gr id o f Copenhagen

S O L A R F I L M

TOTAL AMOUNT OF POWER PRODUCED BY TEN TOWERS

PER ANNUM

= 14 ,093 ,488 kwh / y r

= 1300 s tandard res ident ia l houses / y r(assuming each household uses

10 ,837 kwh / y r )

TOWER F IVE ( the largest tower)

can power 258 s tandard homes

SURFACE AREA & ENERGY OF PANELS IN TOWERS

Tower 5 Tower 10 Other towers

=258

2743.78m 2

946.55m 2

1076.62m 2

0

20

40

60

80

100

120

0

100

200

300

400

500

600

700

Version 1 Version 2 Version 3

EFFICIENCY VS. NUMBER OF PANELS

Solar Panels collecting energy Total Solar Panels Efficency

E N E R G Y

The fo l lowing graph tes ts our three var ious so lar panel ar rangements to the r ight

E F F I C I E N C Y O F S O L A R F I L M P A N E L S

E F F I C I E N C Y O F S O L A R F I L M P A N E L S

V E R S I O N O N E

V E R S I O N T W O

V E R S I O N T H R E E

S E L E C T E D

0 20 40 60 80 100 120 140

LARGEST VS. SMALLEST PANEL

ENERGY PRODUCED IN 10,000 KWH HOMES SUPPLIED AREA COVERED

E N E R G Y

The fo l lowing graph analyses our smal les t and largest so lar f i lm panels through ca lcu la t ing the : Energy Produced by our proposal Homes suppl ied by our proposal Area covered by our proposal

A N A L Y S I S O F S O L A R F I L M P A N E L S

A N A L Y S I S O F S O L A R F I L M P A N E L S

S M A L L E S T P A N E L

L A R G E S T P A N E L

0

200

400

600

800

1000

1200

TOWER 1 TOWER 2 TOWER 3 TOWER 4 TOWER 5 TOWER 6 TOWER 7 TOWER 8 TOWER 9 TOWER 10

AREA OF PANELS IN TOWERS

AREA

0

1000000

2000000

3000000

4000000

TOWER 1 TOWER 2 TOWER 3 TOWER 4 TOWER 5 TOWER 6 TOWER 7 TOWER 8 TOWER 9 TOWER 10

ENERGY PRODUCED IN TOWERS

ENERGY PRODUCED

E N E R G Y

A R E A O F S O L A R F I L M P A N E L S

E N E R G Y P R O D U C E D B Y S O L A R F I L M P A N E L S

0

200

400

600

800

1000

1200

TOWER 1 TOWER 2 TOWER 3 TOWER 4 TOWER 5 TOWER 6 TOWER 7 TOWER 8 TOWER 9 TOWER 10

AREA OF PANELS IN TOWERS

AREA

0

1000000

2000000

3000000

4000000

TOWER 1 TOWER 2 TOWER 3 TOWER 4 TOWER 5 TOWER 6 TOWER 7 TOWER 8 TOWER 9 TOWER 10

ENERGY PRODUCED IN TOWERS

ENERGY PRODUCED

0

200

400

600

800

1000

1200

TOWER 1 TOWER 2 TOWER 3 TOWER 4 TOWER 5 TOWER 6 TOWER 7 TOWER 8 TOWER 9 TOWER 10

AREA OF PANELS IN TOWERS

AREA

0

1000000

2000000

3000000

4000000

TOWER 1 TOWER 2 TOWER 3 TOWER 4 TOWER 5 TOWER 6 TOWER 7 TOWER 8 TOWER 9 TOWER 10

ENERGY PRODUCED IN TOWERS

ENERGY PRODUCED

A R E A O F S O L A R F I L M P A N E L S

E N E R G Y P R O D U C E D B Y S O L A R F I L M P A N E L S

0

200

400

600

800

1000

1200

TOWER 1 TOWER 2 TOWER 3 TOWER 4 TOWER 5 TOWER 6 TOWER 7 TOWER 8 TOWER 9 TOWER 10

AREA OF PANELS IN TOWERS

AREA

0

1000000

2000000

3000000

4000000

TOWER 1 TOWER 2 TOWER 3 TOWER 4 TOWER 5 TOWER 6 TOWER 7 TOWER 8 TOWER 9 TOWER 10

ENERGY PRODUCED IN TOWERS

ENERGY PRODUCED

P L A N 1 : 5 0 0 A T A 1

P L A N 1 : 5 0 0 A T A 1

S O U T H E L E V A T I O N 1 : 5 0 0 A T A 1

S O U T H E L E V A T I O N 1 : 5 0 0 A T A 1

S E C T I O N1 : 5 0 0

S E C T I O N1 : 5 0 0

W E B F O R G E S Y S T E M F O R P L A T F O R M

openings c lose to p la t form coverd in mesh for sa fe ty reasons

B O R E D P I L E S Y S T E M

Depth o f the p i les dependant upon the geotechnica l repor t under the Engineers approval

B A L U S T R A D E S Y S T E M

1.4m galvanised b lack ra i l ing for sa fe ty reasons

L I G H T H O U S EE X P E R I E N T I A L Q U A L I T I E S

L I G H T H O U S EE X P E R I E N T I A L Q U A L I T I E S

P R O J E C T S A M 2 0 1 4

S T E P H A N I E A N T O N O P O U L O S M A T K O M A T K O V I C

A N N A J I A N G

P R O J E C T S A M 2 0 1 4

S T E P H A N I E A N T O N O P O U L O S M A T K O M A T K O V I C

A N N A J I A N G