STT 3000 Series STT150 - RS Components...

Transcript of STT 3000 Series STT150 - RS Components...

PRODUCT OF FRANCE Issue 1 - 12/99 EN1I-6248

STT 3000 Series STT150PROGRAMMABLE TEMPERATURE TRANSMITTER

Models STT15R, STT15U, STT15S

Operator Manual

STT150 Operator Manual 12/99

TABLE OF CONTENTS

1. OVERVIEW ...................................................................................................................................... 11.1. Model STT15R.......................................................................................................................... 11.2. Model STT15U.......................................................................................................................... 11.3. Model STT15S .......................................................................................................................... 1

2. CONFIGURATION TOOLKIT .......................................................................................................... 1

3. TECHNICAL SPECIFICATIONS ..................................................................................................... 2

4. THEORY OF OPERATION.............................................................................................................. 34.1. Input sensors............................................................................................................................. 44.2. Transmitter output levels........................................................................................................... 4

5. INSTALLATION AND COMMISSIONING....................................................................................... 5

6. MAINTENANCE/TROUBLESHOOTING......................................................................................... 76.1. Critical Status Messages........................................................................................................... 76.2. Non Critical Status Messages................................................................................................... 7

7. DIGITAL INDICATION METER ....................................................................................................... 87.1. Introduction ............................................................................................................................... 87.2. Connection Information............................................................................................................. 87.3. Installation/Commissioning ....................................................................................................... 97.4. Diagnostic and Troubleshooting ............................................................................................... 9

12/99 STT150 Operator Manual 1

1. OVERVIEW

The Series STT150 Temperature Transmitter is a microcontroller based unit suitable for accepting awide variety of thermocouples (T/C’s) and resistance temperature detectors (RTD’s). Alternatively,miscellaneous millivolt or ohm based sensors can be connected and the unit will correct the non-linearity of the sensor by using a powerful polynominal compensation.The transmitter is 2 wire loop-powered and gives a 4-20 mA output linearized to temperature.Sensor leadwire compensation is provided for 3 wire RTD’s and internal cold junction compensation isprovided for T/C’s.The compact design allows mounting into most types of housing (e.g. DIN 43729 Form B) orconnection heads available in the market.

Depending on application requirements, the following models are recommended:

1.1. Model STT15R

For RTD type measurements or T/C (with ungrounded or isolated tip) measurements. Using thismodel in combination with grounded sensor types may cause ground loops and introducemeasurement errors. Be aware that, although the sensor may be isolated when new, environmentalconditions such as high humidity, chemical contamination, etc., can reduce the isolation and errorsmay occur some time after installation.

1.2. Model STT15U

For measurements requiring galvanic isolation between the sensor and the transmitter output. Thegalvanic isolation overcomes the most common ground loop problems in temperature measurements.

1.3. Model STT15S

For applications where intrinsic safety is the protection mode for hazardous areas. This model alsoincludes galvanic isolation between input and output.

2. CONFIGURATION TOOLKIT

This tool allows the user to utilize all the versatile functions of the STT15R/U/S.� Measurement configuration: Sensor type, range, linearization, engineering units, output settings,

filter activation, etc.� Monitoring of sensor status: Sensor break detection.� On-screen real time presentation of measured values and output signal in the form of numerical

values and bargraphs.� Transmitter calibration: Field calibration in two points.� Documentation: Configuration files can be saved for future use.� Certificates can be easily printed.

2 STT150 Operator Manual 12/99

3. TECHNICAL SPECIFICATIONS

This chapter provides additional information to the product specification sheet EN0I-6063.

The figure below indicates the load resistance versus voltage of the two-wire power/current loop.

Supply Voltage [Vdc]

652

00

250

1130

9.0 35.0

LoopResistance[Ohms]

14.8 24.0

Operatingarea

Below, the default shipping parameters of the transmitter if no special configuration is specified.

Tag ID : XXXXXXXXSensor Type : Pt100D

Sensor break detection : ONLRV (0%) : 0°C (32°F)

URV (100%) : 100°C (212°F)Failsafe Direction : Upscale

Failsafe High value : 21.80 mAFailsafe Low value : 3.60 mA

Overrange value : 20.80 mAUnderrange value : 3.80 mA

Line filter : 50 HzDamping : 0 Second

12/99 STT150 Operator Manual 3

4. THEORY OF OPERATION

The functional block diagram of the transmitter is shown in the figure below:

CJCA/D

converter

EEprom

Micro-controller

D/Aconverter

+

_

RS232interface

32

1

Voltagereference Connector

Only forSTT15U/S

Sensorinput

4-20 mA

Currentsource

Terminalvalue

Optos

Galvanicisolation

Inputs are sampled at a rate of 1 time per second, digitized by the analog-to-digital (A/D) converter,compensated for cold junction temperature or resistance of lead wires (in 3 wire mode only). Thesensor signal is checked by a diagnostic service to check the signal integrity. Digital data is thenlinearized and converted into the selected engineering units e.g. °C. The measurement is then rangedto the lower and upper range values (LRV & URV) which are held in non volatile memory, and thenconverted back to an analog signal. Any configuration changes are held in non volatile memory so thatthey are secured against power failure.The transmitter configuration can be changed by using the Configuration Toolkit. This tool allows theconfiguration of all parameters, printout of configuration/calibration data, archiving, monitoring andcalibration. Use the help menu of the tool to obtain a comprehensive explanation of the variousparameters.

The transmitter continuously performs internal diagnostics to give maximum reliability of the outputsignal and to help the user to identify any problems. The diagnostics can be entered into twocategories:� Critical status messages will drive the output to Failsafe since a reliable output can not be

guaranteed.� Non-critical status messages will inform the user about a possible problem or transmitter

behaviour. See the troubleshooting section for detailed explanation.

4 STT150 Operator Manual 12/99

4.1. Input sensors

4.1.1. RTD (Resistance Thermometer Device)The transmitter supports both 2-wire and 3-wire RTD’s, see the installation sheet for detailedconnections.3-wire RTD measurements eliminate the sensor leadwire resistance by using a compensation wire.For optimal compensation, all leadwires should have identical resistance, same length, diameter,material, etc.

4.1.2. T/C (Thermocouple)The transmitter is automatically compensated for the cold junction temperature effect. The T/C leadwire resistance is automatically corrected up to a value of 50 ohms. Ensure that the thermocouplewires are connected directly to the transmitter terminals or by using extension/compensation wires.Never use copper wires between the thermocouple and transmitter since the cold junctioncompensation can not be performed in this way.

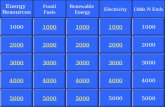

4.2. Transmitter output levels

To ensure that the transmitter operates reliable in the application, it is important to have anunderstanding of the different output levels.

0%(4 mA)

100%(20 mA)

LowerRangeValue

UpperRangeValue

UnderRange

OverRange

FailsafeHigh

(Upscale)

FailsafeLow

(Downscale)

-1.25%(3.8 mA)

-2.5%(3.6 mA)

105%(20.8 mA)

111.25%(21.8 mA)

Normal Operating Range

Extended Operating Range

In normal operation, the transmitter will vary the output between Lower Range Value (LRV) and UpperRange Value (URV). For example, if the process temperature varies normally from 10°C to 70°C, thenit may be decided to set the LRV to 0°C and the URV to 80°C.When the process temperature goes over 80°C, then the transmitter output will enter the extendedrange. This extended range is linear until it reaches the Over Range percentage, in the aboveexample, this will be 105% � 80°C = 84°C. If the process temperature goes beyond the extendedrange, then the output will saturate at the configured Over Range percentage.In case the transmitter detects a critical status by the internal diagnostic service, then the output willbe driven to the Upscale or Downscale output value.Depending on the application, the receiving device will take the appropriate actions to bring theprocess back into the normal operating range. Ensure that the transmitter output settings match thereceiving or alarm device configuration.The Under Range, Over Range as well as the Failsafe Low and Failsafe High values can be changedby using the Configuration Toolkit to meet the appropriate safety standards or guidelines.

12/99 STT150 Operator Manual 5

5. INSTALLATION AND COMMISSIONING

A comprehensive installation sheet is provided with every unit explaining the mechanical and electricalinstallation.If you need to change the configuration of the transmitter, connect the interface to the PC RS232 portand transmitter programming connector, power the transmitter with a 9 volts battery without any loopresistance or a power supply according to the installation sheet.Once the configuration is completed, it is recommended that the tag identifier, sensor type and spanbe written on the adhesive label which is provide with the unit. This minimises use of the configurationtool during future maintenance or handling activities.

If a bench check is intended, the equipment needed is:- An input sensor suitable for the required application or an equivalent calibrator which simulate the

sensor (RTD, T/C, mV or ohms)- A nominal 24 Vdc power supply with less than 100 mV peak ripple and able to supply at least

25 mA- PC based Configuration Toolkit with RS232 programming interface- Connection wiring and accurate 250 ohms resistance with low temperature drift- A Digital Volt Meter (DVM) with range covering 0-5 Vdc. If a high speed sampling DVM is used,

a 1 Hz averaging filter is recommended.

Note 1: If you are going to check the calibration using a thermocouple input, ensure that the coldjunction temperature is stabilized. After connecting and powering up all equipment, includingthe transmitter, protect the transmitter from air drafts and allow at least 1 hour before takingreadings.

Note 2: Output measurement could be made directly by using an milliammeter.

Grounding and shielding techniques:The current output signal will operate in either a floating or grounded system. If the signal appearsnoisy or erratic, it is recommended to ground the loop at the negative terminal of the power supply.Shielding should only be connected to ground at one point to avoid ground loops.

6 STT150 Operator Manual 12/99

Mounting Module in Housing:The STT150 module can be installed in a variety of housings suitable for direct head mounting,2'' (50 mm) pipe mounting or wall mounting.Ensure that the installation location is suitable for reliable transmitter operation (e.g. for hightemperature applications, a thermowell extension is recommended to minimize failure rates due tohigh ambient temperatures near the transmitter).

FIELD MOUNT HOUSINGWITH METERRIGHT VIEW

FIELD MOUNT HOUSINGWITHOUT METER

RIGHT VIEW

FIELD MOUNT HOUSINGWITH OR WITHOUT

METER FRONT VIEW

A46188467-201

AB B

142(5.59)

40(1

.57)

59.5

(2.3

4)

60 (2.3

6)

94(3.7)115

(4.53)

Wall Mounting Dimensions

FIELD MOUNT HOUSING WITHOR WITHOUT METER (FRONT VIEW)

14,9[0.59]

FIELD MOUNT HOUSING WITH METER (RIGHT VIEW)

FIELD MOUNT HOUSINGWITHOUT METER

(RIGHT VIEW)

14,9[0.59]

CLEARANCE FOR CAPREMOVAL CLEARANCE FOR CAP

REMOVAL

AB

AB

142[5.59]

40 [1.5

7]

191,

5[7

.54]

60[2

.36]

61,8

[2.4

3]

39[1

.54]

94[3.7]

115[4.53]129,5

[5.1] 46188468-201

Pipe Mounting Dimensions

Dimensions Aluminium(field mount housing)

316 Stainless Steel(field mount housing)

A B A BWithout integral meter 70 mm

[2.76 inch]120,8 mm[4.76 inch]

95,5 mm[3.76 inch]

146,3 mm[5.76 inch]

With integral meter 127 mm[5.00 inch]

210,8 mm[8.30 inch]

127 mm[5.00 inch]

210,8 mm[8.30 inch]

12/99 STT150 Operator Manual 7

6. MAINTENANCE/TROUBLESHOOTING

Due to the self compensating electronics and autocalibration of the measurement system,recalibration is seldom required.Maintenance of the STT150 transmitter is limited to ensuring that the connections, seals and mountingare tight and secure. There are no moving parts or adjustments, thus, the only reason to open thehousing is to inspect for corrosion or conductive dust entry which could later affect reliable operation.

WARNING: The transmitter module itself is not repairable and should NEVER be opened.

Troubleshooting in the field is in many cases limited to checking of output current, appropriate voltageat the transmitter terminals and the sensor resistance. More detailed examination has to be done inthe maintenance shop using the PC based Configuration Toolkit. Connect your Configuration Toolkitto the transmitter and use the monitoring function to analyse if there are any status messages thatappear. Note that a failsafe output signal (Up or Down) is always caused by a Critical Status message.Below the list of possible messages and recommendations to solve the problem.

6.1. Critical Status Messages

- Input open or wire broken (RTD and T/C). Correctness of wiring is checked, this message canbe caused by a sensor failure or loose connection.

- Short circuit of RTD element (resistance < 5 � is considered as a short). If the RTD sensor hasa much smaller resistance than the values defined by the standard at low temperatures, then thesensor is considered as failed.

- Non Volatile Memory configuration corrupted. All transmitter configuration parameters arestored into this memory and protected by a checksum. This message will appear wheninconsistency occurs between the database contents and checksum. This may be caused bypower interruptions during configuration. Downloading a new configuration will solve this problemin most cases.

- Non Volatile Memory communication failure. This message will appear if the transmitter cannotproperly access the configuration database.

- Critical Ambient Temperature. If the transmitter is operating far beyond the extreme ambientoperating temperatures, this status will appear. These temperatures are: < -55°C and > 100°C.

6.2. Non Critical Status Messages

- Ambient Temperature out of specification. This diagnostic message appears when thetemperature is between: -40°C and –55°C or 85°C and 100°C.

- Configuration update not completed. This message can occur when the configuration downloadfrom PC to transmitter is not successfully completed. Possible causes are power failure ordisconnection of the programming interface.

- Output mode. This message indicates the user that the output value does not reflect a measuredvalue but a manually set output percentage. The output can be restored to normal by eitherclearing the output mode or cycling the power.

- Suspect input. This message is generated when the sensor fault detection is deactivated and theinput is open.

- User Sensor Calibration Activated. This message informs the user that a special sensorcalibration is used instead of the normal factory calibration. Resetting the user calibration clearsthis message.

8 STT150 Operator Manual 12/99

7. DIGITAL INDICATION METER

7.1. Introduction

The optional integral digital meter, only available with the Honeywell fieldmount housing, is suppliedalready installed by the factory and provides a display of the transmitter output. The meter displays alarge bargraph accurate to �3% and visible from 10 meters away. The 4 ½ digit display shows theoutput in % of span or in engineering units and includes various status message/unit information onthe LCD screen.The meter obtains its power in series with the transmitter and requires 2.25 V power supply in additionto the transmitter’s 9.0 V (i.e. 11.25 V minimum supply volts). The minimum loop operating current is3.8 mA.

WARNING: The meter is set in the factory to the same temperature range as the transmitter ifdegrees are specified as engineering units. Re-ranging the temperature transmitter with the PC basedconfigurator will create a wrong temperature indication. Contact your local Honeywell office ordistributor for the application note of re-ranging the digital indicator.

7.2. Connection Information

Wire the meter as shown in the figure below:

Meter Connections - Wiring for smart meter

12/99 STT150 Operator Manual 9

7.3. Installation/Commissioning

After wiring the meter as shown in the previous figure and powering up the transmitter loop, verify thatthe display operates as expected. The digital meter may require access to its configuration pushbutton which is accessible via a hole on the side. This push button enables configuration of thepreferred engineering unit and meter zero/span calibration for a 4-20 mA signal. When the loop poweris applied, the meter runs a self test diagnostic for about 10 seconds to determine correct loopoperation.

Changing engineering units:Press button on the side of the meter to scroll through the display codes to the preferred engineeringunit selection. The display codes are EU1, EU2, ..., EUF (and CAL).

For the STT150: EU1 gives °C displayed on the LCD screenEU2 gives °F displayed on the LCD screenEU3 converts to °K (add on the stick-on label)EU4 converts to °R (add on the stick-on label)EU5 converts to mV (add on the stick-on label)EU6 converts to volts (add on the stick-on label)EU7 converts to ohms (add on the stick-on label)EU8 to EUF gives % (of span) displayed on the LCD screen.

Ignore "CAL" at this stage or refer to Section 7.4.3.Press and hold the button until the desired display code appears. Release the button and the displayreverts to the selected unit display. The Smart Meter is now configured for use. Replace the metercap.

7.4. Diagnostic and Troubleshooting

Every time power is cycled to the transmitter/meter combination, the Smart Meter runs a self test tocheck internal operations and switches on all display segments as shown in the figure below for up to10 seconds. This enables confirmation of their operation.

DIGITAL READOUT

(-19990 to +19990)

17-SEGMENT BARGRAPH(0 to 100%)

ENGINEERING UNIT

INDICATOR

PUSH BUTTON LOCATIONSTATUS MESSAGE

Horizontal Style Bargraph

10 STT150 Operator Manual 12/99

7.4.1. Failed self testIf the self test fails, the display will go blank (i.e. revert to the unpowered display showing only thebasic bargraph outline). Note that some of the temporarily switched on segments should only be seenwith an STT150 in this initial self check e.g. "K" for a 1,000 engineering unit multiplier (only forreadings over 20,000), "GPH", "GPM", "mmHg", "PSI", "%", "FLOW" and "inH20" (only used for flowand pressure transmitters)."ANALOG" is normally switched on the LCD. The display should have a partially switched on bargraphcorresponding to the transmitter % of span output signal and the corresponding digital display in % ofthe selected units.

7.4.2. Meter Fault ConditionsThe various possible fault conditions with corrective action are:

1. At power up, the LCD stays completely blank. Either the self check failed or the meter is notreceiving power. Check the connections.Verify adequate loop power is available.

2. At power up after showing all LCD segments, the display shows "BAD XMTR STATUS" and"_ _ _" instead of the digital engineering unit display. This means that the meter received a criticalstatus diagnostic message from the transmitter at power up. Use the configuration tool todetermine the critical status cause and correct.

3. After successful power up, the display shows "BAD XMTR STATUS" and the bargraph flashes.This means that a critical status condition occurred during operation. The display value may not becorrect. Use the configuration tool to determine the cause and correct.

4. After successful power up, the display shows "FAULT-LAST KNOWN VALUE" and the bargraphflashes. This means that the on-going self diagnostics of the meter detected an internal fault.Cycle the power to see if the condition self clears. If it recurs, check loop wiring for adequate looppower and minimize electrical noise in the loop.

5. The display shows "ANALOG", "0.0%" and no bargraph segments switch on. This means that theSmart Meter requires calibration to the transmitter. (See section 7.4.3.)

7.4.3. 4-20 mA Calibration of the meter

The meter is factory calibrated to convert the received 4-20 mA signal to an engineering unit or 0 to100% of span display. Regardless of the transmitter's actual PV output, a display of 0.0% outputmeans that the meter requires recalibration (See below).

Calibration is beneficial to ensure display accuracy with a 4-20 mA analog signal. It is unnecessary torecalibrate the meter since it is factory calibrated before shipment. However, the facility is included incase recalibration for time drift or transmitter end point offsets are required.Basically, accurate 4 and 20 mA signals are provided to the meter with the "CAL" configuration buttonselected. The 4 and 20 mA signals can be conveniently provided by using the configuration tool toswitch the transmitter to "OUTPUT MODE".

The full calibration procedure for the meter is:

� Step 1 - Put control loop to Manual and use the configuration tool to establish communications.Put the transmitter into 0% output mode by using the PC based configuration tool.

� Step 2 - Press and hold side button on meter. Release the button when "CAL" appears on thedisplay. The meter will now carry out a zero (LRV) calibration and revert to normal operation.

� Step 3 - Change output mode value to 100%.

12/99 STT150 Operator Manual 11

� Step 4 - Press and hold side button on meter. Release button when "CAL" appears on thedisplay. The meter will now carry out a span (URV) calibration and revert to normal operation.Clear the forced output mode to revert transmitter to continuous output operation. Return loop toAutomatic operation.

ATTENTION - If "bAd" appears on the meter display after Step 2 or 4 then the 4 mA or the 20 mAsignal was not within the meter's acceptable accuracy range and calibration was aborted. Check themA values and repeat calibration steps as required.

12 STT150 Operator Manual 12/99

8/02 EN1I-6248-A1 (Addendum to EN1I-6248) 1 of 10

STT 3000 Series STT150Programmable TemperatureTransmitterModels STT15R, STT15U, STT15S

EN1I-6248-A18/02

Addendum(to Operator Manual

EN1I-6248)

Overview ATEX Directive 94/6/EC

The ATEX Directive 94/6/EC is a European CE Mark directive concerning productsthat are designed for use in potentially explosive environments. This “NewApproach” directive is based on, and is an expansion of, European Norms (EN,CENELEC standards).

On June 30, 2003, the ATEX (ATmospheres EXplosibles) directive will replacedirectives currently in effect, and from that time, only products with the ATEXcertification and with ATEX labeling will be approved for free movement in the 19EU (European Union) and EFTA (European Free Trade Association) countries. Asdefined in the directive, “free movement” refers to:

� placing a product on the market, and/or

� placing a product into service.

The ATEX Directive 94/6/EC is a living (set of) document(s), subject to furtherchange and refinement, whose details are beyond the scope of this addendum.Further information can be obtained in the Official Journal of the EuropeanCommunities No L100/1, and in related publications such as Guidelines on theApplication of Directive 94/9/EC. Both of these items are available at:

http://europa.eu.int/comm/enterprise/atex/index.htm

Products that have been previously certified under the EN and CENELEC EuropeanNorms, and which comply fully with all standards in the New Approach directivehave, by application, received certification under ATEX Directive 94/6/EC.

The Honeywell STT 3000, Models STT15_ Temperature Transmitter is now ATEXcertified, and all units manufactured currently and in the future will include labelingthat includes all markings required under the ATEX directive.

Inclusions To ensure that all required information will be available to the user, the followingitems are include with this Addendum for reference:

1. Declaration of Conformity – ATEX CE0344 (Honeywell document number51452505 Revision A).

2. Certificate of Manufacturer II G EEx nA ATEX CE (Honeywell documentnumber 51452325 Revision B).

2 of 10 EN1I-6248-A1 (Addendum to EN1I-6248) 8/02

Purpose andContent of thisAddendum

This Addendum includes information required under the ATEX Directive regarding:

1. The appearance and meaning of each certification mark (CE Mark) that appears onthe label(s) affixed to the product.

2. Instructions for installation and use of the product.

Information required for use of this product is given in:

EN1I-6248 STT 3000 Series STT150 Programmable Transmitter ModelsSTT 15R, STT 15U, STT 15S Operator Manual,

of which this Addendum is a part.

Details regarding certification marks that appear in labeling for this product are given inthis addendum.

Attention

The publication cited above and the functioning and construction (except forlabeling) of the devices described therein are essentially unchanged. Thepurpose of this addendum is to provide details of the purpose andappearance of the labels attached to each device under ATEXDirective 94/6/EC.

Attention

Before installing the equipment in a potentially explosive atmosphere, pleaseread the information provided in this Addendum, which supports the ATEXcertifications for this product.

CE Conformity The Honeywell STT 3000 Model STT150 Smart Temperature Transmitter is inconformity with the protection requirements of the following European CouncilDirectives: 94/9/EC, the Explosive Atmospheres (ATEX) Directive, and 89/336/EEC,the EMC Directive. Conformity of this product with any other “CE Mark”Directive(s) shall not be assumed.

Deviation from the installation procedures and conditions specified in the Operator’sManual may invalidate this product’s conformity with the ATEX and EMCDirectives.

Conformity of this product with any other “CE Mark” Directive(s) shall not beassumed.

8/02 EN1I-6248-A1 (Addendum to EN1I-6248) 3 of 10

Marking,ATEX Directive

Honeywell’s STT 3000, Model STT 150 Smart Temperature Transmitter, with thefollowing nameplates attached, has been certified to comply with Directive 94/9/ECof the European Parliament and the Council as published in the Official Journal of theEuropean Communities No. L 100/1 on 19-April-1994.

The following information is provided as part of the labeling of the transmitter:

� Name and Address of the manufacturer: Honeywell, Phoenix, AZ 85053 USA.

� Notified Body identification: KEMA Quality B.V., Arnhem, the Netherlands

� Complete model number (See the Model Selection Guides 34-44-16-05 and 34-44-16-06.)

The serial number is 10 digits long. The first digit is the STT Type (R, U, or S.)The second digit is the year code (0-9). The third and fourth digits are the weekcode (in hexadecimal). The remaining six digits are the serial number.

4 of 10 EN1I-6248-A1 (Addendum to EN1I-6248) 8/02

Specific Parametersfor Intrinsic Safety

Field terminal parameters:Supply (+/-): Ui = 30 V, Ii = 100 mA, Pi = 1.2WWithout internal lightning protection:- without indicator: Li � 0 (negligible), Ci = 27 nF- with ME indicator: Li � 150 µH, Ci = 27 nF- with SM indicator: Li � 0 (negligible), Ci = 27 nFWith internal lightning protection:- without indicator: Li � 45 µH, Ci = 27 nF- with ME indicator: Li � 195 µH, Ci = 27 nF- with SM indicator: Li � 0 45 µH, Ci = 27 nFSensor entry terminals:

Uo � 10 V (terminals 1-3 and 1-2)Io � 10 mA (terminals 1-3)Io � 8.3 mA (terminals 1-2)Co � 24 nFLo � 100 µH

Special conditionsfor safe use,

Intrinsic Safety (X)

The temperature transmitter is an intrinsically safe apparatus that can be installed inpotentially explosive atmospheres.

The power terminals (+, -) must be connected only to a certified associatedintrinsically safe apparatus.

The sensor entry terminals (1, 2, and 3) must only be connected to certifiedintrinsically safe equipment, or in accordance with paragraph 5.4 of standard EN50020.

The electrical parameters (U, I, and P) of the associated apparatus connected to thepower terminals (+, -) must not exceed the following values:

Ui � 30V Ii � 100 mA Pi � 1,2 W

The electrical parameters (L and C) of the apparatus connected to the sensor terminals(1, 2, and 3) must not exceed the following values:

Cext � 2.9 µF and Lext � 10 mH

Ambient temperature: - 50ºC to 85ºC

Temperature classification: T6 up to Ta � 50ºC

T5 up to Ta � 85ºC

The jumper J1 may only be installed or removed when the area is known to be non-hazardous (Umax � 30 V).

8/02 EN1I-6248-A1 (Addendum to EN1I-6248) 5 of 10

Specific Parametersfor FlameproofInstallation

Power supply to field wiring terminals, + and –: Ucc � 35 V

Output Signal: 4 – 20 mA

Special conditionsfor safe use,FlameproofInstallation

Ambient operating temperature: -50 to 85ºC

Specific Parametersfor Non-SparkingZone 2 Installation(Honeywell certified)

Supply Voltage:

Supply Current:

Ambient Temperate Limits:

Temperature Classification:

9-30 Vdc

23 mA

-50oC to 85oC

T6 at Ta ≤ 65oC

6 of 10 EN1I-6248-A1 (Addendum to EN1I-6248) 8/02

Special Conditionsfor Safe Use,Non-SparkingZone 2 Installation

(Honeywell certified)

� The installation of this equipment in Zone 2 hazardous areas must comply withVDE specification 0165, IEC 60079-14, EN 50021 and/or valid national standardsfor installation and operation.

� Before commissioning of this equipment, it must be verified that the power supplyvoltage cannot exceed the 42 Vdc maximum for 4-20 mA analog and DEequipment.

� The electronic assemblies in these units are non-repairable items and if faulty mustbe replaced. The electrical power supply must be switched off before anyreplacement and during any time that the wiring terminations are being connectedor disconnected.

8/02 EN1I-6248-A1 (Addendum to EN1I-6248) 7 of 10

51452505, Revision A

DECLARATION OF CONFORMITY

ATEX 0344We declare under our sole responsibility that the following products,

STT3000 Smart Temperature Transmitters(per attached list)

to which this declaration relates, are in conformity with the protection requirements of Council Directive:94/9/EC (ATEX Directive) on the approximation of the laws of the Member States concerning equipmentand protective systems intended for use in potentially explosive atmospheres, and 89/336/EEC (EMCDirective) as amended by 92/31/EEC and 93/68/EEC on the approximation of the laws of the Member Statesrelating to Electromagnetic Compatibility.

The models covered by this Declaration and evidence of conformity with the ATEX Directive are shown onthe attached list. Conformity to the ATEX Directive is in accordance with the following Europeanstandards.

EN 50014-1997 Electrical Apparatus for Potentially Explosive Atmospheres - General Requirements

EN 50018-2000 Electrical Apparatus for Potentially Explosive Atmospheres - Flameproof Enclosure “d”

EN 50020-1994 Electrical Apparatus for Potentially Explosive Atmospheres - Intrinsic Safety "i"

EN 50284-1999 Special Requirements for Construction, Test and Marking of Electrical Apparatus ofEquipment Group II, Category 1 G

Manufacturer: Honeywell International Inc.16404 Black Canyon HighwayPhoenix, Arizona 85053 USA

The authorized signatory to this declaration, on behalf of the manufacturer, and the Responsible Person isidentified below.

Honeywell International Inc.

Industrial Measurement & Control1100 Virginia DriveFort Washington, PA 19034 USA

Frederick M. KentStandards & Approvals Engineer,(ATEX Authorized Person)

Issue Date: 19 August, 2002

8 of 10 EN1I-6248-A1 (Addendum to EN1I-6248) 8/02

STT3000 Temperature Transmitters

Certificate Protection Configuration Model Model Description

LCIE 02ATEX6070X

II 1 G,EEx ia IIC

Module only ‘ia’ STT15S-_-… Module only ‘ia’ Smart TemperatureTransmitter, 4-20 mA,Galvanic isolated,Intrinsically Safe

LCIE 02ATEX6080X

II 2 G,EEx d IIC

Module mountedin ‘d’ enclosureonly

STT15R-_-E__-… Module mounted in‘d’ enclosure only

Smart TemperatureTransmitter, 4-20 mA,Non-isolated

LCIE 02ATEX6080X

II 2 G,EEx d IIC

Module mountedin ‘d’ enclosureonly

STT15U-_-E__-… Module mounted in‘d’ enclosure only

Smart TemperatureTransmitter, 4-20 mA,Galvanic isolated

8/02 EN1I-6248-A1 (Addendum to EN1I-6248) 9 of 10

51452325, Revision B

CERTIFICATE OF MANUFACTURER

EEx nA IIC ATEX This certificate applies to the following equipment:

Series STT 3000 Programmable Temperature Transmitter,

Models STT15R, STT15U, STT15S, (Module)This equipment has no arcing or sparking parts and no ignition capable hot surfaces and therefore conformsto Clause 6.3.1.3. of VDE 0165/2.91 and IEC 60079-14 for operation in Zone 2 hazardous areas providingthe following conditions are observed. The equipment contains no intrinsically safe or energy limitingcomponents. The model STT15S is a 2-wire devices receiving its power and signal carrier from the same 4-20 mA signal current. The STT15S supports thermocouple and 2 or 3-wire RTD sensor inputs. In normaloperation, the maximum current is 23 mA.

Conditions for the application of the above equipment in Zone 2 hazardous areas:1. The installation of this equipment in Zone 2 hazardous areas must comply with VDE specification 0165,

IEC 60079-14 and/or valid national standards for installation and operation.

2. Before commissioning of this equipment, it must be verified that the power supply voltage cannotexceed the 30 Vdc maximum for the STT15S transmitters.

3. The temperature transmitter module is a non-repairable item and if faulty must be replaced. Theelectrical power supply must be switched off before any replacement and during any time that the wiringterminations are being connected or disconnected.

4. The technical data supplied by the manufacturer must be adhered to.

Specifications for Use in Zone 2Supply Voltage: 9 to 30 Vdc

Ambient temperature limits: –50 to 85°C

Temperature Classification: T6

Manufacturer:Honeywell International Inc.16404 Black Canyon HighwayPhoenix, Arizona 85053 USA

Honeywell International Inc.Industrial Measurement & Control1100 Virginia DriveFort Washington, PA 19034 USA

Frederick M. KentStandards & Approvals Engineer,

(ATEX Authorized Person)

Issue Date: 16 August, 2002

STT3000 Temperature Transmitters

10 of 10 EN1I-6248-A1 (Addendum to EN1I-6248) 8/02

Certificate Protection Configuration Model Description

LCIE 02 ATEX6080X

II 2 G, EEx d IIC Module mounted in‘d’ enclosure only

STT15R-_-E__-… Smart Temperature Transmitter, 4-20 mA,Non-isolated

LCIE 02 ATEX6080X

II 2 G, EEx d IIC Module mounted in‘d’ enclosure only

STT15U-_-E__-… Smart Temperature Transmitter, 4-20 mA,Galvanic isolated

LCIE 02 ATEX6070X

II 1 G, EEx ia IIC Module only ‘ia’ STT15S-_-… Smart Temperature Transmitter, 4-20 mA,Galvanic isolated, Intrinsically Safe