StrudynaTension plate V1.0

description

Transcript of StrudynaTension plate V1.0

Intropage 2-4.

Menupage 5.

Componentspage 14-22.

Technical Datapage 6-13.

sTrudynA

sTrudynA

Architectural High Tensile Tension Plate Systems Tension plATe V1.0

Tension plATE Tension plATE

SYSTEMS

page 2 strudyna.com

Stainless Steel Tension plate system

Structural Tensile plate systems complete the tie back solution for all the Strudyna architectural high tensile tie-rod system. The welding system was designed so it can be welded on site as required for any project. The carefully designed and engineered cast tension plate range has been specifically produced for work in conjunction with Strudyna Architectural tie-rod systems.

Stainless Stee

STRUCTURAL TENSION PLATE

SCT1 SCTA 90°

SCTF SCTF45°

SCTE 45°

SCTBSC90°

SCP2 SCP2 SCTG SC45°

SCTC SC90°

SCP1 SCP1 SCTBSC SCTF SCTF45°90°

SCP1 SCP1 SCTG SC45°

SCTC SC90°

SCP3 SCP3 SCTHSC45°

SCTD SC90°

1. Welding system: 2. Directly fixing into concrete:

3. Fixing Tension Plate with Struduna Anchor Base Plate:

HIGHTENSILETENSION PLATE SYSTEMS

ARCHITECTURAL

Edge

Load

316L stainless steel is used the welding process because of the low carbon content of 316. Stainless steel 316L is also well suited for use with heavy gauge (more than 6mm) welded components. It’s more resistant to carbide precipitation and can be used in the 425 – 860 degrees centigrade range. Because of these and other desirable properties, 316L should also be used if there is any threat of corrosion in the areas affected by the heat of welding.

Strudyna Tension Plates are designed to be used with a chemical anchor, fixed directly into concrete. NB: When using tension plates in this way, there is a maximum +/-5 degrees angle of load that the plates can operate. For example, a 45 degree tension plate can have load pull from range 40-50 degrees, 90 from 85-95 degrees.

Strudyna tension plates can be attached to anchor base plates for certain applications, before fixing to concrete with a chemical anchor. This is recommended for rod systems with diameter in the M20-M60 range. In this form, there is again a max +/- 5 degree variation in angle of load. For example, a 45 degree tension plate can have load pull from range 40-50 degrees, 90 from 85-95 degrees.

SCT1

StructureWelding

Tension plate

page 3 strudyna.com

1. Welding system:

2. Directly fixing into concrete:

SCTBSC

SCTE SCTA

SCTF SCTF

90°

SCTC SC90°

45°

SCTG SC45°

45°90°

SCP1 SCP1

h ef

h 1

h min

3. Fixing Tension Plate with Struduna Anchor Base Plate:

Welding

House or small buildings

-

-

House and medium buildings

House and medium buildings

House and medium buildings

Commercial building

Resident building ; Public buildings.

Commercial building Resident building ;

Public buildings.

Tie Back Plate Angle Design purpose

Plate By structural engineer

Tension plate system

Any specified rod system must be fit for purpose and designed in such a way that it passes structural requirements as a bare minimum. The tension plate component of any system is as important as the fork or the rod.

TECHNICAL DATA

page 4 strudyna.com

1. Welding system:

-

-

-

-

-

-

-

-

AISI 316

AISI 316

-

-

AISI 316

AISI 316

AISI 316

AISI 316

AISI 316

AISI 316

Duplex

AISI 316 Duplex

Duplex

Duplex

Duplex

M6 - M10

M12 M16

M20 - M60

M12 - M16

M16

M20 - M22

M20 - M39

M24 - M39

M42 - M48

M42 - M60

M52 - M60

Size

Choosing the right tension plate systems

SCT1

SCTHSC

90°

SCTBSC90°

90°

SCTBSC90°

SCTC SC90°

SCTC SC90°

SCTD SC90°

SCTD SC90°

SCTF SC45°

SCTF SC45°

SCTG SC45°

SCTG SC45°

SCTHSC45°

45°

45° MaterialAISI 316 DuplexItemItem

Chemical Anchor Base

Item

House or small buildings

-

-

SCP1 SCP1

SCP1 SCP1

SCP2 SCP2

SCP3 SCP3

- -

AISI 316M6 - M10 45°

SCTE SCTA

2. Directly fixing into concrete:

3. Fixing Tension Plate with Struduna Anchor Base Plate:

Tap : 86.0, 87.0

MENU

STRUCTURAL TENSION PLATESYSTEMS

Intropage 2-4.

Menupage 5.

Componentspage 14-22.

Technical Datapage 6-13.

SCTH page 20

SCTB page 16

PAGE 15

PAGE 19 PAGE 19 PAGE 17 PAGE 20

PAGE 22 PAGE 21 PAGE 21

PAGE 16 PAGE 16 PAGE 17 PAGE 18

COMPONENTs

SCTB page 16

SCTH

Tension Plate Tie Back Plate Angle 90°

Tie Back Plate Angle 45°

Chemical Anchor Base

page 5 strudyna.com

SCT1 SCTC S90°

SCTD SC90°

SCTBSC90°

SCTF SCT45°

SCTG SCT45°

SCTHSCT45°

SCP1 SCP1 SCP2 SCP2 SCP3 SCP3

45°SCTE

90°

45°

90°SCTA

P2H

P2H

Am

Am

B3

B3

Basic

Basic

Tension Plate

M6M8

M10

Size

TECHNICAL DATA

0006-L0300008-L0400010-L045

Tension plate system

RDS

RDS

Combitions with Strudyna products

0012-L0550016-L065

0020-L0750022-L090

0024-L1000027-L1100030-L1300033-L1400036-L1500039-L160

0042-L1700045-L1800048-L1900052-L2000056-L2100060-L220

M12M16

M20M22

M24M27M30M33M36M39

M42M45M48M52M56M60

1/4"

5/16"

3/8"

1/4"

5/16"

3/8"

M6

M8

M10

-

-

-

-

-

-

-

-

-

1/2"

5/8"

1/2"

5/8"

M12

M16

M20

M22

M20

M22

M20

M22

--

--

-

-

-

M16

3/4"

7/8"

3/4"

7/8"

1"

-

-

1 1/4"

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

M24

M27

M30

M33

M36

M39

M24

M27

M30

M33

M36

M39

M24

M27

-

M33

-

M39

M24

-

-

-

-

-

M42

M45

M48

M52

M56

M42

M45

M48

M52

M56

-

M45

-

M52

-

M60

SCT1

SCT1

SCT1

SCT1

SCT1

0020-00120022-0012

---

--

SCP1

0024-00120027-00140030-00160033-00160036-00160039-0020

SCP2

0042-00200045-00240048-0024

DESIGNED BY STRUCTURAL

ENGINEER

SCP3

page 6 strudyna.com

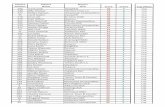

Below is a tabled digest of the Strudyna Tension & Anchor plates and ancillary items. Use the table to help make your product selection; each row details the products types and the sizes that will work in conjunction with the Tension Plate System. The table also outlines when a Chemical Anchor Base is required.

Strudyna products combinations

SCT1 SCT

SCT1 SCT

SCT1 SCT

SCT1 SCT

SCT1 SCT

Order No.Tie Back Plate Angle

Order No. Size Order No.

Chemical Anchor Base

SCTC S90°

SCTC S90°

SCTD SC90°

SCTBSC90°

SCTF SC45°

SCTG SC45°

SCTHSC45°

SCTHSC45°

SCP1 SCP1

SCP2 SCP2

SCP3 SCP3

45°SCTE

0006-D0070008-D0090010-D011

0012-D0130016-D017

0020-D0210022-D024

0020-D0210022-D024

0024-D0270027-D0290030-D0320033-D0340036-D0380039-D041

0024-D0270027-D0290030-D0320033-D0340036-D0380039-D041

0042-D0440045-D0470048-D0500052-D0540056-D0580060-D062

0042-D0440045-D0470048-D0500052-D0540056-D0580060-D062

SCTA0006-D0070008-D0090010-D011

SCTE

SCTB 0012-D0130016-D017

SCTF

SCTC SCTG

SCTC SCTG

SCTD SCTH

- -

90°SCTA SC

Tap : 86.0

TECHNICAL DATA

Strudyna products combinations (SRS)

SRS2016-L065M16

M20M22M24M30M33M36M39M42M45M48M52M56M60

2016-D017SCT1 SCTB 2016-D017SCTF

SCT1 SCTD

2020-L0752022-L0902024-L1002030-L1302033-L1402036-L1502039-L1602042-L1702045-L1802048-L1902052-L2002056-L2102060-L220

2020-D0212022-D0242024-D0272030-D0322033-D0342036-D0382039-D0412042-D0442045-D0472048-D0502052-D0542056-D0582060-D062

SCTH

2020-D0212022-D0242024-D0272030-D0322033-D0342036-D0382039-D0412042-D0442045-D0472048-D0502052-D0542056-D0582060-D062

M16

M20M22M24M30M33M36M39M42M45M48M52M56M60

STRUDYNA

SRS ADJUSTER™

Below is a table generated for helping select the correct product when your system incorporates SRS fork is made from cast 2205 Duplex. The fork has been engineered for higher load applications, so too much the Tension Plate system.

SRSTension plate system

page 7 strudyna.com

SRS Fork + 560HTR

SRS Fork + 448AR + Joiner*

SRS Fork + CABLE

SCT1 SCT

SCT1 SCT

Tension Plate Tie Back Plate Angle Size

Combitions with SRS Order No. Order No. Size

0016-2016

0020-20120022-20120024-20140030-20160033-20160036-20200039-2020

DESIGNED BY STRUCTURAL

ENGINEER

SCP3

SCP1

Order No.

Chemical Anchor Base

SCTD SC90°

SCTBSC90°

SCTF SC45°

SCTHSC45°

SCP1 SCP1

SCP3 SCP3

Tap : 87.0

Technical Information: Please note, any difference in potential electrical conductivity can lead to corrosion caused byElectrolysis.

1. Welding with stainless steel 1.1) Tension Plate material: Stainless steel grade 316L 1.2) Welding wire material must be stainless steel grade 316L

Structure

Welding

Tension plate

TECHNICAL DATA

The installation procedures of Tension plate

STAINLESS STEEL TENSILE TENSION PLATE SYSTEMS

Tension plate

page 8 strudyna.com

Each Tension Plate has been designed so that it can be welded in situ, on site, as required. This welding system is available from sizes M6 – M60.

Welding system:

2. Welding with Steel 2.1) 309L filler wire can be used for welding the tension plate directly. 2.2) For the best aesthetic end result, we recommend to use 309L filler wire should be primed before using 308L filler wire for welding. 2.3) We also recommend that for the best corrosion resistance, all welds and/or areas affected by the heat from the welding process should be painted.

SCT1

The installation procedures of Tension plate

Load

Edge

SCTB 90°

SCTB

SCTF 45°

SCTF

TECHNICAL DATA

0006-D007

0008-D009

0010-D011

0006-D007

0008-D009

0010-D011

65

65

80

65

65

80

100

100

120

100

100

120

53

50

60

53

50

60

C20/25

C20/25

C20/25

C20/25

C20/25

C20/25

Picture Mechanical Anchor Concrete ( Min. )

M6

M8

M10

M6

M8

M10

M12

M16

M12

M16

2

2

2

2

2

2

4

4

4

4

HST-R M8x75/10

HST-R M8x75/10

HST-R M10x90/10

HST-R M8x75/10

HST-R M8x75/10

HST-R M10x90/10

60

60

65

60

180

180

Order No. Size

(PCS)Q’ty

90°

45°

45°

HST-R M10x90/10

HST-R M12x115/20

HST-R M10x90/10

HST-R M12x115/20

60

75

60

75

80

95

80

95

120

150

120

150

65

75

350

370

C20/25

C25/30

C20/25

C25/30

Note(2) : Anchors installation design by ETAG based (Hilti Program) for calculation.Note(1) : Back to page 6 – 7 for more information of Strudyna products combination.

0012-D013

0016-D017

0012-D013

0016-D017

SCTA

SCTE

SCTB

SCTF

Warning ! Post drilling, always thoroughly clean any holes to be used as anchor points with a brush and compressed air or similar. Always refer to the chemical anchor manufacturer’s instructions.

Strudyna recommend the use of Hilti stainless steel anchors with any Strudyna Tension Plate system where applicable. For more information regarding the correct Hilti product and installation instructions, please refer to the Hilti manuals in the first instance. Below is intended as a guide only and as such is for reference only.

page 9 strudyna.com

Dimension Description

Edge

Load

Load

.

Tension Rod

P2H

Installation guide

Directly fixing into concrete:

SCTBSC

SCTE

90°SCTA

SCTF SC

Combination of Tie Back Plate with Hilti Mechanical Anchor (For RDS, P2H, AM, B3 and BASIC series)

hef

h1

hmin

Edge

Strength

(mm) Effective embed. Depth

(mm) Min. Dept of drill hole

(mm) Min. Concrete thickness

(mm) Min. Concrete edge to center anchor

(N/mm2) Strength of concrete

Load

Edge

45°

Edge

45°

h min

h1 hef

SCTA 90°

SCTE 45°

Edge Strengthh min.hef h1

:

:

:

:

:

h min

h min

h1

h1

hef

hef

h min

h1hef

TECHNICAL DATA

SCP3

90o

90o

90o

45o

45o

45o

Installation procedures for Tension Plates.

page 10 strudyna.com

SCP3

Firstly, always connect the chemical anchor base with the Tie Back plate using the Hexagon Bolts.

Connecting with chemical anchor base system

90o

SCTBSC

90o

SCTC 9

SC

90o

SCTC 9

S

90o

SCTD 9

SC

45o

SCTF 45

SC

45o

SCTG SC

45o

SCTH4

SC

Combination of Chemical Anchor Base (SCP2) with Tie Back Plate Angle (SCTC, SCTG)

90o

45o

SCP1

SCP2SCP2

45o

SCTG SC

Combination of Chemical Anchor Base (SCP3) with Tie Back Plate Angle (SCTD, SCTH)

Combination of Chemical Anchor Base (SCP1) with Tie Back Plate Angle (SCTB, SCTC, SCTG, SCTF)

TECHNICAL DATA

0024-0012 0027-00140030-0016 0033-0016 0036-0020 0039-0020

6933-1235-A470 6933-1235-A470 6933-1440-A470 6933-1645-A470 6933-1655-A470 6933-2060-A470 6933-2060-A470

0020-20120022-20120024-20140030-20160033-20160036-20200039-2020

M12x35 M12x35 M14x40 M16x45 M16x55 M20x60M20x60

2020-D0212022-D0242024-D0272030-D0322033-D0342036-D0382039-D041

2020-D0212022-D0242024-D0272030-D0322033-D0342036-D0382039-D041

M42M45M48

M52M56M60

Order No.Picture Order No. Order No. Size Q’ty(PCS)

Q’ty(PCS)

Order No.Size

Hexagon Head Bolt

6933-1230-A4706933-1235-A470

M12x30M12x35

M24M27M30 M33 M36 M39

6933-1235-A4706933-1440-A4706933-1645-A470 6933-1645-A470 6933-2050-A470 6933-2055-A470

M12x35M14x40M16x45M16x45M20x50M20x55

0024-D0270027-D0290030-D0320033-D0340036-D0380039-D041

0024-D0270027-D0290030-D0320033-D0340036-D0380039-D041

Tie Back Plate 90°Chemical Anchor Base Connect

Chemical Anchor Base Connect

Tie Back Plate 45°

6933-2055-A4706933-2465-A4706933-2465-A470

0042-00200045-00240048-0024

M20x55M24x65M24x65

0020-00120022-0012

0020-D0210022-D024

0020-D0210022-D024

M20M22

0042-D0440045-D0470048-D050

0042-D0440045-D0470048-D050

SCP1

SCP2

SCP3

Designed by structural Engineer

Designed by Structural Engineer

SCTC

SCTD SCTH

SCTG

SCTHSCTD

SCTC SCTG

Order No.SizePicture Order No. Order No. SizeOrder No.

Hexagon Head Bolt

6933-1630-A470 M16x30

Tie Back Plate 90° Tie Back Plate 45°

0016-2016 2016-D017

M20 M22 M24 M30 M33 M36 M39

M16 SCP1

SCP3

Combination of Chemical Anchor Base with Tie Back (For SRS series)

SCTF2016-D017SCTB

Installation procedures for Tension Plates

Warning ! Apply loctite with hexagon head bolt for safety

090o

090o

90o

55445o

54 o

545o

9090o 4545o

90o 45o

90o 45o

The below tables detail the matching of Strudyna Chemical Anchor Base with the appropriate Strudyna tie back plate.

page 11 strudyna.com

Connecting with chemical anchor base system

SCTB

SCTC

SCTC

SCTD

SCTD

SCTH

SCTH

H

H

SCTG

SCTG

FSCTF

Note(1) : Back to page 6 – 7 for more information of Strudyna products combination.

0052-D0540056-D0580060-D062

---

---

---

0052-D0540056-D0580060-D062

M27M27M30

44

444444

666

M42M45M48M52M56M60

------

SCTD

90 2042-D0442045-D0472048-D0502052-D0542056-D0582060-D062

2042-D0442045-D0472048-D0502052-D0542056-D0582060-D062

------

------

4

6666666

SCTH

45

SCTD SCTH

90 45

090o

M20M24M24M27M27M30

90 4545o

Combination of Chemical Anchor Base with Tie Back (For RDS, P2H, AM, B3 and BASIC series)

TECHNICAL DATA

SCP1

Edge

SCP2, SCP3

Edge

HIT-RE 500-SD HIT-RE 500-SD HIT-RE 500-SD HIT-RE 500-SD HIT-RE 500-SD HIT-RE 500-SD

HAS-E M16x125/108 HAS-E M16x125/108 HAS-E M20x170/68 HAS-E M20x170/108 HAS-E M24x210/54 HAS-E M27x240/60

210208206245230278

250250260300340350

220250260300340350

390510480560680620

Angle90°

Angle45°

C25/30 C25/30 C25/30 C25/30 C25/30 C25/30

HIT-RE 500-SD HIT-RE 500-SD HIT-RE 500-SD

HAS-E M27x240/60 HAS-E M30x270/70 HAS-E M30x270/70

278310310

350400400

390450500

780850

1,100

Angle90°

Angle45°

C25/30 C25/30 C25/30

0024-0012 0027-00140030-0016 0033-0016 0036-0020 0039-0020

0042-00200045-00240048-0024

0020-00120022-0012SCP1

SCP2

SCP3

HIT-RE 500-SDHIT-RE 500-SD

HAS-E M16x125/38HAS-E M16x125/108

140210

888888

888

44

8888888

4

180250

210260

300340

Angle90°

Angle45°

C25/30C25/30

0020-20120022-20120024-20140030-20160033-20160036-20200039-2020

HIT-RE 500 -SD HIT-RE 500 -SD HIT-RE 500 -SD HIT-RE 500 -SD HIT-RE 500 -SDHIT-RE 500 -SDHIT-RE 500 -SD

HAS-E M16x125/108 HAS-E M16x125/108 HAS-E M20x170x108 HAS-E M20x170x158 HIT-V-5.8 M24x450HAS-E M30x270x70HAS-E M33x300x80

210210245296377305342

250250310360500380420

380360430490780580610

770840930940

1,6701,2001,200

Angle90°

Angle45°

C30/37 C30/37 C30/37 C30/37 C35/45C35/45C40/50

Concrete ( Min. )Chemical Anchor Base Connect

0016-2016

M20M22M24M30M33M36M39

M16 SCP1

SCP3

HIT-RE 500-SD HAS-E M20x170/48 190 240 310 460Angle90°

Angle45°

C30/37

Adhesive injection system Anchor Rod HAS-E

Concrete ( Min. )

M42M45M48

M24M27M30 M33 M36 M39

M20M22

Chemical Anchor Base Connect Adhesive

injection system Anchor Rod HAS-EQ’ty(PCS)

Q’ty(PCS)

Warning ! Post drilling, always thoroughly clean any holes to be used as anchor points with a brush and compressed air or similar. Always refer to the chemical anchor manufacturer’s instructions.

Installation procedures for Tension Plates

Strudyna recommend that Hilti stainless steel anchors are used in conjunction with Strudyna tension plate system. For more information regarding Hilti products, please refer to the Hilti manual before installation, particularly with regard to the size, drilling and cleaning procedure for drilled holes. The below is intend as a guide only.

page 12 strudyna.com

Installation guide

Connecting with chemical anchor base system

(Back to page 9 for more information of Dimension Description)

Combination of Chemical Anchor Base with Tie Back (For RDS, P2H, AM, B3 and BASIC series)

Edge Strengthh1 h min.CodePicture Size

Combination of Chemical Anchor Base with Hilti Chemical Anchor (For SRS series)

Note(2) : Anchors installation design by ETAG based (Hilti Program) for calculation.

Note(1) : Back to page 6 – 7 for more information of Strudyna products combination.

Edge Strengthh1 h min.

hm

in.

h1h1hm

in.

CodePicture Size

PERFORMANCEHigh tensile tension plate systems

* For more design help of coupling plates and tensile system designs, sign in to "www.strudyna.com/designhelp".

Angle alignmentWhen designing coupling plates for SRS, special care must be taken to assure the angle of load alignment are in correspondence to the actual load applied by Rods. Bolts used on the coupling plate must evenly distribute double the working loads at which designed angle of the load is applied.

Tensile alignment

Coupling plates must be designed with at least 80% width of the adjuster grove (refer to dimension B of page 14.) at an even angle and surface. Too short of material on the coupling plate will result in failure due to concentrated sheer of the Pin.

Material alignmentCross section area of any connectors designed for the tension system must carry a Minimum of 2 times to that of rod assembly If same material is used. If different material is used, design with double tensile strength to that of RDS tension system.

Isolation of materialsIf a different material is used to produce the coupling plate, use a isolating washer in Nylon or Teflon material grade to isolate the connecting joints. If paints are to be used, take appropriate precautions for the thickness and installation tolerances.

Adjuster fork alignment

Adjusters are recommended to be aligned on an vertical axial. This orientation allows best distribution of any rod sag due to thermal expansion of materials.

Coupling plate alignment

Improperly aligned tensile systems will create non permissible bending forces resulting in structural fatigues on coupling plates and connectors.

Incorrect fork alignment.Set both fork on a vertical axial.

Correctly aligned axial.

X - area

x- area of Rod

Need min 2x the x-area of Rod or Cable if same material used.

Connecting plate structural fatigue

Properly aligned load distribution. Improper load angle creating structural fatigue.

Deviation should be kept below 1/2 deg of aligment.

Correctly aligned coupling plates. Incorrectly aligned coupling plates.

Coupling plate “A1” should be at least 80% of grove “A”.

Thickness of distance.

Structural tensile rod systems are assumed to have a significant amount of self weight when under tension; this results in receptivity to vibration and fatigue. Fatigue can become an important issue for tensile rod systems. Fatigue can be exacerbated by many factors, including but not limited to: Wind loads, self load, thermal expansion, adjacent construction works, earthquakes, heavy & persistent local traffic etc.

Vibrations can be amplified depending on the frequency, amplitude, and damping as a result of the tension systems mass and applied tension. While assessment of vibration and fatigue is not straight forward due to its many sources, proper design of the tension connector system, correct installation and regular health checks are crucial to longevity and safety.

Tensile connectorsRDS Architectural Tie-Rod Systems

Use isolating washers when coupling plates are of different material.

Isolation tube

Isolation washer

Grove “A” distance listed in Page 14.

A1

Refer to page 19. for more details of stainless steel tie back rod pre-installation procedures. page 13 strudyna.com

Order No.

- 0006 - L030 - 0008 - L040 - 0010 - L045 - 0012 - L055 - 0016 - L065 - 0020 - L075 - 0022 - L090 - 0024 - L100 - 0027 - L110 - 0030 - L130 - 0033 - L140 - 0036 - L150 - 0039 - L160 - 0042 - L170 - 0045 - L180 - 0048 - L190 - 0052 - L200 - 0056 - L210 - 0060 - L220

A(mm)

10111518242932354048505562657076828590

B(mm)

30404555657590

100110130140150160170180190200210220

ØD(mm)

98.511

13.5172124272832353841444750545862

SIZE

M6M8

M10M12M16M20M22M24M27M30M33M36M39M42M45M48M52M56M60

T(mm)

46810121618202222253030353540404550

Yield Load(kN)

7.311.617.531.943.264.285.9

112.1120.3147.0181.8214.1255.7293.7342.2385.9460.6531.9618.8

B A

Technical DataMaterial : Sheet AISI 316LSurface treatment : Electro polished Design Load : Standard safety factor for structural tensile application is 60% of yield load.Tap : 86.2

Technical DataMaterial : Sheet 2205Surface treatment : Electro polished Design Load : Standard safety factor for structural tensile application is 60% of yield load.Tap : 87.2

SCT1

Tension Load(kN)

14.623.335.163.985.0

126.2168.9220.4236.4288.9357.4420.8502.6577.3672.6758.6905.4

1,045.51,216.4

SCT1

- 2016 - L065 - 2020 - L075 - 2022 - L090 - 2024 - L100 - 2030 - L130 - 2033 - L140 - 2036 - L150 - 2039 - L160 - 2042 - L170 - 2045 - L180 - 2048 - L190 - 2052 - L200 - 2056 - L210 - 2060 - L220

2429323548505562657076828590

657590

100130140150160170180190200210220

1721242732353841444750545862

M16M20M22M24M30M33M36M39M42M45M48M52M56M60

1518182222253030353540404550

115.5171.5183.7239.7288.9357.4420.8502.6577.3672.6758.6905.4933.8

1,086.5

144.4 214.4 263.1 343.3 364.7 451.1 531.1 634.4 728.7 848.9 957.5

1,142.7 1,258.6 1,464.4

SCT1

SCT1

Tension Plate

Order No. for connect with SRS series.

D

COMPONENTsStainless steel Tension Plates connections

page 15 strudyna.com

STAINLESS STEEL TENSILE TENSION PLATE SYSTEMS

Tension plate for SRS

A1A2

B1

B2

F

Order No.

- 0006 - D007- 0008 - D009- 0010 - D011

A1(mm)

607080

C(mm)

222733

B(mm)

324252

A2(mm)

92102132

Technical DataMaterial : Casting material AISI316 - DIN 1.4401Surface treatment : Electro polished Design Load : Standard safety factor for structural tensile application is 60% of yield load.Tap : 86.3

SCTA

SCT2 (4 bolts)

SIZE

M6M8

M10SCTA

SCTA

SCTA F

(mm)

9 x 129 x 1211 x 15

E(mm)

101215

T1(mm)

578

T2(mm)

678

Tension Load(kN)

14.623.335.1

Yield Load(kN)

7.311.617.5

SIZE

M6M8

M10

7911

ØD(mm)

Order No.

- 0012 - D013- 0016 - D017

A1(mm)

110130

A2(mm)

155180

B2(mm)

150180

B1(mm)

110130

Technical DataMaterial : Casting material AISI316 - DIN 1.4401Surface treatment : Electro polished Design Load : Standard safety factor for structural tensile application is 60% of yield load.Tap : 86.4

Technical DataMaterial : Casting Duplex 4ASurface treatment : Electro polished Design Load : Standard safety factor for structural tensile application is 60% of yield load.Tap : 87.3

SCT4 (4 bolts)

SIZE

M12M16

NOTE : See more dimension chart

NOTE : See more dimension chart

SCTB

SCTB M16- 2016 - D017 120 180 120 180

SCTB SCTB

Tie Back Plate Angle 90° (2 bolts)

Tie Back Plate Angle 90° (4 bolts)

Tie Back Plate Angle 90 for SRS

CE

D

B

F

A2A1

Order No. for connect with SRS series.

Dimension for connect with SRS series.

DIMENSION CHART

SCTBE

(mm)

2226

T1(mm)

1214

F(mm)

11 x 1513 x 18

T2(mm)

1012

SIZE

M12M16

M16 48 17 26 18 x 24 14 12 144.4115.5

Tension Load(kN)

63.985.0

Yield Load(kN)

31.943.2

C(mm)

4048

ØD(mm)

13.517

COMPONENTsStainless steel Tension Plates connections

page 16 strudyna.com

CE

D

90°

90°

T2T2

T1

T1

Order No.

- 0020 - D021- 0022 - D024- 0024 - D027- 0027 - D029- 0030 - D032- 0033 - D034- 0036 - D038- 0039 - D041

A1(mm)

90100110120140160180180

A2(mm)

135155165185205225260260

B1(mm)

90100110120140160180180

B2(mm)

130150160180200220250250

SCTC

Technical DataMaterial : Casting material AISI316 - DIN 1.4401Surface treatment : Electro polished Design Load : Standard safety factor for structural tensile application is 60% of yield load.Tap : 86.5, 86.6

SIZE

M20M22M24M27M30M33M36M39

SCTC

NOTE : See more dimension chart

CE

D

DIMENSION CHARTSCTC

E(mm)

3235404245505560

T1(mm)

1618192022242630

T2(mm)

1416181820222426

13 x 18 13 x 18

13 x 18 15 x 20 18 x 24 18 x 24 21 x 29

21 x 29

F(mm)

ØD(mm)

2124272932343841

Tension Load(kN)

126.2168.9220.4236.4288.9357.4420.8502.6

Yield Load(kN)64.285.9

112.1120.3147.0181.8214.1255.7

SIZE

M20M22M24M27M30M33M36M39

SCTG3235404245505560

2124272932343841

13 x 1813 x 1813 x 18 15 x 20 18 x 24 18 x 24 21 x 29 21 x 29

1618192022242630

1416181820222426

M20M22M24M27M30M33M36M39

126.2168.9220.4 236.4 288.9 357.4 420.8 502.6

64.285.9

112.1120.3147.0181.8214.1

255.7

596873808590

104111

Technical DataMaterial : Casting material AISI316 - DIN 1.4401Surface treatment : Electro polished Design Load : Standard safety factor for structural tensile application is 60% of yield load.Tap : 86.11, 86.12

Order No.

- 0020 - D021- 0022 - D024- 0024 - D027- 0027 - D029- 0030 - D032- 0033 - D034- 0036 - D038- 0039 - D041

A1(mm)

90100110120140160180180

B1(mm)

90100110120140160180180

B2(mm)

137155170186210228260265

A2(mm)

134155165185205225260260

SCTG

SIZE

M20M22M24M27M30M33M36M39

NOTE : See more dimension chart

SCTG

CD

E

COMPONENTsStainless steel Tension Plates connections

page 17 strudyna.com

C(mm)

596873808590104111

Tie Back Plate Angle 45° (4 bolts)

SCTG

SCTC

Tie Back Plate Angle 90° (4 bolts)

45°

90°

T2T2 F

A1A2

B1

B2

T1

B2

B1

T1

A1A2

F

DIMENSION CHART

Order No.

- 0042 - D044- 0045 - D047- 0048 - D050- 0052 - D054- 0056 - D058- 0060 - D062

A1(mm)

195200220220240250

A2(mm)

260280300315335360

B1(mm)

98105110118128135

B2(mm)

255290290320340370

SCTD

Technical DataMaterial : Casting material AISI316 - DIN 1.4401Surface treatment : Electro polished Design Load : Standard safety factor for structural tensile application is 60% of yield load.Tap : 86.7, 86.8

Technical DataMaterial : Casting Duplex 4ASurface treatment : Electro polished Design Load : Standard safety factor for structural tensile application is 60% of yield load.Tap : 87.4, 87.5

SCT5 (6 bolts)SCT5 (6 bolts)

M42M45M48M52M56M60

SIZE

SCTD

- 2020 - D021- 2022 - D024- 2024 - D027- 2030 - D032- 2033 - D034- 2036 - D038- 2039 - D041- 2042 - D044- 2045 - D047- 2048 - D050- 2052 - D054- 2056 - D058- 2060 - D062

90100110140160180180195200220220240250

135155165205225260260260280300315335360

4550557080909098

105110118128135

130150160200220250250255290290320340370

M20M22M24M30M33M36M39

M42 M45 M48 M52 M56 M60

SCTD

Tie Back Plate Angle 90° (6 bolts)

SCTD

SCTD

214.4 263.1 343.3 364.7 451.1 531.1 634.4 728.7 848.9 957.5 1142.7 1258.6 1464.4

577.3 672.6

758.6905.4

1045.5 1216.4

Tension Load(kN)

14161820222426283032343840

283032343840

T2(mm)

171.5183.7239.7288.9357.4420.8502.6577.3672.6758.6905.4933.8

1086.5

293.7342.2385.9460.6531.9618.8

Yield Load(kN)

16181922242630303238384450

303238384450

T1(mm)

32354045505560657075809095

657075809095

E(mm)

13 x 18 13 x 18 15 x 20 18 x 24 18 x 24 21 x 29 21 x 2921 x 29 26 x 34 26 x 34 29 x 39 29 x 39 32 x 42

21 x 2926 x 3426 x 3429 x 3929 x 3932 x 42

F(mm)

21242732343841444750545862

444750545862

ØD(mm)

5968738590104111118125132139148160

118125132139148160

C(mm)

M42 M45 M48M52M56M60

M20M22M24M30M33M36M39M42M45M48M52M56M60

SIZE

NOTE : See more dimension chart

A1A2

CE

D

F

B2

B1

B1

T2

T1

Order No. for connect with SRS series.

Dimension for connect with SRS series.

COMPONENTsStainless steel Tension Plates connections

page 18 strudyna.com

Tie Back Plate Angle 90° for SRS

90°

Technical DataMaterial : Casting Duplex 4ASurface treatment : Electro polished Design Load : Standard safety factor for structural tensile application is 60% of yield load.Tap : 87.6

Tie Back Plate Angle 45° for SRS

DIMENSION CHART

- 2016 - D017 M16 120 180 120 180SCTF

SCTET1

(mm)

578

Tension Load(kN)

14.623.335.1

SIZE

M6M8M10

Order No. for connect with SRS series.

Dimension for connect with SRS series.

SCTF63.985.0

31.943.2

1214

M12M16

144.4115.514

ØD(mm)

7911

13.517

17M16

E(mm)

101215

2226

26

F(mm)

9 x 129 x 1211 x 15

11 x 1513 x 18

18 x 24

T2(mm)

678

Yield Load(kN)

7.311.617.5

1012

12

Order No.

- 0012 - D013- 0016 - D017

A1(mm)

110130

A2(mm)

155180

B2(mm)

150180

B1(mm)

110130

C(mm)

222733

48

4048

SIZE

M12M16

Technical DataMaterial : Casting material AISI316 - DIN 1.4401Surface treatment : Electro polished Design Load : Standard safety factor for structural tensile application is 60% of yield load.Tap : 86.10

SCTF

SCTF

F

B1

B2

A1A2

Order No.

- 0006 - D007- 0008 - D009- 0010 - D011

A1(mm)

607080

B1(mm)

141620

B2(mm)

404860

A2(mm)

90100128

Technical DataMaterial : Casting material AISI316 - DIN 1.4401Surface treatment : Electro polished Design Load : Standard safety factor for structural tensile application is 60% of yield load.Tap : 86.9

SCTE

SIZE

M6M8

M10NOTE : See more dimension chart

NOTE : See more dimension chart

SCTE

Tie Back Plate Angle 45° (2 bolts)

SCTE

SCTF

Tie Back Plate Angle 45° (4 bolts)

COMPONENTsStainless steel Tension Plates connections

page 19 strudyna.com

45°

45°

B1

T1

T2

F

A1A2

CE

D

B2

T1

D

CE

T2

Order No.

- 0042 - D044- 0045 - D047- 0048 - D050- 0052 - D054- 0056 - D058- 0060 - D062

A1(mm)

195200220220240250

A2(mm)

260280300315335360

B1(mm)

98105110118128135

B2(mm)

280310320345370390

SIZE

M42M45M48M52M56M60

Technical DataMaterial : Casting material AISI316 - DIN 1.4401Surface treatment : Electro polished Design Load : Standard safety factor for structural tensile application is 60% of yield load.Tap : 86.13, 86.14

Technical DataMaterial : Casting Duplex 4ASurface treatment : Electro polished Design Load : Standard safety factor for structural tensile application is 60% of yield load.Tap : 87.7, 87.8

SCTH

SCTH

SCTH

Tie Back Plate Angle 45° (6 bolts)

B1

B1

B2

F

T1

A1A2

D

CE

DIMENSION CHART

- 2020 - D021- 2022 - D024- 2024 - D027- 2030 - D032- 2033 - D034- 2036 - D038- 2039 - D041- 2042 - D044- 2045 - D047- 2048 - D050- 2052 - D054- 2056 - D058- 2060 - D062

90100110140160180180195200220220240250

134155165205225260260260280300315335360

4550557080909098

105110118128135

137155170210228260265280310320345370390

M20 M22 M24 M30 M33 M36 M39M42 M45 M48 M52 M56 M60

SCTH

SCTH

214.4263.1343.3364.7451.1531.1634.4728.7848.9957.5

1142.7 1258.6 1464.4

577.3672.6758.6905.4

1,045.51,216.4

Tension Load(kN)

14161820222426283032343840

283032343840

T2(mm)

16181922242630303238384450

303238384450

T1(mm)

32354045505560657075809095

657075809095

E(mm)

13 x 18 13 x 18 15 x 20 18 x 24 18 x 24 21 x 29 21 x 2921 x 29 26 x 34 26 x 34 29 x 39 29 x 39 32 x 42

21 x 2926 x 3426 x 3429 x 3929 x 3932 x 42

F1(mm)

21242732343841444750545862

444750545862

D(mm)

5968738590

104111118125132139148160

118125132139148160

C(mm)

M42 M45 M48M52M56M60

M20M22M24M30M33M36M39M42M45M48M52M56M60

SIZE

NOTE : See more dimension chart

Order No. for connect with SRS series.

Dimension for connect with SRS series.

COMPONENTsStainless steel Tension Plates connections

page 20 strudyna.com

Tie Back Plate Angle 45° for SRS

45°

T2

171.5183.7239.7288.9357.4420.8502.6577.3672.6758.6905.4933.8

1086.5

293.7342.2385.9460.6531.9618.8

Yield Load(kN)

COMPONENTsStainless steel Tension Plates connections

DIMENSION CHARTSCP1

SCP2

Order No.

- 0020 - 0012- 0022 - 0012

A3(mm)

190210

A1(mm)

90100

A4(mm)

255290

B1(mm)

90100

SIZE

SCP1

Technical DataMaterial : Steel plate A36Surface treatment : N/A Design Load : Standard safety factor for structural tensile application is 60% of yield load.Tap : 86.15, 87.9

SCT6 (4 bolts)

M20M22SCP1

- 0016 - 2016 M16 120 220 300 120SCP1

Chemical Anchor Base Type SCP1 (4 bolts , 4 Anchor Rod)

SCP1

T3

F2

A3A4

B3

B4

A1

B1

M

Order No. for connect with SRS series.

Dimension for connect with SRS series.

Order No.

- 0024 - 0012 - 0027 - 0014 - 0030 - 0016 - 0033 - 0016 - 0036 - 0020 - 0039 - 0020

A3(mm)

125125150160185220

A1(mm)

110120140160180180

A4(mm)

315315380400460540

B1(mm)

110120140160180180

SCP2

Technical DataMaterial : Steel plate A36Surface treatment : N/A Design Load : Standard safety factor for structural tensile application is 60% of yield load.Tap : 86.16

SCT7 (8 bolts)

NOTE : See more dimension chart

NOTE : See more dimension chart

SIZE

M24 M27 M30 M33 M36 M39

SCP2

SCP2

(Connect Tie back plate SCTC, SCTG size M20, M22 see more page 17)

(Connect Tie back plate SCTC, SCTG size M24-M39 see more page 17)

(Connect Tie back plate SCTB, SCTF size M16 see more page 16, 19)

T3

F2

A1

B1

A3 A3

B3

B3

B4

A4

M

Chemical Anchor Base Type SCP2 (4 bolts , 8 Anchor Rod)

SIZE

M20M22

M16

M24M27M30M33M36M39

B4(mm)

250280

290

310310370390450530

B3(mm)

190210

220

125125150160185220

F2(mm)

18 x 2418 x 24

21 x 29

18 x 2418 x 2421 x 2921 x 2926 x 3428 x 36

M(thread)

M12M12

M16

M12M14M16M16M20M20

20

T3(mm)

1820

202225252830

115.5

Yield Load(kN)

64.285.9

112.1120.3147.0181.8214.1255.7

144.4

Tension Load(kN)

126.2168.9

220.4236.4288.9357.4420.8502.6

page 21 strudyna.com

90oBSCTBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBSC

90o

SCTC C9SCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCC

45o

SCTF F45

SCFFFFFFFFFFFFFFFFFFFFFFFFFFFFFFFFFFFFFFFFFFFFFFFFFFFFFFFFFFFFFFFFFFFFF

45o

SCTG G

SCGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGG

SCP1

90o

SCTC C9SCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCC

45o

SCTG G

SCGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGSCP2SCP2

SCP2 Connect Tie back plate SCTC, SCTG

SCP1 Connect Tie back plate SCTC, SCTG, SCTB, SCTF

Order No.

- 0042 - 0020- 0045 - 0024- 0048 - 0024

A1(mm)

195200220

A3(mm)

235240250

A4(mm)

570580600

B1(mm)

98105110

SIZE

SCP3

Technical DataMaterial : Steel plate A36Surface treatment : N/A Design Load : Standard safety factor for structural tensile application is 60% of yield load.Tap : 86.17, 87.10, 87.11

SCT6 (4 bolts)

NOTE : See more dimension chart

M42M45M48

SCP3

T3

COMPONENTsStainless steel Tension Plates connections

DIMENSION CHARTSCP3

214.4 263.1 343.3 364.7 451.1531.1634.4

577.3 672.6 758.6

Tension Load(kN)

20202525354040

303535

T3(mm)

171.5183.7239.7288.9357.4420.8502.6

293.7342.2385.9

Yield Load(kN)

M12M12M14M16M16M20M20

M20M24M24

M(thread)

18 x 24 18 x 24 21 x 29 21 x 29 26 x 3432 x 4235 x 45

28 x 36 32 x 42 32 x 42

F2(mm)

290310340380410520570

560580600

B4(mm)

110120135155170210230

235240250

B3(mm)

M42 M45 M48

M20 M22 M24 M30 M33M36 M39

SIZE

Dimension Tension plate for connect with SRS series.

- 0020 - 2012 - 0022 - 2012 - 0024 - 2014 - 0030 - 2016 - 0033 - 2016 - 0036 - 2020 - 0039 - 2020

90100110140160180180

110120135155170210230

M20 M22 M24 M30 M33M36M39

300320350390420530580

45505570809090

SCP3

page 22 strudyna.com

Order No. for connect with SRS series.

(Connect Tie back plate SCTD, SCTH size 20-39 see more page 18, 20)

NOTE : See more dimension chart (Connect Tie back plate SCTD, SCTH size 42-48 see more page 18, 20)

Chemical Anchor Base Type SCP3 (6 bolts , 8 Anchor Rod)

SCP3

A3

A1

A3A4

B1

B3

B3

B4

M

B1

F2

SCP3SCP3

90o

SCTD D9SCDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDD

45o

SCTHH4SCHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH

SCP3 Connect Tie back plate SCTD, SCTH

SCP1 Connect Tie back plate SCTB SCP2 Connect Tie back plate SCTC SCP3 Connect Tie back plate SCTD

page 23 strudyna.com

SRS fork:

P2H fork:

RDS fork:

B3 fork:

B1 fork:

AM fork:

RDS eye:

Visit strudyna.com for more information on strudyna’s tension rod systems.

HIGH TIE-ROD SYSTEMSARCHITECTURALTo complement Strudyna tensile cable range, Strudyna has also developed a complete range of stainless steel tensile rod systems . Contact any of our sales office for more information or visit Strudyna.com for the latest updates.ToT complemenany of our sale

Size available 560HTRM16 M20 M22 M24 M30 M33 M36 M39 M42 M45 M48

109 171 169 197 288 357 420 502 577 672 758

137 214 243 283 364 451 531 634 728 848 957

YS

TM52 M56 M60 M64 M68 M72 M76 M80 M85 M90 M100

905 933 1,086 1,231 1,405 1,593 1,788 1,998 2,275 2,571 3,220

1,142 1,258 1,464 1,659 1,894 2,147 2,411 2,693 3,067 3,465 4,340

YS

T

TAP : 10006

TAP : 10006Size available 262ARM16 M20 M22 M24 M27 M33 M42 M52 M56

40 67 79 100 126 199 314 485 514

80 132 163 197 254 391 620

M45

365

718 978 1,143

YS

T

Size available 262AR imperial size

Size available 262AR metric sizeM27 M30 M33 M36 M39 M42 M45 M48 M52 M56

YS

T120 147 181 214 255 293 342 385 460 531

236 288 357 420 502 577 672 758 905 1,045

1/4” 5/16” 3/8” 1/2” 5/8” 3/4” 7/8” 1” 1”-1/4”

7.0 11.6 12.9 24.6 33.8 49.4 67.2 87.7 141.9

14.6 23.3 30.6 58.2 85.0 124.1 168.9 220.4 356.4

YS

T

S = SIZE, Y = Yield load, T = Tensile load.

SRS + 560HTR Tie-Rod System

SRSSRS

P2H - 262AR Tie-Rod System

RDS - 262AR Tie-Rod System

RDS

P2H

ensile cable range, Strudyna has also developemore information or visit Strudyna.com for the la

nt Strudyna tees office for m

able 560HTRze availa0 M22 M24 M30 M33 M36 M39 M42 M45 M48

TATT P : 10006

P2H

RDS

RDS

B2 toggle:

B1 fork:P2H fork:

B3 fork:

SRS fork:

RDS fork:

Visit strudyna.com for more information on strudyna’s tensile cable systems.

STAINLESSSTEELAND CABLESYSTEMS

P2H

1x19 1x25

1x19 7x7 7x19

1x37 1x61

MBL (kN)After swaging*

Construction

MBL (kN)After swaging*

Construction

MBL (kN)After swaging*

N/A

N/A

N/A

Construction

Size Cable(mm) 4

1x7

15

1x19

11

5

1x19

23

1x19

18

6

1x19

32

1x19

26

8

1x19

57

1x19

47

10

1x19

85

1x19

74

12

1x19

124

1x19

106

14

1x25

168

1x19

145

16

1x19

180

19

1x19

267

20

1x37

279

22

1x37

341

24

1x37

410

28

1x37

561

30

1x61

695

34

1x62

849

1x19 1x25

1x19 7x7 7x19

1x37 1x61

MBL (kN)After swaging*

Construction

MBL (kN)After swaging*

Construction

MBL (kN)After swaging*

N/A

N/A

N/A

Construction

Size Cable(mm) 10

1x19

90

1x19

74

12

1x19

127

1x19

106

14

1x25

170

1x19

145

16

1x25

218

1x19

180

19

1x25

282

1x19

267

20

1x37

279

22

1x37

341

24

1x37

410

28

1x37

561

30

1x61

695

34

1x61

849

36

1x61

870

42

1x61

1,008

1x19 1x25

1x19 7x7 7x19

1x37 1x61

MBL (kN)After swaging*

Construction

MBL (kN)After swaging*

Construction

MBL (kN)After swaging*

N/A

N/A

N/A

Construction

Size Cable(mm) 8

1x19

57

1x19

47

10

1x19

90

1x19

74

12

1x19

127

1x19

106

14

1x25

170

1x19

145

16

1x25

225

1x19

180

19

1x25

282

1x19

267

20

1x37

279

22

1x37

341

24

1x37

410

28

1x37

561

30

1x61

695

34

1x61

849

36

1x61

870

42

1x61

1008

RDS

SRSSize C

(m

page 24 strudyna.com

Strudyna Product Warranty

1. Confirm all pallet and carton quantity are correct before unpacking.2. Equipped with all personal safety equipment as requested by local law.3. Use steel cutter to gently cut steel band.4. Use knife to gently cut each carton. Do not cut too deep into the carton as this may result in product surface being damaged.5. Always move and store carton and pallets in upright position.6. Never stack one pallet above another.7. Do not stack carton over 100cm height.

Proper unpacking procedures:Stainless steel tensile cable unpacking

1. Product are supplied free of defect from craftsmanship and material at the time of the shipment. Should the receiver have any comment or dissatisfaction on the delivered products, a written notice to Strudyna must be submitted within 14 days of product receipt.2. Product in correct usage (following proper documentation record and submit to [email protected] of unpacking, inspection and installation procedures as well as correct and continues load bearing inspections) and with proper maintenance , goods will pe rform under it's specifications for a period of 5 years from the date of delivery.3. Shall the aforesaid be concluded by Strudyna to be of Strudyna fault, Strudyna will replace or repair the goods in question at Strudyna's choice.

Remarks: Strudyna makes no representations for suitability to a particular design or application settings.

Proper unpacking procedures:Stainless steel tensile cable selections

1. Do not install any damaged part found in pre-installation procedures.2. Do not install any item found not in proper working conditions.3. Always tighten screws or thread slowly without exceeding a speed of 15 sec per revolution or 3 sec per quarter revolution. 4. Do not shock load any thread.5. Do not allow any surface to be damaged as this will create pivot corrosions.6. Clean throughly clean all contamination caused by tools onto products prior to installation. 7. Check all Pins and screws are in full in position after installation.8. Cover and protect all installed stainless steel products if subject to further contamination caused by surrounding instantiation.9. This process may not be skipped as surrounding welding or metal dust may be cause contamination on the stainless steel fittings.10.Proper documentation is crucial to maintaining products in warranty condition. Record all documentations and pictures of all process carried out and submit report to [email protected]

within 60 days of installation completion.

Proper installation procedures:Stainless steel tensile cable installation

1. Check all installation for correct tension 2 weeks after initial installation.2. Check regularly in 8 weeks interval for any loosening or damage to product.3. All product requires this inspection by a trained professional, and this process may not be skipped as products are effected by wear, tear, overloading or improper installation.4. Proper inspection is necessary to maintaining products in warranty condition. Record all documentations and pictures of all process carried out with each inspection and submit report to [email protected] within 30 days of each inspection.

Proper inspection procedures:Stainless steel tensile cable inspection

1. Always move and store carton and pallets in upright position.2. Never stack one pallet above another.3. Do not stack carton over 100cm height.4. Do not store carton or pallet in outdoor conditions without proper rain and snow cover.5. Never expose products to iron dust or welding sparks as this may cause surface damage and stains.

Proper storage procedures:Stainless steel tensile cable storage

1. Check for proper design loading prior to installation.2. Check all base structure are not damaged prior to installation.3. Check all parts are not damaged prior to installation. (Do not install a damaged part)4. Check for any dirt or damage to thread before installation.5. Clean any dirt or foreign object found in thread.6. Lightly turn all thread prior to installation to check for their working condition.

Proper pre-installation procedures:Stainless steel tensile cable pre-installation procedures

1. Clean all surface from contamination in a 2 weeks interval. (This process may not be skipped, as dust can be accumulated on the surface and destroy the oxidizing protective layer of stainless )2. Proper maintenance may not be skipped to retain stainless steel's component's property. Record documentations and pictures of all process carried out and submit monthly report to [email protected]. Use ordinary household liquid soap diluted with water and apply with soft cloth or synthetic sponge.4. Never apply chlorine base cleaner or any abrasive liquids. 5. Rinse well, dry with soft cloth.6. Regular cleaning will remove most form of heavy soiling or accumulated staining.

Proper maintenance procedures:Stainless steel tensile cable maintenance

copy

right

@St

rudy

na C

o., L

td. 2

011.

page 25 strudyna.com

Terms and Conditions of SaleSpecifications

learn more about strudyna and strudyna's product ranges at www.strudyna.com/en/product

The manufacturer is constantly testing and improving the performance of products, thus specifications are subject to change wit hout notice. For the latest information please contact your local distributor.

GeneralFor the purpose of these terms and conditions of sale, Structural Dynamics Co., Ltd. (Strudyna) should be referred to as "Manuf acturer". Any related companies and representatives of Strudyna is referred to as a "Local distributor". Any Client purchasing Structural Dyn amic items shall be referred to as the "Buyer". Products described and presented in this catalog shall be referred to as the "goods". These gene ral terms and conditions of sale will apply to all sales of Structural Dynamic items described in this catalog and serves as a binding contra ct and agreement between manufacturer, local distributor and buyer. Contact your local strudyna sales office for additional or local agreements and warranties.

Title and RiskThe local distributor shall hold the title and proprietary ownership of the goods until 100% of payment to the goods have been paid by the buyer to the local distributor. However unless prior written consent is agreed, the risk of damage to the goods shall be passed to the buyer upon the receipt of the goods by the buyer.

CancellationGoods purchased and confirmed by buyer may not be subject to cancellation, unless a prior written consent is given by the manuf acturer or local distributor to the buyer.

Force majeureIn the event of unpredictable natural or political cause beyond the manufacturer's and local distributor's control such as but not limited to: War, Rebellion, Piracy, Civil Commotion, Political unrest, Strike or industrial dispute, fire, earthquake, flooding or draught or ba d weather, the unavailability of materials or delay delivery of suppliers, the inability to secure labour force or by any other cause whatsoev er beyond the Manufacturer's and Local distributor's control, the manufacture and local distributor shall notify promptly to the buyer the ca use of force majeure. The manufacture and Local distributor shall have the right to cancel the contract to deliver so long as the force maje ure shall continue.

WarrantyThe products listed in this catalog are supplied to the buyer with a guarantee of being free from detective craftsmanship and m aterials at the time of shipment. Shall to buyer be dissatisfied with the product, a written notice must be sent to local distributor within 14 days from receipt of goods and subject to replacement or cancellation of order by choice of local distributor and manufacture. The manufacture wa rrants that in normal usage and with proper maintenance, goods will perform under its specifications for a period of 5 years. Any goods which prove to be defective under normal use will be repaired or replaced at the manufacturer's option. The manufacture and local distributor acc ept no responsibility if the goods purchased from this catalog are used in applications where their safe working load listed in this c atalog is exceeded or in cases where goods are improperly installed. The manufacture and local supplier make no representations for suitability to a particular design application setting. All good supplied in this catalog carry a limited lifetime warranty from the manufacture.

Price conditionsPrices quoted by local distributor to buyer shall remain unchanged for the duration of 14 days unless quantities, packaging ins tructions,delivery destinations or any contract details are changed. Unless further stated in order confirmation, prices are ex-local dis tributor premises. Should a delivery destination be reached by local distributor and buyer, the local distributor is entitled to choose any means of transport the local distributor sees it fit.

page 26 strudyna.com

www.strudyna.com

STRUDYNA.commmm

R

Exclusive AgentsYear 2014

Structural Dynamics Co., Ltd.Satorn Business Park 21/18Krungthonburi Rd. KlongtonsaiKlongsan Bangkok 10600 ThailandTel : +(66) 2862 2487Fax : +(66) 2862 2488Email : [email protected]

Keng Wah Hardware Co., Pte. Ltd.Blk 2 Kitchener Road #01-85Singapore 200002Tel : +(65) 6392 4896Fax : +(65) 6296 4736Email : [email protected]

Structural Dynamics Australia4 / 14 Dover Drive BurleighHeads Queensland 4220 AustraliaTel : +07 5568 7084Fax : +07 5576 5166Email : [email protected]

Structural Dynamics Europe Limited.Unit 10 Wingate Rd. Gosport HampshireUK. PO12 4DPTel : +44 (0) 845 262 5557Fax : +44 (0) 239 294 0272Email : [email protected]

Anzor Fasteners Ltd.8 Arrenway Drive Albany,Auckland, New ZealandTel : +(64) 9 476 0001Fax : +(64) 9 476 0090Email : [email protected]

copyright@Strudyna Co., Ltd. 2014.