Structural roof decking and trays brochure

Transcript of Structural roof decking and trays brochure

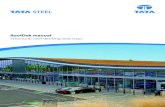

About Tata Steel

Tata Steel, formerly known as Corus, is one of Europe's largest steelproducers. We serve many different and demanding marketsworldwide, including aerospace, automotive, construction, energyand power, and packaging. Our primary steelmaking operations inthe UK and the Netherlands are supported by a global sales anddistribution network.

Innovation and continuous improvement are at the heart of ourperformance culture. We aim to create value by offering a sustainableand value-added steel product range supported by unrivalled customerservice. By working in partnership with you, we find the best solutionsto meet your needs and help your business to perform.

Our European operations are a subsidiary of Tata Steel Group, one ofthe world’s top ten steel producers. With a combined presence innearly 50 countries, the Tata Steel Group including the Europeoperations, Tata Steel Thailand and NatSteel Asia, has approximately 80,000employees across five continents and a crude steel production capacityof over 28 million tonnes.

We are able to offer a wide range of products, systems and servicesspecifically developed for the construction market. These includeColorcoat® pre-finished steel products, roof and wall cladding systemsfor the building envelope, hot rolled and tubular sections for theprimary structure, lintels and other ancillary construction components.

Contents

3 Introduction

4 Shallow deck profile range

6 Deep deck profile range

8 Liner tray profiles

10 Acoustic profiles

13 Technical information

14 Structural design

15 Diaphragm design

16 Acoustic systems

18 Roof Safety

19 Service and support

20 Sustainability

21 Case Study Peacehaven

22 Case Study West Cheshire College

23 Case Study West Burton Power Station

2

RoofDek Introduction

Introducing RoofDekStructural roof decking and traysTata Steel offers the most comprehensive range of structural roof decking all under one UKmanufacturer’s roof

To offer the structural deck specifier more choice, we can supply additional profiles tocompliment our UK manufactured range from Tata Steel Europe.

Technically the best, with a structural designservice providing diaphragm design for decksand full support calculations for all profiles.

With decks ranging from 32mm to 210mmdeep and a range of structural trays, wesupport all types of insulated roof systems:

• Single ply membrane

• Standing seam systems

• Green roofs

• Slates and tiles

• Three ply felt

• Asphalt

Quality assuranceTo provide the best quality and the most up todate design information, Tata Steel is qualityassured to BS ISO 9001:2000 Quality systems.Tata Steel is an active member of MCRMA(Metal Cladding and Roofing ManufacturersAssociation), SPRA (Single ply RoofingAssociation), BCSA (British ConstructionalSteelwork Association) and supports R&Dthroughout the industry.

Professional supportTata Steel maintains a friendly technical helpdesk which is freely available to all Architects,Consulting Engineers and Contractors to assistall aspects of roof deck and liner tray design

The technical help desk is available on: 01244 892 199 or via [email protected]

Shotton WorksOur Shotton operations take place in anenvironmentally sensitive area. We aresurrounded by the Dee Estuary, which isdesignated as a Special Area for Conservation,Special Protection Area and Site of SpecialScientific Interest.

An area of man-made lagoons within ourboundary has similar environmentaldesignations, being a breeding ground forCommon Terns and an important reed bedhabitat, leading to our proud tradition of co-existing with the natural world in thisspecial place without compromisingbiodiversity.

Clearance and maintenance work is regularlyundertaken to ensure the lagoon areas arepreserved in optimum conditions and wemanage the open areas of our site tomaximise their potential as habitats to floraand fauna, including a wide range of breedingand migratory birds.

01244 892 199 | www.tatasteelconstruction.com/roofdek 3

RoofDek Introduction

4

Shallow deck profile rangeDeveloped to optimise the designer’s needs forefficiency, aesthetics and structural performance

RoofDek Profile ranges

Structural RoofDek profile rangeTata Steel provides the designers needs for efficiency, aethestics andstructural performance by offering a comprehensive portfolio ofshallow RoofDek profiles.

Load/span figuresThe tables are based on a total ‘Dead & Super’ imposed load of1.50kN/m2, a line load of 2.00kN/m and a deflection limit of L/200. Thefactor of safety used is 1.5 for live load and 1.35 for dead load. Whereactual design loads exceed these, the spans must be reduced. Subjectto satisfactory fixings, the decks will resist wind uplift to at least thevalue of 1.50kN/m2, and a deflection limit of L/90. Full load span tablesmay be obtained from our website: www.tatasteelconstruction.com or from our technical department.

Maximum cantilevers assume a 0.9kN point load on the end, with theadjacent span being the single span as shown in the table. The end ofthe cantilever must be stiffened with an angle flashing. Steel type istaken as galvanised and coated at 280N/mm2.

Point and impact loadsMetal decking may mark if subjected to extreme point or impact load.Where the sheet is required as an exposed soffit, a thicker gauge shouldbe considered if localised marking is not acceptable.

CurvingSelf curving can induce stress marking in the sheet. The radius limitssuggested in the tables reduce the visible effect of this; however someperceptible distortion may occur.

D32s

D35

D46

D60

For material specification see page 13.

01244 892 199 | www.tatasteelconstruction.com/roofdek 5

RoofDek Profile ranges

Structural profile specifications

Profile Material Gauge and Weight Load/span Load/span Minimum Minimum Cantilever finish maximum maximum self curve factory single span double span curve (mm) (kg/m2) (mm) (mm) (m) (mm) (mm)

Steel 0.70 Interior Liner & Galvatite® 6.67 1650* 1800 40 – 325

Steel 0.90 Interior Liner & Galvatite® 8.58 1875* 2300 45 – 375

D32s Steel 1.20 Interior Liner & Galvatite® 11.46 2100* 2800 50 – 450

Aluminium 0.90 Stucco 2.98 1075* 1500* 40 – 250

Aluminium 1.20 Mill 3.97 1250* 1900* 50 – 300

Steel 0.70 Interior Liner & Galvatite® 7.08 1803 2519 40 400 400

Steel 0.90 Interior Liner & Galvatite® 9.11 2114 2835 50 400 475

D35 Steel 1.20 Interior Liner & Galvatite® 12.16 2404 3224 60 – 575

Aluminium 0.90 Stucco 3.16 1311 1960 40 400 300

Aluminium 1.20 Mill 4.21 1525 2267 50 – 350

Steel 0.70 Interior Liner & Galvatite® 7.20 2433 3120 55 400 575

Steel 0.90 Interior Liner & Galvatite® 9.26 2708 3631 65 400 650

D46 Steel 1.20 Interior Liner & Galvatite® 12.37 2994 4015 75 – 725

Aluminium 0.90 Stucco 3.21 1762 2501 55 400 400

Aluminium 1.20 Mill 4.28 2051 2761 65 – 475

Steel 0.70 Interior Liner & Galvatite® 8.34 3022 3772 70 – 725

Steel 0.90 Interior Liner & Galvatite® 10.73 3348 4489 80 – 800

D60 Steel 1.20 Interior Liner & Galvatite® 14.32 3672 4923 85 – 875

Aluminium 0.90 Stucco 3.72 2300 3060 70 – 575

Aluminium 1.20 Mill 4.96 2542 3408 80 – 625

Notes *Span limited by 2kN/m line load.1. RoofDek profiles are available with Colorcoat HPS 200 Ultra® pre-finished steel, however these load tables do not apply - please

contact us for load span data. Aluminium, other finishes and materials are available subject to minimum order quantity.2. Calculations accord to Eurocode, however a fixings check is also required.3. Load table is based on the deck bearing onto 100mm min. flange steel beam.4. Load spans calculated to Eurocode 3 and 9.

6

Deep deck profile rangeDesigned for exceptional strength and span capabilityfor all roofing types

RoofDek Profile ranges

D100

D135

D153

D159

D200

D210

For material specification see page 13.

Structural RoofDek profile rangeDeep decks have exceptional strength and span capability, providing arugged structural platform for all roofing types. They are ideal forarchitecturally interesting large space buildings as they eliminate theneed for purlins, but are used in any situation where a strong solid basefor the roof is required.

Single ply roofs, metal standing seam, asphalt and bitumen roofs all usedeep RoofDek, and in recent years they have been the default choicefor green roofs, which impose a heavy dead load.

When specifying deep decks, designers frequently take advantage ofTata Steel's free diaphragm design service to reduce or eliminate inplane roof bracing.

Load/span figuresThe tables are based on a total ‘Dead & Super’ imposed load of1.50kN/m2, a line load of 2.00kN/m and a deflection limit of L/200. Thefactor of safety used is 1.5 for live load and 1.35 for dead load. Whereactual design loads exceed these, the spans must be reduced. Subjectto satisfactory fixings, the decks will resist wind uplift to at least thevalue of 1.50kN/m2, and a deflection limit of L/90. Full load span tablesmay be obtained from our website: www.tatasteelconstruction.com or from our technical department.

Sheet lengths – extended end lapsSheet lengths in excess of 12 metres are not practical for installation onsite and may also be subject to delivery restrictions. Extended end lapscan be used to create a double span whilst keeping the deck length toa minimum. If a deck length in excess of 12 metres is neverthelessrequired, contact our Technical Department for assistance.

01244 892 199 | www.tatasteelconstruction.com/roofdek 7

RoofDek Profile ranges

Structural profile specifications

Profile Material Gauge and Weight Load/span Load/span Minimum Minimum Cantilever finish maximum maximum self curve factory single span double span curve (mm) (kg/m2) (mm) (mm) (m) (mm) (mm)

Steel 0.70 Interior Liner & Galvatite® 9.64 4409 4696 110 – 1000

Steel 0.90 Interior Liner & Galvatite® 12.41 4788 5869 120 – 1150

D100 Steel 1.20 Interior Liner & Galvatite® 16.57 5245 7034 125 – 1250

Aluminium 0.90 Stucco 4.30 3298 3769 110 – 850

Aluminium 1.20 Mill 5.74 3642 4883 120 – 925

Steel 0.75 Interior Liner 9.49 4929 4506 150 – 1100

D135 Steel 0.88 Interior Liner 11.14 5511 5376 160 – 1200

Steel 1.25 Interior Liner 15.84 6164 7435 180 – 1350

Steel 0.75 Interior Liner 10.50 5162 4898 165 – 1250

D153 Steel 0.88 Interior Liner 12.33 5946 5865 175 – 1300

Steel 1.25 Interior Liner 17.54 6737 8150 195 – 1400

D159 Steel 1.25 Interior Liner 19.19 7101 8595 220 – 1550

Aluminium 1.50 Mill 7.97 5243 6559 200 – 1200

Steel 0.88 Interior Liner 13.81 5698 6405 260 – 1550

D200 Steel 1.25 Interior Liner 19.65 8403 9217 280 – 1800

Steel 1.50 Interior Liner 23.59 8947 10781 300 – 1900

D210 Steel 1.25 Galvatite® 16.24 7600 See note 4 250 – 1750

Notes1. RoofDek profiles are available with Colorcoat HPS 200 Ultra® pre-finished steel, however these 3. Load table is based on the deck bearing onto 100mm min. flange steel beam.

load tables do not apply - please contact us for load span data. Aluminium, other finishes and 4. For maximum Load/Span in double span conditions, contact the technical department.materials are available subject to minimum order quantity. 5. The Interior Liner colour on D135, D153 and D200 is RAL9002.

2. Calculations accord to Eurocode, however a fixings check is also required.

HLT90/600

HLT130/600

HLT145/600

For material specification see page 13.

8

RoofDek Liner trays

Liner tray profiles

Structural liner traysStructural liner trays provide a neat planar inner surface, flat except forthe stiffening ribs. It is suitable for both roof and wall claddingapplications spanning across the main steels and omitting the need forpurlins or cladding rails.

01244 892 199 | www.tatasteelconstruction.com/roofdek 9

RoofDek Liner trays

Structural liner tray profile specifications

Profile Material Gauge and Weight Load/span Load/span Minimum Minimum Cantilever finish maximum maximum self curve factory single span double span curve (mm) (kg/m2) (mm) (mm) (m) (mm) (mm)

Steel 0.75 Interior Liner 8.62 3100 3000 – – 700

HLT90/600 Steel 1.00 Interior Liner 11.49 3800 3900 – – 1150

Steel 1.25 Interior Liner 14.36 4100 4300 – – 1300

Steel 0.75 Interior Liner 9.57 4100 4100 – – 800

HLT130/600 Steel 1.00 Interior Liner 12.75 5100 5300 – – 1500

Steel 1.25 Interior Liner 15.95 5500 5900 – – 1700

Steel 0.75 Interior Liner 9.81 4300 4000 – – 650

HLT145/600 Steel 1.00 Interior Liner 13.08 5300 5600 – – 1450

Steel 1.25 Interior Liner 16.35 6000 6300 – – 1700

The colour of the Interior Liner on all HLT profiles is RAL 9002.

Acoustic profiles

10

RoofDek Acoustic profile ranges

Acoustic RoofDek rangeTata Steel offers a range of tried and tested acoustic profiles whichachieve various sound absorption ratings from A–D. Please contactour technical department for more information.

AcousticsThe decks illustrated on this page are available with perforated webs to provide acoustic absorption. Two different open area percentagefigures are in general use and both are shown. The percentage ofexposed area is the open area divided by the exposed area of steelfollowing around the profiles. The percentage of cover area is the openarea divided by the plan area of the soffit. The perforating patterns areillustrated here.

D46, D60 and D100 use perforating pattern 45464.5mm holes at 6.3mm triangularcentres. Pattern open area 46%.

D159 uses perforating pattern 33273.3mm holes at 6.0mm triangular centres.Pattern open area 27%. Fully perforated deck may be available, please enquire if required.

D135, D153 and D200 use perforating pattern P3L-S3.0mm holes at 5.5mm square centres.Pattern open area 23.5%.

D46

Perforated

D60

Perforated

D100

Perforated

D135

Perforated

D153

Perforated

D159

Perforated

D200

Perforated

4.5

6.3

60°

3.3

6.0

60°

3.0

5.5

10.7% of exposed area13.0% of cover area

13.9% of exposed area19.6% of cover area

13.3% of exposed area21.1% of cover area

6.1% of exposed area10.0% of cover area

6.2% of exposed area11.0% of cover area

7.6% of exposed area14.2% of cover area

5.0% of exposed area10.0% of cover area

01244 892 199 | www.tatasteelconstruction.com/roofdek 11

RoofDek Acoustic profile ranges

Acoustic profile specifications

Profile Material Gauge and Weight Load/span Load/span Minimum Minimum Cantilever finish maximum maximum self curve factory single span double span curve (mm) (kg/m2) (mm) (mm) (m) (mm) (mm)

Steel 0.70 Interior Liner & Galvatite® 6.49 1614 2152 55 400 475

Steel 0.90 Interior Liner & Galvatite® 8.35 2667 3003 65 400 550D46

Steel 1.20 Interior Liner & Galvatite® 11.15 2959 3874 75 – 600Perforated

Aluminium 0.90 Stucco 2.89 1202* 1602 55 400 325

Aluminium 1.20 Mill 3.86 2037 2441 65 – 400

Steel 0.70 Interior Liner & Galvatite® 7.25 1647 2196 70 – 600

Steel 0.90 Interior Liner & Galvatite® 9.33 2725 3425 80 – 675D60

Steel 1.20 Interior Liner & Galvatite® 12.45 3621 4499 85 – 725Perforated

Aluminium 0.90 Stucco 3.23 1232 1642 70 – 475

Aluminium 1.20 Mill 4.31 2123 2778 80 – 525

Steel 0.90 Interior Liner & Galvatite® 10.92 3574 4453 120 – 975

D100 Steel 1.20 Interior Liner & Galvatite® 14.58 5212 6066 125 – 1050

Perforated Aluminium 0.90 Stucco 3.79 1647 2196 110 – 700

Aluminium 1.20 Mill 5.05 3062 3733 120 – 775

Steel 0.75 Interior Liner 8.90 3150 3772 150 – 1000D135

Steel 0.88 Interior Liner 10.46 4526 4626 160 – 1100Perforated

Steel 1.25 Interior Liner 14.87 6142 6717 180 – 1200

Steel 0.75 Interior Liner 9.86 3421 4200 165 – 1100D153

Steel 0.88 Interior Liner 11.58 5012 5150 175 – 1150Perforated

Steel 1.25 Interior Liner 16.46 6730 7442 195 – 1250

D159 Steel 1.25 Interior Liner 17.80 7084 7853 220 – 1400

Perforated Aluminium 1.50 Mill 7.40 5222 5942 200 – 1100

Steel 0.88 Interior Liner 13.13 3583 4778 260 – 1200D200

Steel 1.25 Interior Liner 18.67 7739 7890 280 – 1700Perforated

Steel 1.50 Interior Liner 22.41 8945 9494 300 – 1800

Notes *Span limited by 2kN/m line load.1. Aluminium profiles are subject to minimum order quantities.2. Calculations accord to Eurocode, however a fixings check is also required.3. Load table is based on the deck bearing onto 100mm min. flange steel beam.4. The Interior Liner colour on D135, D153 & D200 is RAL 9002.

12

RoofDek Acoustic profile ranges

Acoustic profile specifications

Profile Material Gauge and Weight Load/span Load/span Minimum Minimum Cantilever finish maximum maximum self curve factory single span double span curve (mm) (kg/m2) (mm) (mm) (m) (mm) (mm)

Steel 0.75 Interior Liner 7.52 3100 2900 – – 700HLT90/600

Steel 1.00 Interior Liner 10.02 3400 3800 – – 1100Perforated

Steel 1.25 Interior Liner 12.52 3700 4300 – – 1300

Steel 0.75 Interior Liner 8.47 4000 3900 – – 750HLT130/600

Steel 1.00 Interior Liner 11.28 4900 5000 – – 1400Perforated

Steel 1.25 Interior Liner 14.12 5300 5600 – – 1600

Steel 0.75 Interior Liner 8.72 4200 3700 – – 650HLT145/600

Steel 1.00 Interior Liner 11.63 5200 5200 – – 1350Perforated

Steel 1.25 Interior Liner 14.54 5700 5900 – – 1600

The colour of the Interior Liner on all HLT profiles is RAL 9002.

Acoustic structural liner trayTata Steel offers a range of acoustic liner trays which achieve a ClassA sound absorption rating. Structural Trays offer a wider flat soffitenabling a greater perforated area, achieving the best acousticabsorption result.

The percentage of exposed area is the open area divided by theexposed area of steel following around the profiles. The percentage ofcover area is the open area divided by the plan area of the soffit. The perforating pattern is P3 ZZ, illustrated below:

3.0mm holes at 5.5mm square centres.Pattern open area 23.5%.

3.0

5.5

Acoustic profiles

HLT90/600

Perforated

HLT130/600

Perforated

HLT145/600

Perforated

18.8% of exposed area18.8% of cover area

18.8% of exposed area18.8% of cover area

18.8% of exposed area18.8% of cover area

01244 892 199 | www.tatasteelconstruction.com/roofdek 13

RoofDek Technical Information

Fire ratingAll non-perforated deck sheets provide a fire rating of Class 1 to BS476: Part 7 and Class 0 in accordance with current Building Regulations.

Fixing

Profile Main fixings at Main fixings Side lap ridge and eaves (Intermediate) fixingD32s every pitch every other pitch* not essential**

D35 –> D200 every pitch every pitch 450mm centres

D210 every pitch every pitch 350mm centres

HLT 130/600 4 per tray 4 per tray 450mm centres

D210 requires alignment cleats to prevent profile spread.* Every other pitch is based on always starting with a fixing in the first pitch of every sheet, and a profile pitch of 200mm or less.** Side lap fixing is not essential where using a fully supported under lap, otherwise it’s recommended to fix at 450mm centres.

Extended end lapsSheet lengths in excess of 12 metres are notpractical for installation on-site and may alsobe subject to delivery restrictions. Extendedend laps can be used to create a double spanwhilst keeping the deck length to a minimum.Load span data for double spanningcontinuous sheet can conservatively beapplied, provided these rules are followed.

The end lap must extend into 10% of each spanand must be tail fixed by means of 5.5mmdiameter self drilling steel stitching screwsconnecting each web (not the flange) of theoverlying profile, to the web of the underlyingprofile, one fixing in each web (2 per pitch orthe sheet) at each end of the end lap.

The web is the inclined upright part of theprofile (as opposed to the horizontal flanges).The deck is fixed to the support in the normalway.

The web fixings must not be made throughperforated sections of webs. Extended laps arenot recommended for perforated profiles.

Material specificationGalvanised steel:Tata Steel Galvatite®, hot dip zinc coated steelEN 10326-S280GD+Z275. Guaranteed minimum yield stress 280N/mm2.Minimum zinc coating mass 275g/m2 totalboth sides. (Except D159 which uses EN 10326-S320GD+Z275).

Interior liner steel (standard decks):Tata Steel Galvatite®, hot dip zinc coated steelEN 10326-S280+ZA80 substrate, withColorcoat® Interior Liner 15 microncoating to interior, colour bright white.

Interior liner (D159):Tata Steel Galvatite®, hot dip zinc coated steelEN 10326-S320GD+ZA100 substrate, withColorcoat® Interior Liner 15 micron coating tointerior, colour: bright white.

Interior liner (Tata Steel NL Profiles):Tata Steel Galvatite®, hot dip zinc coated steelEN 10326-S320GD+ZMA100 substrate, withColorcoat® Interior Liner 15 micron coating tointerior, colour: Hamlet (RAL 9002) for TataSteel Europe decks.

Aluminium:Stucco embossed or plain Aluminium.Aluminium alloy to BS EN 485-1/2/3/4:1995.Mill and stucco - grade 3005 H27.ARS coated - grade 3004 H44.

RoofDek profiles are also available withColorcoat HPS200 Ultra® pre-finished steel. For further information please contact us.

Technical information

Every web isstitched at theend of the lap

Fixing toSupport

Total overlap20% of span

10% ofspan

10% ofspan

5.5mm diameter self drilling steelstitching screws connecting eachweb

RoofDek Structural design

14

StructuralEurocode designBS EN 1993 Eurocode 3: Design of steelstructures.

Part 1-3: Cold-formed thin gauge membersand sheeting.

BS EN 1999 Eurocode 9: Design of aluminiumstructures.

Part 1-4: Cold-formed structural sheeting.

British Standards designBS5950 Structural use of steelwork in building.

Part 6: Code of practice for design of lightgauge profiled steel sheeting.

Part 9: Code of practice for stressed skindesign.

LoadingEurocode designCalculate loading to BS EN 1991 Eurocode 1:Basis of design and actions on structures.

Part 1-1: BS EN 1991-1-1 General actions –Densities, self-weight, imposed loads forbuildings.

Part 1-3: BS EN 1991-1-3 General actions –Snow loads.

Part 1-4: BS EN 1991-1-4 General actions –Wind actions.

British Standards designCalculate loads to BS 6399.

Part 2: 1997 Code of Practice for wind loads.

Part 3: 1988 Code of Practice for imposed roofloads (including snow and snow drifting).

FragilityNon-fragility requirements are determined byACR(M)001:2000 Test For Fragility of RoofingAssemblies (second edition).

UK National Annex to Eurocode 1Actions on structuresPart 1-1: General actions – Densities, self-weight, imposed loads for buildings

Table NA.7 – Imposed loads on roofs notaccessible except for normal maintenanceand repair

Roof slope, αk Qkα degrees kN/m2 kNα < 30º 0,630 º < α < 60º 0,6[(60 – α)/30] 0,9α >= 60º 0

Span typesSingle span – one length of deck with asupport at each end.

Double span – one length of deck with asupport at each end plus a support in themiddle.

Multi span – The length of deck extends overmore than 3 supports.

Where the deck end laps, it must be lappedover by at least 50mm. This does not providecontinuity – extended end laps are requiredfor continuity, please see previous page.

Structural design

01244 892 199 | www.tatasteelconstruction.com/roofdek 15

RoofDek Diaphragm design

Function of diaphragm action• Transfers wind load from walls to brace

walls running perpendicular.• Replaces in plane roof bracing.

Benefits• Removes visual clutter in the roof - popular

with architects• Saves money by removing some of the steel

elements.

Limitations• Diaphragm area must be surrounded by at

least 3 braced walls.• Deck must be fixed to the structure on all 4

edges of diaphragm area.

To design we need:• Drawings showing deck layout and braced

walls.• Line loads at diaphragm edges.

Diaphragm analysisprogramWe offer a free diaphragm design service.The analysis assumes that the diaphragm areais rectangular and braced on at least 3 sides.

At the time of publication, our analysis uses BS EN 1993-1-3.

Diaphragm design

C

A

B

D

Vertical bracing

Roof Light

Irregular roof planshowing division intodiaphragms.

Seam Fasteners

Edge Member(Purlin)

Purlin

Rafter

Purlin/Rafterconnector

Sheet/Shearconnector fastener

Shear Connector

Sheet PurlinFastener

16

RoofDek Tested acoustic systems

PIR – for sound reduction• Kingspan insulation (SRL test report

C/00/5L/7950/1)• Weighted Sound Reduction Index Rw =

27dB• Mechanically fastened single ply membrane

system• Kingspan Thermaroof TR26 (85mm)• Polythene vapour control layer• Tata Steel D60 0.7mm steel deck

PIR + Rubbertech – for soundreduction• Kingspan insulation (SRL test report

C/03/5L/0830/2).• Weighted Sound Reduction Index Rw =

35dB.• Mechanically fastened single ply membrane

system.• Kingspan Thermaroof TR26 (85mm).• Rubbertech R10 Acoustic Membrane.• Polythene vapour control layer.• Tata Steel D60 0.7mm steel deck.

Rain noiseApproved Document E, 2004Amendment requires construction of newschool buildings to follow guidance providedby Building Bulletin 93. BB 93 advisesdesigners to consider the effect of impactnoise from rain at an early stage of the roofdesign in order to minimise disturbancewithin the building.

What constitutes a problem level of rain noiseis subjective. Roof systems employing aweatherproofing layer in full contact withinsulation, supported by a metal deck are notusually problematic in practice. However formore critical applications rain noise may bereduced by the selective specification of theinsulation system, and to a lesser extent themembrane, the fixing system, and the vapourcontrol layer.

Rain generated impact sound transmission ismeasured by a test to Draft InternationalStandard ISO 140-18.

A tank positioned 3.5m above the test roof isfilled with water and consistently recharged.The perforated base area, height and flow rateare calibrated to ensure a rainfall intensity of0.67 Lmin/m3 (40mm/h). Sound intensitymeasurements are taken below the roofconstruction in the frequency range of 50 Hzto 5000 Hz.

Indicative sound level test results on D600.7mm deck are between 52 - 60dB.

The sound intensity level measures theamount of sound being transmitted throughthe roof and therefore the lower this figure is,the better.

Further details, test reports and details ofother combinations are available fromRockwool Limited and Kingspan InsulationLimited respectively.

Acoustic systemsSound absorption and reduction

Tata Steel has carried out a number of acoustic tests at Salford University which examines the sound absorption of the most popular acousticdecks and trays in the range.

Absorption (αp)

D46 D60 D100 D159 HLT130/600Frequency Open Filled Open Filled Open Filled Open Filled (Hz) trough trough trough trough trough trough trough trough 125 0.95 1.00 0.90 1.00 0.95 1.00 0.95 1.00 1.00

250 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00

500 1.00 0.95 1.00 1.00 1.00 1.00 1.00 1.00 1.00

1000 0.85 0.90 0.85 0.90 0.80 0.85 0.50 0.60 0.95

2000 0.50 0.60 0.50 0.60 0.50 0.60 0.30 0.55 0.85

4000 0.40 0.40 0.35 0.45 0.40 0.45 0.35 0.50 0.85

αw 0.55 0.60 0.50 0.60 0.55 0.60 0.40 0.60 0.95

CLASS D C D C D C D C A

01244 892 199 | www.tatasteelconstruction.com/roofdek 17

RoofDek Tested acoustic systems

Sound reductionThe acoustic performance of the profiled metal cladding constructiondetailed below has been predicted using a computer programmedeveloped by the Department of Applied Acoustics at the University ofSalford under a research contract funded by the Metal Cladding andRoofing Manufacturers Association.

CAUTION: The Predicted SRI values should be used only to provideguidance for preliminary design and/or appraisal of build constructionsystems. Laboratory measurements should still be used to providedefinitive acoustic data. For a project specific calculation contact Tata Steel Technical Department on 01244 892 199 or e-mail:[email protected]

Construction details (typical)Weather sheet: Membrane thickness = 1.2mm

Insulation: Cavity width = 200mm Insulation thickness = 200mm Density = 80kg/m3. Fixing spacing = 233mm Purlin spacing = 4000mm Type = SOFT

Liner Sheet: D100 Pitch = 233mm Crown = 109mm Valley = 63mm Depth = 100mm Thickness = 0.7/0.9/1.2mm

Sound reduction

RoofDek D60 typical acoustic build up

• Absorption co-efficient (αw) = 0.55• Absorption Class D• Weighted sound reduction (Rw) = 39dB

Fully bonded single ply membrane system

1.5mm thick PVC single ply membrane fully adhered

100mm thick Hardrock Dual Density SPA

2mm thick aluminium cored vapour control

50mm thick Hardrock Dual Density TFA layer

Tata Steel RoofDek D60 web perforated deck

Predicted sound reduction values (dB)

Frequency 0.7 mm 0.9 mm 1.2 mm (Hz) 100 17.4 19.4 21.7

125 19.2 21.2 23.7

160 21.8 24.0 26.5

200 26.1 28.3 30.8

250 30.4 29.9 29.5

315 30.1 35.7 35.4

400 29.3 40.2 40.6

500 22.4 39.2 45.1

630 37.0 37.8 50.0

800 45.3 31.2 48.6

1000 56.4 45.3 47.2

1250 60.8 56.4 39.3

1600 59.9 67.0 56.7

2000 70.6 66.9 67.2

2500 75.5 76.6 74.9

3150 77.8 81.9 83.1

4000 86.4 85.1 88.8

5000 91.9 93.0 92.8

Weighted Rw 37.0 dB 40.5 dB 43.2 dB

18

RoofDek Roof safety

Latchways have conducted numerous testsusing the Constant Force® Post inconjunction with Tata Steel RoofDek. The information below shows a typicalapplication of a Latchways Mansafe® systemwith a Single Ply membrane roof.

Installation, Annual Inspectionand CertificationOnly a Latchways Registered Installer is able todesign, supply, install and certify LatchwaysManSafe products.

Thereafter Latchways Plc. stronglyrecommend that any annual inspection, re-certification or servicing of ManSafe productsbe undertaken by a Latchways RegisteredInstaller.

Only a Latchways Registered Installer will havereceived the necessary Latchways training,have access to technical documentation andoriginal parts should replacement benecessary.

For further details please contact Latchwaysdirectly on +44 (0) 1380 732700.

Profiles & widths

Base plate Steel deckfixing centres specification

459 D32S

459 D35

210 D46

210 D60

210 D100

The Single Ply Constant Force post is suitable for use with insulation thicknesses’ of 50 mm – 220 mm. The advice of the Single Plymanufacturer should be sought when specifying all aspects of the vapour control layer, fasteners, waterproof covering and overallroof construction.All roofing components must be installed strictly in accordance with the manufacturers’ recommendations and specification.The standard colour of the post is Dark Grey – RAL 7037. Other colours are available to order at additional cost subject to availabilityand lead time. Contact Latchways technical department for further information. The post is not suitable for use within gutters orareas where standing water occurs. Adequate falls for drainage must be provided within the finished roof construction.The welding of the Single Ply membrane to the Constant Force post base plate must strictly follow the Single Ply manufacturer'srecommendations regarding application and working temperatures.

Base plate fixing centres†

The base plate fixing centres must line up with the crowns ofthe steel deck.

† Latchways reference to base plate fixing centres is defined asthe width of the fixing points for the Latchways base plate.

Single Ply membrane

Protective plastic cap

Plastic toggle guide

Toggle bolt

WeldWeld

6,000 – 10,000mm 6,000 – 10,000mm

245mm

Roof safety

01244 892 199 | www.tatasteelconstruction.com/roofdek 19

Service and support

RoofDek Service and support

Tata Steel maintains a friendly technical helpdesk which is freely available to allArchitects, Engineers and Contractors toassist with all aspects of RoofDek and linertray design.

Specification serviceThe Tata Steel RoofDek team are able toprovide a comprehensive SpecificationService. Assistance in creating NBSspecifications for RoofDek and trays can beprovided to ensure the correct deck or tray isspecificed for the right application.

Design calculations & diaphagmdesignTo assist the specifier, the team are able toprovide design calculations for live, dead,wind and snow drift loads and where requireddiaphragn design calculations.

Analysis SoftwareRoofDek Analysis Software has been createdin partnership with leading internationaldeveloper CSC, best known for the verywidely-adopted Tedds structural designsoftware. With all calculations compliant withEurocodes, the package enables structuralengineers and designers to carry out full deckanalysis to achieve optimum design and costefficiencies.

To download the RoofDek software, visitwww.tatasteelconstruction.com/roofdek

20

RoofDek Sustainability

CO2 is a by-product of the steel makingprocess and we have a well-developedstrategy to minimise our CO2 footprint. In fact,over the last 40 years we have reduced theenergy needed to produce steel by 50%. Andwe have set a target of reducing our CO2

emissions by a further 20% in the next tenyears.

Some of our savings in CO2 come from majorinvestments, like the recovery of waste gasesat our Port Talbot site. This investment of£60m is already saving 297,000 tonnes of CO2

emissions annually. Other reductions havecome from smaller site-based initiatives suchas the zero-carbon scheme at our Shotton site.Since starting this in 2005, the site hasreduced its CO2 footprint by more than 25%.

We are also investing in the future to realise amajor step-change in steel making with lower

CO2 emissions. We are a leading partner in the€59m ULCOS project which aims to cut theCO2 emissions from steel production by 50%by 2050.

The first phase of ULCOS involved research toevaluate a new generation of steel makingtechnologies, while the second phase willoperate the most promising of these on ademonstration plant. The pilot HIsarnafurnace is operated by Tata Steel, incooperation with representatives from steelplants across Europe and will demonstratetechnology for producing steel with up to50% less CO2 emissions. This is potentially thefirst step to the dawn of a new era in steelmaking.

For Tata Steel, sustainability is not all aboutCO2. There are initiatives ongoing across oursites to reduce waste, minimise emissions andcontribute to our communities.

All Tata Steel manufacturing sites are certifiedto ISO 14001, the international standard forenvironmental management systems. We alsorecognise the responsibility we have both upand down our supply chains and we work toensure that sustainable practices are adoptedthroughout by close co-operation with bothsuppliers and customers.

For more information on our sustainabilitystrategy, visit www.tatasteelconstruction.com/sustainability

“We take ourresponsibility as asustainable steelproducer veryseriously and havetaken a leading rolein reducing CO2emissions across the steel industry.”

Tata Steel’s Shotton site – now with 25% less CO2

emissions than in 2005.

SustainabilityAt Tata Steel, we are committed to making theproducts society needs and to making them inthe safest and most responsible way possible.

Wastewater Treatment WorksPeacehaven, E. SussexFeaturing the UK’s largest curved green roofand covering an area equal to 2.5 footballpitches, Southern Water’s £300m, state-of-the-art water treatment plant will service theentire Brighton and Hove area. The rooffeatures over 18,000m2 of Tata SteelRoofDek D100 and the Tata Steel C19 profileon the walls, all in Olive Green, double-sidedColorcoat HPS200 Ultra®.

Peacehaven Wastewater Treatment Works isan environmental improvement scheme atLower Hoddern Farm in Peacehaven, EastSussex, UK. The project will treat 95 millionlitres (ML) of wastewater a day.

Designed to blend in with the landscape theplant will treat wastewater generated fromBrighton and Hove, Rottingdean, Saltdean,Telscombe, Woodingdean and Peacehavenand is scheduled to be fully operational byspring 2013.

The biggest challenge on-site was logistics interms of transferring the thousands of tonnesof substrate onto the roof and covering thecomplete area using mobile tower cranes. Toovercome this issue, a series of conveyor beltswere used to transport the volume of material,which was then raked to follow the curve ofthe building.

The green roof has been installed over18,000m2 of Tata Steel RoofDek D100 in OliveGreen double-sided 0.9mm Colorcoat HPS200Ultra®.

Designed to accommodate the additionalloadings imposed by green roof construction,RoofDek D100 features a 700mm cover widthand a 233.3mm pitch that provides a verystrong deck and offers excellent insulationsupport. Its lightweight construction alsominimises the load on the building structure.

“The metal deck single ply structure withshear batten support overcame initial designconcerns,” explained Project Manager PaulWebb.

The project involved a total envelope solution,including walls featuring the Tata Steel C19profile in Olive Green 0.7mm double-sidedColorcoat HPS200 Ultra® in single and doubleskin configurations. Colorcoat HPS200 Ultra® isthe most durable pre-finished steel on themarket.

Based upon a revolutionary coating system,Colorcoat HPS200 Ultra® provides outstandingcolour and gloss retention, and corrosionresistance even at the cut edge.

Double-sided Colorcoat HPS200 Ultra® is idealfor the demanding internal environment atPeacehaven Wastewater Treatment Works,where the same unique formulation topcoatand corrosion-resistant primer applied to thereverse side provides a robust barrier on bothsides of the steel substrate.

RoofDek Case Studies

01244 892 199 | www.tatasteelconstruction.com/roofdek 21

PeacehavenRoofDek D100 Case Study

22

RoofDek Case Studies

Ellesmere Port Campusand Chester CampusWest Cheshire College prides itself on itsstandards of teaching and the courses itprovides. In order to enhance the learningexperience offered, it has committed tobuilding two new high-quality campuses.Featuring ComFlor® composite floor deckingand RoofDek Structural Roof Decking, thenew facilities will improve vocationalopportunities for young people and extendthe range of opportunities for adults todevelop skills.

The Ellesmere Port Campus involves theconstruction of a 19,500m2 new build art,design and media, hospitality and cateringand hairdressing and beauty block. Running inparallel, the Chester Campus constructionprogramme consists of a 6,000m2 state-of-the-art science and technology teaching facility.The main focus of both campuses is aninternal project court where vocationalstudents of different trades are able to workalongside one another in building a house,within the project court itself.

As part of the new build programme, 11,000m2 of ComFlor® 80 composite floordecking was specified for both campuses.Alongside this, 2,300m2 of RoofDek D135structural metal roof decking was specified.

By offering a comprehensive range of steelcomposite floor and roof decking systems, TataSteel were in the unique position of being ableto meet all of the roofing and flooringrequirements for the College project.

West Cheshire CollegeRoofDek D135 case study

CCGT Power Station, West Burton,NottinghamshireEDF Energy's 1300MW Combined Cycle GasTurbine (CCGT) power station at WestBurton, Nottinghamshire, will meet theneeds of 1.5 million people. The projectfeatures 40,000m2 of a Tata Steel AcousticStructural Liner Tray Built Up System, forhigh sound reduction and absorption levelsin three giant turbine halls.

It is adjacent to EDF’s existing 2,000MW coalfired power station and has been built usingadvanced, yet proven technology to providean efficient and flexible power station to meetfuture energy supply requirements and tohelp reduce the intensity of the company’sCO2 emissions from its electricity production.

A major construction project by any standard,West Burton CCGT saw over 1000 individualcontractors working on site at the height ofthe very complex build programme.

The project’s three 32m tall, steel-framedturbine halls, each measuring 82m long x 35mwide, feature a total of 40,000m2 of a TataSteel Acoustic Structural Liner Tray Built UpSystem, installed by Hertel Technical Services.

The very stringent acoustic requirements werefully met at West Burton, thanks to the wealthof experience Tata Steel could bring to theproject, drawing on an excellent track recordin full acoustic systems at other CCGT powerstation projects at Rye House, Hertfordshireand Killlingholme, Lincolnshire.

The roof and wall constructions feature theTata Steel HLT130/600 0.75mm gaugeacoustic structural liner tray.

Forming the base of a roof and wallconstruction incorporating two dense mineralfibre insulation layers, HLT130/600’s inherentproperties greatly assisted sound reductionand absorption, simultaneously controllingnoise breakout and reducing internal high andlow frequency noise levels in the three halls.

A sound reduction figure of 36dB wasachieved in each of the halls, significantlyreducing their acoustic impact in thesurrounding area.

The built up roofing and cladding systemincluded a rigid mineral fibre slab in the pansof the HLT130/600 structural liner tray.

A further semi-rigid mineral fibre slab wasinserted above the tray flanges. This wasseparated from the rigid insulation layer by aflat 0.7mm galvanised steel sheet, helping toprovide vital mass in the built-up system

The external roofs feature the Panels andProfiles R32 profile. The external walls are cladin the C32 profile.

Both products have a 0.7mm ColorcoatPrisma® Silver Metallic finish, plus a Denimfinish on the lower levels of C32. Versatile,lightweight and strong, Colorcoat Prisma® isan ideal choice when it comes to exposedexternal environments like West Burton.

Offering outstanding UV resistance, ColorcoatPrisma® gives first-class colour and glossretention, following comprehensive naturalweathering testing in a variety of contrastingclimates.

The R32 roof profile accommodates 800metres of lightweight aluminium walkways,complete with tubular handrails, with stainlesssteel fixings to the Panels and Profiles sheets.This facilitates easy servicing of 100 rooflightsand ventilators on each of the three roofs,which also feature parapet walls in C32 on allsides.

RoofDek Case Studies

West Burton Power StationHLT130/600 liner tray case study

01244 892 199 | www.tatasteelconstruction.com/roofdek 23

www.tatasteelconstruction.com/roofdek

Trademarks of Tata SteelColorcoat, Colorcoat HPS200 Ultra, Colorcoat Prismaand Galvatite are trademarks are registeredtrademarks of Tata Steel UK Limited.

Care has been taken to ensure that the contents ofthis publication are accurate, but Tata Steel EuropeLimited and its subsidiaries, (including Tata Steel UKLimited), do not accept responsibility or liability forerrors or information that is found to be misleading.Suggestions for, or descriptions of, the end use orapplication of products or methods of working arefor information only and Tata Steel Europe Limitedand its subsidiaries accept no liability in respectthereof.

Before using products or services supplied ormanufactured by Tata Steel Europe Limited and itssubsidiaries, customers should satisfy themselves asto their suitability.

Printed with biodegradable vegetable inks onmaterial sourced from responsibly managed forests,certified in accordance with the FSC. Contains 10%recovered fibre, diverting waste from landfill.

Sales Contact Details

Tata SteelShottonDeesideFlintshireCH5 2NHUnited KingdomT: +44 (0) 1244 892 199F: +44 (0) 1244 892 121E: [email protected]

Copyright 2016 Tata Steel UK Limited, Registered Office: 30 Millbank London SW1P 4WY, Registered in England No. 2280000

Language English UK 0716