Stokes Hot Rod Cat-f

Transcript of Stokes Hot Rod Cat-f

Hot RodImmersion Heaters &

Accessories Catalogue

Stokes Hot Rod Cat-f 24/5/07 5:45 PM Page 1

HEAD OFFICE AND FACTORY

24 Palmerston Road West, Ringwood, Victoria 3134, AustraliaP.O. Box 168, Mitcham, Victoria 3132, AustraliaTel: +61 3 9845 8300 Fax: +61 3 9874 1077E-mail: [email protected] Web: www.stokessynertec.comA.C.N. 004 554 929 A.B.N. 24 004 554 929

AGENTS

International

NEW ZEALANDSTOKES (NEW ZEALAND) LIMITED41 Fairfax Avenue, Penrose, Auckland, New ZealandP.O. Box 12 - 105, Auckland, New ZealandTel: (64) 9 526 4750 Fax: (64) 9 526 4759E-mail: [email protected]

UNITED KINGDOMMRC TECHNOLOGIES LIMITEDUnit 1, Block 4 Mountjoy Research Centre,Stockton Road, Durham BH13SW, United KingdomTel: (44) 191 384 1365 Fax: (44) 191 525 0817E-mail: [email protected]@compuserve.com

SINGAPORE, INDONESIA, MALAYSIA, BRUNEIJELCO PRIVATE LIMITEDBlock 2036, Bukit Batok Industrial Park A,Street 23, #01-314, Singapore 659541P.O. Box 94 Alexandra Post Office, Singapore 911504Tel: (65) 561 1988 Fax: (65) 567 6242E-mail: [email protected]

HONG KONGEXTENSIVE TRADING CO., LTDFlat A, 8/F Chaiwan Industrial Centre Building20 Lee Chung Street, Chaiwan, Hong KongTel: (852) 2889 1681 Fax: (852) 2556 6029

Australia

NEW SOUTH WALESCONTROL DISTRIBUTIONS PTY LTD150 Bellevue Parade, Carlton, N.S.W. 2218Tel: (02) 9546 6860 Fax: (02) 9546 6927E-mail: [email protected]

QUEENSLAND, PAPUA NEW GUINEALOU J. MURRAY & CO. PTY LTD30 McKechnie Drive, Eight Mile Plains, Qld. 4113Tel: (07) 3841 0088 Fax: (07) 3841 2200E-mail: [email protected]

TASMANIATASMANIAN APPLIANCE SPARES51 Burnett Street, North Hobart, Tas. 7000Tel: (03) 6236 9799 Fax: (03) 6236 9069

SOUTH AUSTRALIA, NORTHERN TERRITORYSTOKESUnit 4, 197 Richmond Road, Richmond, S.A. 5033Tel: (08) 8354 2300 Fax: (08) 8354 2301

VICTORIATHERMAL PRODUCTS PTY LTD178-180 Holt Parade, Thomastown, Vic. 3074Tel: (03) 9464 0822 Fax: (03) 9464 0630

Stokes Hot Rod Cat-f 24/5/07 5:45 PM Page 2

1. STANDARD HOT RODS ..................................................................................................... 2

1.1 VITROSOL ..................................................................................................................... 21.2 TITANIUM ...................................................................................................................... 21.3 STAINLESS STEEL 316 ................................................................................................ 2

2. INSTALLATION .................................................................................................................. 4

3. STANDARD RANGE OF HOT RODS ................................................................................ 5

4. SPARE PARTS ................................................................................................................... 6

4.1 STANDARD HOT ROD ELEMENTS ONLY- SET OF THREE ........................................ 64.2 STANDARD HOT ROD SHEATHS ................................................................................. 7

5. OPTIONAL PARTS ............................................................................................................. 8

5.1 HEATER GUARDS ........................................................................................................ 85.2 MOUNTING BRACKETS ............................................................................................... 9

6. STOKES MINI HOT RODS ................................................................................................ 10

7. SPARE PARTS FOR MINI HOT RODS .............................................................................. 11

7.1 STANDARD MINI HOT ROD ELEMENT ONLY ............................................................. 117.2 STANDARD MINI HOT ROD SHEATHS ........................................................................ 11

8. OPTIONAL PARTS ............................................................................................................. 12

8.1 STOKES MINI HEATER GUARDS ................................................................................. 128.2 MINI MOUNTING BRACKETS ...................................................................................... 12

9. STANDARD RANGE OF TEFLON HOT ROD HEATERS ...................................................13

10. LIQUID LEVEL AND TEMPERATURE CONTROL ......................................................... 14

10.1 LIQUID LEVEL PROBES ............................................................................................. 1410.2 PT100 TEMPERATURE PROBES ............................................................................... 1510.3 LIQUID LEVEL CONTROLLER .................................................................................... 1610.4 PT100 TEMPERATURE CONTROLLER - ANALOGUE, Non Indicating...................... 1610.5 PT100 TEMPERATURE CONTROLLER - DIGITAL ..................................................... 17

11. TECHNICAL INFORMATION ........................................................................................... 18

11.1 QUICK CALCULATION CHART FOR HEAT REQUIREMENTS ................................... 1811.2 HOT ROD HEATER SOLUTION GUIDE ...................................................................... 1911.3 TEMPERATURE CONVERSIONS ................................................................................ 22

ELECTRICAL INSTALLATION

• In all cases Stokes recommends that electrical installation must only be performed by a Qualified Electrician, and be in accordance with AS/NZS 3000

• Also it is further recommended that earth leakage circuit breakers be incorporated in all installations

• Stokes Australasia Ltd. Reserves the right to amend manufacturing methods or specifications without notification

STOKES SYNERTEC Hot Rod Immersion Heaters & Accessories Catalogue

24 Palmerston Road West, Ringwood, Victoria 3134, Australia. Phone: +61 9 9845 8300 Fax: +61 3 9874 1077

1

Contents

Stokes Hot Rod Cat-f 24/5/07 5:45 PM Page 3

Stokes Hot Rods are a type of over the side immersion heaters which have wide applications in Electroplating, AquaCulture, Fishery, Hatchery, Mechanical Services and many other industries. The elements are ceramic filled incoloytubes contained within an outer sheath of either stainless steel, titanium or vitrosol glass. Please refer to the Heatersolution Guide section of Technical Information to determine the appropriate sheath material.

1.1 VITROSOLStokes Vitrosol heaters are made from translucent fused silica which has an extremely low co-efficient of expansionand is inert to most acids. This makes it an ideal choice for the heating of acid solutions. Hence they are used inaqueous acidic plating solutions such as nickel plating, acid copper and chrome plating etc. They are also used inpickling tanks, eg. in Sulphuric acid and Hydrochloric acid pickling.

Note: Vitrosol is a form of glass and must not be used in hydrofluoric acid or strong alkaline solutions.

Protection from mechanical damage should also be considered. This can be achieved by means of polypropylene guard or PVC in the case of chrome or nitric solutions. Please refer to our Heater Guards section for further information.

1.2 TITANIUMStokes Titanium heaters can be used in a wide range of acid and alkaline solutions, but chemical attack can occur in some instances at varying rates, depending on temperature and concentration of the solutions. In electroplatingprocesses such as nickel plating it is advisable to connect the Titanium sheath anodically to prevent corrosion.

1.3 STAINLESS STEEL 316Stokes Stainless steel heaters are ideal for use in phosphating solutions and in solutions with an alkaline or neutral PH value. Certain acidic chemical processes recommend the use of stainless steel tanks but this does notnecessarily mean the use of stainless steel heaters. In these instances it is advisable to use Vitrosol heaters due to the chemical attack on stainless steel at the elevated surface temperatures of the heater tube. In brass platingprocesses, liquid ammonia must be used, not ammonium chloride, as the chloride will attack the stainless steel sheath.

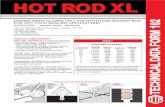

The following shows the hot rod dimensions, and tank dimensions.

HOT ROD DIMENSIONS

Fig.1 Hot Rod Dimensions

STOKES SYNERTEC Hot Rod Immersion Heaters & Accessories Catalogue

24 Palmerston Road West, Ringwood, Victoria 3134, Australia. Phone: +61 9 9845 8300 Fax: +61 3 9874 1077

2

1 Standard Hot Rods

C = COLD ZONE

H = HOT ZONE

L = TOTAL LENGTH

D = DIAMETER

Stokes Hot Rod Cat-f 24/5/07 5:45 PM Page 4

TANK DIMENSIONS

Fig.2 Rectangular Tank Dimensions

Fig. 3 Circular Tank Dimensions

Please note that it is essential to give us the exact internal dimensions and solution height.

The Kilowatts required depends on type of solution, temperature difference, insulation, and heat up time. Refer toour Heater Solution guide to determine appropriate sheath material. Refer to our Technical Information for requiredkilowatts calculations. Please contact us if you need any assistance with the calculations of kilowatts required.

STOKES SYNERTEC Hot Rod Immersion Heaters & Accessories Catalogue

24 Palmerston Road West, Ringwood, Victoria 3134, Australia. Phone: +61 9 9845 8300 Fax: +61 3 9874 1077

3

1 Standard Hot Rods

L

DH

W

D

LH

L = LENGTH

W = WIDTH

H = HEIGHT OF TANK

D = DEPTH OF TANK

D = DIAMETER

H = HEIGHT OF TANK

L = LEVEL OF LIQUIDS

Stokes Hot Rod Cat-f 24/5/07 5:45 PM Page 5

TYPICAL INSTALLATION

TEMPERATURE PROBELEVEL CONTROL

SOLUTION LEVEL

COLD ZONE

HEATERS

Fig.4 Typical installation

• Minimum Liquid level must be maintained at all times

• Max solution temperature not to exceed 65 °C

Where possible it is advisable to install heaters in multiples of 3 in order to keep the phases balanced. It is desirable to locate the temperature probe at a reasonable distance from the heaters in order to obtain accurate control. Solution level must never be allowed to fall below the cold zone of the heater or the heater will fail.

CAUTION

• Stainless Steel Heaters:

When using S/ Steel sheathed units, care should be used in preventing high temperatures being transferred up the sheath, otherwise melting of the PVC cap may occur.

• Vitrosol Heaters:

When using the Vitrosol heaters extreme care should be used to prevent thermal shock that could cause the sheath to crack. It is important therefore to maintain the correct solution level at all times.

This can be controlled automatically by the use of a level control unit used in conjunction with a solenoid operated valve to maintain the solution level, or a safety device to isolate the heaters in the event of rapid loss of solution.

• To improve heat up times it is recommended that the tank be insulated and have a top to reduce temperature losses.

• It is recommended to install earth leakage circuit breakers with all quartz heaters, in accordance with local codes.

STOKES SYNERTEC Hot Rod Immersion Heaters & Accessories Catalogue

24 Palmerston Road West, Ringwood, Victoria 3134, Australia. Phone: +61 9 9845 8300 Fax: +61 3 9874 1077

4

2 Installation

Stokes Hot Rod Cat-f 24/5/07 5:45 PM Page 6

# -

She

ath

Mat

eria

l Co

de

The

Cat

alog

ue N

o. a

s lis

ted

ab

ove

is n

ot c

omp

lete

.

Sel

ect

the

shea

th c

ode

from

the

fol

low

ing

tab

le t

o co

mp

lete

the

C

atal

ogue

No.

Exa

mp

le:

Tita

nium

She

ath,

Cat

alog

ue N

o. #

3003

HR

bec

omes

T300

3HR

.

No

te:

1 K

w t

o 5

Kw

Hea

ters

are

sup

plie

d w

ith

2000

mm

cab

les

7 K

w h

eate

rs a

re s

upp

lied

wit

h 40

00 m

m c

able

s

STOKES SYNERTEC Hot Rod Immersion Heaters & Accessories Catalogue

24 Palmerston Road West, Ringwood, Victoria 3134, Australia. Phone: +61 9 9845 8300 Fax: +61 3 9874 1077

5

3 Standard Range of Hot Rods

C =

CO

LD Z

ON

E

H =

HO

T Z

ON

E

L =

TO

TAL

LEN

GTH

D =

DIA

ME

TER

She

ath

Mat

eria

lS

heat

h C

od

e (#

)

Sta

inle

ss S

teel

S

Vitr

osol

V

Tita

nium

T

Cat

alo

gue

No

.#7

000H

R#3

003H

R#5

000H

R#4

000H

R

#300

2HR

#150

3HR

#300

1HR

#150

2HR

#200

0HR

#150

1HR

#100

0HR

Wat

ts70

00

3000

*50

00

4000

30

00

1500

*30

0015

00*

2000

15

0010

00

Volts

240

240

240

240

24

0 24

024

0 24

0 24

0 24

0 24

0

Lmm

1500

1500

1000

1000

1000

1000

750

750

600

500

300

Cm

m35

035

025

025

025

025

025

025

020

020

010

0

Hm

m11

5011

5075

075

075

075

050

050

040

030

020

0

Dm

m40

4040

4040

4040

4040

4040

The

abov

e ta

ble

sho

ws

the

stan

dar

d

rang

e of

HO

T R

OD

hea

ters

.

* In

pho

spha

ting

solu

tions

it is

ad

visa

ble

to

use

a m

ultip

le o

f lo

w k

ilow

att

heat

ers

rath

er t

han

one

high

kilo

wat

t he

ater

Thi

s w

ill lo

wer

the

wat

ts d

ensi

ty

and

avo

id a

rap

id b

uild

-up

of

pho

spha

te s

lud

ge o

n th

e he

ater

tub

e w

hich

fo

rms

an in

sula

ting

crus

t an

d c

an c

ause

the

ele

men

t to

ove

rhea

t.

Sp

ecia

ls c

an b

e m

ade

to a

ny le

ngth

in in

crem

ents

of

25m

m w

ith h

ot a

nd

cold

zon

es t

o su

it m

ost

app

licat

ions

.

Stokes Hot Rod Cat-f 24/5/07 5:45 PM Page 7

The following spares are also available.

4.1 STANDARD HOT ROD ELEMENTS ONLY – SET OF THREE

Fig.5 Element Assembly

STOKES SYNERTEC Hot Rod Immersion Heaters & Accessories Catalogue

24 Palmerston Road West, Ringwood, Victoria 3134, Australia. Phone: +61 9 9845 8300 Fax: +61 3 9874 1077

6

4 Spare Parts

Catalogue No. Description

E1000HR 1 kW 240 V 300 mm element assembly

E1501HR 1.5 kW 240 V 500 mm element assembly

E1502HR 1.5 kW 240 V 750 mm element assembly

E1503HR 1.5 kW 240 V 1000 mm element assembly

E2000HR 2 kW 240 V 600 mm element assembly

E3001HR 3 kW 240 V 750 mm element assembly

E3002HR 3 kW 240 V 1000 mm element assembly

E3003HR 3 kW 240 V 1500 mm element assembly

E4000HR 4 kW 240 V 1000 mm element assembly

E5000HR 5 kW 240 V 1000 mm element assembly

E7000HR 7 kW 240 V 1500 mm element assembly

Stokes Hot Rod Cat-f 24/5/07 5:45 PM Page 8

Catalogue No. Length (mm)

#S0300HR 300

#S0500HR 500

#S0600HR 600

#S0750HR 750

#S1000HR 1000

#S1500HR 1500

STOKES SYNERTEC Hot Rod Immersion Heaters & Accessories Catalogue

24 Palmerston Road West, Ringwood, Victoria 3134, Australia. Phone: +61 9 9845 8300 Fax: +61 3 9874 1077

7

4 Spare Parts

Sheath Material Sheath Code (#)

Stainless Steel S

Vitrosol V

Titanium T

4.2 STANDARD HOT ROD SHEATHS

# - Sheath Material Code

The Catalogue No. as listed above is not complete. Select the sheath code from the following table to complete theCatalogue No.

Example: Titanium Sheath, Catalogue No. #S0300HR becomes TS0300HR

Fig.6 Sheath

Stokes Hot Rod Cat-f 24/5/07 5:45 PM Page 9

5.1 HEATER GUARDSStokes Heater guards are used with vitrosol heaters for mounting and protection against mechanical damage.

Available in:

• Polypropylene and

• PVC

Fig.7 Guards

Chemical compatibility should be checked. It is recommended to use PVC for solution temperature below 70°C andPolypropylene for temperatures between 70°C and 100°C (Excluding Chrome and Nitric Solutions).

# - Guard Material

STOKES SYNERTEC Hot Rod Immersion Heaters & Accessories Catalogue

24 Palmerston Road West, Ringwood, Victoria 3134, Australia. Phone: +61 9 9845 8300 Fax: +61 3 9874 1077

8

5 Optional Parts

Catalogue No. Length (mm)

G#300HR 300

G#500HR 500

G#600HR 600

G#750HR 750

G#1000HR 1000

G#1500HR 1500

Stokes Hot Rod Cat-f 24/5/07 5:45 PM Page 10

The Catalogue No. as listed above is not complete. Select the guard material from the following table to completethe Catalogue No.

Example: Polypropylene guard, Catalogue No. G#300HR becomes GPP300HR

5.2 MOUNTING BRACKETSPVC mounting brackets, complete with bolts and nuts when using Stainless Steel or Titanium heaters.

Cat No. SBPVCHR

Description: Standard Bracket, Nuts and Bolts, PVCDimensions: 175mm X 100 mm X 20 mm

Fig.8 Mounting Brackets

STOKES SYNERTEC Hot Rod Immersion Heaters & Accessories Catalogue

24 Palmerston Road West, Ringwood, Victoria 3134, Australia. Phone: +61 9 9845 8300 Fax: +61 3 9874 1077

9

5 Optional Parts

Guard Material Material Code (#)

PVC PV

Polypropolene PP

Stokes Hot Rod Cat-f 24/5/07 5:45 PM Page 11

Stokes Mini HOT RODS are used when small immersion heaters and low wattages are required.

APPLICATIONS

Metal Treatment processes

Small electroplating installations, jewellery production, gunsmith-processes and PC board production.

Other Uses

Water distillation units, large fish tanks, pilot plants and laboratories.

Standard range of Mini HOT ROD heaters.

Specials can be made to any length in increments of 16 mm with hot and cold zones to suit most applications.

#- Sheath Material Code.

Catalogue No. as listed above is not complete. Select sheath code from the following table to complete Catalogue No.

Example: Titanium Sheath, Catalogue No. M#0300HR becomes MT0300HR.

STOKES SYNERTEC Hot Rod Immersion Heaters & Accessories Catalogue

24 Palmerston Road West, Ringwood, Victoria 3134, Australia. Phone: +61 9 9845 8300 Fax: +61 3 9874 1077

10

6 Stokes Mini Hot Rods

C = COLD ZONE

H = HOT ZONE

L = TOTAL LENGTH

D = DIAMETER

Sheath Material Sheath Code (#)

Stainless Steel S

Vitrosol V

Titanium T

Catalogue No. M#0800HR M#0700HR M#0600HR M#0450HR M#0350HR

Watts 800 700 600 450 350

Volts 240 240 240 240 240

L mm 400 350 300 250 200

C mm 120 100 100 90 70

H mm 280 250 200 160 130

D mm 20 20 20 20 20

Stokes Hot Rod Cat-f 24/5/07 5:45 PM Page 12

The following spares are also available.

7.1 STANDARD MINI HOT ROD ELEMENT ONLY

7.2 STANDARD MINI HOT ROD SHEATHS

# - Sheath Material Code

Catalogue No. as listed above is not complete. Select sheath code from the following table to complete CatalogueNo.

Example: Titanium Sheath, Catalogue No. M#S300HR becomes MTS300HR.

STOKES SYNERTEC Hot Rod Immersion Heaters & Accessories Catalogue

24 Palmerston Road West, Ringwood, Victoria 3134, Australia. Phone: +61 9 9845 8300 Fax: +61 3 9874 1077

11

7 Spare Parts for Mini Hot Rods

Sheath Material Sheath Code (#)

Stainless Steel S

Vitrosol V

Titanium T

Catalogue No. Description

ME350HR 350W 240V 200mm element

ME450HR 450W 240V 250mm element

ME600HR 600W 240V 300mm element

ME700HR 700W 240V 350mm element

ME800HR 800W 240V 400mm element

ME1250HR 1250W 240V 400mm element

Catalogue No. Length (mm)

M#S200HR 200

M#S250HR 250

M#S300HR 300

M#S350HR 350

M#S400HR 400

Stokes Hot Rod Cat-f 24/5/07 5:45 PM Page 13

8.1 STOKES MINI HEATER GUARDSMini Heaters guards are used with Vitrosol heaters for mounting and protection against mechanical damage.

Available in:

• Polypropylene and

• PVC

Fig.10 Mini Heating Guards

Chemical compatibility should also be checked. It is recommended to use PVC for solution temperatures below70°C and Polypropylene for temperatures between 70°C and 100°C (Excluding Chrome and Nitric Solutions).

# - Guard Material

The Catalogue No. as listed above is not complete. Select the guard material from the following table to completethe Catalogue No.

Example: Polypropylene guard, Catalogue No. MG#300HR becomes MGPP300HR

8.2 MINI MOUNTING BRACKETSPVC mounting brackets, supplied complete with bolts and nuts when used with stainless steel and Titaniumheaters. They are also used for mounting temperature and liquid level probes.

Cat No. MBPVCHR

Description: Mini Bracket and Bolts, PVCDimensions: 100mm X 56 mm X 12 mm

Fig.11 Mini Mounting Bracket

STOKES SYNERTEC Hot Rod Immersion Heaters & Accessories Catalogue

24 Palmerston Road West, Ringwood, Victoria 3134, Australia. Phone: +61 9 9845 8300 Fax: +61 3 9874 1077

12

8 Optional Parts

Guard Material Material Code (#)

PVC PV

Polypropolene PP

Catalogue No. Length (mm)

MG#200HR 200

MG#250HR 250

MG#300HR 300

MG#350HR 350

MG#400HR 400

Stokes Hot Rod Cat-f 24/5/07 5:45 PM Page 14

Hot rod Teflon® (PTFE) heaters are manufactured from mineral tubular sheathed elements covered with PTFE sleeving. The PTFE is acid and temperature resistant up to 280°C and is the only heater that can be applied to solutions containing hydrofluoric acid or fluoride forms in chemical heating applications.

Hot rod Teflon® heaters are also suitable for other acid solutions and because of the low watts density loading can increase the expected life.

Hot rod Teflon® heaters are custom manufactured in various bending configurations and kilowatt ratings to suit your specific requirements.

PTFE has a good mechanical strength and does not become brittle.

Note: The element must not operate in sludge deposits that accumulate at the bottom of chemical tanks.

Teflon® is a Du Pont® registered name.

Fig.12 Sample Teflon Heaters

Note: Heaters custom built on application (Consult Factory).

STOKES SYNERTEC Hot Rod Immersion Heaters & Accessories Catalogue

24 Palmerston Road West, Ringwood, Victoria 3134, Australia. Phone: +61 9 9845 8300 Fax: +61 3 9874 1077

13

9 Standard Range of Teflon Hot Rod Heaters

Standard Range

500 Watt 240 Volt 2000 mm full length 250 mm cold end

1000 Watt 240 Volt 3300 mm full length 300 mm cold end

1500 Watt 240 Volt 4500 mm full length 350 mm cold end

2000 Watt 240 Volt 6000 mm full length 350 mm cold end

3000 Watt 240 Volt 7600 mm full length 450 mm cold end

4000 Watt 240 volt 7600 mm full length 450 mm cold end

Stokes Hot Rod Cat-f 24/5/07 5:45 PM Page 15

10.1 LIQUID LEVEL PROBES

Fig.13 3-Leg Liquid Level Probe Fig.14 5-Leg Liquid Level Probe

• Stainless Steel 316

• Option Lengths: a) 300mm longb) 700mm long

• 3 legs: Hi Level; Low Level; Common

• 5 legs: Hi Level; Low Level; Common; Hi-Hi; Low-Low;Purely extra Safety to the Normal Liquid Level. The Extra two probes can be used as an Indicating light, beacon, solenoid switch or alarm. Please note additional controller must be used to switch the extra two probes.

• Special Lengths made to suit.

• Sizes cut to suit customer requirements.

• All above liquid level probes also available in Halar (Teflon®) coated with either LEAD TIPS or TITANIUM, depending on the chemical type.

Cat No. LPSHR

Description: Standard liquid level probe, S/SThe Number of legs and length of probe should be specified.

Cat No. MLPSHR

Description: Mini liquid level probe, S/SThe Number of legs and length of probe should be specified.

STOKES SYNERTEC Hot Rod Immersion Heaters & Accessories Catalogue

24 Palmerston Road West, Ringwood, Victoria 3134, Australia. Phone: +61 9 9845 8300 Fax: +61 3 9874 1077

14

10 Liquid Level and Temperature Control

Stokes Hot Rod Cat-f 24/5/07 5:45 PM Page 16

10.2 PT100 TEMPERATURE PROBES

Fig.15 Temp probe

• 0-100°C available in standard sizes in both Stainless Steel 316 and Halar (Teflon®) coated.

• 200mm; 300mm; 400mm; 500mm; 600mm, 750mm; 1000mm; 1500mm sizes.

• All above sizes standard with 2 metre cable. Extra cable lengths available on request.

# - Probe Material

The above listed Catalogue No. is not complete. Select the sheath code from the following table to complete theCatalogue No.

Example: Stainless Sheath, Catalogue No. P#200HR becomes PTS200HR

STOKES SYNERTEC Hot Rod Immersion Heaters & Accessories Catalogue

24 Palmerston Road West, Ringwood, Victoria 3134, Australia. Phone: +61 9 9845 8300 Fax: +61 3 9874 1077

15

10 Liquid Level and Temperature Control

Catalogue No. Description

P#200HR PT 100 Probe 200 mm

P#300HR PT 100 Probe 300 mm

P#400HR PT 100 Probe 400 mm

P#500HR PT 100 Probe 500 mm

P#600HR PT 100 Probe 600 mm

P#750HR PT 100 Probe 750 mm

P#1000HR PT 100 Probe 1000 mm

P#1500HR PT 100 Probe 1500 mm

Probe Material Code (#)

Stainless Steel TS

Halar(Teflon) HP

Stokes Hot Rod Cat-f 24/5/07 5:45 PM Page 17

10.3 LIQUID LEVEL CONTROLLER• Available to suit liquid level probe

Cat No. LCON

FIG.16 Liquid Level Controller

10.4 PT100 TEMPERATURE CONTROLLER – ANALOGUE, NON INDICATING• 11 Pin base

• 0-100°C

• 0-50°C

• PT 100

FIG.17 Temperature Controller TC100HR

Cat No. TC100HR

Description: PT100, analogue temperature controller

STOKES SYNERTEC Hot Rod Immersion Heaters & Accessories Catalogue

24 Palmerston Road West, Ringwood, Victoria 3134, Australia. Phone: +61 9 9845 8300 Fax: +61 3 9874 1077

16

10 Liquid Level and Temperature Control

Stokes Hot Rod Cat-f 24/5/07 5:45 PM Page 18

10.5 PT100 TEMPERATURE CONTROLLER – DIGITAL(New Model) now available

• Standard alarm and relay output functions.

• 11 Pin base.

• Variable programmable inputs.

• PT 100; Type J, K, R, S, T.

Fig.18 Temp Controller Digital

(Teflon® is a Du Pont registered name)

STOKES SYNERTEC Hot Rod Immersion Heaters & Accessories Catalogue

24 Palmerston Road West, Ringwood, Victoria 3134, Australia. Phone: +61 9 9845 8300 Fax: +61 3 9874 1077

17

10 Liquid Level and Temperature Control

Stokes Hot Rod Cat-f 24/5/07 5:45 PM Page 19

11.1 QUICK CALCULATION CHART FOR HEAT REQUIREMENTS

Note:

• These wattages are based on an 8 hour heat-up time with an ambient temperature of 21°C (70°F).

• Kilowatt ratings are calculated on enclosed tanks having 50mm insulation.

• To reduce heat-up time increase the wattage proportionately.

STOKES SYNERTEC Hot Rod Immersion Heaters & Accessories Catalogue

24 Palmerston Road West, Ringwood, Victoria 3134, Australia. Phone: +61 9 9845 8300 Fax: +61 3 9874 1077

18

11 Technical Information

Operating Temperature

Fahr. 100° 110° 120° 130° 140° 150° 160° 170° 180° 190° 200°

Cent. 38° 43° 49° 55° 60° 65° 71° 77° 82° 88° 93°

Tank Capacity

Gallons Litres

kW kW kW kW kW kW kW kW kW kW kW

50 227 0.5 0.75 1 1.5 1.5 2 2 2 3 3 3

75 341 1 1 1.5 1.5 2 2 3 3 3 4 4

100 455 1.5 1.5 2 3 3 3 4 4 4 5 5

125 568 1.5 2 3 3 4 4 4 5 5 5 6

150 682 2 2 3 3 4 4 5 5 6 6 7

175 796 3 3 4 4 5 5 5 6 6 7 7

200 910 3 3 4 4 5 5 6 6 7 8 9

250 1137 3 4 4 5 5 7 7 8 9 10 11

300 1365 4 5 6 6 8 9 10 10 11 11 12

350 1592 5 6 7 8 9 10 11 12 13 14 15

400 1820 6 7 8 9 10 11 12 13 14 16 17

450 2047 6 7 9 10 11 12 14 15 16 18 18

500 2275 7 8 9 11 12 13 15 17 18 20 21

Stokes Hot Rod Cat-f 24/5/07 5:45 PM Page 20

11.2 HOT ROD HEATER SOLUTION GUIDESOLUTION TYPE OF HEATER Acetic Acid ................................................................................ PTFE* or QuartzActane 70, 80 ............................................................................ PTFE*Actane Salt ................................................................................ PTFE*Acid Sulfate ............................................................................... PTFE* or QuartzAlcorite ...................................................................................... PTFE* or QuartzAlkaline Cleaners (Electrified) .................................................... 304 Stainless SteelAlkaline Soaking Cleaners ......................................................... 304 Stainless SteelAlodine (most formulas) ............................................................ 316 Stainless SteelAlstan ........................................................................................ 304 Stainless SteelAluminum Bright Dip ................................................................. PTFE* or QuartzAluminum Cleaners ................................................................. 304 Stainless SteelAluminum Chloride .................................................................... PTFE* or QuartzAluminum Sulfate ...................................................................... 304 Stainless SteelAmmonia ................................................................................... 304 Stainless SteelAmmonia Persulfate .................................................................. PTFE* or QuartzAmmonium Bi Fluoride ............................................................. PTFE*Ammonium Chloride .................................................................. TitaniumAmmonium Nitrate .................................................................... 316 Stainless SteelAnodizing (Aluminum) ................................................................ PTFE* or QuartzARP 28, 80 Blackening Salts .................................................... PTFE* or QuartzArsenic ....................................................................................... 304 Stainless SteelBarium Chloride ......................................................................... Quartz or TitaniumBenzoic Acid .............................................................................. TitaniumBlack Nickel ............................................................................... PTFE* or QuartzBlack Oxide (Hi-Temp) ..........................................……........... 304 Stainless SteelBlack Oxide (Low-Temp) ........................................................... TitaniumBonderizing .......................................................................…... 316 Stainless SteelBoric Acid .................................................................................. TitaniumBrass Cyanide ........................................................................... 304 Stainless SteelBright Nickel .............................................................................. PTFE*, Quartz, or TitaniumBright Copper Cyanide ............................................................. 304 Stainless SteelBronze (Alkaline)......................................................................... 304 Stainless SteelBrown Oxide .............................................................................. TitaniumBurnite ....................................................................................... PTFE* or QuartzButyric Acid ............................................................................... TitaniumCadmium Black ......................................................................... PTFE* or QuartzCadmium (Alkaline) .................................................................... 304 Stainless SteelCadmium Fluoborate ................................................................. PTFE*Calcium Chloride ....................................................................... TitaniumCalcium Hypochlorite ................................................................ TitaniumCarbonic Acid ............................................................................ TitaniumCaustic Etch ............................................................................ SteelCaustics ..................................................................................... SteelCaustics (highly concentrated 20% and over) ..................... SteelChlorine/Wet .............................................................................. PTFE* or QuartzChloride ..................................................................................... PTFE*, Quartz or TitaniumChlorosulfuric Acid .................................................................... TitaniumChromic Anodizing .................................................................... PTFE* or QuartzChromic Acetate ....................................................................... PTFE* or QuartzChromic Nickel .......................................................................... PTFE* or QuartzChromium (No Fluorides) ...........................………..........……… PTFE*, Quartz, or TitaniumChromium (Fluoride) .................................................................. PTFE*Citric Acid .................................................................................. TitaniumClear Chromate ......................................................................... PTFE* or QuartzCobalt Nickel ............................................................................. PTFE*, Quartz, or TitaniumCobalt Plating ............................................................................ 304 Stainless SteelCobra Etch ................................................................................ PTFE*Copper Acid .............................................................................. PTFE* or QuartzCopper Bright Acid ................................................................... PTFE* or QuartzCopper Cyanide ........................................................................ 304 Stainless SteelCopper Fluoborate .................................................................... PTFE*Copper Pyrophosphate ............................................................. 304 Stainless SteelCopper Strike ............................................................................ 304 Stainless SteelCopper Sulfate .......................................................................... PTFE* or QuartzCyanide ..................................................................................... 304 Stainless Steel

Solutions requiring de-rated heaters are indicated by blue, bold, italicized type.

*PTFE is a polytetrafluoroethelene fluoropolymer.

STOKES SYNERTEC Hot Rod Immersion Heaters & Accessories Catalogue

24 Palmerston Road West, Ringwood, Victoria 3134, Australia. Phone: +61 9 9845 8300 Fax: +61 3 9874 1077

19

11 Technical Information

Stokes Hot Rod Cat-f 24/5/07 5:45 PM Page 21

11.2 HOT ROD HEATER SOLUTION GUIDESOLUTION TYPE OF HEATERDeionized Water ........................................................................ 316 Stainless Steel or TitaniumDeoxidizer (Etching) .................................................................. PTFE* or QuartzDeoxidizer Non-Chromated ...................................................... 316 Stainless SteelDichromic Seal .......................................................................... SteelDiethylene Glycol ...................................................................... 304 Stainless SteelDiversey, 511, 514 ..................................................................... PTFE*Dow Therm .............................................................................. 316 Stainless SteelDye Solutions ............................................................................ 304 Stainless SteelEbonal C .................................................................................... TitaniumElectroless Copper .................................................................... PTFE*Electroless Nickel ................................................................… PTFE* or TitaniumElectroless Tin (Acid) ................................................................. PTFE* or QuartzElectroless Tin (Alkaline) ........................................................... 316 Stainless SteelElectro Cleaner .......................................................................... 304 Stainless SteelElectro Polishing ....................................................................... PTFE* or QuartzEnthone 80 Acid ........................................................................ PTFE*Ethylene Glycol ........................................................................ SteelFerric Ammonium Oxide ........................................................... 316 Stainless SteelFerric Chloride .......................................................................... PTFE*, Quartz, or TitaniumFerric Nitrate ............................................................................. 304 Stainless SteelFerric Sulfate ............................................................................. 304 Stainless SteelFluoborate ................................................................................. PTFE*Formic Acid ............................................................................... 316 Stainless SteelGlycerol .................................................................................... 304 Stainless SteelImmersion Gold ......................................................................... 304 Stainless SteelGold-Acid .................................................................................. PTFE*, Quartz, or TitaniumGold Cyanide ............................................................................ 304 Stainless SteelGrey Nickel ................................................................................ PTFE*, Quartz, or TitaniumHot Seal Dichromate ................................................................. 316 Stainless SteelHydrochloric Acid ..................................................................... PTFE* or QuartzHydrofluoric Acid ...................................................................... PTFE*Hydrogen Peroxide ...................………................................... PTFE* or QuartzIndium ....................................................................................... PTFE* or QuartzIridite (4-75,4-73,14,14-2,14-9).................................................. 316 Stainless SteelIridite (1,2,3,4-C,7,8,15) ............................................................ PTFE* or QuartzIron Fluoborate .......................................................................... PTFE*Iron Phosphate .....................................................................… 316 Stainless SteelIsoprep (186,187,188) ............................................................... 316 Stainless SteelIsoprep Acid Salts ..................................................................... PTFE*Jetal ........................................................................................... 304 Stainless SteelLead Acetate ............................................................................. 304 Stainless SteelLime Saturated Water (Alkaline) ...............…......................... 316 Stainless SteelLinseed Oil ................................................................................ 304 Stainless SteelMagnesium Hydroxide .............................……........................ 304 Stainless SteelMagnesium Nitrate .................................................................... PTFE* or QuartzManganese Phosphate ........................................................... 316 Stainless SteelMcDermid 629 ........................................................................... PTFE*Mercuric Chloride ...................................................................... TitaniumMuriatic Acid ............................................................................. PTFE* or QuartzNickel (Plating Solution) (Watts) ................................................ PTFE*, Quartz, or TitaniumNickel Acetate Seal ................................................................... 316 Stainless SteelNickel Chloride .......................................................................... TitaniumNitric Acid .................................................................................. PTFE* or QuartzNitric Hydrochloric Acids ........................................................... PTFE* or QuartzNitric Phosphoric .................................……............................ QuartzOil .............................................................…........................…. SteelOleic Acid .................................................................................. PTFE* or QuartzOxalic Acid ................................................................................ PTFE* or QuartzPaint Stripper (Alkaline) ..........................….........................… 304 Stainless SteelPerchlorethylene .....................................….........................… 316 Stainless SteelPhosphoric Acid (No Fluoride) ............................................... PTFE* or QuartzPhosphate Cleaner ................................................................. 304 Stainless SteelPhosphate ................................................................................ 316 Stainless Steel

Solutions requiring de-rated heaters are indicated by blue, bold, italicized type.

*PTFE is a polytetrafluoroethelene fluoropolymer.

STOKES SYNERTEC Hot Rod Immersion Heaters & Accessories Catalogue

24 Palmerston Road West, Ringwood, Victoria 3134, Australia. Phone: +61 9 9845 8300 Fax: +61 3 9874 1077

20

11 Technical Information

Stokes Hot Rod Cat-f 24/5/07 5:45 PM Page 22

11.2 HOT ROD HEATER SOLUTION GUIDESOLUTION TYPE OF HEATERPotassium Acid Sulfate ............................................................. PTFE* or QuartzPotassium Cyanide ................................................................... 04 Stainless SteelPotassium Hydroxide ................................................................ 304 Stainless SteelPotassium Hydrochloric ............................................................ PTFE* or QuartzPotassium Permanganate ...........…...................................... PTFE* or TitaniumRhodium .................................................................................... PTFE* or QuartzRochelle Salt Cyanide ............................................................... 304 Stainless SteelRuthenium Plating...................................................................... PTFE* or QuartzSalt (Actine) ............................................................................... PTFE*Sea Water .................................................................................. TitaniumSilver Bromide ........................................................................... 316 Stainless SteelSilver Cyanide ........................................................................... 304 Stainless SteelSilver Lume ............................................................................... 304 Stainless SteelSilver Nitrate .............................................................................. 316 Stainless SteelSodium Bisulfate ....................................................................... PTFE* or QuartzSodium Carbonate .................................................................... TitaniumSodium Chlorate ....................................................................... TitaniumSodium Chloride ....................................................................... TitaniumSodium Cyanide ........................................................................ 304 Stainless SteelSodium Dichromate (Hot Seal) ................................................. 316 Stainless SteelSodium Hydroxide .................................................................... SteelSodium Hypochlorite ................................................................ PTFE*Sodium Persulfate ..................................................................... PTFE* or QuartzStannate .................................................................................... SteelStanostar ................................................................................... PTFE* or QuartzStearic Acid ............................................................................... QuartzSulfamate Nickel ....................................................................... PTFE*, Quartz, or TitaniumSulfur ......................................................................................... PTFE* or QuartzSulfur Peroxide .......................................................................... PTFE* or QuartzSulfuric Acid .............................................................................. PTFE* or QuartzSulphamic Acid ......................................................................... PTFE* or QuartzTannic Acid ................................................................................ TitaniumTin Nickel .................................................................................. PTFE*Tin Plating (Acid)(Stanus/Sulphate) ........................................... PTFE* or QuartzTin Plating Acid (Fluoborate) ..................................................... PTFE*Tin Plating (Alkaline) .................................................................. 304 Stainless SteelTrichlorethylene ......................................................................... 316 Stainless SteelTrioxide (Pickle) ......................................................................... PTFE* or QuartzTurco (4181, 4338) .................................................................... 316 Stainless SteelUnichrome ................................................................................. PTFE* or QuartzWater ......................................................................................... 316 Stainless Steel or QuartzWood.s Nickel Strike ................................................................. Titanium, PTFE*, or QuartzYellow Dichromate .................................................................... PTFE* or QuartzZinc Acid ................................................................................... PTFE* or TitaniumZinc Ammonium Chloride ......................................................... Quartz or TitaniumZinc Cyanide ............................................................................. 304 Stainless SteelZinc Phosphate ..................................…...........................…… 316 Stainless SteelZinc Phosphate (Fluoride).......................................................... PTFEZincate ...................................................................................... 304 Stainless Steel

Solutions requiring de-rated heaters are indicated by blue, bold, italicized type.

*PTFE is a polytetrafluoroethelene fluoropolymer.

THE DATA LISTED IS PROVIDED GRATIS AND IS OFFERED AS A GUIDE ONLY. IT IS NOT INTENDED TO BE USED AS THE SOLE BASIS OF DESIGN OR TO ESTABLISH SPECIFICATION LIMITS. STOKES AUSTRALASIA LTD. ASSUMES NO OBLIGATION OR LIABILITY FOR ANY ADVICE FURNISHED BY IT OR FOR RESULTS OBTAINED FROM USE. DUE TO THE COMPLEXITIES OF SOLUTIONS AND APPLICATIONS,IT IS THE CUSTOMERS RESPONSIBILITY TO CONTACT THEIR CHEMICAL SUPPLIER FOR HEATER MATERIAL COMPATIBILITY AND RECOMMENDATIONS.

STOKES SYNERTEC Hot Rod Immersion Heaters & Accessories Catalogue

24 Palmerston Road West, Ringwood, Victoria 3134, Australia. Phone: +61 9 9845 8300 Fax: +61 3 9874 1077

21

11 Technical Information

Stokes Hot Rod Cat-f 24/5/07 5:45 PM Page 23

1°C = 1.80°F 4°C = 7.2°F 7°C = 12.6°F2°C = 3.60°F 5°C = 9.0°F 8°C = 14.4°F3°C = 5.40°F 6°C = 10.8°F 9°C = 16.2°F

1°F = 0.55°C 4°F = 2.22°C 7°F = 3.88°C2°F = 1.11°C 5°F = 2.77°C 8°F = 4.44°C3°F = 1.66°C 6°F = 3.33°C 9°F = 5.00°C

STOKES GUARANTEE SHALL NOT APPLY FOR ANY PREMATURE FAILURE DUE TO CORROSION OR CHEMICAL DESTRUCTION DUE TO UNUSUAL CONDITIONS, SUCH AS:

• Chemical concentration

• Excessive variation in operating temperatures and pressure

• Presence of oxygen or oxidizing agent or any dissolved gases in the solution

• Erosion or aeration or vacuum conditions

• Presence of inhibitors or agents causing secondary reactions

• Flux over the surface and stray currents

• Stagnant solution and excessive sludge buildup

• Turbulent flow of solution

11.3 TEMPERATURE CONVERSIONS

STOKES SYNERTEC Hot Rod Immersion Heaters & Accessories Catalogue

24 Palmerston Road West, Ringwood, Victoria 3134, Australia. Phone: +61 9 9845 8300 Fax: +61 3 9874 1077

22

11 Technical Information

Cent. Fahr. Cent. Fahr. Cent. Fahr. Cent. Fahr. Cent. Fahr. Cent. Fahr. Cent. Fahr. Cent. Fahr.

0° 32° 125° 257° 250° 482° 375° 707° 500° 932° 625° 1157° 750° 1382° 875° 1607°5° 41° 130° 266° 255° 491° 380° 716° 505° 941° 630° 1166° 755° 1391° 880° 1616°10° 50° 135° 275° 260° 500° 385° 725° 510° 950° 635° 1175° 760° 1400° 885° 1625°15° 59° 140° 284° 265° 509° 390° 734° 515° 959° 640° 1184° 765° 1409° 890° 1634°20° 68° 145° 293° 270° 518° 395° 743° 520° 968° 645° 1193° 770° 1418° 895° 1643°

25° 77° 150° 302° 275° 527° 400° 752° 525° 977° 650° 1202° 775° 1427° 900° 1652°30° 86° 155° 311° 280° 536° 405° 761° 530° 986° 655° 1211° 780° 1436° 905° 1661°35° 95° 160° 320° 285° 545° 410° 770° 535° 995° 660° 1220° 785° 1445° 910° 1670°40° 104° 165° 329° 290° 554° 415° 779° 540° 1004° 665° 1229° 790° 1454° 915° 1679°45° 113° 170° 338° 295° 563° 420° 788° 545° 1013° 670° 1238° 795° 1463° 920° 1688°

50° 122° 175° 347° 300° 572° 425° 797° 550° 1022° 675° 1247° 800° 1472° 925° 1697°55° 131° 180° 356° 305° 581° 430° 806° 555° 1031° 680° 1256° 805° 1481° 930° 1706°60° 140° 185° 365° 310° 590° 435° 815° 560° 1040° 685° 1265° 810° 1490° 935° 1715°65° 149° 190° 374° 315° 599° 440° 824° 565° 1049° 690° 1274° 815° 1499° 940° 1724°70° 158° 195° 383° 320° 608° 445° 833° 570° 1058° 695° 1283° 820° 1508° 945° 1733°

75° 167° 200° 392° 325° 617° 450° 824° 575° 1067° 700° 1292° 825° 1517°80° 176° 205° 401° 330° 626° 455° 851° 580° 1076° 705° 1301° 830° 1526°85° 185° 210° 410° 335° 635° 460° 860° 585° 1085° 710° 1310° 835° 1535°90° 194° 215° 419° 340° 644° 465° 869° 590° 1094° 715° 1319° 840° 1544°95° 203° 220° 428° 345° 653° 470° 878° 595° 1103° 720° 1328° 845° 1553°

100° 212° 225° 437° 350° 662° 475° 887° 600° 1112° 725° 1337° 850° 1562°105° 221° 230° 446° 355° 671° 480° 896° 605° 1121° 730° 1346° 855° 1571°110° 230° 235° 455° 360° 680° 485° 905° 610° 1130° 735° 1355° 860° 1580°115° 239° 240° 464° 365° 689° 490° 914° 615° 1139° 740° 1364° 865° 1589°120° 248° 245° 473° 370° 698° 495° 923° 620° 1148° 745° 1373° 870° 1598°

FORMULAE

Fahrenheit to Celsius (°C) = 5/9(°F - 32)

Celcius to Fahrenheit (°F) = (9/5°C) + 32

Celcius to Kelvin K = °C + 273.15

TABLE OF VALUES FOR INTERPOLATION IN ABOVE

Stokes Hot Rod Cat-f 29/5/07 10:52 AM Page 24

GUARANTEEStokes Synertec guarantee electric heating elements manufactured by it to befree from defects in workmanship and materials. Its obligations pursuant to this guarantee are limited to the repair or replacement of any such element whichproves defective within the guarantee period, or at Stokes Synertec’s optionrefund of purchase price. The repair, replacement or refund should be effectedupon the defective element being returned freight pre-paid to the RegisteredOffice of Stokes Synertec or to the offices of its accredited Electrical Agents.

Stokes Synertec shall not be responsible for the cost of removing any defective element or reinstalling the repaired or replacement element.

(Where Stokes Synertec supplies goods not of Stokes Synertec’s manufacturethe customer shall only be entitled to any such benefits as Stokes may receiveunder any guarantee given to it in respect thereof).

GUARANTEE PERIODTwelve (12) months from the date of sale by Stokes Synertec or twenty-four (24) months from the date of manufacture by Stokes, whichever period shallexpire first.

CONDITIONSThis guarantee shall not apply:

(a) If notice of the defect has not been given to Stokes Synertec within the guarantee period.

(b) To consequential damage arising out of the alleged failure of the elements supplied.

(c) If the heating element has been:(i) subject to misuse, abuse, negligence or accident;(ii) subjected to conditions giving rise to sheath corrosion;(iii) installed, maintained or operated otherwise than in the manner for

which it has been designed;(iv) operated on an electrical supply, the voltage of which varies more than

10% from the rated voltage applicable to the element;(v) used for any duty or subjected to any abnormal operating condition

varying from that for which it was supplied by Stokes Synertec.

Orders will only be accepted and all sales shall proceed subject to StokesSynertec’s general condition of sale, copies of which are available on request.

Stokes Hot Rod Cat-f 24/5/07 5:45 PM Page 25

Also refer to other products available from Stokes at

www.stokes-aus.com.au

Industrial Heating Air Heating

Heating CableAppliance Spare PartsValves and Camlocks

Innovation by Design

Stokes Hot Rod Cat-f 24/5/07 5:45 PM Page 26