STEEL PLATE AND SECTIONS

-

Upload

preston-puckett -

Category

Documents

-

view

88 -

download

2

description

Transcript of STEEL PLATE AND SECTIONS

STEEL PLATE AND SECTIONS

by GROUP-E

MEMBERS 1 JUDE RINALDO2 JUDE PRADEEP3 AARYL D’SA4 SWAROOP SUNDER

Describe the three processes used for the manufacture of steel? Explain the common properties of steel that is commonly used today and state the importance of various grades of steel and aluminium alloys

STEEL steel is the basic shipbuilding material in use today Steel may be regarded as an iron-carbon alloy, usually containing other

elements.

There are three particular processes currently used for the manufacture of

steel:

1. Open-hearth process

2. Oxygen or basic oxygen process( BOS process)

3. Electric furnace process

In all these processes the hot molten metal is exposed to air or oxygen, which oxidizes the impurities to refine the pig iron into high quality steel

Open-hearth process

The open-hearth uses a type of furnace called a regenerative furnace Instead of a firebox at one end and a flue at the other, it has devices at each

end for the intake and outflow of both fuel and air. The air is preheated by a system of current reversals that causes very high

temperatures

Open-hearth processOpen-hearth process

Process In the furnace, which has a wide, saucer-shaped hearth and a low roof,

molten pig iron and scrap are packed into the shallow hearth and heated by overhead gas burners using preheated air

Fires blazed at both sides of the hearth, passing heated currents of air and gas alternately from each fire over the molten iron.

The waste gas passed into chambers above the two fires, trapping heat in special firebrick and making the next flow of gas even hotter.

The extreme heat eventually burned out the impurities in the iron, resulting in silvery white steel.

Open-hearth processOpen-hearth process

Oxygen or basic oxygen process

The primary raw materials for the BOP are 70-80% liquid hot metal from the blast furnace and the balance is steel scrap.

These are charged into the Basic Oxygen Furnace (BOF) vessel. Oxygen ( pure) is "blown" into the BOF at supersonic velocities.

It oxidizes the carbon and silicon contained in the hot metal liberating great quantities of heat which melts the scrap.

The product of the BOS is molten steel with a specified chemical analysis at 2900°F-3000°F.

From here it may undergo further refining in a secondary refining process or be sent directly to the continuous caster where it is solidified into semi-finished shapes: blooms, billets, or slabs.

Electric furnace process

The electric are furnace (EAF) is the principle furnace type for the electric production of steel.

The primary application of the EAF is for the re-melting of steel scrap.

however, EAF’s can be charged with limited amounts of iron scrap, pig iron, and direct reduced iron.

With 100% of the charge coming from scrap it is difficult to control the purity and quality of the steel produced

manufacturers centered on EAF steel production have concentrated on market segments where steel quality is not as critical.

Properties of steel

The main properties can be classified as:

1. Tensile strength

2. Ductility

3. Hardness

4. Toughness

Properties of steel

Tensile strength It is a measure of the material’s ability to withstand the loads upon it in

service. Terms such as stress, strain, ultimate tensile strength, yield stress and

proof stress are all different methods of quantifying the tensile strength of the material.

This is the main single criterion with reference to metals

The two factors affecting tensile strength of steel are:

1. Carbon content of the steel

2. Heat treatment following manufacture

Properties of steel

Ductility This is the ability of a material to undergo permanent changes in shape

without rupture or loss of strength. It is particularly important where metals undergo forming processes during

manufacture

Properties of steel

Hardness this is a measure of the workability of the material It is used as an assessment of the machinability of the material and its

resistance to abrasion

Properties of steel

Toughness This is a condition midway between brittleness and softness It is often quantified by the value obtained in a notched bar test

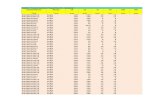

Various grades of steel The various grades of steel that have been developed constitute the best available

materials for hull construction Depending on the features provided there are five grades of mild steel(A-E)

designated by the societies A special grade mark “H” is used by the classification societies to denote higher

tensile steel The steel for ship construction must be manufactured under approved conditions,

and inspected, and prescribed tests must be carried out on selected specimens Advance in steel production and alloying methods have resulted in good higher

strength steel for ship construction

Benefits arising from the use of these steels in ship construction include reduced structural weight

Larger unit fabrications are possible for the same weight, and hence, less welding time

Various grades of steel

Some of the various grades of steel commonly used today are: Traditional/ Original Japanese steel AISI/American 1050/10xx AISI/American 5160 A2 Tool Steel D2 Tool Steel S-5 Steel S-7 Steel CK55 Krupp Steel 50CRV4

420, 440A, 440B, 440C, 440V, ATS-34

ALUMIINIUM ALLOYS They have a particular applications in the construction of superstructures,

especially on passenger ships The increasing use of aluminium alloy has resulted from its several

advantages over steel The use of aluminium alloys in a structure can result in reduction of 60%

of the weight of an equivalent steel structure

This reduction in weight, particularly in the upper regions of the structure, can improve the stability of the vessel. This follows from the lowering of the vessel’s centre of gravity, resulting in an increased metacentric height

ALUMIINIUM ALLOYS

The corrosion resistance of aluminium is very good The properties required of an aluminium alloy to be used in ship

construction are much the same as for steel They can be formed into unusual shapes to suit particular applications

some of the alloys of aluminium are: AL-Li ( Lithium ) Alumel (Nickel ) Duralumin ( copper ) Magnox ( magnesium oxide ) Zamak ( zinc,aluminium,magnesium,copper )