ACCUMULATORS Home Stauff Accumulators - K.R. West is a Fluid Power

STAUFF Fluid Technology Components for Mobile Construction Machinery.pdf 2015

-

Upload

nigel-roberts -

Category

Documents

-

view

54 -

download

0

Transcript of STAUFF Fluid Technology Components for Mobile Construction Machinery.pdf 2015

Tube Couplings

Onsite Design & Development

Tube Manipulation

QRCs & Adaptors

Scanwill®

Spir Star®

Superlok®

Safeplast®

Hose & Connectors

Hydraulic Pipework Components & Accessories Test Components

Hydraulic Accessories

Diagtronics

Valves

Steel Tube

SAE Flanges

Clamping Solutions

Filtration Technology

Local Solutions for Individual Customers WorldwideLocal Solutions for Individual Customers Worldwide

Fluid Technology Componentsfor Mobile Construction Machinery

CQMS'15-15-03 V2.indd 1 08/04/2015 12:48

www.stauff.co.uk

Fluid Technology Componentsfor Mobile Construction Machinery

STAUFF UK Ltd is an established manufacturer and supplier of a vast range of quality hydraulic components

to a wide variety of industries.

Equally comfortable fulfilling the demands of OEM requirements as servicing our distribution clients,

STAUFF offer a wide range of associated services from tube manipulating, hose assembly to kitting,

consignment stock management and a research and development arrangement that puts our engineers

at the core of your design process.

The Global organisation founded in Werdohl in the German Sauerland region has established itself

as an internationally leading developer, manufacturer and supplier of pipework equipment and hydraulic

components under the brand name STAUFF.

Decades of experience, highly-motivated and qualified staff, state-of-the-art manufacturing technologies

and a foresighted management give us the reputation of being a competitive partner.

The STAUFF companies worldwide have many years experience in serving Mobile Construction Machinery

manufacturers with a comprehensive range of fluid technology components, some of which have been

exclusively developed according to individual requirements in these markets.

Local Solutions for Individual Customers Worldwide

CQMS'15-15-03 V2.indd 2 08/04/2015 12:48

Operate on a Safe SiteTube Fitting Technology by STAUFF24° tube fittings and accessories made from carbon steel complement

the extensive range of original STAUFF components for fluid power

applications from own development and manufacturing. Due to the

careful selection and processing of materials, pressure ratings as

defined in the DIN/ISO standards can even be exceeded;

the premium Zinc/Nickel coating sets a new benchmark in terms of

corrosion protection. Get yourself convinced of outstanding product

quality and increased operational safety and reliability for your

machines and equipment, and experience the advantages of single-

sourcing all hydraulic pipework components from the manufacturer.

Learn more at www.stauffconnect.com

NEW!

STAUFF

Connect

• Design and manufacture of: Ultra High Pressure (UHP up to 5000 bar)

Very High Pressure (VHP up to 700 bar)

High, medium and low pressure flexible hose for a wide range of applications including: hydraulic, industrial, chemical, utility and process

• PTFE hose smooth bore and convoluted

• Manufactured to DIN, SAE and other International Standards

• End connectors to all major thread and flange standards and international specification, working pressures up to 5000 bar

• 1, 2 and 3 wire braid reinforced plus 4, 6 and even 8 spiral wire reinforced

• Thermoplastic for hydraulics, water jetting and jacking

• Combination hose and tube assemblies

• Hose test to ISO7751 performed and certified

www.stauff.co.uk

Flexible Hose AssemblyProduction Capabilities for Mobile Construction Machinery

Hose assemblies produced with clear markings identifying:

Date of manufacture

Batch number

Part number

Testing to globally recognised

Standards

Other customer specific details can be included for example: Certificate number

CQMS'15-15-03 V2.indd 4 08/04/2015 12:48

• Design and manufacture of: Ultra High Pressure (UHP up to 5000 bar)

Very High Pressure (VHP up to 700 bar)

High, medium and low pressure flexible hose for a wide range of applications including: hydraulic, industrial, chemical, utility and process

• PTFE hose smooth bore and convoluted

• Manufactured to DIN, SAE and other International Standards

• End connectors to all major thread and flange standards and international specification, working pressures up to 5000 bar

• 1, 2 and 3 wire braid reinforced plus 4, 6 and even 8 spiral wire reinforced

• Thermoplastic for hydraulics, water jetting and jacking

• Combination hose and tube assemblies

• Hose test to ISO7751 performed and certified

Product Portfolio

With state of-the-art CAD facilities – V-Tube conversions are undertaken into a Step File Format for customer and internal requirements. A full range of non hydraulic fabricated tube assemblies are available for customers• walkway handrails • gear lever assemblies • mirror arms • clamp brackets • handles

CQMS'15-15-03 V2.indd 5 08/04/2015 12:48

A range of high pressure spiral hoses with a

greater flexibilityCurrently available in 4000, 5000 and 6000 PSI, the new series of isobaric spiral hoses offer serious advantages over the competition, improving ease of routing for installations and service work.

Flexibility ...Greater flexibility in comparison with conventional spiral hoses.

Easier to handle, which enables a more manageable hose assembly procedure.

Up to half bend radius ...Guaranteeing very high performance. With a bend radius that is respectively half that of the norm SAE 100 R12, SAE 100 R13 and SAE 100 R15.

Impulse testing ...Tested to 1,000,000 cycles, guaranteeing an outstanding performance, even in the most arduous conditions.

Competitor 1

Competitor 2

Competitor 3

Competitor 4

Competitor 5

Competitor 6

Comparison of bending force toreach minimum bend radius

Comparison of bending force to reach minimum bend radius

The CS range comprises a multi-spiral hose insert and ferrule system that is claimed to eliminate all internal and most external skiving.

Please call your nearest STAUFF for more details.

The CS range comprises a multi-spiral hose insert

Please call your nearest STAUFF for more details.

The CS range comprises a multi-spiral hose insert

COMPATIBLE WITH THE CS RANGE OF HOSE INSERTS

CQMS'15-15-03 V2.indd 7 08/04/2015 12:48

� Crucial part of any contamination control program � Determining the ISO cleanliness level of hydr aulic media � Suitable for phosphate ester and specific water-glycol fluids � For permanent installation or to be used as portable devices � Sampling units and moisture / temperature sensors available

Hand-Held Hydraulic Testers

Laser Particle Counters

� Monitoring all relevant parameters in fluid power systems, including pressure, differential pressure, ` temperature, flow etc. � Measuring and display of over 50 channels at the same time � Integrated data storage for up to 1 billion measured values � Remote monitoring and analysis using LAN and USB interfaces

� Rapid and accurate monitoring of mobile hydraulic systems � Simultaneous measurement the most relevant parameters in fluid power systems, such as pressure, temperature and flow � Suitable for max. working pressures up to 420 bar / 6000 PSI � Suitable for nominal flow rates up to 200 l/min / 53 US GPM

Reversible Flow Testers

Mobile Filter Systems

� Compact and versatile units designed for long-lasting use � Supporting the preventive maintenance of fluid power systems, thus reducing machine downtime and saving

operating costs � Suitable for nominal flow rates up to 110 l/min / 30 US GPM � Can also be used as offline filters and oil transfer units

Desiccant Air Breathers � Air entering the reservoir / gearbox is filtered and dehumidified � Preventing fluid oxidation, thus reducing machine downtime and costs � Easy to retrofit on top of hydraulic reservoirs and gearboxes � Drying agent gradually changes colour with increasing moisture � No toxic or dangerous substances according to latest EC directives

� Comprehensive range of replacement filter elements for hydraulic and lubrication applications covering almost every major international filter brand � Direct replacements for most OEM filter elements � For pressure, suction-line and return-line applications

Replacement Filter Elements

Bypass and Offline Filters

� Supporting the preventive maintenance of fluid power systems, thus reducing machine downtimes and saving operating cost � Bypass filters without integrated motor-pump units � Offline filters with integrated motor-pump units � Pre-heated and water-absorbing versions available

www.stauff.co.uk

Service, Maintenance and Retrofit Equipment for Mobile Construction Machinery

� Monitoring and ensuring the functioning of fluid power systems � Panel / stem mount gauges with various connection types available � Scales range from –1 ... 1000 bar / –14,5 ... 14500 PSI � For permanent installation or to be used as portable devices � Also available as part of pressure test kits including accessories

Analog / Digital Pressure Gauges

High-Pressure Ball Valves

Two-way and multi-way ball shut-off valves for working pressures up to 800 bar / 12000 PSI

Block, forged or round body design, available in Steel and StainlessSteel

Threaded or flanged connections

up to DN 125 / 5 inch

CQMS'15-15-03 V2.indd 8 08/04/2015 12:48

Product Portfolio

Gear Pump Flanges Wide range of different variations, divided into various types, such as a straight or 90° design Three-hole or four-hole fastening manufactured according to German and Italian connection standards

SAE Flanges 3000 / 6000 PSI series according to ISO 6162-1/2 and SAE J 518 C up to DN 127 / 5 inch Safe and leak-free alternative to regular tube connectors, available in Steel and Stainless steel Continuous pressure level of 400 bar / 5800 PSI up to DN 51 / 2 inch

Tank Filler Breathers Filler ports allowing the hydraulic reservoir to

breathe while protecting it from contamination Metal and plastic versions available Comprehensive range of accessories including

baskets, dipsticks and mounting adaptors

Level Gauges Visual / visual-electrical fluid level indication, also in conjunction with temperature sensors

Special designs and sizes up to nominal lengths of 950 mm / 37.40 inch according to customer’s requirements

Pressure Filters Medium and high-pressure filters designed

for in-line and manifold mounting Suitable for working pressures

up to 420 bar / 6000 PSI Suitable for nominal flow rates up to 1135 l/min / 300 US GPM

Return-Line Filters Low-pressure return-line filters designed

for in-line, tank-top and tank-inside mounting Suitable for working pressures

up to 25 bar / 365 PSI Suitable for nominal flow rates up to 1135 l/min / 300 US GPM

Spin-On Filter Housings Low-pressure return-line or suction-line

filters designed for in-line mounting Suitable for working pressures

up to 14 bar / 200 PSI Suitable for nominal flow rates up to 460 l/min / 120 US GPM

Test Points / Hoses Leak-free connections into fluid power systems for monitoring the system pressure on the suction, pressure or return side Used at full pressure without machine downtimes Venting of fluid power systems Obtaining representative fluid samples

High-Pressure Ball Valves

Two-way and multi-way ball shut-off valves for working pressures up to 800 bar / 12000 PSI

Block, forged or round body design, available in Steel and StainlessSteel

Threaded or flanged connections

up to DN 125 / 5 inch

Flow Control Valves

Throttle and shut-off vales for liquid media, available in Steel and Stainless Steel

Suitable for in-line, manifold or cartridge assembly

Medium-duty and heavy-duty check valves

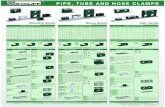

Pipe, Tube and Hose Clamps according to DIN 3015 Most economical solution available for quick and easy pipe, tube and hose installation

Environmental protection due to vibration-damping and noise-reducing features

CQMS'15-15-03 V2.indd 9 08/04/2015 12:48

• Bending metric 4mm - 65mm tube

• Bending Imperial 3/16" - 2" tube

• Fully coded TIG and MIG welders, brazing and silver soldering

• Tooling to perform tube forming, flaring and beading

• 6 x saws plus multi-saw for bundle cuts, computer controlled, fully integrated system

• Tube flushing and pelleting to NAS6

• Addison Addata - 5-axis co-ordinate measuring machine

Tube Production for Mobile Construction Machinery

Tube Material• Dual certified: 316L ASTM A269, ASTM A213, cold drawn bright annealed, metric OD

• High alloy seamless ASTM B165 - 93, nickel copper alloy to UNS0400 (duplex), metric OD

• ERW stainless steel welded to EN10217-7 steel number 1.4301

• Metric: DIN 2391/c ST 37.4NBK 4mm to 42mm

• Imperial and nominal bore tubes 3602 CFS 360 up to 2" NB

• Also available to contract requirements: Cupro nickel 70/30, 90/10; copper BS287/C106, single wall bundy tube

• Other specialist metals available

www.stauff.co.uk

CQMS'15-15-03 V2.indd 10 08/04/2015 12:48

STAUFF are pleased to introduce a new product range in specialist absorbents

Our new range of absorbent products offer -

• Industry leading absorbency, technology and performance

• Environmentally friendly options that out-perform regular meltblown (polypropylene) varieties and that can contribute to ISO 14001 Environmental Management Systems Accreditation

• Three types of absorbent to tackle different types of fluid recovery from oil-only, water based or aggressive and unknown fluids

• A wide range of formats, weights and constructions; from simple pads and rolls to booms, socks and pillows

• Unbeatable STAUFF value and customer service with next day delivery available

SORBAbsorbents and Spill Management Range

Call your Sales Team for further information Aberdeen: 01224 786166 Ireland: 02892 606900Sheffield: 0114 251 8518 Southampton: 023 8069 8700

Absorb spills, not costs

What is the cost of a hydraulic oil spill?

CQMS'15-15-03 V2.indd 11 08/04/2015 12:48

PLWRX/06/15

Local Solutions for Individual Customers

Worldwide

ABERDEEN tel: 01224 786166 Badentoy Avenue [email protected] Industrial EstatePortlethen, Aberdeen AB12 4YB fax: 01224 786177

IRELAND tel: 02892 6069009 Ferguson Drive [email protected] Hill Industrial ParkLisburn, County AntrimBT28 2EX fax: 02892 602688

SHEFFIELD tel: 0114 251 8518500 Carlisle Street East [email protected] Downgate DriveSheffieldS4 8BS fax: 0114 251 8519

SOUTHAMPTON tel: 023 8069 8700Unit 9, Southampton Trade Park [email protected] Avenue, Millbrook SouthamptonSO15 0AD fax: 023 8069 8701

www.stauff.co.uk

www.stauffwebshop.co.uk