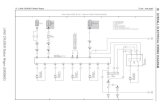

Station Wagon Skiff

Transcript of Station Wagon Skiff

ByM. E.

Daniels

YOU CAN build this family-size, 16-ft. skiff just as easily and inexpen-

sively as a flat-bottom rowboat. Yet ithas the wave-splitting, bump-smoothingbow of a true semi-V, readily convertsto a sailboat and can be carried in a sta-tion wagon!

And all of this is accomplished with-out any tricky plywood bends. The for-ward V-bottom contours are shapedfrom Styrofoam with saw and rasp andresorcinol-glued to a centerpiece. Thenthe job is skinned over with Dynelbonded with epoxy. The result is notonly a smooth ride but built-in flotationand a tough, armored hide where itcounts most when beaching the boat.

The use of Weldwood resorcinol gluein all joints and seams boosts strengthenough to permit you to weight-trimframing parts in aircraft fashion and

makes possible a finished hull thatweighs about 120 lbs.—light enough fortwo people to carry.

Total cost of materials for this boatwas just $80.

Its resin-bonded seams never needcaulking and small, 3- to 5-hp outboardmotors will push it along at 6 to 10 mph.A Mercury 110 (10-hp) motor was usedwith the prototype and speeds in the 20-mph range were achieved. The sailingversion is simple to operate and adds an-other whole dimension to this attractiveboat.

Let the lumberyard start the job foryou. For your side planking you needfour 16-in.-wide strips ripped length-

wise from 1/4-in. exterior plywood pan-els. Most yards have a panel-cutting rigand can do this job easier than you can.There may be a nominal charge but ifyou give them your materials list firstand tell them you're buying only if, youget those ripping cuts free you'll prob-ably win.

One other tip on the materials: do a

the wide ones run through the sawto make them match the narrowones.

Assemble each joint dry (withoutglue), using about five 1/2-in. #6 flat-head brass screws on each side of theseam. Be sure you're making a left anda right side—not two of a kind! Afterdry assembly, back out the screws, coat

FASTEN SIDES to stem, mid-irame, transom.Spot mid-frame 1/2 in. ahead of butt joint.

AFTER CHINES are installed, flip hull,bend forward bottom section into place.

little phone shopping in advance. Theplywood planking for the original hull,for example, was bought at a cash-and-carry yard for $3 a panel, though priceselsewhere ran from 30 to 80 cents higherper sheet.

No construction mold or form is re-quired if you assemble the parts in theproper sequence. First, join the 8-ft. x16-in. side planking strips end-to-endwith butt pieces 10-in. long cut from thesame thickness plywood. The buttpieces don't extend all the way fromedge to edge at the joint but stop 3/4-in.short of the bottom edge to allow spacefor the chine.

Incidentally, while still at the lumberyard make sure all your side plankingstrips are the same width. Because ofthe thickness of the saw blade some maybe a trifle narrower than others. Have

all mating surfaces with resorcinol resinglue and reassemble.

Squeeze-out should be about even allaround if the surfaces have been coatedproperly. Lack of squeeze-out meanspoor contact. Add extra screws wherethis is apparent.

Cut the stem and glue up the midshipframe and transom next. The frame andtransom can be tacked together lightlywith copper nails for dry assembly.

Since only the back section of thestem is involved at this stage, it doesn'trequire glue. Unless you're in a rush it'sbest to do the foregoing gluing the day(or night) before all-out constructionbegins. Leave the joints overnight at 70degrees and they'll be good and solid inthe morning.

To plot the bow's up-curve, clamp ortemporarily screw-fasten one of the

chines along the lower edge of one ofthe sides, setting the last clamp or screw(from the stern end) just 4 ft. 3 in. fromthe bow end. Then spring the free por-tion of the chine upward so its bottomedge is 7-1/4 in. from the bottom edge ofthe plywood and clamp or screw thechine in this position.

Then draw a pencil line along the en-tire curved run of the chine's loweredge. This gives you the fair curve yourbottom planking will follow later—along the area where the foam contourswill be. Use a saber saw to cut the ply-wood along this line after the chine hasbeen removed.

Actual hull assembly comes next.Start by fastening the forward ends ofthe plywood sides to the stem with acouple of 3/4-in. #6 brass flatheads oneach side. Then set the mid-frame inplace 1/2, in. forward of the midship buttseam so the two screws you'll use oneach side won't go through the seam.Use a scrap of 1/4-in. plywood under themidship frame to allow for a butt-jointpiece between bottom sections.

After the mid-frame is screwed inplace (with screwheads slightly above

the surface to allow some play), springthe aft ends of the plywood sides inwardand screw them to the rim of the tran-som. The transom angle should bemarked on the inner surfaces of thesides beforehand. This entire assemblyis made dry and is easiest if the sides arein inverted position.

The chines are fitted in next along thestraight run of the hull and the upcurveat the bow, held by 3/4-in. #6 brass flat-heads 18 in. to 24 in. apart. Space themcloser only at points where chine andplywood fail to draw together snugly.

Once the chines are in, turn the as-sembly right side up. Then fasten therubrails in place along the outside of theplanking at the top edge.

Check over the stem and transomjoints in case any plane-trimming is nec-essary (not likely). Also, measure thediagonal distance from each transomcorner to the opposite planking mid-frame joint. If these match to within 1/4in., that's good enough. If they're off bymore than that, use twine in crisscrosspattern to pull them as required tomatch.

After this the parts are disassembled,

glue coated and reassembled. Turn theassembly bottom side up and wipe offthe squeeze-out along the chine-plank-ing seam. Add screws where thesqueeze-out is thin.

The bottom goes on next. Lay a panelof 1/4-in. plywood good side outward onthe forward section of the assembly.You'll find the forward end can be bentdown easily along the bow's curved sec-tion and fastened temporarily with a1-1/2-in. roundhead steel screw into thebottom of the stem. Put a washer underthe screwhead so it won't pull through.

Bend the panel's midship end downand clamp it to the frame or fasten witha few 3/4-in. it 6 brass flatheads into thechines. Add extras anywhere the seamshows a gap. Then mark the panel alongthe outside of the planking on bothsides. Butt the stern section's panelagainst the forward one and follow thesame procedure. Remove and cut witha saber saw.

Before you replace the bottom panelsfor gluing, cut and fit the butt piece thatruns across underneath the mid-frame.

Like the side planking butt pieces, itshould be 10 in. fore and aft. Plane-fitthe ends to seat snugly against the innersurfaces of the chines.

When the butt piece is fitted, glue andscrew it to the bottom edge of the mid-frame, using three 3/4-in. #6 flatheads.Then lay the forward bottom panel inplace and mark it where the glue is togo. Glue, assemble and tighten all to-gether. Be sure to get a good seal acrossthe base of transom!

After the bottom panels are on, trimoff the side and bottom planking at thetransom angle and turn boat right sideup. Use a rounded stick to smooth theinner squeeze-out into the chine seamsto form a rounded fillet. You now havea watertight hull. The original onereached this stage at the end of the firstday's work.

Begin the foam bow job by adding thefirst section of the false stem. As thedrawing shows, this is beveled to thesame angles as the stem already gluedin place but it comes out flush with theouter surface of the side planking. And

EFFICIENT but simple sail rig moves thislight hull along even in lightest breeze.

it extends all the way down to the full16-in. depth of the hull.

It's glued to the original stem and alsoheld by a 2-in. galvanized screw (#12)driven into it from inside the existingstem. Once this false stem section is inplace, you can fit the skeg-like forwardsection of keel behind it.

By holding this against the side plank-ing along the up-curved section androcking it around the side plankingcurve as you pencil-mark it, you candraw a pretty accurate cutting line.Allow a little waste at each end fortrimming.

Bore through the stem into the for-ward end of [Continued ]

DETAILED PLANSinclude additional details for sailingrig and a Bill of Materials. To order,send $5 to MI Plans Service, FawcettBldg., Greenwich, Conn. 06830. Pleasespecify Station Wagon Skiff, Plan SW-3-67.

Station Wagon Skiff[Continued

the keel piece for a 1/2 -in. dowel. Then glueall meeting surfaces, glue in the dowel andfasten the aft end of the keel piece to thebottom planking with a flathead brassscrew. After this, you can turn the hullright side up and drive more brass screwsdown through the planking into the keelpiece.

The next section of false stem is gluedand screwed on with two 2-in. flatheadscrews driven from front to back into thepreceding section. The final (point) sectionof stem is glued and held by a couple offinishing nails. Twisted wire through thekeel piece and around the whole businesshelps tighten it up while the glue hardens.

After this, it's a good idea to turn the hullover and fit in the rest of the frames andthe seats. All these are simply cut andfitted on the spot and at the spacings indi-cated in the drawing. The vertical sidemembers of the frames are planed to fit fairagainst the planking.

If the trim-fitting causes some frames tosnug in place slightly forward or aft ofthe prescribed spacing, don't worry aboutit. The metal fastenings are just there forclamping until the glue hardens, anyway.

But make sure you do a good glue joball around. It's the stuff that gives yourboat its strength. Don't skimp on it anddefinitely don't build this boat without it.

The foam bow job begins with half a[Continued on next page]

Station Wagon Skiffstandard log of Styrofoam. This is 4-1/2 ft.long and approximately 22 in. wide by 7-1/2in. thick with slightly convex surfaces.Mark it to cut off a half-inch slice from eachconvex edge so you'll have flat surfaces forfitting. Then cut the resulting blockdiagonally. You'll be using one of thesetriangular pie-wedges on each side of theforward keel piece.

The cutting is best done with either acoarse rip saw or a narrow-blade buck saw.The buck saw is best because it has lessblade surface to bind in the cut and it cancut the curve where the foam fits againstthe up-curve of the plywood hull.

It pays to do your cutting on the safeside of the line, then trim to a final fit withthe rasp. You mark for the curve-cut in thesame manner that you marked the forwardkeel piece. But mark with a red or bluepencil. On foam it's difficult to tell a blackpencil line from an accidental dig or sawscratch.

When the foam pie-wedges are fitted tothe bottom you can hold them in place byhand while you shape them to the desiredbottom contours with saw and a StanleySurform tool.

You can use either resorcinol glue orepoxy to stick the foam to the plywood. Butyou should have ample leftovers from yourresorcinol gallon so it will pay to use thatat this stage. Then you can get by with onlya quart of epoxy.

Applying Dynel to the foam is the easiestpart of the whole project. This stuff hassuch give that you can pull it over almostany shape in sweater-girl fashion. Thenjust staple it tight at about 2-in. spacingalong the edges. To bond it on forever,merely brush, roll or squeeze the epoxythrough it.

There must be enough epoxy on theDynel to close its weave, however, becauseoil paint should not get through to thefoam. Before painting, disk-sand the edgesof the bonded-on Dynel to fair them outsmooth with the plywood.

The final, full-length 3/4-in. x 3/4in. keelstrip and the skids are resorcinol-glued tothe hull—although you can epoxy the frontportion of the keel strip if you have anyepoxy left after the Dynel job. All thestrips also are fastened with brass screws. •