ST. BRIGID ELEMENTARY SCHOOL - Anacond

Transcript of ST. BRIGID ELEMENTARY SCHOOL - Anacond

ISSUED FOR TENDER

JUNE 2020

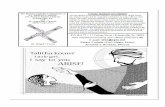

ST. BRIGID ELEMENTARY SCHOOL

ROOF RENOVATION

81 TORRANCE WOODS, BRAMPTON, ON L6Y 2X4

Dufferin-Peel

Catholic District

School Board

ST. BRIGID

ELEMENTARY SCHOOL

T

O

R

R

A

N

C

E

W

O

O

D

S

SCALE:

1

A001

SITE PLAN

N.T.S.

DRAWING LIST

ARCHITECTURAL DRAWINGS:

COVER PAGE

A001 DRAWING LIST, GENERAL NOTES & CONDITIONS, SITE PLAN AND KEY PLAN

A002 ROOF PLAN - DEMOLITION AND NEW

GENERAL NOTES & CONDITIONS

SCALE:

2

A001

KEY PLAN

N.T.S.

ISSUES

NO. DESCRIPTION DATE

REVISIONS

ISSUED FOR CONSTRUCTION DATE

The contractor shall check and verify all dimensions

and report all errors and ommisions to the architect

and the design professional whose seal is affixed to

this drawing. Do not scale the drawings.

This drawing shall not be used for construction

purposes until issued for construction by the design

professional whose seal is affixed to this drawing

and whose signature is below.

SHEET NO. DRAWN BY CHECKED

PROJECT NO.

SCALE

STRUCTURAL CONSULTANT

MECHANICAL CONSULTANT

ELECTRICAL CONSULTANT

PROJECT

ST. BRIGID

ELEMENTARY SCHOOL

81 TORRANCE WOODS,

BRAMPTON, ON L6Y 2X4

SHEET TITLE

DRAWING LIST, GENERAL NOTES

& CONDITIONS, SITE PLAN AND

KEY PLAN

A001

-

-

-

40 Matheson Boulevard West, Missisuaga, ON L5R 1C5

TEL: (905) 890-0708

2200678

AS_SHOWN

RNBG

Dufferin-Peel

Catholic District

School Board

ISSUED FOR CLIENT REVIEW 2020.03.171.

ISSUED FOR TENDER 2020.JUNE2.

ROOF SCOPE OF WORK NOTES:

1. EXISTING ROOF ASSEMBLIES

1.1 IT IS THE CONTRACTOR’S CHOICE TO CUT AND CONFIRM

THE ROOF ASSEMBLY. NO ADDITIONAL COSTS WILL BE

ACCEPTED OR APPROVED FOR/OR BY THE OWNER. THE

EXISTING ROOFING ASSEMBLY IS:

1.1.1 ROOFS: R1, R2, R3, R4, R5 & R6

(a) PEA GRAVEL AND ASPHALT TOP POUR

(b) (4-PLY FELT AND ASPHALT

(c) 3.0” FIBREGLASS INSULATION

(d) KRAFT PAPER VAPOUR RETARDER

(e) ½” GYPSUM BOARD

(f) (METAL DECK

2. NEW ROOF ASSEMBLY

2.1 SUPPLY AND INSTALL THE NEW ROOFING SYSTEM

COMPRISED OF THE FOLLOWING (FROM THE TOP DOWN):

2.1.1 ROOFS: R1, R2, R3, R4, R5 & R6

(a) FLOODCOAT OF ASPHALT & GRAVEL

(b) 4-PLIES OF TYPE IV FIBERGLASS FELT IN TYPE II

ASPHALT

(c) (1-PLY OF NO. 15 ORGANIC FELT IN TYPE II ASPHALT

(d) 12.7MM (½”) HIGH DENSITY FIBERBOARD (ASPHALT

COATED ON 6 SIDES) IN TYPE II ASPHALT

(e) 1% TAPERED INSULATION IN TYPE II ASPHALT

(f) 1 LAYER 63.5MM (2.5”) POLYISOCYANURATE INSULATION

MECHANICALLY FASTENED IN PLACE (FASTENED IN

PLACE THROUGH BOTH LAYERS OF POLYISOCYANURATE

INSULATION)

(g) 1 LAYER 63.5MM (2.5”) POLYISOCYANURATE INSULATION

LOOSE LAID IN PLACE

(h) 1-PLY OF SELF-ADHERING VAPOUR RETARDER, OVER

THE EXISTING GYPSUM BOARD

(i) ALL MEMBRANE FLASHINGS ARE TO BE 2-PLY MODIFIED

BITUMINOUS MEMBRANES, 1-PLY MODIFIED BITUMINOUS

MEMBRANE (BASE SHEET) MOPPED IN PLACE WITH TYPE

III ASPHALT AND 1-PLY GRANULATED MODIFIED

BITUMINOUS MEMBRANE (CAP SHEET) MOPPED IN PLACE

WITH TYPE III ASPHALT, ALL LAPS/SEAMS IN THE CAP

SHEET ARE TO BE HOT AIR WELDED.

2.1.2 CONFORM TO SECTION 07 51 13 – BUILT-UP ASPHALT

ROOFING.

3. ADDITIONAL REQUIREMENTS

3.1 REMOVE AND DISPOSE OF THE EXISTING ROOFING

COMPONENTS, THAT ARE NOT REQUIRED TO REMAIN AS

PART OF THE NEW ROOFING SYSTEM

3.2 SUPPLY AND INSTALL THE NEW ROOFING COMPONENTS

IN ACCORDANCE WITH THE CONTRACT DOCUMENTS.

3.3 UTILIZE A SINGLE SOURCE SUPPLIER OF MEMBRANE

AND RELATED PRIMARY MATERIALS.

3.4 PROVIDE THE MEMBRANE MANUFACTURER’S WARRANTY

AS SPECIFIED.

3.5 DISPOSE OF ALL DEBRIS/WASTE IN APPROVED

CONTAINERS AND TRANSFER TO AN APPROVED

MUNICIPAL AND/OR PROVINCIAL DISPOSAL SITE(S).

RECOMMENDED ROOFING SUB-CONTRACTORS:

· APPLEWOOD

· ATLANTIC

· ATLAS-APEX

· FLYNN

· LAFLECHE

· SCHREIBER BROS.

· SEEBAC

· SEMPLE-GOODER

EXTENT OF EXIST. ROOF TO BE

REMOVED AND REPLACED

(REFER TO ROOFING

SPECIFICATIONS & DETAILS,

AND ROOF SCOPE OF WORK NOTES

- SEE ON THE RIGHT)

(M.G.A.T.)(TYP.)

WORK TO BE COMPLETED IN PHASES.

PHASE 1 : ROOF 1, ROOF 2, ROOF 3.

PHASE 2: ROOF 4, ROOF 5, ROOF 6.

R1

DENOTES ROOF SECTION

ROOF LEGEND:

EXIST. ENTRANCE HATCH

EXIST. UNUSED CURB

EXIST. MECHANICAL / ELECTRICAL

UNIT W/ DUCTS ON CURB

EXIST. ROOF DRAIN

EXIST. FURNACE / SOIL / VENT STACK

UNIT

EXIST. MECHANICAL / ELECTRICAL

UNIT ON PAVERS

EXIST. MECHANICAL / ELECTRICAL

UNIT ON CURB

EXIST. GAS-LINE ON WOOD /

RUBBER SLEEPERS

GENERAL NOTES:

1. GENERAL CONTRACTOR IS FULLY RESPONSIBLE FOR ALL THE COST RELATED TO THE REMOVAL,

MODIFICATION, EXTENSION AND REINSTALLATION TO ALL MECHANICAL UNITS AND EQUIPMENT

AND RELATED ELECTRICAL WORK. THE BOARD WILL NOT ALLOW ANY EXTRA COST CHARGES

BY THE GENERAL CONTRACTOR FOR THIS ITEM.

2. GENERAL CONTRACTOR IS FULLY RESPONSIBLE TO HIRE AND COORDINATE WITH THE BOARD'S

APPROVED MECHANICAL AND ELECTRICAL CONTRACTOR (WHERE APPLICABLE) FOR THE REMOVAL

AND REINSTALLATION OF THE MECHANICAL UNITS AND EQUIPMENT, AND ALL RELATED WORK.

3. GENERAL CONTRACTOR IS RESPONSIBLE TO HOIST, PROVIDE STORAGE ON WOOD SLEEPERS

IN FENCED IN AREA AND PROTECTION OF ALL UNITS AND EQUIPMENT FROM BEING DAMAGED AND

WEATHERED.

4. PERFORM A DETAILED SITE SURVEY OF THE SITE AND ALL AFFILIATED WORK AREAS AND

REVIEW EXISTING CONDITIONS PRIOR TO ANY DEMOLITION, ERECTION, AND MOBILIZATION.

REPORT ANY CONFLICTS WITH THE ENGINEER.

5. LOCATIONS OF EQUIPMENT AND CONNECTING SERVICES. ANY INFORMATION REGARDING

ACCURATE MEASUREMENT OF THE BUILDING ARE TO BE TAKEN AT THE SITE. DO NOT SCALE

THE DRAWINGS, AND DO NOT USE THE DRAWINGS FOR PREFABRICATION WORK.

6. COORDINATE ALL TEMPORARY SHUT DOWNS WITH THE SCHOOL BOARD. PROVIDE ISOLATION

VALVES AS REQUIRED.

7. IF ASBESTOS CONTAINING MATERIAL IS SUSPECTED OR IDENTIFIED IN THE WORK AREA WHICH

IS NOT IDENTIFIED IN THE ASBESTOS LOCATION REPORT, AND REQUIRED TO BE HANDLED AS PART

OF THE DEMOLITION PHASE OF THE PROJECT, CONTRACTOR SHALL HALT WORK AND INFORM

PRIME CONSULTANT OF SUCH CONDITIONS. CONTRACTOR SHALL NOT PROCEED WITH DEMOLITION OF

SUCH AREAS WITHOUT AUTHORIZATION BY PRIME CONSULTANT. REMOVAL OF SUCH MATERIALS TO

ACCOMMODATE THE WORK DESCRIBED AND OUTLINED IN THESE DRAWINGS SHALL BE ARRANGED

THROUGH THE OWNER.

8. ALL ABANDONED OR OBSOLETE MECHANICAL SERVICES SUCH AS VALVES, PIPING, EQUIPMENT,

INSTRUMENTATION, ETC. SHALL BE REMOVED WITHIN THE WORK AREA TO FACILITATE ALL NEW

MECHANICAL WORK. ANY OF THE FOR NOTED ITEMS IF BEING REMOVED THAT MAY CONTAIN ANY

GASKET OR PACKING, ASBESTOS CONSULTANT (NORROX) SHOULD BE CONTACTED FOR SAMPLE

COLLECTION AND ANALYSIS. WHERE ASBESTOS IS CONFIRMED FURTHER DIRECTION WILL BE

PROVIDED. THE APPROPRIATE MECHANICAL, PLUMBING OR PIPE FITTING TRADE WILL BE

RESPONSIBLE FOR OPENING THE COMPONENT.

9. INSULATE ALL EXISTING PIPING WHERE INSULATION HAS BEEN REMOVED OR DAMAGED BY THIS

WORK . REFER TO SPECIFICATIONS FOR ADDITIONAL REQUIREMENTS.

10. ALL PIPE WORK TO BE TESTED FOR LEAKS WHEREVER NEW CONNECTIONS ARE MADE.

11. WHERE CONNECTIONS ARE MADE TO EXISTING SERVICES, CONTRACTOR SHALL MATCH ALL

EXISTING PIPE SIZES.

12. CLOSE-OUT DOCUMENT, ESA REPORT AND RE-BALANCING REPORT SHALL BE INCLUDED IN THE

SCOPE OF WORK.

13. GENERAL CONTRACTOR IS RESPONSIBLE TO PROVIDE FULL COMMISSIONING SERVICE TO ALL

UNITS AND EQUIPMENT. GENERAL CONTRACTOR TO PROVIDE ALL TESTS AND EQUIPMENT

START UP TEST REPORTS, INCLUDING BUT NOT LIMITED TO ROOFTOP UNITS, EXHAUST FANS AND

REFRIGERANT UNITS.

14. DISCONNECT AND RECONNECT BUILDING ENERGY MANAGEMENT SYSTEM BY QUALIFIED

PERSONNEL. RECOMMISSION THE CONTROLS AND UNITS OPERATION AT THE COMPLETION

OF THE WORK.

15. COVER EXISTING ROOF CURBS WITH PLYWOOD AND GALVANIZED FLASHING TO MAKE SECURE AND

WATER TIGHT.

16. ALL UNITS AND EQUIPMENT MUST BE REINSTALLED ON ROOF LEVEL AND OPERATIONAL BY

AUGUST 30, 2020. IF THE WORK HAS NOT BEEN COMPLETED BY AUGUST 30, 2020, THE WORK WILL BE

SUSPENDED UNTIL 2021 AT NO ADDITIONAL COST TO THE BOARD

17. GENERAL CONTRACTOR IS TO ALLOW FOR OVERTIME TO COMPLETE THE ABOVE WORK BY

COMPLETION DATE SET BY THE SCHOOL BOARD.

MECHANICAL NOTES (TO BE DONE IN EACH PHASE, AS REQUIRED):

18. GAS:

.1 GAS METER TO BE LOCKED OFF BY TSSA GAS CONTRACTOR UNTIL PIPE IS REINSTALLED.

ISOLATE EACH PIECE OF EQUIPMENT PRIOR TO DISCONNECTING FROM THE GAS LINE.

GAS PIPES TO BE LABELED AND SHALL BE REMOVED AND STORED ON PLYWOOD AND SKIDS

ON EXISTING ROOF. ALL PIPES TO BE CAPPED AND PROTECTED FROM DIRT AND DAMAGE.

.2 ALL EXISTING GAS PIPING TO BE DISCONNECTED FROM EXISTING ROOF TOP UNITS,

MODIFIED AS REQUIRED AND RECONNECTED TO EXISTING UNIT UPON RE-INSTALLATION OF

UNIT(S) TO ACCOMMODATE REPLACEMENT OF EXISTING ROOF. EXISTING GAS PIPING SHALL

ALSO BE EXTENDED/RAISED AS REQUIRED TO SUIT ROOF REPLACEMENT. INCLUDE FOR

ADDITIONAL CURBING, PIPING, FITTINGS AND ANY RETROFIT WORK AS REQUIRED TO SUIT.

.3 PROVIDE NEW ISOLATION VALVES FOR CONNECTION TO EQUIPMENT AND AT EACH RISER.

ALL REINSTALLED GAS PIPING TO BE TESTED. ANY WELDED PIPING TO BE DONE SHALL BE

DONE BY A LICENSED PRESSURE WELDER AND TAGGED WITH TSSA NUMBER. GAS PIPING

SHALL BE PAINTED YELLOW.

19. PLUMBING AND BOILER VENTS:

.1 EXISTING ROOF VENT PIPING TO BE EXTENDED TO ACCOMMODATE NEW ROOF INSTALLATION.

TERMINATIONS SHALL BE PER CURRENT PLUMBING CODE REQUIREMENTS. RE-FLASH ALL

ROOF PENETRATIONS.

.2 PROVIDE NEW CONES FOR PIPING PENETRATION AS REQUIRED.

.3 BOILERS MUST BE LOCKED OUT WHEN VENTING IS TEMPORARILY CAPPED.

20. UNITS, EXHAUST FANS AND DUCTWORK:

.1 EXISTING ROOF MOUNTED AIR HANDLING UNITS (RTUS) AND/OR EXHAUST FANS TO BE

DISCONNECTED AND REMOVED, INCLUDING REPLACEMENT OF EXISTING ROOF CURB TO

ACCOMMODATE ROOF REPLACEMENT AND ADDITIONAL INSULATION. CONTRACTOR SHALL

BE RESPONSIBLE TO CONFIRM EXACT ROOF CURB DIMENSIONS ON SITE. ALL EXISTING

DUCTWORK TO BE DISCONNECTED FROM EXISTING ROOF TOP AIR HANDLING UNITS AND/OR

EXHAUST FANS, INCLUDING INTERIOR DUCTWORK BELOW THE UNITS AND WITHIN

EXISTING ROOF CURBS. DUCTWORK TO BE MODIFIED AND EXTENDED AS REQUIRED TO

ACCOMMODATE NEW ROOF CURBS AND ROOF REPLACEMENT. BE RESPONSIBLE TO

RE-INSULATE EXISTING DUCTWORK AS REQUIRED TO SUIT MODIFICATION WORK AND

RECONNECT TO EXISTING UNIT UPON RE-INSTALLATION.

.2 SUPPLY AND INSTALL ADAPTER CURBS AND EXTEND DUCTWORK WHERE NECESSARY.

PROVIDE NEW FLEXIBLE CONNECTIONS BETWEEN THE DUCTWORK AND UNITS.

21. REFRIGERATION EQUIPMENT:

.1 SAFELY REMOVE THE REFRIGERANT FROM ALL CONDENSING UNITS AND ROOFTOP UNITS

CONDENSER IN ACCORDANCE WITH APPLICABLE CODES AND BY-LAWS. REFRIGERANT WILL

NEED TO BE PUMPED DOWN AND RECLAIMED FROM EACH UNIT PRIOR TO REMOVAL.

DISCONNECT REFRIGERANT LINES FROM THE EQUIPMENT AND CAP TO PROTECT THE

INTERIOR. MAKE PIPES SAFE ON THE ROOF TO ALLOW FOR THE ROOF INSTALLATION.

.2 ALL EXISTING REFRIGERATION PIPING TO BE DISCONNECTED FROM EXISTING ROOF TOP

CONDENSING UNITS, MODIFIED AS REQUIRED AND RECONNECTED TO EXISTING UNIT UPON

RE-INSTALLATION OF UNIT(S) TO ACCOMMODATE REPLACEMENT OF EXISTING ROOF.

EXISTING REFRIGERATION PIPING SHALL ALSO BE EXTENDED/RAISED AS REQUIRED TO SUIT

ROOF REPLACEMENT. INCLUDE FOR ADDITIONAL PIPING, FITTINGS AND ANY RETROFIT WORK

AS REQUIRED TO SUIT.

.3 ONCE REINSTALLED ALL LINE-SETS TO BE WELDED AND REINSULATED, EACH SYSTEM

CHARGED PER DESIGN PARAMETERS. ALL SYSTEMS TESTED, SET-UP PER ORIGINAL DESIGN.

START-UP/TESTING WITNESSED BY THE BOARD. ODP DOCUMENTATION TO ACCOMPANY ALL

CLOSE-OUT DOCUMENTS/REPORTS

ELECTRICAL NOTES (TO BE DONE IN EACH PHASE, AS REQUIRED):

22. DISCONNECT EXISTING FEEDER TO EXISTING RTU, CONDENSING UNIT, EXHAUST FAN, ETC. TO

ALLOW FOR REMOVAL OF EQUIPMENT AND REPLACEMENT OF EXISTING ROOF AND ROOF CURBS

WERE NECESSARY. BE RESPONSIBLE TO COIL EXISTING FEEDER AT ROOF LEVEL SAFELY,

MODIFY AS REQUIRED AND RECONNECT TO EXISTING EQUIPMENT UPON REINSTALLATION.

CONTRACTOR IS RESPONSIBLE TO CONFIRM EXISTING FEEDER AND CONDUIT SIZE ON SITE.

23. PROVIDE NEW INSULATED ELECTRICAL STACK SLEEVES TO ACCOMMODATE NEW ROOF ELEVATION

AND RE-CONNECT ALL ELECTRICAL WIRING TO ALL UNITS AND EQUIPMENT. FLASH IN SLEEVES AS

SPECIFIED FOR STACK FLASHING.

R1

R2

R3

R4

R5

PHASE 2

R4, R5, R6

R7

2 3 4 5 6 7

A

C

E

G

B

F

D

1

±28920 ±7840 ±8105 ±14030 ±4500

±11107

±12685

±3065

±8120

±12743

±3780

±9825

EXISTING METAL ROOF

TO REMAIN

EXISTING METAL

ROOF TO REMAIN

PHASE 1

R1, R2, R3

R6

SCALE:

1

A001

ROOF PLAN

1:150

ISSUES

NO. DESCRIPTION DATE

REVISIONS

ISSUED FOR CONSTRUCTION DATE

The contractor shall check and verify all dimensions

and report all errors and ommisions to the architect

and the design professional whose seal is affixed to

this drawing. Do not scale the drawings.

This drawing shall not be used for construction

purposes until issued for construction by the design

professional whose seal is affixed to this drawing

and whose signature is below.

SHEET NO. DRAWN BY CHECKED

PROJECT NO.

SCALE

STRUCTURAL CONSULTANT

MECHANICAL CONSULTANT

ELECTRICAL CONSULTANT

PROJECT

SHEET TITLE

ROOF PLAN - DEMOLITION AND NEW

A002

-

-

-

40 Matheson Boulevard West, Missisuaga, ON L5R 1C5

TEL: (905) 890-0708

2200678

AS_SHOWN

RNBG

ST. BRIGID

ELEMENTARY SCHOOL

81 TORRANCE WOODS,

BRAMPTON, ON L6Y 2X4

Dufferin-Peel

Catholic District

School Board

ISSUED FOR CLIENT REVIEW 2020.03.171.

ISSUED FOR TENDER 2020.JUNE2.

ISSUED FOR TENDER

JUNE 2020

ST. HILARY ELEMENTARY SCHOOL

ROOF RENOVATIONS

5070 Fairwind Dr, Mississauga, ON L5R 2N4

Dufferin-Peel

Catholic District

School Board

SO

D

PLAYGROUND

PLAY-

GROUND

A

S

P

H

A

L

T

CONC.

ASPHALT

ASPHALT

ASPHALT

CONC.

CONC. S/W

GARB.

ENCL.

ASPHALT

ASPHALT

CONC.

SOD

SOD

A

S

P

H

A

L

T

CO

NC

. S

/W

CONC.

ASPHALT

CONC.

SOD

SPORTS FIELD SPORTS FIELD

ST. HILARY

ELEMENTARY

SCHOOL

(2 STOREY

BUILDING)

EXISTING

RESIDENTIAL

EXISTING

RESIDENTIAL

EXISTING

RESIDENTIAL

F

A

IR

W

IN

D

D

R

IV

E

1 STOREY

ADDITION

SO

D

PARKING SPACES

PA

RK

IN

G S

PA

CE

S

P

A

R

K

I

N

G

S

P

A

C

E

S

SCALE:

1

A001

SITE PLAN

N.T.S.

DRAWING LIST

ARCHITECTURAL DRAWINGS:

COVER PAGE

A001 DRAWING LIST, GENERAL NOTES & CONDITIONS, SITE PLAN AND KEY PLAN

A002 ROOF PLAN - DEMOLITION AND NEW

GENERAL NOTES & CONIDITIONS

SCALE:

2

A001

KEY PLAN

N.T.S.

ISSUES

NO. DESCRIPTION DATE

REVISIONS

ISSUED FOR CONSTRUCTION DATE

The contractor shall check and verify all dimensions

and report all errors and ommisions to the architect

and the design professional whose seal is affixed to

this drawing. Do not scale the drawings.

This drawing shall not be used for construction

purposes until issued for construction by the design

professional whose seal is affixed to this drawing

and whose signature is below.

SHEET NO. DRAWN BY CHECKED

PROJECT NO.

SCALE

STRUCTURAL CONSULTANT

MECHANICAL CONSULTANT

ELECTRICAL CONSULTANT

PROJECT

ST HILARY

ELEMENTARY SCHOOL

5070 Fairwind Dr,

Mississauga, ON L5R 2N4

SHEET TITLE

DRAWING LIST, GENERAL NOTES

& CONDITIONS, SITE PLAN AND

KEY PLAN

Dufferin-Peel

Catholic District

School Board

40 Matheson Boulevard West, Missisuaga, ON L5R 1C5

TEL: (905) 890-0708

AS SHOWN

A001

ME RN

2190661

-

-

-

1. ISSUED FOR TENDER 2020.JUNE

LEGEND

EXIST./EX. EXISTING

TYP. TYPICAL

VIF VERIFY IN FIELD

NIC NOT IN CONTRACT

M.G.A.T. MAKE GOOD ON

AT ALL TRADES

AT JUNCTIONS

A B C D E F G H I J K

1

2

3

4

5

6

7

8

9

10

11

12

±1660

±61

95

±4715

±2605

±1

0825

±1047

1±8171

±4

40

8±8

00

5±5

06

5±2

00

0

±10380 ±6027 ±5048 ±13130 ±10430 ±3554 ±7463 ±10380 ±10603±2860

R1

R1

R2

R4

R3

R5

R6

R7

R5

SKYLIGHT SKYLIGHT

PHASE 2

R5, R6, R7

PHASE 1

R2, R3, R4, R5

EXTENT OF EXIST. ROOF TO BE

REMOVED AND REPLACED

(REFER TO ROOFING

SPECIFICATIONS & DETAILS,

AND ROOF SCOPE OF WORK NOTES

- SEE ON THE RIGHT)

WORK TO BE COMPLETED IN PHASES.

PHASE 1 : ROOF 2, ROOF 3, ROOF 4,

ROOF 5.

PHASE 2 : ROOF 5, ROOF 6, ROOF 7.

(M.G.A.T.)(TYP.)

R1

DENOTES ROOF SECTION

ROOF LEGEND:

EXIST. UNUSED CURB

EXIST. MECHANICAL / ELECTRICAL

UNIT ON PAVERS

EXIST. MECHANICAL / ELECTRICAL

UNIT ON CURB

EXIST. ROOF DRAIN

EXIST. FURNACE OR SOIL OR

VENT STACK

EXIST. GAS-LINE ON RUBBER /

WOOD SLEEPERS

EXIST. ENTRANCE HATCH

ROOF SCOPE OF WORK NOTES:

1. EXISTING ROOF ASSEMBLIES

1.1 IT IS THE CONTRACTOR’S CHOICE TO CUT AND CONFIRM THE ROOF ASSEMBLY. NO ADDITIONAL COSTS WILL BE ACCEPTED

OR APPROVED FOR/OR BY THE OWNER. THE EXISTING ROOFING ASSEMBLY IS:

1.1.1 ROOFS: R2, R3, R4, R5, R6 & R7

(a) PEA GRAVEL

(b) 4-PLY FELT AND ASPHALT

(c) 3.0” FIBREGLASS INSULATION

(d) METAL DECK

2. NEW ROOF ASSEMBLIES

2.1 SUPPLY AND INSTALL THE NEW ROOFING SYSTEM COMPRISED OF THE FOLLOWING (FROM THE TOP DOWN):

2.1.1 ROOFS: R2, R3, R4, R5, R6 & R7

(a) 1-PLY OF MODIFIED BITUMINOUS GRANULATED CAP SHEET TORCHED IN PLACE

(b) 1-PLY OF MODIFIED BITUMINOUS BASE SHEET FACTORY LAMINATED TO ASPHALT PROTECTION BOARD ADHERED IN PLACE.

(c) 2% SLOPE, TAPERED POLYISOCYANURATE INSULATION ADHERED IN PLACE

(d) 63.5MM(2.5”) POLYISOCYANURATE INSULATION ADHERED IN PLACE

(e) 63.5MM(2.5”) POLYISOCYANURATE INSULATION ADHERED IN PLACE

(f) 1-PLY SELF-ADHERING VAPOUR RETARDER ADHERED IN PLACE OVER 12.7MM (0.5”) SHEATHING BOARD

(g) 12.7MM (0.5”) SHEATHING BOARD MECHANICALLY ATTACHED TO METAL DECK

(h) METAL DECK

(i) ALL MEMBRANE FLASHINGS ARE TO BE 1 PLY MODIFIED BITUMINOUS MEMBRANE (BASE SHEET) ADHERED IN PLACE AND

1 PLY OF GRANULATED MODIFIED BITUMINOUS MEMBRANE (CAP SHEET) TORCHED IN PLACE

2.1.2 CONFORM TO SECTION 07 52 16– STYRENE-BUTADIENE-STYRENE MODIFIED BITUMINOUS MEMBRANE ROOFING

3. ADDITIONAL REQUIREMENTS

3.1 REMOVE AND DISPOSE OF THE EXISTING ROOFING COMPONENTS THAT ARE NOT REQUIRED TO REMAIN AS PART OF THE

NEW ROOFING SYSTEM.

3.2 SUPPLY AND INSTALL THE NEW ROOFING COMPONENTS IN ACCORDANCE WITH THE CONTRACT DOCUMENTS.

3.3 UTILIZE A SINGLE SOURCE SUPPLIER OF MEMBRANE AND RELATED PRIMARY MATERIALS.

3.4 PROVIDE THE MEMBRANE MANUFACTURER’S WARRANTY AS SPECIFIED.

3.5 DISPOSE OF ALL DEBRIS/WASTE IN APPROVED CONTAINERS AND TRANSFER TO AN APPROVED MUNICIPAL AND/OR

PROVINCIAL DISPOSAL SITE(S).

3.6 DISCONNECT AND RECONNECT ALL MECHANICAL UNITS AFTER RAISING CURBS TO SUIT NEW ROOF ASSEMBLY.

3.7 REMOVE ALL REDUNDANT MECHANICAL EQUIPMENT AND CURBS, COVER OPENING IN DECK.

GENERAL NOTES:

1. GENERAL CONTRACTOR IS FULLY RESPONSIBLE FOR ALL THE COST RELATED TO THE REMOVAL, MODIFICATION, EXTENSION

AND REINSTALLATION TO ALL MECHANICAL UNITS AND EQUIPMENT AND RELATED ELECTRICAL WORK. THE BOARD WILL NOT

ALLOW ANY EXTRA COST CHARGES BY THE GENERAL CONTRACTOR FOR THIS ITEM.

2. GENERAL CONTRACTOR IS FULLY RESPONSIBLE TO HIRE AND COORDINATE WITH THE BOARD'S APPROVED MECHANICAL AND

ELECTRICAL CONTRACTOR (WHERE APPLICABLE) FOR THE REMOVAL AND REINSTALLATION OF THE MECHANICAL UNITS AND

EQUIPMENT, AND ALL RELATED WORK.

3. GENERAL CONTRACTOR IS RESPONSIBLE TO HOIST, PROVIDE STORAGE ON WOOD SLEEPERS IN FENCED IN AREA AND

PROTECTION OF ALL UNITS AND EQUIPMENT FROM BEING DAMAGED AND WEATHERED.

4. PERFORM A DETAILED SITE SURVEY OF THE SITE AND ALL AFFILIATED WORK AREAS AND REVIEW EXISTING CONDITIONS

PRIOR TO ANY DEMOLITION, ERECTION, AND MOBILIZATION. REPORT ANY CONFLICTS WITH THE ENGINEER.

5. LOCATIONS OF EQUIPMENT AND CONNECTING SERVICES. ANY INFORMATION REGARDING ACCURATE MEASUREMENT OF THE

BUILDING ARE TO BE TAKEN AT THE SITE. DO NOT SCALE THE DRAWINGS, AND DO NOT USE THE DRAWINGS FOR

PREFABRICATION WORK.

6. COORDINATE ALL TEMPORARY SHUT DOWNS WITH THE SCHOOL BOARD. PROVIDE ISOLATION VALVES AS REQUIRED.

7. IF ASBESTOS CONTAINING MATERIAL IS SUSPECTED OR IDENTIFIED IN THE WORK AREA WHICH IS NOT IDENTIFIED IN THE

ASBESTOS LOCATION REPORT, AND REQUIRED TO BE HANDLED AS PART OF THE DEMOLITION PHASE OF THE PROJECT,

CONTRACTOR SHALL HALT WORK AND INFORM PRIME CONSULTANT OF SUCH CONDITIONS. CONTRACTOR SHALL NOT

PROCEED WITH DEMOLITION OF SUCH AREAS WITHOUT AUTHORIZATION BY PRIME CONSULTANT. REMOVAL OF SUCH

MATERIALS TO ACCOMMODATE THE WORK DESCRIBED AND OUTLINED IN THESE DRAWINGS SHALL BE ARRANGED

THROUGH THE OWNER.

8. ALL ABANDONED OR OBSOLETE MECHANICAL SERVICES SUCH AS VALVES, PIPING, EQUIPMENT, INSTRUMENTATION, ETC.

SHALL BE REMOVED WITHIN THE WORK AREA TO FACILITATE ALL NEW MECHANICAL WORK. ANY OF THE FOR NOTED ITEMS IF

BEING REMOVED THAT MAY CONTAIN ANY GASKET OR PACKING, ASBESTOS CONSULTANT (NORROX) SHOULD BE CONTACTED

FOR SAMPLE COLLECTION AND ANALYSIS. WHERE ASBESTOS IS CONFIRMED FURTHER DIRECTION WILL BE PROVIDED. THE

APPROPRIATE MECHANICAL, PLUMBING OR PIPE FITTING TRADE WILL BE RESPONSIBLE FOR OPENING THE COMPONENT.

9. INSULATE ALL EXISTING PIPING WHERE INSULATION HAS BEEN REMOVED OR DAMAGED BY THIS WORK . REFER TO

SPECIFICATIONS FOR ADDITIONAL REQUIREMENTS.

10. ALL PIPE WORK TO BE TESTED FOR LEAKS WHEREVER NEW CONNECTIONS ARE MADE.

11. WHERE CONNECTIONS ARE MADE TO EXISTING SERVICES, CONTRACTOR SHALL MATCH ALL EXISTING PIPE SIZES.

12. CLOSE-OUT DOCUMENT, ESA REPORT AND RE-BALANCING REPORT SHALL BE INCLUDED IN THE SCOPE OF WORK.

13. GENERAL CONTRACTOR IS RESPONSIBLE TO PROVIDE FULL COMMISSIONING SERVICE TO ALL UNITS AND EQUIPMENT.

GENERAL CONTRACTOR TO PROVIDE ALL TESTS AND EQUIPMENT START UP TEST REPORTS, INCLUDING BUT NOT LIMITED TO

ROOFTOP UNITS, EXHAUST FANS AND REFRIGERANT UNITS.

14. DISCONNECT AND RECONNECT BUILDING ENERGY MANAGEMENT SYSTEM BY QUALIFIED PERSONNEL. RECOMMISSION THE

CONTROLS AND UNITS OPERATION AT THE COMPLETION OF THE WORK.

15. COVER EXISTING ROOF CURBS WITH PLYWOOD AND GALVANIZED FLASHING TO MAKE SECURE AND WATER TIGHT.

16. ALL UNITS AND EQUIPMENT MUST BE REINSTALLED ON ROOF LEVEL AND OPERATIONAL BY AUGUST 30, 2020. IF THE WORK

HAS NOT BEEN COMPLETED BY AUGUST 30, 2020, THE WORK WILL BE SUSPENDED UNTIL 2021 AT NO ADDITIONAL COST TO THE

BOARD

17. GENERAL CONTRACTOR IS TO ALLOW FOR OVERTIME TO COMPLETE THE ABOVE WORK BY COMPLETION DATE SET BY THE

SCHOOL BOARD.

MECHANICAL NOTES (TO BE DONE IN EACH PHASE, AS REQUIRED):

18. GAS:

.1 GAS METER TO BE LOCKED OFF BY TSSA GAS CONTRACTOR UNTIL PIPE IS REINSTALLED. ISOLATE EACH PIECE OF

EQUIPMENT PRIOR TO DISCONNECTING FROM THE GAS LINE. GAS PIPES TO BE LABELED AND SHALL BE REMOVED AND

STORED ON PLYWOOD AND SKIDS ON EXISTING ROOF. ALL PIPES TO BE CAPPED AND PROTECTED FROM DIRT AND

DAMAGE.

.2 ALL EXISTING GAS PIPING TO BE DISCONNECTED FROM EXISTING ROOF TOP UNITS, MODIFIED AS REQUIRED AND

RECONNECTED TO EXISTING UNIT UPON RE-INSTALLATION OF UNIT(S) TO ACCOMMODATE REPLACEMENT OF EXISTING

ROOF. EXISTING GAS PIPING SHALL ALSO BE EXTENDED/RAISED AS REQUIRED TO SUIT ROOF REPLACEMENT.

INCLUDE FOR ADDITIONAL CURBING, PIPING, FITTINGS AND ANY RETROFIT WORK AS REQUIRED TO SUIT.

.3 PROVIDE NEW ISOLATION VALVES FOR CONNECTION TO EQUIPMENT AND AT EACH RISER. ALL REINSTALLED GAS

PIPING TO BE TESTED. ANY WELDED PIPING TO BE DONE SHALL BE DONE BY A LICENSED PRESSURE WELDER AND

TAGGED WITH TSSA NUMBER. GAS PIPING SHALL BE PAINTED YELLOW.

19. PLUMBING AND BOILER VENTS:

.1 EXISTING ROOF VENT PIPING TO BE EXTENDED TO ACCOMMODATE NEW ROOF INSTALLATION. TERMINATIONS SHALL

BE PER CURRENT PLUMBING CODE REQUIREMENTS. RE-FLASH ALL ROOF PENETRATIONS.

.2 PROVIDE NEW CONES FOR PIPING PENETRATION AS REQUIRED.

.3 BOILERS MUST BE LOCKED OUT WHEN VENTING IS TEMPORARILY CAPPED.

20. UNITS, EXHAUST FANS AND DUCTWORK:

.1 EXISTING ROOF MOUNTED AIR HANDLING UNITS (RTUS) AND/OR EXHAUST FANS TO BE DISCONNECTED AND REMOVED,

INCLUDING REPLACEMENT OF EXISTING ROOF CURB TO ACCOMMODATE ROOF REPLACEMENT AND ADDITIONAL

INSULATION. CONTRACTOR SHALL BE RESPONSIBLE TO CONFIRM EXACT ROOF CURB DIMENSIONS ON SITE. ALL

EXISTING DUCTWORK TO BE DISCONNECTED FROM EXISTING ROOF TOP AIR HANDLING UNITS AND/OR EXHAUST FANS,

INCLUDING INTERIOR DUCTWORK BELOW THE UNITS AND WITHIN EXISTING ROOF CURBS. DUCTWORK TO BE

MODIFIED AND EXTENDED AS REQUIRED TO ACCOMMODATE NEW ROOF CURBS AND ROOF REPLACEMENT.

BE RESPONSIBLE TO RE-INSULATE EXISTING DUCTWORK AS REQUIRED TO SUIT MODIFICATION WORK AND

RECONNECT TO EXISTING UNIT UPON RE-INSTALLATION.

.2 SUPPLY AND INSTALL ADAPTER CURBS AND EXTEND DUCTWORK WHERE NECESSARY.

PROVIDE NEW FLEXIBLE CONNECTIONS BETWEEN THE DUCTWORK AND UNITS.

21. REFRIGERATION EQUIPMENT:

.1 SAFELY REMOVE THE REFRIGERANT FROM ALL CONDENSING UNITS AND ROOFTOP UNITS CONDENSER IN

ACCORDANCE WITH APPLICABLE CODES AND BY-LAWS. REFRIGERANT WILL NEED TO BE PUMPED DOWN AND

RECLAIMED FROM EACH UNIT PRIOR TO REMOVAL. DISCONNECT REFRIGERANT LINES FROM THE EQUIPMENT AND CAP

TO PROTECT THE INTERIOR. MAKE PIPES SAFE ON THE ROOF TO ALLOW FOR THE ROOF INSTALLATION.

.2 ALL EXISTING REFRIGERATION PIPING TO BE DISCONNECTED FROM EXISTING ROOF TOP CONDENSING UNITS,

MODIFIED AS REQUIRED AND RECONNECTED TO EXISTING UNIT UPON RE-INSTALLATION OF UNIT(S) TO ACCOMMODATE

REPLACEMENT OF EXISTING ROOF. EXISTING REFRIGERATION PIPING SHALL ALSO BE EXTENDED/RAISED AS REQUIRED

TO SUIT ROOF REPLACEMENT. INCLUDE FOR ADDITIONAL PIPING, FITTINGS AND ANY RETROFIT WORK

AS REQUIRED TO SUIT.

.3 ONCE REINSTALLED ALL LINE-SETS TO BE WELDED AND REINSULATED, EACH SYSTEM CHARGED PER DESIGN

PARAMETERS. ALL SYSTEMS TESTED, SET-UP PER ORIGINAL DESIGN. START-UP/TESTING WITNESSED BY THE BOARD.

ODP DOCUMENTATION TO ACCOMPANY ALL CLOSE-OUT DOCUMENTS/REPORTS

ELECTRICAL NOTES (TO BE DONE IN EACH PHASE, AS REQUIRED):

22. DISCONNECT EXISTING FEEDER TO EXISTING RTU, CONDENSING UNIT, EXHAUST FAN, ETC. TO ALLOW FOR REMOVAL OF

EQUIPMENT AND REPLACEMENT OF EXISTING ROOF AND ROOF CURBS WERE NECESSARY. BE RESPONSIBLE TO COIL EXISTING

FEEDER AT ROOF LEVEL SAFELY, MODIFY AS REQUIRED AND RECONNECT TO EXISTING EQUIPMENT UPON REINSTALLATION.

CONTRACTOR IS RESPONSIBLE TO CONFIRM EXISTING FEEDER AND CONDUIT SIZE ON SITE.

23. PROVIDE NEW INSULATED ELECTRICAL STACK SLEEVES TO ACCOMMODATE NEW ROOF ELEVATION AND RE-CONNECT ALL

ELECTRICAL WIRING TO ALL UNITS AND EQUIPMENT. FLASH IN SLEEVES AS SPECIFIED FOR STACK FLASHING.

RECOMMENDED ROOFING SUB-CONTRACTORS:

· ATLAS-APEX

· FLYNN

· SEMPLE-GOODER

· ATLANTIC

· SCHREIBER BROS.

· LAFLECHE

· SEEBAC

ISSUES

NO. DESCRIPTION DATE

REVISIONS

ISSUED FOR CONSTRUCTION DATE

The contractor shall check and verify all dimensions

and report all errors and ommisions to the architect

and the design professional whose seal is affixed to

this drawing. Do not scale the drawings.

This drawing shall not be used for construction

purposes until issued for construction by the design

professional whose seal is affixed to this drawing

and whose signature is below.

SHEET NO. DRAWN BY CHECKED

PROJECT NO.

SCALE

STRUCTURAL CONSULTANT

MECHANICAL CONSULTANT

ELECTRICAL CONSULTANT

PROJECT

ST HILARY

ELEMENTARY SCHOOL

5070 Fairwind Dr,

Mississauga, ON L5R 2N4

SHEET TITLE

Dufferin-Peel

Catholic District

School Board

40 Matheson Boulevard West, Missisuaga, ON L5R 1C5

TEL: (905) 890-0708

1:150

A002

IP

2190661

-

-

-

ROOF PLAN

- DEMOLITION AND NEW

RN

SCALE:

1

A002

ROOF PLAN - DEMOLITION AND NEW

1:150

1. ISSUED FOR TENDER 2020.JUNE

ISSUED FOR TENDER

JUNE 2020

ST. JULIA ELEMENTARY SCHOOL

ROOF RENOVATION

6770 HISTORIC TRAIL, MISSISSAUGA, ON L5W 1J3

Dufferin-Peel

Catholic District

School Board

ST. JULIA ELEMENTARY

SCHOOL

H

IS

TO

R

IC

T

R

AIL

SCALE:

1

A001

SITE PLAN

N.T.S.

DRAWING LIST

ARCHITECTURAL DRAWINGS:

COVER PAGE

A001 DRAWING LIST, GENERAL NOTES & CONDITIONS, SITE PLAN AND KEY PLAN

A002 ROOF PLAN - DEMOLITION AND NEW

GENERAL NOTES & CONDITIONS

SCALE:

2

A001

KEY PLAN

N.T.S.

ISSUES

NO. DESCRIPTION DATE

REVISIONS

ISSUED FOR CONSTRUCTION DATE

The contractor shall check and verify all dimensions

and report all errors and ommisions to the architect

and the design professional whose seal is affixed to

this drawing. Do not scale the drawings.

This drawing shall not be used for construction

purposes until issued for construction by the design

professional whose seal is affixed to this drawing

and whose signature is below.

SHEET NO. DRAWN BY CHECKED

PROJECT NO.

SCALE

STRUCTURAL CONSULTANT

MECHANICAL CONSULTANT

ELECTRICAL CONSULTANT

PROJECT

ST. JULIA ELEMENTARY

SCHOOL

6770 HISTORIC TRAIL

MISSISSAUGA, ON L5W 1J3

SHEET TITLE

DRAWING LIST, GENERAL NOTES

& CONDITIONS, SITE PLAN AND

KEY PLAN

A001

-

-

-

40 Matheson Boulevard West, Missisuaga, ON L5R 1C5

TEL: (905) 890-0708

2200676

AS_SHOWN

RNBG

Dufferin-Peel

Catholic District

School Board

ISSUED FOR CLIENT REVIEW 2020.03.171.

ISSUED FOR TENDER 2020.JUNE2.

ROOF SCOPE OF WORK NOTES:

1. EXISTING ROOF ASSEMBLIES

1.1 IT IS THE CONTRACTOR’S CHOICE TO CUT AND CONFIRM THE ROOF

ASSEMBLY. NO ADDITIONAL COSTS WILL BE ACCEPTED OR APPROVED FOR/OR

BY THE OWNER. THE EXISTING ROOFING ASSEMBLY IS:

1.1.1 ROOFS: R1, R2, R3, R4, R5, R6, R7, R8, R9 & R10

(a) 2 PLIES OF MODIFIED BITUMINOUS MEMBRANES

(b) ½” FIBREBOARD INSULATION

(c) 3” POLYISOCYANURATE INSULATION

(d) ½” GYPSUM BOARD

(e) METAL DECK

2. NEW ROOF ASSEMBLY

2.1 SUPPLY AND INSTALL THE NEW ROOFING SYSTEM COMPRISED OF THE

FOLLOWING (FROM THE TOP DOWN):

2.1.1 ROOFS: R1, R2, R7, R8, R9 & R10

(a) FLOODCOAT OF ASPHALT & GRAVEL

(b) 4-PLIES OF TYPE IV FIBERGLASS FELT IN TYPE II ASPHALT

(c) 1-PLY OF NO. 15 ORGANIC FELT IN TYPE II ASPHALT

(d) 12.7MM (½”) HIGH DENSITY FIBERBOARD (ASPHALT COATED ON 6 SIDES) IN

TYPE II ASPHALT

(e) 1% TAPERED INSULATION IN TYPE II ASPHALT

(f) 1 LAYER 63.5MM (2.5”) POLYISOCYANURATE INSULATION MECHANICALLY

FASTENED IN PLACE (FASTENED IN PLACE THROUGH BOTH LAYERS OF

POLYISOCYANURATE INSULATION)

(g) 1 LAYER 63.5MM (2.5”) POLYISOCYANURATE INSULATION LOOSE LAID IN PLACE

(h) 1-PLY OF SELF-ADHERING VAPOUR RETARDER, OVER THE EXISTING GYPSUM

BOARD

i) ALL MEMBRANE FLASHINGS ARE TO BE 2-PLY MODIFIED

BITUMINOUS MEMBRANES, 1-PLY MODIFIED BITUMINOUS MEMBRANE (BASE

SHEET) MOPPED IN PLACE WITH TYPE III ASPHALT AND 1-PLY GRANULATED

MODIFIED BITUMINOUS MEMBRANE (CAP SHEET) MOPPED IN PLACE WITH

TYPE III ASPHALT, ALL LAPS/SEAMS IN THE CAP SHEET ARE TO BE HOT AIR

WELDED.

2.1.2 CONFORM TO SECTION 07 51 13 – BUILT-UP ASPHALT ROOFING

2.2 SUPPLY AND INSTALL THE NEW ROOFING SYSTEM COMPRISED OF THE

FOLLOWING (FROM THE TOP DOWN):

2.2.1 ROOFS: R3, R4, R5 & R6

(a) 250GM SBS MODIFIED BITUMEN CAP SHEET MEMBRANE, IN TYPE II ASPHALT

(b) 180GM SBS MODIFIED BITUMEN BASE SHEET MEMBRANE, IN TYPE II ASPHALT

(c) 12.7MM (½”) HIGH DENSITY FIBERBOARD (ASPHALT COATED ON 6 SIDES) IN

TYPE II ASPHALT

(d) 1% TAPERED INSULATION IN TYPE II ASPHALT

(e) 1-PLY OF SELF-ADHERING VAPOUR RETARDER, OVER THE EXISTING GYPSUM

BOARD

(f) ALL MEMBRANE FLASHINGS ARE TO BE 2-PLY MODIFIED BITUMINOUS

MEMBRANES, 1-PLY MODIFIED BITUMINOUS MEMBRANE (BASE SHEET) MOPPED

IN PLACE WITH TYPE III ASPHALT AND 1-PLY GRANULATED MODIFIED

BITUMINOUS MEMBRANE (CAP SHEET) MOPPED IN PLACE WITH TYPE III

ASPHALT, ALL LAPS/SEAMS IN THE CAP SHEET ARE TO BE HOT AIR WELDED.

2.2.2 CONFORM TO SECTION 07 52 16 SBS MODIFIED BITUMINOUS MEMBRANE

ROOFING.

3. ADDITIONAL REQUIREMENTS

3.1 REMOVE AND DISPOSE OF THE EXISTING ROOFING COMPONENTS, THAT ARE

NOT REQUIRED TO REMAIN AS PART OF THE NEW ROOFING SYSTEM.

3.2 SUPPLY AND INSTALL THE NEW ROOFING COMPONENTS IN ACCORDANCE WITH

THE CONTRACT DOCUMENTS.

3.3 UTILIZE A SINGLE SOURCE SUPPLIER OF MEMBRANE AND RELATED PRIMARY

MATERIALS.

3.4 PROVIDE THE MEMBRANE MANUFACTURER’S WARRANTY AS SPECIFIED.

3.5 DISPOSE OF ALL DEBRIS/WASTE IN APPROVED CONTAINERS AND TRANSFER

TO AN APPROVED MUNICIPAL AND/OR PROVINCIAL DISPOSAL SITE(S).

RECOMMENDED ROOFING SUB-CONTRACTORS:

· APPLEWOOD

· ATLANTIC

· ATLAS-APEX

· FLYNN

· LAFLECHE

· SCHREIBER BROS.

· SEEBAC

· SEMPLE-GOODER

EXTENT OF EXIST. ROOF TO BE

REMOVED AND REPLACED

(REFER TO ROOFING

SPECIFICATIONS & DETAILS,

AND ROOF SCOPE OF WORK NOTES

- SEE ON THE RIGHT)

(M.G.A.T.)(TYP.)

WORK TO BE COMPLETED IN PHASES.

PHASE 1 : ROOF 1, ROOF 2, ROOF 3,

ROOF 4, ROOF 5, ROOF 6.

PHASE 2 : ROOF 7, ROOF 8, ROOF 9,

ROOF 10.

R1

DENOTES ROOF SECTION

ROOF LEGEND:

EXIST. ENTRANCE HATCH

EXIST. UNUSED CURB

EXIST. MECHANICAL / ELECTRICAL

UNIT W/ DUCTS ON CURB

EXIST. ROOF DRAIN

EXIST. FURNACE / SOIL / VENT STACK

UNIT

EXIST. MECHANICAL / ELECTRICAL

UNIT ON PAVERS

EXIST. MECHANICAL / ELECTRICAL

UNIT ON CURB

EXIST. GAS-LINE ON CONCRETE

PAVERS

GENERAL NOTES:

1. GENERAL CONTRACTOR IS FULLY RESPONSIBLE FOR ALL THE COST RELATED TO THE REMOVAL,

MODIFICATION, EXTENSION AND REINSTALLATION TO ALL MECHANICAL UNITS AND EQUIPMENT

AND RELATED ELECTRICAL WORK. THE BOARD WILL NOT ALLOW ANY EXTRA COST CHARGES

BY THE GENERAL CONTRACTOR FOR THIS ITEM.

2. GENERAL CONTRACTOR IS FULLY RESPONSIBLE TO HIRE AND COORDINATE WITH THE BOARD'S

APPROVED MECHANICAL AND ELECTRICAL CONTRACTOR (WHERE APPLICABLE) FOR THE REMOVAL

AND REINSTALLATION OF THE MECHANICAL UNITS AND EQUIPMENT, AND ALL RELATED WORK.

3. GENERAL CONTRACTOR IS RESPONSIBLE TO HOIST, PROVIDE STORAGE ON WOOD SLEEPERS

IN FENCED IN AREA AND PROTECTION OF ALL UNITS AND EQUIPMENT FROM BEING DAMAGED AND

WEATHERED.

4. PERFORM A DETAILED SITE SURVEY OF THE SITE AND ALL AFFILIATED WORK AREAS AND

REVIEW EXISTING CONDITIONS PRIOR TO ANY DEMOLITION, ERECTION, AND MOBILIZATION.

REPORT ANY CONFLICTS WITH THE ENGINEER.

5. LOCATIONS OF EQUIPMENT AND CONNECTING SERVICES. ANY INFORMATION REGARDING

ACCURATE MEASUREMENT OF THE BUILDING ARE TO BE TAKEN AT THE SITE. DO NOT SCALE

THE DRAWINGS, AND DO NOT USE THE DRAWINGS FOR PREFABRICATION WORK.

6. COORDINATE ALL TEMPORARY SHUT DOWNS WITH THE SCHOOL BOARD. PROVIDE ISOLATION

VALVES AS REQUIRED.

7. IF ASBESTOS CONTAINING MATERIAL IS SUSPECTED OR IDENTIFIED IN THE WORK AREA WHICH

IS NOT IDENTIFIED IN THE ASBESTOS LOCATION REPORT, AND REQUIRED TO BE HANDLED AS PART

OF THE DEMOLITION PHASE OF THE PROJECT, CONTRACTOR SHALL HALT WORK AND INFORM

PRIME CONSULTANT OF SUCH CONDITIONS. CONTRACTOR SHALL NOT PROCEED WITH DEMOLITION OF

SUCH AREAS WITHOUT AUTHORIZATION BY PRIME CONSULTANT. REMOVAL OF SUCH MATERIALS TO

ACCOMMODATE THE WORK DESCRIBED AND OUTLINED IN THESE DRAWINGS SHALL BE ARRANGED

THROUGH THE OWNER.

8. ALL ABANDONED OR OBSOLETE MECHANICAL SERVICES SUCH AS VALVES, PIPING, EQUIPMENT,

INSTRUMENTATION, ETC. SHALL BE REMOVED WITHIN THE WORK AREA TO FACILITATE ALL NEW

MECHANICAL WORK. ANY OF THE FOR NOTED ITEMS IF BEING REMOVED THAT MAY CONTAIN ANY

GASKET OR PACKING, ASBESTOS CONSULTANT (NORROX) SHOULD BE CONTACTED FOR SAMPLE

COLLECTION AND ANALYSIS. WHERE ASBESTOS IS CONFIRMED FURTHER DIRECTION WILL BE

PROVIDED. THE APPROPRIATE MECHANICAL, PLUMBING OR PIPE FITTING TRADE WILL BE

RESPONSIBLE FOR OPENING THE COMPONENT.

9. INSULATE ALL EXISTING PIPING WHERE INSULATION HAS BEEN REMOVED OR DAMAGED BY THIS

WORK . REFER TO SPECIFICATIONS FOR ADDITIONAL REQUIREMENTS.

10. ALL PIPE WORK TO BE TESTED FOR LEAKS WHEREVER NEW CONNECTIONS ARE MADE.

11. WHERE CONNECTIONS ARE MADE TO EXISTING SERVICES, CONTRACTOR SHALL MATCH ALL

EXISTING PIPE SIZES.

12. CLOSE-OUT DOCUMENT, ESA REPORT AND RE-BALANCING REPORT SHALL BE INCLUDED IN THE

SCOPE OF WORK.

13. GENERAL CONTRACTOR IS RESPONSIBLE TO PROVIDE FULL COMMISSIONING SERVICE TO ALL

UNITS AND EQUIPMENT. GENERAL CONTRACTOR TO PROVIDE ALL TESTS AND EQUIPMENT

START UP TEST REPORTS, INCLUDING BUT NOT LIMITED TO ROOFTOP UNITS, EXHAUST FANS AND

REFRIGERANT UNITS.

14. DISCONNECT AND RECONNECT BUILDING ENERGY MANAGEMENT SYSTEM BY QUALIFIED

PERSONNEL. RECOMMISSION THE CONTROLS AND UNITS OPERATION AT THE COMPLETION

OF THE WORK.

15. COVER EXISTING ROOF CURBS WITH PLYWOOD AND GALVANIZED FLASHING TO MAKE SECURE AND

WATER TIGHT.

16. ALL UNITS AND EQUIPMENT MUST BE REINSTALLED ON ROOF LEVEL AND OPERATIONAL BY

AUGUST 30, 2020. IF THE WORK HAS NOT BEEN COMPLETED BY AUGUST 30, 2020, THE WORK WILL BE

SUSPENDED UNTIL 2021 AT NO ADDITIONAL COST TO THE BOARD

17. GENERAL CONTRACTOR IS TO ALLOW FOR OVERTIME TO COMPLETE THE ABOVE WORK BY

COMPLETION DATE SET BY THE SCHOOL BOARD.

MECHANICAL NOTES (TO BE DONE IN EACH PHASE, AS REQUIRED):

18. GAS:

.1 GAS METER TO BE LOCKED OFF BY TSSA GAS CONTRACTOR UNTIL PIPE IS REINSTALLED.

ISOLATE EACH PIECE OF EQUIPMENT PRIOR TO DISCONNECTING FROM THE GAS LINE.

GAS PIPES TO BE LABELED AND SHALL BE REMOVED AND STORED ON PLYWOOD AND SKIDS

ON EXISTING ROOF. ALL PIPES TO BE CAPPED AND PROTECTED FROM DIRT AND DAMAGE.

.2 ALL EXISTING GAS PIPING TO BE DISCONNECTED FROM EXISTING ROOF TOP UNITS,

MODIFIED AS REQUIRED AND RECONNECTED TO EXISTING UNIT UPON RE-INSTALLATION OF

UNIT(S) TO ACCOMMODATE REPLACEMENT OF EXISTING ROOF. EXISTING GAS PIPING SHALL

ALSO BE EXTENDED/RAISED AS REQUIRED TO SUIT ROOF REPLACEMENT. INCLUDE FOR

ADDITIONAL CURBING, PIPING, FITTINGS AND ANY RETROFIT WORK AS REQUIRED TO SUIT.

.3 PROVIDE NEW ISOLATION VALVES FOR CONNECTION TO EQUIPMENT AND AT EACH RISER.

ALL REINSTALLED GAS PIPING TO BE TESTED. ANY WELDED PIPING TO BE DONE SHALL BE

DONE BY A LICENSED PRESSURE WELDER AND TAGGED WITH TSSA NUMBER. GAS PIPING

SHALL BE PAINTED YELLOW.

19. PLUMBING AND BOILER VENTS:

.1 EXISTING ROOF VENT PIPING TO BE EXTENDED TO ACCOMMODATE NEW ROOF INSTALLATION.

TERMINATIONS SHALL BE PER CURRENT PLUMBING CODE REQUIREMENTS. RE-FLASH ALL

ROOF PENETRATIONS.

.2 PROVIDE NEW CONES FOR PIPING PENETRATION AS REQUIRED.

.3 BOILERS MUST BE LOCKED OUT WHEN VENTING IS TEMPORARILY CAPPED.

20. UNITS, EXHAUST FANS AND DUCTWORK:

.1 EXISTING ROOF MOUNTED AIR HANDLING UNITS (RTUS) AND/OR EXHAUST FANS TO BE

DISCONNECTED AND REMOVED, INCLUDING REPLACEMENT OF EXISTING ROOF CURB TO

ACCOMMODATE ROOF REPLACEMENT AND ADDITIONAL INSULATION. CONTRACTOR SHALL

BE RESPONSIBLE TO CONFIRM EXACT ROOF CURB DIMENSIONS ON SITE. ALL EXISTING

DUCTWORK TO BE DISCONNECTED FROM EXISTING ROOF TOP AIR HANDLING UNITS AND/OR

EXHAUST FANS, INCLUDING INTERIOR DUCTWORK BELOW THE UNITS AND WITHIN

EXISTING ROOF CURBS. DUCTWORK TO BE MODIFIED AND EXTENDED AS REQUIRED TO

ACCOMMODATE NEW ROOF CURBS AND ROOF REPLACEMENT. BE RESPONSIBLE TO

RE-INSULATE EXISTING DUCTWORK AS REQUIRED TO SUIT MODIFICATION WORK AND

RECONNECT TO EXISTING UNIT UPON RE-INSTALLATION.

.2 SUPPLY AND INSTALL ADAPTER CURBS AND EXTEND DUCTWORK WHERE NECESSARY.

PROVIDE NEW FLEXIBLE CONNECTIONS BETWEEN THE DUCTWORK AND UNITS.

21. REFRIGERATION EQUIPMENT:

.1 SAFELY REMOVE THE REFRIGERANT FROM ALL CONDENSING UNITS AND ROOFTOP UNITS

CONDENSER IN ACCORDANCE WITH APPLICABLE CODES AND BY-LAWS. REFRIGERANT WILL

NEED TO BE PUMPED DOWN AND RECLAIMED FROM EACH UNIT PRIOR TO REMOVAL.

DISCONNECT REFRIGERANT LINES FROM THE EQUIPMENT AND CAP TO PROTECT THE

INTERIOR. MAKE PIPES SAFE ON THE ROOF TO ALLOW FOR THE ROOF INSTALLATION.

.2 ALL EXISTING REFRIGERATION PIPING TO BE DISCONNECTED FROM EXISTING ROOF TOP

CONDENSING UNITS, MODIFIED AS REQUIRED AND RECONNECTED TO EXISTING UNIT UPON

RE-INSTALLATION OF UNIT(S) TO ACCOMMODATE REPLACEMENT OF EXISTING ROOF.

EXISTING REFRIGERATION PIPING SHALL ALSO BE EXTENDED/RAISED AS REQUIRED TO SUIT

ROOF REPLACEMENT. INCLUDE FOR ADDITIONAL PIPING, FITTINGS AND ANY RETROFIT WORK

AS REQUIRED TO SUIT.

.3 ONCE REINSTALLED ALL LINE-SETS TO BE WELDED AND REINSULATED, EACH SYSTEM

CHARGED PER DESIGN PARAMETERS. ALL SYSTEMS TESTED, SET-UP PER ORIGINAL DESIGN.

START-UP/TESTING WITNESSED BY THE BOARD. ODP DOCUMENTATION TO ACCOMPANY ALL

CLOSE-OUT DOCUMENTS/REPORTS

ELECTRICAL NOTES (TO BE DONE IN EACH PHASE, AS REQUIRED):

22. DISCONNECT EXISTING FEEDER TO EXISTING RTU, CONDENSING UNIT, EXHAUST FAN, ETC. TO

ALLOW FOR REMOVAL OF EQUIPMENT AND REPLACEMENT OF EXISTING ROOF AND ROOF CURBS

WERE NECESSARY. BE RESPONSIBLE TO COIL EXISTING FEEDER AT ROOF LEVEL SAFELY,

MODIFY AS REQUIRED AND RECONNECT TO EXISTING EQUIPMENT UPON REINSTALLATION.

CONTRACTOR IS RESPONSIBLE TO CONFIRM EXISTING FEEDER AND CONDUIT SIZE ON SITE.

23. PROVIDE NEW INSULATED ELECTRICAL STACK SLEEVES TO ACCOMMODATE NEW ROOF ELEVATION

AND RE-CONNECT ALL ELECTRICAL WIRING TO ALL UNITS AND EQUIPMENT. FLASH IN SLEEVES AS

SPECIFIED FOR STACK FLASHING.

A C D E F G HB

±3920

±7775

±4050

±11575

±7800

±4650

±4125

±12020

±4470

±6500

±2375

±3150

2

±3910

1

±2100

3

4

5

6

7

8

9

10

11

13

14

15

J L M

±3870 ±3680 ±7900 ±8000 ±7900 ±2600

±1185

±3770 ±4465

R7

R9

R8

R11

R2

R1

PHASE 2

R7, R8, R9, R10

PHASE 1

R1, R2, R3, R4, R5 ,R6

R3

R4

R5

R6

R10

SCALE:

1

A001

ROOF PLAN

1:150

ISSUES

NO. DESCRIPTION DATE

REVISIONS

ISSUED FOR CONSTRUCTION DATE

The contractor shall check and verify all dimensions

and report all errors and ommisions to the architect

and the design professional whose seal is affixed to

this drawing. Do not scale the drawings.

This drawing shall not be used for construction

purposes until issued for construction by the design

professional whose seal is affixed to this drawing

and whose signature is below.

SHEET NO. DRAWN BY CHECKED

PROJECT NO.

SCALE

STRUCTURAL CONSULTANT

MECHANICAL CONSULTANT

ELECTRICAL CONSULTANT

PROJECT

SHEET TITLE

ROOF PLAN - DEMOLITION AND NEW

A002

-

-

-

40 Matheson Boulevard West, Missisuaga, ON L5R 1C5

TEL: (905) 890-0708

2200676

AS_SHOWN

RNBG

ST. JULIA ELEMENTARY

SCHOOL

6770 HISTORIC TRAIL

MISSISSAUGA, ON L5W 1J3

Dufferin-Peel

Catholic District

School Board

ISSUED FOR CLIENT REVIEW 2020.03.171.

ISSUED FOR TENDER 2020.JUNE2.

![Brigid a[1]. Wilson - Final Dissertation](https://static.fdocuments.us/doc/165x107/577dab8d1a28ab223f8c9651/brigid-a1-wilson-final-dissertation.jpg)